Mississippi State University Mississippi State University

Scholars Junction Scholars Junction

Theses and Dissertations Theses and Dissertations

8-6-2011

An open virtual testbed for industrial control system security An open virtual testbed for industrial control system security

research research

Bradley Galloway Reaves

Follow this and additional works at: https://scholarsjunction.msstate.edu/td

Recommended Citation Recommended Citation

Reaves, Bradley Galloway, "An open virtual testbed for industrial control system security research" (2011).

Theses and Dissertations

. 613.

https://scholarsjunction.msstate.edu/td/613

This Graduate Thesis - Open Access is brought to you for free and open access by the Theses and Dissertations at

Scholars Junction. It has been accepted for inclusion in Theses and Dissertations by an authorized administrator of

Scholars Junction. For more information, please contact [email protected].

AN OPEN VIRTUAL TESTBED FOR INDUSTRIAL CONTROL SYSTEM

SECURITY RESEARCH

By

Bradley Galloway Reaves

A Thesis

Submitted to the Faculty of

Mississippi State University

in Partial Fulfillment of the Requirements

for the Degree of Master of Science

in Computer Engineering

in the Department of Electrical and Computer Engineering

Mississippi State, Mississippi

August 2011

Copyright by

Bradley Galloway Reaves

2011

AN OPEN VIRTUAL TESTBED FOR INDUSTRIAL CONTROL SYSTEM

SECURITY RESEARCH

By

Bradley Galloway Reaves

Approved:

Thomas Morris

Assistant Professor of Electrical and

Computer Engineering

(Major Professor)

Yoginder Dandass

Associate Professor of Computer

Science and Engineering

(Committee Member)

Rayford B. Vaughn

Associate Vice President for Research,

Professor of Computer Science and Engi-

neering

(Committee Member)

James Fowler

Professor of Electrical and

Computer Engineering,

Graduate Coordinator

Sarah A. Rajala

Dean of the James Worth Bagley College

of Engineering

Name: Bradley Galloway Reaves

Date of Degree: August 6, 2011

Institution: Mississippi State University

Major Field: Computer Engineering

Major Professor: Dr. Thomas Morris

Title of Study: AN OPEN VIRTUAL TESTBED FOR INDUSTRIAL CONTROL

SYSTEM SECURITY RESEARCH

Pages in Study: 144

Candidate for Degree of Master of Science

ICS security has been a topic of scrutiny and research for several years, and many

security issues are well known. However, research efforts are impeded by a lack of an

open virtual industrial control system testbed for security research. This thesis describes a

virtual testbed framework using Python to create discrete testbed components (including

virtual devices and process simulators). This testbed is designed such that the testbeds are

interoperable with real ICS devices and that the virtual testbeds can provide comparable

ICS network behavior to a laboratory testbed. Two testbeds based on laboratory testbeds

have been developed and have been shown to be interoperable with real industrial control

system equipment and vulnerable to attacks in the same manner as a real system. Addition-

ally, these testbeds have been quantitatively shown to produce traffic close to laboratory

systems (within 90% similarity on most metrics).

DEDICATION

To Sarah.

ii

ACKNOWLEDGMENTS

This thesis would not be possible without the support of a number of people. I would

first like to thank my advisor, Dr. Thomas Morris, for his help and guidance over the

years. I would also like to thank Dr. Dandass and Dr. Vaughn for their encouragement and

helpful advice.

Discussions with Jacob Brodsky about wireless insecurity and ICS security in gen-

eral were enlightening. Terry Brugger provided source code which inspired my imple-

mentation of similarity metrics. Wei Gao’s help with maintaining the MSU ICS security

laboratory and attack code is greatly appreciated.

This material is based upon work supported by the National Science Foundation Grad-

uate Research Fellowship under Grant No. DEG-1125191.

iii

TABLE OF CONTENTS

DEDICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

ACKNOWLEDGMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

LIST OF TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

LIST OF FIGURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

LIST OF APPREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

CHAPTER

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Motivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Problems in ICS Security . . . . . . . . . . . . . . . . . . . . 1

1.1.2 Problems Faced by ICS Security Research . . . . . . . . . . 3

1.1.3 Need for an open testbed for ICS security development . . . . 5

1.2 Contribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2. RELATED WORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Industrial Control Systems . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.1 Programmable Logic Controllers . . . . . . . . . . . . . . . 12

2.1.2 ICS Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1.2.1 Modbus . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1.2.2 HART . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 Related Testbeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2.1 MSU Lab . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3 Intrusion Detection Systems . . . . . . . . . . . . . . . . . . . . . . 20

2.3.1 IDS Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.4 PCS IDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3. SURVEY OF ICS WIRELESS ATTACK LITERATURE . . . . . . . . . . 25

iv

3.1 IEEE 802.11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.2 IEEE 802.15.4 PHY and MAC Layer . . . . . . . . . . . . . . . . . 33

3.3 WirelessHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.4 ZigBee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.5 Proprietary Wireless . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.6 Bluetooth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4. OVERVIEW OF VIRTUAL TESTBED . . . . . . . . . . . . . . . . . . . 51

4.1 Design Goals of Virtual Testbed . . . . . . . . . . . . . . . . . . . . 52

4.2 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.2.1 Process Simulator . . . . . . . . . . . . . . . . . . . . . . . 57

4.2.2 Virtual Devices . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.2.3 Configuration Files . . . . . . . . . . . . . . . . . . . . . . . 58

4.3 Use Cases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.4 Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.4.1 TCP/IP Logging . . . . . . . . . . . . . . . . . . . . . . . . 61

4.4.2 Serial System Logging . . . . . . . . . . . . . . . . . . . . . 62

4.5 Testbed Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.5.1 Pipeline . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.5.2 Ground Tank . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5. PROCESS SIMULATORS . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.1 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.2 Simulated Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.3 How to create a new simulation . . . . . . . . . . . . . . . . . . . . 72

6. VIRTUAL ICS DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.1 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.1.1 Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.1.2 Control Logic . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.1.3 Simulator interface . . . . . . . . . . . . . . . . . . . . . . . 84

6.1.4 ICS protocol interfaces . . . . . . . . . . . . . . . . . . . . . 86

6.1.4.1 Modbus Implementation . . . . . . . . . . . . . . . 88

6.2 Implementing a vdev . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7. EVALUATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7.1 Virtual Testbed Integration with Actual ICS Devices . . . . . . . . . 94

7.1.1 Integration with ICS Radio . . . . . . . . . . . . . . . . . . . 94

7.1.2 Integrating a Virtual Devices with Actual Devices . . . . . . . 98

v

7.2 Virtual Testbed under Attack . . . . . . . . . . . . . . . . . . . . . . 99

7.3 Traffic Fidelity Analysis . . . . . . . . . . . . . . . . . . . . . . . . 108

7.3.1 Methodology . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.3.1.1 Mathematics . . . . . . . . . . . . . . . . . . . . . 109

7.3.1.2 ModbusRTU Metrics . . . . . . . . . . . . . . . . . 111

7.3.2 Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

7.3.2.1 Ground Tank System . . . . . . . . . . . . . . . . . 114

7.3.2.2 Pipeline System . . . . . . . . . . . . . . . . . . . . 116

8. CONCLUSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

8.1 Contributions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

8.2 Future work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

APPENDIX

A. TIMING CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . 130

A.1 Timing calibration method for ModbusRTU systems . . . . . . . . . 131

A.2 Calibration Example: Ground Tank System . . . . . . . . . . . . . . 134

A.2.1 Initial Similarity Scores . . . . . . . . . . . . . . . . . . . . 134

A.2.2 Communications delay . . . . . . . . . . . . . . . . . . . . . 135

A.2.3 Message Processing Delay . . . . . . . . . . . . . . . . . . . 136

A.2.4 Master Program Scan Time . . . . . . . . . . . . . . . . . . 137

vi

LIST OF TABLES

2.1 Sample Modbus Function Codes . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2 IDS performance metrics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 IEEE 802.11 Vulnerabilities . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2 IEEE 802.15.4 Vulnerabilities . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3 WirelessHART Vulnerabilities . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.4 ZigBee Vulnerabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.5 Example Proprietary Wireless Systems . . . . . . . . . . . . . . . . . . . . . 44

3.6 Proprietary Wireless System Vulnerabilities . . . . . . . . . . . . . . . . . . 45

7.1 Similarity Metrics for Ground Tank (Off) Connected with Radios . . . . . . . 96

7.2 Similarity Metrics for Ground Tank (Auto) Connected with Radios . . . . . . 97

7.3 Similarity Metrics For the Ground Tank System(Off Mode) . . . . . . . . . . 115

7.4 Similarity Metrics For the Ground Tank System(Auto Mode) . . . . . . . . . 116

7.5 Similarity Metrics For the Pipeline System (Auto Mode) . . . . . . . . . . . 117

7.6 Similarity Metrics For the Pipeline System (Off Mode) . . . . . . . . . . . . 118

A.1 Ground Tank Initial Similarity Scores . . . . . . . . . . . . . . . . . . . . . 135

A.2 Ground Tank Similarity Scores After Adding Baud Rate Delay . . . . . . . . 136

A.3 Ground Tank Similarity Scores After Message Processing Delay . . . . . . . 141

A.4 Ground Tank Similarity Scores After Adjusting Master Scan Time . . . . . . 144

vii

LIST OF FIGURES

2.1 Diagram of an ICS System . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Testbed Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.1 Simulator Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.2 Ground Tank Empty to Full . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.3 Ground Tank Full to Empty . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.4 Ground Tank Simulation Comparisons: Ground Tank Auto Mode . . . . . . . 75

5.5 Pressures of Pipeline Systems in Auto Mode . . . . . . . . . . . . . . . . . . 76

6.1 Virtual Device Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.2 Sample Process Control Logic . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.1 Virtual Device Radio Integration Testing . . . . . . . . . . . . . . . . . . . . 95

7.2 Real Device Interoperability Test Setups . . . . . . . . . . . . . . . . . . . . 98

7.3 One Hertz Injection Attack Setup . . . . . . . . . . . . . . . . . . . . . . . . 100

7.4 Virtual System Tank Levels During Injection Attack . . . . . . . . . . . . . . 102

7.5 Laboratory System Tank Levels During Injection Attack . . . . . . . . . . . 103

7.6 Virtual Pipeline Pressures During Radio DoS Attack . . . . . . . . . . . . . . 104

7.7 Laboratory Pipeline Pressures During Radio DoS Attack . . . . . . . . . . . 105

7.8 Virtual Pipeline Pressures Received During Radio DoS/Injection Attack . . . 106

7.9 Laboratory Pipeline Pressures Received During Radio DoS/Injection Attack . 107

viii

A.1 Master-Slave Interarrival Distribution (Write Command) . . . . . . . . . . . 138

A.2 Master-Slave Interarrival Distribution (Read Command) . . . . . . . . . . . . 139

A.3 Master-Slave Interarrival Distribution (Read) After Processing Delay . . . . . 140

A.4 Ground Tank Master-Master Interarrival Time Before Adding Delay . . . . . 142

A.5 Plot of Interarrival Distribution After Calibration . . . . . . . . . . . . . . . 143

ix

LIST OF APPREVIATIONS

AES — Advanced Encryption Standard

ARP — Address Resolution Protocol

CAC — Bluetooth Channel Access Code

AES-CBC — AES Cipherblock Chaining Mode

CCA — Clear Channel Assessment

MS-CHAP — Microsoft Challenge Handshake Authentication Protocol

CRC — Cyclic Redundancy Check

CSV — Comma Separated Value file

AES-CTR — AES Counter Mode

DCS — Distributed Control System

DMZ — DeMilitarized Zone

DNP3 — Distributed Network Protocol 3

DNS — Domain Name System

EAP — Extensible Authentication Protocol

x

EAP-TTLS — Extensible Authentication Protocol Tunneled Transport Layer Security

ECDH — Elliptic Curve Diffie-Hellman

FHSS — Frequency Hopping Spread-Spectrum

FTP — File Transfer Protocol

GTK — Group Temporal Key

GUI — Graphical User Interface

HART — Highway Addressible Remote Transducer protocol

HMI — Human Machine Interface

HTTP — HyperText Transfer Protocol

ICS — Industrial Control System

IDS — Intrusion Detection System

IP — Internet Protocol

ISM — Industrial, Scientific, Medical RF Frequency Band

JSON — JavaScript Object Notation

LAN — Local Area Network

LAND — Local Area Network Denial attack

LEAP — Lightweight Extensible Authentication Protocol

xi

MAC — Medium Access Control (network layer) or Message Authentication Code

MD5 — Message Digest 5 Hash Algorithm

MIC — Message Integrity Code

MITM — Man-in-the-Middle attack

MTU — Master Terminal Unit

NERC — North American Electric Reliability Corporation

PAC — Programmable Automation Controller

PAN — Personal Area Networks

PCAP — Packet Capture (file format)

PCS — Process Control System

PDC — Phasor Data Concentrator

PEAP — Protected Extensible Authentication Protocol

PID — Proportional-Integral-Derivative control scheme

PLC — Programmable Logic Controller

PMU — Phasor Measurement Unit

PSK — Pre-Shared Key (IEEE 802.11)

PTK — Pairwise Transient Key

xii

RADIUS — Remote Authentication Dial-In User Service

RC4 — Rivest Cipher 4 stream cipher

RTDS — Real Time Digital Simulator

RTU — Remote Terminal Unit

SCADA — Supervisory Control And Data Acquisition

SIFS — Short Interframe Space (IEEE 802.11)

SKKE — Symmetric-Key Key Exchange

SPAN — Switched Port Analyzer

SSID — Service Set Identifier

SSP — Secure Simple Pairing

TCP — Transmission Control Protocol

TDMA — Time Domain Multiple Access

TKIP — Temporal Key Integrity Protocol

TTL — Time-to-Live (counter in IP headers)

UDP — User Datagram Protocol

USRP — Universal Software Radio Peripheral

VLAN — Virtual LAN

xiii

VPN — Virtual Private Network

WEP — Wired-Equivalent Privacy

WPA — WiFi Protected Access

WPA2 — WiFi Protected Access 2

xiv

CHAPTER 1

INTRODUCTION

1.1 Motivation

1.1.1 Problems in ICS Security

Industrial Control Systems (ICS), also known as Distributed Control Systems (DCS),

Process Control Systems (PCS), and Supervisory Control and Data Acquisition (SCADA)

systems are computer systems used to monitor control physical processes in manufac-

turing, chemical processing, electric generation, electric transmission and distribution,

water/wastewater systems, and other industries. PCS collect data from remote facilities

about the state of the physical process and send commands to control the physical process.

Process control system communications are characterized by mainly machine-to-machine

communications in point-to-point links and networks consisting of mainly computation-

ally limited devices.

ICS security has been a topic of scrutiny and research for several years, and many secu-

rity issues are well known[21, 22]. First, ICS often have poor security policies, including

not enforcing strong, secret passwords for individual users. Second, human-machine in-

terface software has been shown to have major flaws in user authentication [48]. Third,

ICS communication protocols provide no mechanisms to guarantee integrity, authenticity,

1

or confidentiality of data, making injection or tampering of ICS communications possi-

ble (and in some cases, trivial). This is made worse by the fact that while historically

ICS were directly connected using serial and fieldbus protocols, new advances in Ether-

net and TCP/IP networking used in enterprise networks have become integrated into ICS

networks. These advances allow previously separate ICS and enterprise networks to be

bridged, allowing attackers of the enterprise network potential access to the ICS network

as well.

Moreover, operators are reticent to patch ICS devices as patching requires downtime,

and patches may break currently working systems; ICS, despite the reliability of the in-

dustrial hardware, are quite difficult to operate and maintain. As such, ICS operators are

reticent to change anything in a working system. Some ICS devices use commercial off-

the-shelf operating systems, including Microsoft Windows. These devices are vulnerable

to attacks against these operating systems in the same way as PCs. Other systems use cus-

tom embedded or real-time operating systems; these proprietary systems are less tested for

vulnerabilities by product developers, security researchers, and hackers, and may harbor

many common programming and design errors like buffer overflows. For example, labo-

ratory testing of ICS equipment has shown some devices to be vulnerable to common TCP

SYN flood and LAND attacks; these vulnerabilities are no longer present in commodity

operating system network stacks.

Much of the current research focuses on TCP/IP-based networks, and as such there

is an emphasis on securing so-called “routable” protocols and ignoring “non-routable”

protocols. Non-routable protocols are believed to be secure against any attacker without

2

physical access. The NERC Critical Infrastructure Protection [8] requirements show this

philosophy in action. While it is, in fact, impractical to attack non-routable systems that

use, for example, RS-232 connections without physical access, industrial wireless sys-

tem use is becoming more and more prevalent in both routable and non-routable systems.

These wireless systems introduce a number of vulnerabilities that can be exploited by

attackers.

Additionally, these wireless systems sometimes make non-routable systems routable,

and in all cases there is a greater risk of attack as attackers no longer need physical access

to the systems to attack them because they can be attacked beyond logical boundaries

(connection points). As an example of this, attackers may jam, eavesdrop, or inject packets

between two wireless radios that are within a security perimeter, even in a secure building.

This greatly complicates the concept of security perimeter, and even more challenges the

assumption that non-routable systems are not in need of additional security practices. This

is discussed further in Chapter 3.

1.1.2 Problems Faced by ICS Security Research

As discussed in the previous section, the development of security practices and tech-

niques in the realm of process control systems has lagged the development seen in tra-

ditional information technology. However, researchers and industry practitioners have

taken notice of the issue and are developing best practices, secure protocols[46, 32], and

intrusion detection systems to meet the security needs of industrial control systems. Re-

searchers have explored a number of different approaches to performing intrusion detec-

3

tion in process control systems, including signature-based, anomaly-based, model-based,

state-based, and hybrid techniques. These will be discussed in further detail in the related

work. However, research efforts are hampered by a number of issues.

First, industrial control systems are quite diverse in network size and topology, the

number of standard communication protocols, communications media, as well as types of

process to be controlled. Presently, researchers are only able to test their work in their own

laboratory testbeds, which are necessarily limited in size and scope and not able to exhibit

the diversity seen in real-world applications.

A second issue to ICS research follows from the first: it is difficult for researchers

to develop generic solutions that can be used in many different process control systems

because of their limited test systems. The solutions designed often only work given certain

assumptions about the ICS system configuration, and reported results can only be provided

in terms of the single system it was tested in.

Third, many of these testbeds are actually simulations developed in common network

simulation toolkits like OmNet++ or NS2. These are purely simulated systems, and no

work has been done to measure the similarity of the results of this traffic compared to actual

ICS. Research results from these testbeds are dependent on fundamental assumptionsmade

by the testbed designers, which may or may not hold true in practice. This limits the types

of possible research approaches and the trustworthiness of the results.

The fourth issue is a grave problem for the scientific process: in some cases, solu-

tions developed in one testbed are not easily distributed and tested in a different testbed

for comparison. This means that, at present, it is difficult to quantitatively compare differ-

4

ent approaches directly to determine which approaches are more promising and effective.

Currently, there is no “standard” test scenario for ICS security solutions.

1.1.3 Need for an open testbed for ICS security development

There are two approaches to creating a testbed: laboratory-scale ICS with real equip-

ment and virtual testbeds. Some researchers use small, laboratory-scale processes con-

trolled by ICS consisting of a few devices. Other researchers use virtual testbeds; these

consist of simulated ICS devices, and may include a simulated process as well.

Laboratory scale systems have a number of advantages compared to virtual systems.

First, the data will reflect realistic measurement variations that would be present in an ac-

tual process control system. Second, the communication patterns and latencies will be en-

tirely accurate and not vulnerable to inaccuracies in simulated variables like OS scheduling

load. Third, PCS devices are individually vulnerable to many attacks that may not affect all

systems. These vulnerabilities may not be present in the specification of the system that the

virtual testbed was designed to emulate; examples include protocol implementation bugs

that cause the device to be vulnerable to Teardrop attacks, LAND attacks, web application

attacks, or buffer overflows. Other security issues like poorly protected or hard-coded de-

fault passwords to devices will also not be present. With laboratory scale process control

systems, captures of these attacks can be provided in addition to protocol-based attacks

and normal background traffic.

In spite of their benefits, laboratory scale systems have a number of disadvantages.

First, laboratory-scale systems are expensive to develop and can be difficult to maintain.

5

In particular, ICS software can be brittle and not user-friendly, and laboratory scale pro-

cesses require maintenance to stay operational. Second, adding or changing features in

a laboratory-scale system can be difficult. Third, the size of laboratory-scale systems is

limited by the required space and funds, so by necessity the systems will be smaller and

less featured than a real ICS.

Virtual systems, on the other hand, can be simpler to develop and have practically no

maintenance costs. Doubling the size of a virtual system requires only development time,

not a large purchase order. Furthermore, virtual system configurations can be backed up

and recalled instantly, so changing or adding features to a virtual testbed after does not

permanently alter the system. However, making changes or adding features to a virtual

system is arguably easier than in a laboratory system. While the captures taken from ei-

ther a laboratory or a virtual ICS may be distributed, a major advantage of a virtual system

is that a virtual system can be distributed widely to many researchers. For example, re-

searchers may use a virtual testbed provided by another group to place intrusion prevention

systems in the testbed to test effectiveness; such distribution is impossible with laboratory

testbeds. Being able to distribute the virtual testbed also means that any researcher can

recreate traffic captures if necessary; such capture regeneration may be necessary if bi-

ases or problems are found with previously released datasets. This openness can help the

testbed and datasets avoid obsolescence. Virtual testbeds are also more convenient to use

than laboratory testbeds for developing and debugging ICS security projects because they

are portable and require little set up for an experiment. While virtual testbeds provide a

number of benefits, there are some disadvantages to their use. Certain attacks, especially

6

attacks that rely on device implementation errors, may not work against virtual testbeds.

Also, virtual systems may not perfectly exhibit the same behavior as a real ICS system.

In spite of the advantages of a laboratory testbed, a virtual testbed that is open and

freely available will solve the four problems described in the last section.

First, an open testbed will reduce duplication of effort as research groups do not have to

all create their own testbeds; rather, if the open testbed does not fit a group’s needs it may

be improved in less time than creation of a new testbed. This results in a higher quality

testbed for all researchers with less effort. Additionally, other researchers may contribute

virtualized versions of their laboratory testbeds for all to use. By enabling the creation of

more diverse testbeds, the first two problems of the previous section can be solved.

Second, an open testbed provides a common ground for research; even if researchers

wish to use their existing testbeds, they can also test and distribute projects in the open

testbed. The benefit of this is that research groups can share code, and published results

can be duplicated and compared. This solves the fourth issue discussed in the previous

section.

Third, this testbed may be used to generate captures of normal system network traffic

and captures of attack or anomalous traffic for IDS researchers. These captures may be

distributed with or independently of the testbed itself. This is a benefit to IDS researchers

who prefer to work with captures instead of live testbeds. If the system is open, distributed

captures may be recreated to correct for unexpected biases. This reduces the possibility of

capture obsolescence.

7

Fourth, an open testbed opens the ICS security research area to more groups. Presently,

ICS research requires substantial investment. With an open testbed, researchers can ex-

plore the area without having to purchase large laboratory setups. Additionally, amateur

researchers and students can use the testbed without having to have the backing of a large

organization.

Finally, while this thesis will later describe verification of the virtual testbed, an open

testbed can be audited and verified by anyone. Because problems may be identified easier

(according to the adage “Many eyes make bugs shallow”), and corrected by any inclined

researcher, the third issue of the previous section is solved.

While the testbed can be used to address prior problems, additional features can extend

its usefulness. First, interoperability of the virtual system with actual ICS equipment will

allow for hybrid testbeds and extend the usefulness of the virtual testbed. Second, design-

ing the testbed such that important characteristics like ICS protocols or communications

interfaces can be changed will greatly enhance the ease of use of the system, especially

compared with laboratory systems. Third, designing the testbed such that components can

be replaced or extended easily will encourage use, reuse, and contribution to the testbed.

1.2 Contribution

In response to this problems discussed previously, this thesis forms the following hy-

pothesis:

It possible to:

1. Create a virtual testbed frameworkusing Python to create discrete testbed

components

8

2. that is designed such that the testbeds are interoperable with real ICS

devices and

3. that virtual testbeds can provide comparable (within 90% similarity) ICS

network behavior to a laboratory testbed.

The first clause of the hypothesis indicates that instead of a single, monolithic testbed,

a framework will be created to allow for the construction of many independent testbeds;

this framework will consist of discrete, replaceable components. From the second clause,

the created testbeds will be interoperable with real ICS devices; this extends the usefulness

of the virtual testbed, but also serves as a guarantee of realism — a virtual testbed that is

not similar to a real ICS will not be interoperable. The third clause indicates that the

virtual testbed behavior (especially with respect to network traffic) will be very similar to

laboratory testbeds; this is defined in greater detail in Chapter 7.

This thesis describes the development and evaluation of an open virtual testbed frame-

work to test this hypothesis. The design of the virtual testbed framework is broken up

into discrete components. The main components are the process simulator and the virtual

device; other components include a module for analyzing packet captures and a module

for logging and creating virtual serial ports. Two simulated systems have been created for

the testbed, and both have been designed to match existing laboratory testbeds in the MSU

laboratory (Described in Subsection 2.2.1). These are the laboratory-scale pipeline and

ground tank.

The following chapters detail the contribution of this thesis. Chapter 2 provides a

summary of related work, including more information about ICS, IDS, and related testbed

projects. Chapter 3 provides a survey of known attacks against common ICS wireless

9

systems to show how ICS wireless systems can be used to violate security assumptions

in ICS; this motivates the need for further security research in ICS, particularly in IDS.

Chapter 4 provides an overview of the virtual testbed design goals, components, use cases,

and the two implemented systems. Chapter 5 discusses process simulation, while Chapter

6 describes the design of virtual ICS devices for the testbed. Chapter 7 discusses the

verification methodology, and verification results, and use of the testbed. Finally, Chapter

8 provides conclusions and future work.

10

CHAPTER 2

RELATED WORK

2.1 Industrial Control Systems

Industrial Control Systems (ICS), also known as Distributed Control Systems (DCS),

Process Control Systems (PCS), and Supervisory Control and Data Acquisition (SCADA)

systems are computer systems used to monitor control physical processes in manufac-

turing, chemical processing, electric generation, electric transmission and distribution,

water/wastewater systems, and other industries. ICS interconnect and monitor physical

processes. An example ICS system is shown in 2.1.

ICS collect data from remote facilities about the state of the physical process and send

commands to control the physical process creating a feedback control loop. At the center

of Figure 2.1 is the Master ICS computer, termed the Master Terminal Unit (MTU). The

MTU may be a personal computer or a programmable logic controller (PLC). The MTU

interfaces with Human Machine Interface (HMI) software, and may also connect to a

historian server (not shown) or the company’s corporate network to allow engineers and

managers access to information about ongoing processes. The master unit is connected

to Remote Terminal Units (RTU), which may be termed “slaves” in some systems and

protocols. RTU may be smart instruments themselves or computers or PLCs that interface

with instruments, sensors, and actuators. Legacy ICS are connected over RS-232, RS-485,

11

Figure 2.1

Diagram of an ICS System

and other directly connected physical media. Modern ICS can incorporate those media

with Ethernet, Internet Protocol (IP), TCP, and/or UDP, and may be directly connected

to the Internet, or connected to corporate intranets which may have connections to the

Internet. In addition to the wired media of RS-232, RS-485, CANBUS, and Ethernet,

ICS systems make use of a plethora of standards-based and proprietary short-range and

long-range wireless protocols.

2.1.1 Programmable Logic Controllers

PLCs are digital computer systems that are designed to run industrial control systems.

They feature robust, rugged physical designs to withstand rough industrial environments,

and typically run embedded system or custom operating systems.Their primary purpose

12

is to send analog and digital control signals to physical equipment, The values of these

control signals will be based on the PLC programming and analog and digital inputs.PLCs

are primarily programmed using a graphical programming language known as “ladder

logic,” which emulates the original control system paradigm of using physical relays to

automate processes. However, they may also be programmed in a high-level programming

language, such as C. Once programmed, PLC programming rarely changes. PLCs run a

processing loop that consists of reading inputs, running ladder logic, and updating outputs

appropriately.A single run of this loop is known as a “scan,” and the time from the start of

one loop run to the next is known as the “scan time”

2.1.2 ICS Protocols

This section details two commonly used standards-based application protocols in ICS

systems: Modbus and HART. These protocols are used to communicate between RTU’s,

MTU’s, HMI software, and other ICS devices. Many ICS application communication

protocols, including the ones listed here, lack authentication features to prove the origin or

freshness of network traffic. This lack of authentication capability leads to the potential for

external network penetrators or disgruntled insiders to inject false data and false command

packets into a SCADA system either through direct creation of such packets or replay

attacks. These attacks may take place in either a wired or wireless context.

13

2.1.2.1 Modbus

Modbus[54] is a common protocol used in industrial control systems and SCADA sys-

tems. Modbus uses a master-slave paradigm for communications. Within Modbus, there

is no authentication of masters or slaves. Modbus may be carried over serial connections

(RS-232 or RS-485) or may be carried over TCP/IP, which is known as Modbus/TCP[55].

The Modbus data model considers data elements as being stored in four tables, each

consisting of: discrete inputs (1-bit) , coils (1-bit outputs), input registers (16-bit), and

holding registers (16-bit). Discrete inputs and input registers are read-only, and the data

comes from the device’s analog and digital inputs. These tables are addressed indepen-

dently, and the number of data elements in each table varies from device to device. Modbus

data elements may be considered as the main memory of the device, or Modbus addresses

may be mapped to the device’s memory in some other fashion.

Modbus uses a request-response messaging paradigm between masters and slaves. A

master will send a request, and the addressed slave will send a response. Broadcast mes-

sages from one master to many slaves are supported; in this case, the slaves do not respond.

Slaves do not send messages without first receiving a request from the master.

A request message consists of a slave address, a function code, and data. Modbus/RTU

packets include a CRC checksum after the data. The slave address is a unique number from

0-247, and the address is the first byte of the request. The function code is one byte spec-

ifies the type of request and what action should be taken by the slave. Example function

codes are given in Table 2.1. Not all function codes are implemented for all devices. The

data of the request varies based on the function code. For a “Read Holding Registers”

14

request, the data includes the number of registers to read and the starting address, while

for a “Write Multiple Registers” request the data includes the starting address to write to,

the number of registers to be written, the byte length of registers to be written, and the data

to be written. Responses use an similar format to the request, although the data will differ.

For a “Read Holding Registers” response, the message will contain the responding slave’s

address, the function code, the number of data bytes, and the requested register data (and

CRC in Modbus/RTU).

Table 2.1

Sample Modbus Function Codes

Function Code Description

1 Read Coils

3 Read Holding Registers

6 Write Single Holding Register

16 Write Multiple Holding Registers

Daniel Grzelak performed a security analysis of Modbus/TCP networks. He notes

that many Modbus/TCP devices have web interfaces, and he was able to find a number of

SCADA devices open on the web[36]. Identification of Modbus devices can be difficult, as

the protocol is simple and by itself gives little information about the devices in the system.

Grzelak notes that web interfaces and DNS records can give clues about the type of device

in use as well as manufacturer and other information.

15

2.1.2.2 HART

HART (Highway Addressable Remote Transducer protocol) is a fieldbus protocol used

in 4 to 20 mA analog control loops. A 4 to 20 mA analog control loop is a method of ana-

log control where a level is indicated electrically by a current in the range of 4 to 20

mA; it can transmit sensor values within a range (pressure, temperature, etc.) or con-

trol values (actuator positions, motor speed, etc.). HART provides advanced field device

functionality, including configuration and debugging, by superimposing digital communi-

cations on 4 to 20 mA loops. A common situation in process control systems is the use of

HART-compatible devices with non-HART compatible controllers. WirelessHART was

developed to add to HART a wireless mesh network that permits use of HART data in

non-HART control systems, the direct connection of PCs into the HART network, and the

use of handheld devices in the HART network.

2.2 Related Testbeds

A number of universities and government agencies are developing or have developed

testbeds for studying SCADA system attacks. These testbeds are outlined below; follow-

ing that discussion, the ICS and Electric Grid testbeds at MSU are discussed in detail.

Giani et al. proposed, but did not implement, a SCADA testbed[34]. First, they defined

reference architecture of a SCADA system (in a configuration similar to Figure 2.1). Next,

the authors considered three types of testbed: single simulation (all in a simulation frame-

work like MathWorks’ Simulink), implementation-based (where real SCADA devices are

used) and a federation simulation(simulation is combined with real SCADA devices). To

16

tackle the problem of device synchronization, the authors recommended the use of the US

Department of Defense High Level Architecture system.

In a Master’s thesis, David Bergman developed a simulated testbed for modeling Elec-

tric Grid SCADA systems [16]. A network simulator, RINSE, was used to model com-

munications between simulated devices; these simulated devices include relays and data

aggregators. PowerWorld software was used to simulate the Power Grid. This simulated

testbed has the ability to be integrated with real hardware. This work, while featureful,

will not be released to other researchers. Additionally, no verification was done to ensure

that the simulated testbed traffic is similar to actual traffic. Furthermore, this testbed is

aimed for electric grid control systems and not general ICS.

In [31], the authors take the approach of using a small "complex electromechanical

device consisting of pipes, valves, sensors, pumps, etc" to model a power plant. Their

system uses a number of different PLCs and field devices. They also use a DeltaV DCS

system. They also included a small office intranet with interconnections with VLAN ,

VPNs, RADIUS, a DMZ and "external network" system. The authors have used this

system to demonstrate four different attack scenarios.

[39] discusses the work of a senior design team at Iowa State University. They vir-

tualize two substations controlled by a control center which includes an HMI. They also

discuss possible attack vectors, including relay configuration changes, denial of service

attacks, fabricating/modifying/disrupting alarms/data from relay, and injecting incorrect

data into historian. [59] describes the use of a Lego NXT robotics kit to act as a physical

system controlled by an ICS simulated with OMNet++. While the NXT provides a phys-

17

ical system, all ICS processing occurs in the simulation. HMI software is included in this

testbed.

[23] uses the Command and Control Windtunnel discrete-event simulation framework

with Simulink to create a simulation of a chemical processing plant. Information about

plant variables is sent using Ethernet to simulated parts of the plant, but device semantics

(including ICS protocols) are not simulated. The authors tested a DDoS attack against this

system.

[56] describes a honeypot that emulates a TCP/IP-connected PLC using honeyd. The

authors focused on emulating device appearance to an external attacker, and they include

FTP, HTTP, and Telnet in addition to Modbus/TCP. They do not include a process under

simulation, nor do they program behavior to initiate interaction with other devices.

2.2.1 MSU Lab

Mississippi State University’s laboratory-scale process control system cybersecurity

testbed uses process control system equipment to control and monitor small, laboratory-

scale processes. MSU has two types of testbed: five laboratory-scale ICS and a laboratory-

scale electrical substation (in which power flows are simulated). The ICS systems include

an oil pipeline system, an oil storage tank, water tower, industrial air blower, manufactur-

ing conveyor, rolled sheet metal plant. The rolled sheet metal plant and electric substation

simulators use Allen-Bradley PLCs controlling their systems using the Ethernet/IP proto-

col. The remaining systems are controlled by single Control Microsystems PLCs commu-

18

nicating over Modbus wirelessly to a single master PLC unit, which is in turn connected

to an HMI. The electric substation testbed is described in further detail in [64].

Two of the ICS systems — the pipeline and the oil storage tank — are discussed in

later chapters, so a more thorough treatment of them will be given here. The oil pipeline

model system consists of a pipe with a pump, an electrically controlled release valve, and

a pressure meter, all connected to the controlling slave PLC. Air is used in place of oil for

safety and simplicity. The system has three modes of operation: off, manual, and auto. In

off mode, the slave closes the valve and turns off the pump. In manual mode, the pump

and valve status are set by the master PLC based on input from the HMI. In automatic

mode, a PID loop is used to maintain the pressure at a setpoint specified by the master

PLC based on input from the HMI. Two modes may be selected: pump mode, where

the valve is always open and the pump is modulated on and off to control the pressure,

and solenoid mode where the pump is always on and the valve is opened or closed as

necessary to control the pressure. The ground tank system uses water in place of oil for

safety reasons, and consists of a plastic water tank, a reservoir, and a pressure gauge and

a pump connected to the slave PLC. The reservoir holds water not in the tank, and the

pump moves water from the reservoir to the ground tank; a pipe drains water continuously

from the tank to the reservoir. Like the pipeline, the ground tank has auto, off, and manual

modes. The off and manual modes work similar to the pipeline system. The auto mode

has a low and high setpoint; the pump is turned on when the water level is below the low

setpoint, and turned off when the water level is above the high setpoint.

19

The MSU Power Systems group has developed a smart grid testbed that models an

electric transmissions substation for developing new algorithms for data management and

decision making as well as cybersecurity testing. This testbed consists of a real-time dig-

ital simulator (RTDS) that is capable of simulating the physics of a power system. The

RTDS is controlled by a support PC running RSCAD simulator control software. The

RTDS is presently configured to simulate two transmission lines; analog outputs of this

simulation is fed to General Electric Multilin PMU for monitoring. These PMU are con-

nected over Ethernet to a Schweitzer Engineering Laboratories phasor processor PDC for

aggregation and analysis. There is also one Allen-Bradley CompactLogix programmable

automation controller (PAC) in the power lab for breaker control. Another CompactLogix

PAC is located in the Center for Critical Infrastructure Protection in Butler Hall; it con-

trols a model sheet steel processing plant, and is connected to the testbed LAN via an

industrial 900MHz wireless Ethernet link. This model plant is to be considered a load in

a future use of the testbed. The PMUs send voltage and current phasor data at a rate of 60

measurements/second to the PDC using the IEEE C37.118 synchrophasor communication

standard. This connection uses TCP/IP over Ethernet. The PMU also support data streams

via UDP/IP over Ethernet.

2.3 Intrusion Detection Systems

Intrusion detection systems (IDS) are computer systems that attempt to detect possible

intrusions in a computer system. Two principal types are host-based and network-based

IDS. Host IDS monitor single computers for intrusions; they typically ensure that sensitive

20

system files are not accessed or modified. Network IDS monitor network activity looking

for network traffic indicative of network attacks and intrusion attempts. In this thesis, all

references to IDS refer to network-based intrusion detection systems.

IDS performance is measured with four metrics: true positives, false positives, true

negatives, and false negatives. These are described in the table below. True positives are

malicious behavior that is detected as malicious, but false positives are benign behavior

that is detected as malicious. True negatives are benign behavior that is recognized as

benign, while false negatives are malicious behavior that is detected as benign.

Table 2.2

IDS performance metrics

Behavior Detected: Benign Detected: Malicious

Actual: Malicious False Negative True Positive

Actual: Benign True Negative False Positive

IDS may be anomaly-based or signature-based. Anomaly-based IDS use statistical

and/or machine learning techniques to determine “normal” network behavior and to note

deviations from normal as intrusions. They require training and are more prone to false

positives, but they are also better able to detect new types of malicious behavior. Signa-

ture based IDS use compiled lists of signatures or rules that describe malicious behavior.

Signature-based IDS are simpler to deploy, as they require no training. Also, as the signa-

tures are based on known attacks, the false positive rate is much lower.

21

2.3.1 IDS Testing

Intrusion detection system testing is discussed here because it is expected to be a pri-

mary use case for the testbed. A number of projects have looked into the testing of intru-

sion detection systems. One of the first projects describes a testing methodology and an

Expect-based framework for running attacks in a laboratory environment[58, 57].

An important milestone on the topic of intrusion detection systems was the DARPA

Intrusion Detection System Evaluations[43, 25, 45], which generated the DARPA datasets.

This project simulated a medium-sized US Air Force local area network using a number

of hosts running Expect scripts to simulate user activity (mail, FTP, HTTP, telnet). In

the simulated traffic, a number of known network attacks were performed. The captured

data (9 weeks’ worth) was condensed into the KDD99 Cup dataset [1], which provided

researchers with a CSV file with connection information for the entire dataset; the KDD

dataset was useful because it tagged which connections were malicious, making it possible

to train and verify IDS that use machine learning techniques. The DARPA datasets, the

first of their kind, did have a number of flaws which were only apparent in retrospect[19,

49]. One major issue was that it had not been shown that the DARPA network traffic, being

simulated, actually resembled true network traffic. Another issue was that all packets had

four possible values for the IP TTL field; benign packets could have one of two TTL

values, and malicious packets used one of two others.

[60] discusses that author’s experiences with benchmarking IDS systems and details a

number of methodology flaws in commercial IDS product testing. [12] outlines the flaws

in the existing IDS testing methodologies and calls for a new open-source IDS testing

22

methodology. [50] recommends the use of shared data of attack logs for IDS testing. [77]

describes the application of mutations to known attacks to test the robustness of signature-

based intrusion detection systems. In [84], Stefano Zanero provides a thorough discussion

of necessary characteristics to measure intrusion detection system performance; these in-

clude true/false positives/negatives,coverage, resistance to polymorphism, throughput and

latency, and response time (for intrusion prevention systems). Zanero then discusses issues

generating background traffic (i.e. benign traffic) and attack sets. Zanero ends by stating

that intrusion detection system testing is still an open problem and mentions future work

similar to that proposed by Athanasiades et al.

2.4 PCS IDS

[83] discusses an anomaly intrusion detection system developed using a Matlab toolkit.

To test its effectiveness, the authors used a testbed consisting of Sun Microsystems servers

and workstations and ping flood, IP fragmentation, and LAND flood attack denial of ser-

vice attacks.

[24] discusses the use of models for intrusion detection. Simply, model-based intru-

sion detection consists of creating a model of the expected behavior of the system and

noting behavior that violates that model. Cheung et al. developed models for the Modbus

specification, communication pattern models for their testbed equipment, and sensors for

detecting server/service availability. The models for Modbus and communication pattern

models were implemented as Snort rules. Their IDS was tested using a single multi-step

attack scenario in Sandia National Labs’ SCADA testbed, which consists of process con-

23

trol system equipment. In [65], Roosta et al. propose a model-based IDS for wirelessly

connected process control systems. Their proposed system has both a centralized IDS at

the network gateway and a distributed IDS at each radio node. They provide threat mod-

els and proposed policy. In [76], Valdes and Cheung extend their work in [24] to use a

multilayer monitoring architecture for event correlation that uses model-based intrusion

detection. Additionally, they present visualization tool for showing communication pat-

tern anomalies

Hadeli et al. attempt to use machine-readable configuration files for creation of IDS

rules in [38]. They developed a tool that combines ABB DCS configuration files and some

user provided information to develop Snort and IP Tables rules. They also developed a

Snort Preprocessor to look for absent traffic as a sign of malicious activity. The authors

used laboratory equipment to validate the functionality of the system, but describe no

actual attacks. Svendsen and Wolthusen argue for the use of IDS that use models of the

process being controlled, not only models of the PCS equipment, for intrusion detection

[72]. They also provide several models of hydroelectric plants to demonstrate how the

process may be modeled. Valdes and Cheung also explore the use of network patterns and

flows to detect communication anomalies with machine learning techniques [75]. They

implemented this system in an Invensys distributed control system. They used an nmap

scan and modscan[17] scan as attacks that their system successfully detected. Gao et al.

describe the use of neural networks for detecting injected Modbus packets in a model

water system testbed[33]. Digital Bond has developed rules and preprocessors to detect

IDS attacks using the open source signature-based IDS Snort[3].

24

CHAPTER 3

SURVEY OF ICS WIRELESS ATTACK LITERATURE

As more robust radio solutions become available, wireless systems are becoming vital

parts of ICS systems. They provide a relatively inexpensive way to add new communi-

cation links. Short-range wireless systems include IEEE 802.11 (Wi-Fi), IEEE 802.15.4,

WirelessHART, and ZigBee, BlueTooth, and proprietary systems. Each system presents a

unique set of security challenges. Each subsection provides a basic introduction to a sys-

tem’s technologies and applications, known security vulnerabilities, and mitigation strate-

gies. Each section identifies attacks with an identifier in parentheses; this identifier is to aid

the reader in clearly identifying references to attacks in later sections and was not assigned

systematically.

The following sections detail attacks that are possible given that an attacker has “com-

promised” a node. A compromised node is a member of the target network that an attacker

can control in some way; obtaining this level of control typically involves changing the

software or firmware of the node to be malicious. A node may be compromised by an

insider with physical access to a device or by an outsider with trojaned factory firmware

or malware. In many cases, wireless devices are placed outside of an organization’s area

of physical control; examples include smart meters in customer’s homes (in the Smart

Grid Advanced Metering Infrastructure) or sensors placed in the field. In these cases,

25

even external attackers can be assumed to have physical access to the device and are able

to exploit low-level design vulnerabilities. This can include sniffing bus traffic before it

is encrypted, extracting and modifying the firmware, or bypassing or replacing hardware

components[35]. If a node is controlled by a PC, as is common with Bluetooth or IEEE

802.11, an internal or external attacker can compromise that PC and thus also compromise

the wireless interface.

3.1 IEEE 802.11

IEEE 802.11 is a standard for wireless local area networks. IEEE 802.11 networks,

also known under the trade name Wi-Fi, are now ubiquitous in home, office, and educa-

tional environments. Wi-Fi systems are also increasingly used in industrial applications,

and ruggedized access points are available for industrial use. IEEE 802.11 provides physi-

cal, MAC, and network layer services. IEEE 802.11 provides Ethernet access to operators’

PCs as well as MTU and RTU. These systems have a short range, but many access points

may be distributed throughout an area. Several amendments to the IEEE 802.11 specifi-

cation have been approved to add features and define communications suites. 802.11 a, b,

g, and n, approved in 1999 1999, 2003, and 2009 respectively, are communications suites.

These vary in speed, effective range, frequency use, and modulation.

IEEE 802.11 provides multiple mechanisms for communication confidentiality and

network access control. These include Wired Equivalent Privacy (WEP), now deprecated,

and IEEE 802.11i. IEEE 802.11i is known as Wi-Fi Protected Access 2 (WPA2). Wi-

Fi Protected Access (WPA) is a weaker subset of 802.11i and is now deprecated; it was

26

Table 3.1

IEEE 802.11 Vulnerabilities

Vulnerability ID

WEP Key Recovery WF1

802.11e/WPA-TKIP Packet Injection WF2

802.11 MITM WPA-TKIP Packet Injection WF3

WPA PSK Bruteforcing WF5

WPA2 GTK Packet Injection WF12

802.1X Credential Theft WF6

Physical Layer Jamming WF7

Short Interframe Space Jamming WF8

Clear Channel Assessment Jamming WF9

Deauthentication Forgery DoS WF10

Disassociation Forgery DoS WF11

Rogue Access Point WF14

EAP Offline Dictionary Attack WF13

intended as a “stop-gap” measure that could replace WEP in older hardware with only a

firmware upgrade. IEEE 802.11i is a direct replacement for WEP, which was found to have

a number of security vulnerabilities (discussed in the next paragraph). IEEE 802.11 also

supports the IEEE 802.1X standard for port-based LAN authentication. 802.1X is popular

in enterprise 802.11 networks where preshared keys are undesirable. The standard itself

mandates the use of the Extensible Authentication Protocol (EAP), of which there are

several varieties, including EAP-MD5, EAP-TTLS (Tunneled transport layer security),

LEAP (lightweight EAP), and Protected EAP (PEAP).

The first attack against WEP was published in 2001[30]. This technique attacks the

RC4 encryption scheme used in IEEE 802.11; in the attacker’s best case, he can recover

the key with 1,000,000 captured encrypted packets (Attack WF1). In the latest attack [74],

27

an attacker can recover the encryption key and can have full access to the wireless network

under attack by sniffing only around 24,200 packets; this is possible in under 60 seconds.

Two attacks against WPA using the Temporal Key Integrity Protocol (TKIP) were dis-

covered in 2009. The first attack (Attack WF2) works against networks using 802.11e

Quality of Service features [73]. The 802.11e amendment specifies 8 priority levels for

traffic to permit higher-priority traffic to have a lower latency. This attack can allow an

attacker to inject up to 7 packets in 12 minutes; 12 minutes is required to gather enough

traffic to perform the attack, and 7 packets are available from the remaining priority levels

which may have a replay counter low enough to let the injected packets pass. Although

this is is a small number of packets, precision packets may be crafted that can cause sys-

tems to crash or otherwise exhibit undesired behavior. One example of a small attack

packet is a Local Area Denial of Service (LAND) attack. In a LAND attack, an attacker

sends a TCP/IP or UDP/IP packet with source and destination IP and port numbers equal;

LAND-attack vulnerable systems will continuously send responses to this first packet back

to itself and prevent other connections from taking place. Attack WF2 has been extended

to obtain up to 586 bytes of keystream; this allows an attacker to inject larger packets than

was possible with the original attack[40].

The second attack (Attack WF3) against WPA will work against any WPA TKIP net-

work; this attack uses a man-in-the-middle approach and can provide an attacker one short

packet injection every minute[53].

Finally, WPA using the pre-shared key (PSK) mode is vulnerable to offline brute-force

key guessing if the connection handshake can be eavesdropped and the key is too short

28

(Attack WF5) [11, 52]. This handshake can be forced by briefly using the deauthentication

denial of service attack (WF10 or WF11, discussed below). For WPA-PSK, the use of a

random 16-hexadecimal digit number is recommended; the use of passphrases for WPA

preshared keys is not recommended as they are more likely to be in dictionaries [52].

Another attack (Attack WF12) that effects both WPA and WPA2 is not a cryptographic

break but rather exploits the usage of keys for all clients using an access point. There are

two keys used by WPA and WPA2 access points to encrypt communications with clients:

the Group Temporal Key (GTK) and the Pairwise Transient Key (PTK). The GTK is used

to encrypt broadcast messages from the access point to all clients; all clients associated

with an access point share a GTK. Separate PTKs are established between the access point

and each client. The individual PTKs are meant to protect each client connection from

network attacks, like sniffing other clients’ traffic or injecting messages to other clients,

from (rogue) authorized clients. However, clients will readily accept spoofed messages

encrypted with the GTK [9]. This allows an attacker who has authenticated with the access

point to perform several attacks. The first of these is that an attacker may become a man-

in-the-middle between two clients by ARP spoofing; by using the GTK flaw, the attacker

can perform the ARP spoofing in an encrypted channel over the air, where traditional IDS

can not detect the attack. A second attack permits the attacker to send any TCP/IP payload

to a client; this payload may be a TCP/IP packet attack (like a LAND attack), or malicious

code. With the GTK, an attacker can perform a third attack: a denial-of-service against the

other clients associated with the access point. Each WPA2 packet contains a 48-bit packet

number that is meant to act as a replay counter – packets with packet numbers lower than

29

the highest seen by a client are dropped. An attacker using the GTK vulnerability can

spoof a packet with a very high replay counter, and cause all legitimate group-addressed

packets to be dropped; this can cause a client to not respond to an ARP request and prevent

IP traffic from reaching that client.

An attacker can sidestep authentication mechanisms entirely by establishing a rogue

access point (Attack WF14)[70][14]. This attack is also known as an “evil twin” attack. In

this attack, an attacker establishes his own IEEE 802.11 access point that broadcasts the

same service set identifier (SSID) as the network being targeted. If this rogue access point

happens to have higher signal strength than a legitimate access point, victims will switch

from the legitimate access point to the rogue access point. These victims will provide

authentication information to the rogue access point which the attacker can then use to

gain access to the legitimate network.

In addition to the vulnerabilities in WEP and WPA, there can be problems with 802.1X

authentication as well. Many PEAP supplicants (user clients) are configured to not authen-

ticate the RADIUS authentication server; an attacker can set up a rogue access point using

a fake RADIUS server to steal the authentication details (user name, password or challenge

and response) in systems using EAP-TTLS and PEAP (Attack WF6) [82]. This may be

mitigated by requiring all clients to verify the certificates of the servers they are trying to

connect to. Additionally, tools have been released that can perform an off-line dictionary

attack against LEAP, EAP-MD5, and systems that use MS-CHAP (Microsoft Challenge

Handshake Authentication Protocol)(Attack WF13) [79, 80]. As this is a dictionary attack,

30

systems using weak passwords are most vulnerable. These attacks grant authentication

information that an attacker may use to infiltrate a network.

Additional attacks have been found against the IEEE 802.11 protocol itself, not just the

authentication mechanisms, and include denial of service attacks and man in the middle

attacks.

IEEE 802.11, like all wireless systems, is vulnerable to physical layer jamming (Attack

WF7). Physical layer jamming can be as simple as a single RF oscillator transmitting

on one channel of the transmission band, or may be as sophisticated as monitoring the

state of each protocol packet to predict the optimal time and period to jam to minimize

throughput[13].

IEEE 802.11 is vulnerable to two MAC layer denial of service attacks against its car-

rier sense collision detection mechanisms. The first of these involves the waiting period

between frames (Attack WF8). An 802.11 radio waits a brief period before transmitting to

check to see if the channel is in use; this period is known as the Short Inter-frame Space

(SIFS). If an attacker transmits briefly during this space, other radios will wait to transmit.

This process could be repeated indefinitely, denying service to the network[15]. However,

this attack is power-intensive and would require a transmission rate of 50000 packets/sec-

ond. In the second attack (Attack WF9), the clear-channel assessment (CCA) mechanism

of 802.11b devices is attacked. The clear-channel assessment mechanism is used to pre-

vent collisions, and actually operates below the MAC layer. To attack the CCA of a device,

another 802.11b device can be placed into a debugging mode that continuously transmits;

this continuous transmission is seen as network activity by the CCA and prevents other

31

devices from transmitting[5]. This continuous transmission forms a simple yet effective

denial of service attack.

The network layer is also vulnerable to denial of service attacks[15]. During connec-

tion, a client must first authenticate with an access point, then must associate with a given

access point. The association step is required because a client may authenticate with more

than one access point at a time (for example, in a plant-wide IEEE 802.11 network) but

may only be associated with a single access point for network access. The IEEE 802.11

standard defines a ’deauthenticate’ packet used to end a connection; the packet is sent

from the client to the access point to indicate an end in connection. This packet is unau-

thenticated and can be spoofed by an attacker. An attacker can generate deauthenticate

packets with the address of one victim, many victims, or even the entire network (Attack

WF10). This packet can be flooded or used only when a victim reconnects to the network

to create a full denial of service attack. A similar attack (Attack WF11) is possible with

the disassociation packet, although that attack requires slightly more power on behalf of

the attacker. More power is required in the dissassociation attack because more time is

necessary for a client under attack to reauthenticate and then reassociate than to merely

reassociate; the faster a client can reauthenticate and/or reauthenticate affects the rate at

which deauthentication or disassociation packets must be sent, and thus power expended.

The use of only WPA2 encryption is recommended for IEEE 802.11 networks. While

this may seem obvious to enterprise security professionals, it is important to clearly state

because some recent, popular industrial access points do not support WPA2. Additionally,

strong passwords/preshared keys are essential to preventing dictionary attacks. Finally, in

32

deployments making use of 802.1X with PEAP, all supplicants should be configured to

verify the certificates of the enterprise RADIUS server.

3.2 IEEE 802.15.4 PHY and MAC Layer

The IEEE 802.15.4 networking standard describes a common physical and MAC layer

for Personal Area Networks (PANs). It is meant to be a common underlying layer for de-

velopment of many different low-power, short-range wireless communication protocols.

Use of a common layer allows for more rapid development of different protocols for dif-

ferent purposes. 802.15.4 protocols that may be found in critical infrastructure include

WirelessHART, ZigBee, and ISA 100-11a. While a common base allows for easier devel-

opment of standards as well as product development, vulnerabilities present in the 802.15.4

standard will likely be present in devices making use of any of the above listed protocols.

For this reason, 802.15.4 vulnerabilities are treated in this separate section.

Table 3.2

IEEE 802.15.4 Vulnerabilities

Vulnerability ID

AES-CTR Packet Corruption E1

AES-CTR Replay Counter Abuse E2

Physical Layer Jamming E3

Acknowledgement Fabrication E4

The 802.15.4 standard mandates the use of the CCM* mode of AES for encryption.

CCM* provides several security suites: AES-CTR provides message confidentiality by

33

encrypting data payloads, AES-CBC-MAC ensures message integrity with a 32, 64, or

128-bit message authentication code (MAC), and AES-CCM combines the two former

suites. In the AES-CTR mode, a cyclic redundancy check (CRC) is used to provide mes-

sage frame integrity. This is insecure as it makes the following attack (Attack E1) possible

[66]. Suppose Alice is sending Bob a message routed through Mallory. Mallory may

change the cipher text without decrypting it, because she knows that it will do damage to

the plaintext (by the avalanche effect). Mallory then retransmits the bad ciphertext with

a valid CRC. The packet will be accepted by Bob as “good” when, in fact, it has been

modified. When the payload is decrypted and the data is given to the application layer, it

will not be valid.

802.15.4 provides replay protection in the form of key and frame counters. Each packet

is numbered with these counters. If a device receives a frame that has key or frame counters

lower than the highest one seen by that device, the frame will be ignored. In the AES-CTR

mode, which provides no cryptographic integrity protection, it is possible for an attacker

to forge a packet with the maximum values of frame and key counters and send it to any

device in the network (Attack E2)[66]. This packet will cause any subsequent frame (which

will necessarily have a lower frame and key counter value) to be discarded; this effectively

forms a denial of service to the device that received the forged packet.

Physical layer jamming attacks (Attack E3) have been implemented against a popular

802.15.4 device(Texas Instrument’s CC2480 transceiver)[18]. This transceiver transmits

at 1 milliwatt using a “nearly isotropic” antenna; it is specified for use up to 100 feet

(approximately 30 meters). The test setup used placed two CC2480’s 1.2 meters apart.

34

A simple, inexpensive jamming unit consisting of a voltage-controlled oscillator and a

mixer unit was able to jam communications between the two devices from 15 feet (4.6m)

away from the two devices under test; this test used the same power output and similar

antennas to the CC2480. This distance could be greatly increased by the jammer’s use of

higher-gain antennas and amplifiers.

While this test shows the effects of continuous jamming, selective jamming attacks

against IEEE 802.15.4 have also been studied[71]. A Universal Software Radio Peripheral

(USRP) can be used to briefly corrupt portions of packets as they are transmitted; this

has the effect of causing CRC and MAC checks to fail and for a receiver to drop the

packets that are jammed. Advantages of selective jamming are low power usage and low

probability of detection, as the short bursts use little power and they are too short to be

seen on a spectrum analyzer. Such selective jamming can be made more effective if the

attacker fabricates an acknowledgment from the recipient to the sender [66]. In IEEE

802.15.4, acknowledgments are optional, requested by the sender, and not authenticated;

the lack of authentication makes it possible for an attacker to falsify the acknowledgment

to prevent the sender from attempting to retransmit[66].

IEEE 802.11b,g,n radios and IEEE 802.15.4 radios both operate in the same 2.4 GHz

ISM band. Because of this, it is possible for IEEE 802.11 radios to unintentionally jam

IEEE 802.15.4 radios. As few as four 802.11 radios operating on different channels could

effectively cover the entire frequency space used by 802.15.4 devices[18]. Fortunately,

it requires significant 802.11 network traffic to cause disruption to the 802.15.4 devices.

35

However, system planners should carefully manage the wireless systems used to prevent

spectrum conflicts between systems.

One mitigation strategy against jamming is to use directional antennas. These antennas

will reduce noise, improve signal strength and throughput, and make jamming by a mali-

cious attacker more difficult. A drawback to directional antennas is that they will reduce

the effectiveness of mesh networks; as the transmission area is no longer omnidirectional,

fewer nodes will be within communications range. A second strategy is to place cen-

tral wireless devices as close as possible to ground level to minimize exterior interference

(malicious or otherwise). Using directional antennas to target the more central devices

will cause exterior interference to be filtered out of the network[18].

It is recommended that critical infrastructure control systems employ devices that use

the more effective AES-CBC-MAC and AES-CCM modes of encryption in their imple-

mentations and employ the wireless practices given in the previous paragraph to prevent

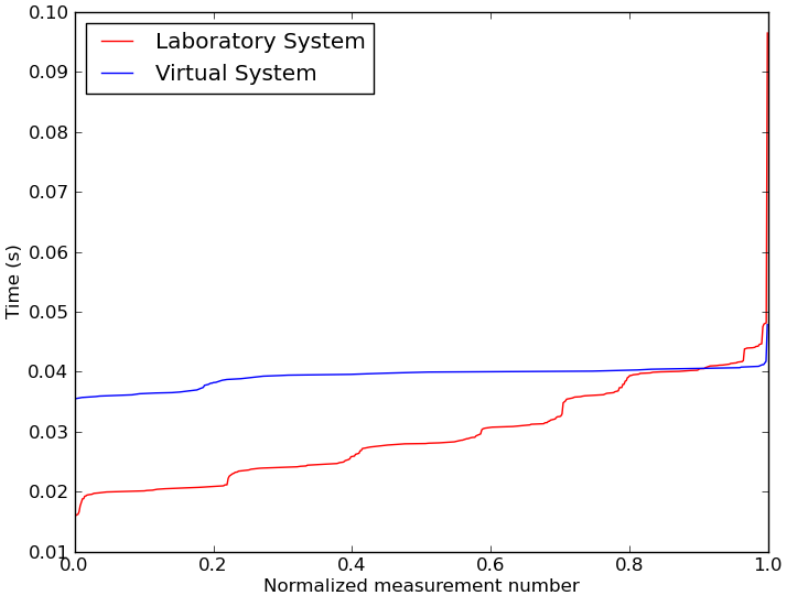

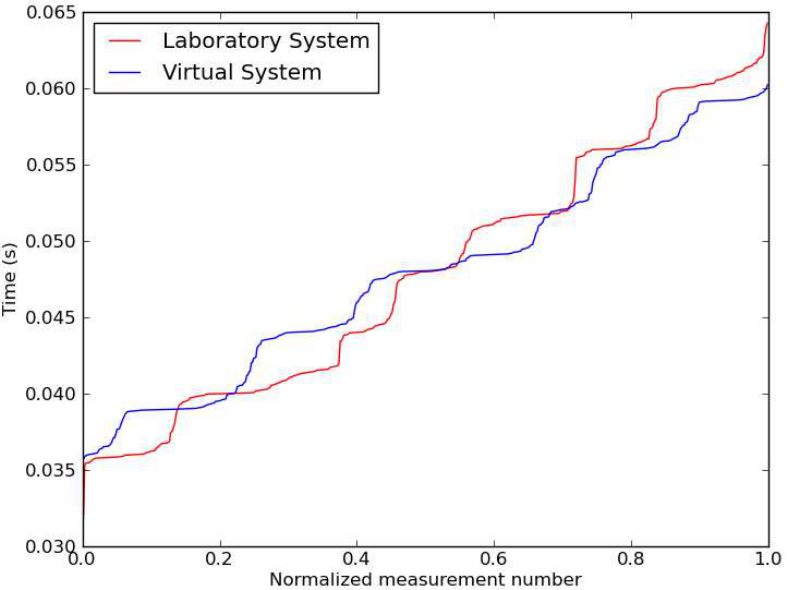

intentional or unintentional jamming.