U.S.

Department of Commerce, Bureau of Standards

RESEARCH

PAPER

RP650

Part

of

Bureau

of

Standards

Journal

of

Research,

Vol.

12,

February 1934

SOME

PHYSICAL

PROPERTIES OF

PLATINUM-RHODIUM

ALLOYS

By

J.

S.

Acken

1

abstract

In a

continuation of the

study

at the

Bureau of the metals of

the platinum

group, a

series of

platinum-rhodium alloys containing approximately

10, 20,

40,

60,

and 80

percent rhodium

was prepared

from pure

platinum

and pure

rhodium.

The

melting

point, hardness, density, electrical resistivity, temperature

coefficient

of

resistance, and

thermal electromotive force against

platinum

were

determined

for

each alloy.

The microstructure of each alloy appeared to

be

that

of

a

solid

solution.

The particular qualifications of

the

alloys

containing

20

to

40

percent

of

rhodium,

for

use as resistance

furnace windings for service

at

high

temperatures,

are discussed.

CONTENTS

Page

I.

Introduction

249

II.

Preparation

and mechanical working :

250

III.

Physical

properties

252

1.

Melting point

252

2.

Hardness

255

3.

Density

256

4.

Electrical resistivity

256

5.

Temperature coefficient of

electrical resistance

256

6.

Thermal electromotive

force against

pure

platinum

256

7.

Structure of

platinum-rhodium alloys 257

IV.

Discussion

257

I.

INTRODUCTION

As part

of the

study

at

the Bureau of

Standards

of the platinum-

group metals

of

high

purity, and to

supplement the determination of

a number of

physical properties of pure rhodium,

the preparation

and

properties of platinum-rhodium

alloys were given

consideration.

Since rhodium

is much less abundant

than platinum and the alloys

high in rhodium

are

not

easily worked, interest

in platinum-rhodium

alloys has

been

limited largely

to

those containing less

than

20 percent

of

rhodium. Alloys containing about 10

percent of rhodium are

used

as

positive

elements in

thermocouples, as

catalytic gauzes

for the

oxidation of ammonia to nitric acid,

and to some

extent as

the heating

element in resistance furnaces. Alloys

containing

3

to 4 percent

of

rhodium are used for

crucibles

and

similar laboratory ware.

Published

information

on

the physical

properties

of platinum-

rhodium alloys

is

scattered and

incomplete. Some

of the

early work

is

of doubtful value since reliable

methods for

the

separation, purifica-

tion,

and analysis of the metals of the

platinum group were

not avail-

1

With

the cooperation

of members

of

the Bureau

staff,

as

indicated

by footnote to

several

sections of this

paper.

249

250

Bureau

of

Standards Journal

of

Research

[Voi it

able until

recently. Some of the more important early

investigations

were

those of Le

Chatelier,

2

Dewar and Fleming,

3 4

Holborn

and

Wien,

5

and Barus.

6

Later, when somewhat better

methods for

purification had been developed, Burgess,

7

Sosman,

8

and

Adams

9

studied the use of platinum-rhodium alloys for measuring high

temperatures. Subsequently,

Neville

10

described

in detail a method

for the preparation of

the

10 percent rhodium

alloy

of

high

purity

for use

in thermocouples.

Data

on

hardness,

tensile strength,

electrical resistivity,

and temper-

ature coefficients of electrical resistance of

platinum-rhodium

alloys

containing

3.5, 10, 20,

and 50

percent

of

rhodium were

presented by

Carter;

11

Von

Wartenberg

12

determined the melting

point of

the 10

percent alloy, and Muller

13

the

melting

points of a series

of platinum-

rhodium alloys.

In

the present

investigation the

"melting point",

density, hardness,

electrical resistivity, temperature

coefficient of

electrical resistance, and

thermal electromotive

force against platinum

were determined for a

series

of alloys which covered the range from

pure platinum

to

pure rhodium.

II.

PREPARATION

AND MECHANICAL WORKING

The alloys were prepared from platinum and rhodium purified

in

the Chemistry Division

of

the Bureau

by

the

methods

described

by

Wichers, Gilchrist,

and

Swanger.

14

Spectroscopic analysis

of

the

platinum

and

rhodium showed that the

total amount of

metallic

impurities in each

was

definitely

not

over 0.01 percent, probably

not

over

0.001

percent.

Platinum-rhodium

alloys of a nominal rhodium content of

10,

20,

40,

50, 55,

60,

and

80

percent, respectively, were prepared in amounts

of

50 to

75

grams

by

melting in a high-frequency induction furnace.

16

For all of the alloys,

the constituent metals were prepared

in the

form

of

pellets made by compressing the spongy metal and

sintering

the

compressed

pellets

on a block of

lime with

an oxy-hydrogen torch.

The alloys

containing 60 percent or less of rhodium were melted in

air

in zirconium-oxide

crucibles and the 80 percent rhodium alloy in

vacuo in a thorium-oxide crucible. The alloys containing

10

and

20

percent of rhodium were cast into

graphite

molds; the others were

allowed to freeze in the crucible. All appeared to

be

homogeneous.

2

H. Le Chatelier,

De

La

Mesure des Temperatures

Elevees

par les Couples

Thermo-Electriques. Jour,

de

Phys.,

(2),

vol.

6,

pp.

23-31,

1887.

3

J. Dewar

and J.

A. Fleming, On the Electrical Resistance of Pure Metals, Alloys and Non-Metals at

the Boiling Point of Oxygen. Phil. Mag.,

(5),

vol.

34,

pp.

326-337, 1892.

4

J. Dewar and

J.

A. Fleming, The Electrical Resistance of Metals

and

Alloys

at

Temperatures Approach-

ing

the Absolute Zero.

Phil.

Mag.,

(5),

vol.

36, pp.

271-299, 1893.

5

L.

Holborn and W. Wien, Ueber die Messung hoher Temperaturen. Ann.

Physik. vol.

47, pp.

107-134

1892.

6

C. Barus,

Thermoelectrics of Platinum-Iridium

and of

Platinum-Rhodium.

Phil. Mag.,

(5),

vol.

34,,

pp.

376-381, 1892.

'

G. K. Burgess, On

Methods of Obtaining Cooling Curves.

B.S. Bull., vol.

5, pp.

199-225,

1908.

8

R.

B.

Sosman, The

Platinum-Rhodium Thermoelement from

0°

to

1,755°.

Am.

Jour.

Sci.,

(4),

vol.

30,

pp.

1-15,

1910.

9

L. H. Adams,

Calibration Tables

for Copper-Constantan and

Platinum-Rhodium Alloys. Jour.

Am.

Chem. Soc,

vol.

36, pp.

65-72; 1914.

10

R. P. Neville,

The preparation of Platinum and of Platinum-

Rhodium

Alloy

for Thermocouples.

Trans.

Amer. Electrochem.

Soc, vol.

43,

pp.

371-384,

1923.

»

F. E.

Carter, The

Platinum Metals

and

Their Alloys, A.I.M.E., Proc,

Inst. Met. Div.,

pp.

759-785,

1928.

12

H,

V.

Wartenberg, tjber

optische

Temperaturmessung blanker Korper, Verhandl. deut.

Physik.

Ges.,

vol.

12,

pp.

121-127,

1910.

13

L. Muller,

Bestimmung

der

Schemlzpunkte von Platinlegierungen.

Ann. Physik

(5),

vol.

7, pp.

9-47,

1930.

14

E.

Wichers,

R.

Gilchrist,

and W. H. Swanger,

Purification of the Six Platinum Metals. Trans.

A.I.M.E.,

vol.

76,

pp.

602-630,

1928.

i*

The

technique

of melting,

casting, and working these

alloys

is

essentially that described

in references

10 and 18.

Ackeri]

Properties

of

Platinum-Rhodium Alloys

251

The

ingots were

hand forged

at

1,100

C

(approximate)

to

bars

about

10 mm

in diameter. The alloys

containing

40

and

80

percent

of

rhodium were extremely coarse

grained in

the initial

state,

i.e.,

furnace

cooled,

and were not forgeable. However, after the ingots

had been

remelted on lime

with an oxy-hydrogen flame, they

could

be forged.

Each

of the hot-forged

bars was swaged

to wire about

1 mm

in

diameter. The

10

percent alloy was swaged

at room

temperature,

the others

at

900

to

1,000

C.

The

20

percent

alloy

could be swaged

at

room

temperature

if

annealed after

each reduction.

Further reduction of

the 1 mm swaged wires

was accomplished

by

drawing through dies.

The alloys containing

more than 40

percent

of

rhodium

were

drawn hot through

tungsten

carbide dies

until

the

diameter was reduced to 0.5

mm. The temperature

of the wire

was

maintained

at about 900 C

for the

first few draughts, and

then

gradually

lowered

for successive draughts

to

about

550 C

for

the

draught through the 0.5

mm die. Reduction

to 0.2 mm

diameter

was accomplished

by

drawing

through

sapphire dies,

at room

tem-

perature and without

annealing. The

alloys

containing

less than

40

percent

of

rhodium were drawn at room temperature

from

1 mm

swaged bar

to

wire of 0.2 mm

diameter.

Determinations

of

the various physical properties

were

made

during

the course

of

the

mechanical working when

the

form

was

suitable

for specimens

for the particular determination

desired.

Before any

determinations

were made the specimens

were cleaned

by

immersion in

molten

potassium bisulphate. This removed

surface

contamination,

especially

iron,

accumulated

during

the

mechanical

working.

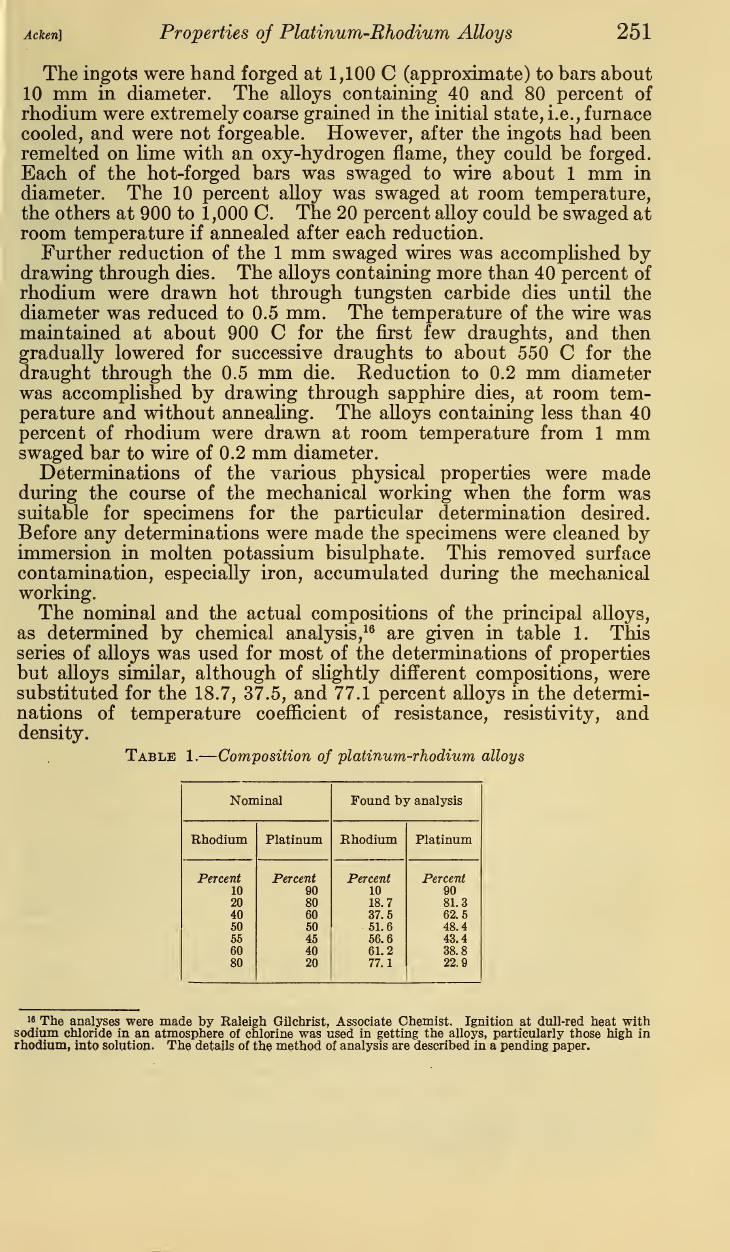

The nominal and

the actual compositions of the principal

alloys,

as determined

by

chemical analysis,

16

are given in

table 1. This

series

of alloys was used for most of the

determinations

of properties

but alloys similar, although

of

slightly different

compositions, were

substituted

for the

18.7, 37.5,

and

77.1 percent alloys in the

determi-

nations

of temperature coefficient

of resistance, resistivity, and

density.

Table

1.

—

Composition

of

platinum-rhodium

alloys

Nominal Found by analysis

Rhodium Platinum Rhodium

Platinum

Percent

10

20

40

50

55

60

80

Percent

90

80

60

50

45

40

20

Percent

10

18.7

37.5

51.6

56.6

61.2

77.1

Percent

90

81.3

62.5

48.4

43.4

38.8

22.9

w

The

analyses

were made

by

Raleigh

Gilchrist,

Associate

Chemist.

Ignition at dull-red

heat

with

sodium

chloride in

an atmosphere of

chlorine

was

used

in getting

the alloys,

particularly those high in

rhodium,

into

solution.

The

details

of

the

method

of

analysis

are described in a pending paper.

252

Bureau

of

Standards Journal

of

Research

[Vol. 12

III. PHYSICAL

PROPERTIES

1. MELTING

POINT

Determinations

were made

of

the approximate " melting

point"

of

each

of the alloys

containing

10,

18.7, 37.5, 56.6,

and

77.1 percent

of

rhodium.

Platinum and rhodium are generally believed

to form

a

continuous

series of

solid

solutions

and the melting or freezing

in

each case occurs

over

a

range of

temperature rather than

at a

single

temperature.

The

apparatus

and

procedure

were similar

to

those used in

previ-

ously

reported

determinations of the

melting

points of high-purity

platinum

and rhodium.

17

18

An

ingot

(50

to 75

g)

of the alloy

with

a

hole

drilled

axially from

top to bottom was

placed

in

a thorium-oxide

crucible

fitted with

a

thorium-oxide sight-tube which

was inserted

2000

rtGHT

ptR

C£N

T

O

1900

Id

0:

W

,""

u-«

/

s

3

£

1800

2

<

id

t

{'?

1700

Figure

1.

20 40

60

80

!O0

COMPOSITION,

PER

CENT RHODIUM

Melting

Points"

of

alloys

of

platinum

and rhodium.

in

the

hole.

The

power input

to the

high-frequency

induction

furnace

which

was

used for

melting

the

ingot

was

controlled

so that several

observations

of

the

temperature

could

be made during

melting

or

freezing.

The

alloys

containing

40 percent

or less

of rhodium

were

melted in

air;

those

of higher

rhodium

content

in an

evacuated

furnace

tube,

under

pressure

of less

than 1

mm of

mercury.

Temperatures

were

measured

with

a

Leeds

and

Northrup

optical

pyrometer

which

was

calibrated

by

the

pyrometry

section of the

Bureau

before

the

observations

were

made and

again

after they had

been

completed.

The

calibration

of this

pyrometer

was certified

to

± 20

C

for

temperatures

between

1,700

and

2,000

C. Consequently

the

accuracy

of the

temperature

observations

cannot exceed the

accuracy,

±20

C, of the

pyrometer

calibration.

» Win.

F.

Roeser, F.

R.

Caldwell

and

H.

T.

Wensel,

The

Freezing Point

of

Platinum,

B.S. Jour.

Re-

search,

vol.

6, pp.

1119-1129,

1931.

i

8

Wm.

H.

Swanger,

Melting,

Mechanical

Working

and

Some Physical Properties

of Rhodium, B.S.

Jour.

Research,

vol.

3,

pp.

1029-1040,

1929.

Acken]

Properties

of

Platinum-Rhodium Alloys

253

In each

of the

time-temperature curves summarizing the observa-

tions

during

melting

and

freezing of the different alloys only one break

was detected

instead of

the two that might

be expected at

the solidus

and liquidus

temperatures

of a solid-solution

alloy. In every case,

the

break was

pronounced,

and temperatures

that were constant,

within the

uncertainty

to

which they

are

given,

were obtained

both

on

melting

and on

freezing over periods of from 2

to 5 minutes. For

each of the

alloys there was close

agreement between

the temperatures

at

which

melting and freezing occurred, which indicates

that the range

between

the solidus

and liquidus temperatures is

probably small.

Evidently, at

the

high

temperatures at

which the

observations

were

made,

the change

in the rates of heating or cooling at the

solidus and

liquidus

temperatures was too slight

to be

detected with the

optical

pyrometer

and

the

procedure

employed.

Table

2.

—

"Melting points"

of

platinum-rhodium

alloys

Composition

Arrest on

heating

Arrest

on

cooling

"Melting

point"

»

Rhodium

(percent)

Platinum

(percent)

10

Average

90

°C

f

1,848

\

1,

845

[

1,845

°C

1,845

1,851

1,845

[

1, 845±20

\

1,

900±20

1 1, 945±20

\ 1,940±20

I

1,

960±20

1,846 1,847

18.7

81.3

I 1,899

I 1, 906

1

1, 889

I

1,906

1,890

1,905

1,880

1,899

1,900 1,894

37.5

Average

62.

5

f 1,940

1,946

{

1,

951

1,949

I

1,943

1,953

1,942

1,933

1,942

1,930

1,946 1,940

56.

6

Average

43.4

( 1,955

J

1,

946

1 1,

934

I

1,948

1,936

1,938

1,933

1,945

1,946

1,938

77.1

Average

22.9

f

1,962

1

1, 965

I 1, 957

I

1,967

1,

964

1,963

1,965

1,

954

1,963 1,961

»

The limit of

accuracy (±20C) ascribed to each

"melting

point

"

is the limit of

accuracy of the pyrometer

calibration.

From

3

to 5 sets of

temperature observations

were made during

melting

and during freezing

of each of the alloys. The temperatures

during

the period in which

they

remained constant

(while

melting

or

freezing

occurred)

are given in table

2.

The data show

that the

precision

of the experimental results is well within the limits

of accu-

racyof

the pyrometer calibration. The average

of the arrests during

heating

and

cooling of each alloy, rounded

off to the nearest

5 C,

is

designated

as

the

"

melting point."

Actually

this temperature is

254

Bureau

of

Standards

Journal

of

Research

[Vol.

it

somewhere

between

the

solidus and

the

liquidus

temperatures.

In

figure

1,

the

"

melting

points"

are

summarized

for

the various

platinum-rhodium

alloys,

together

with the melting

(or freezing)

points

of platinum

1,773.5

C,

19

and of rhodium,

1,966

C.

20

The melting

140

6

9

VICKERS

120

r"

®~

x

X

BABY

BRINELL

100

-i

X

a

X

80

if)

/

/

*

*

B

ROC

s

m

:kwell "e'

1

1

kJ

U

7

\m!

tr

2

60

Z

o

Ml

»

(0

u

z .

a

4Q

i

<

X

20

i

1

20 40

60

"

80 100

COMPOSITION, PER

CENT

RHODIUM

Figure

2.

—

Hardness

of

platinum-rhodium

alloys.

points

of all the

alloys

lie

between

those

of

pure platinum

and

pure

rhodium.

When

plotted

on the basis of weight

percent,

the melting

point curve

rises

sharply from

the melting point

of pure

platinum

as

the rhodium

content is

increased

to about 40 percent.

Further

increase

in

the rhodium

content, however,

is accompanied

by

rela-

1

9

See footnote

»

p.

252.

86

Determination

by W. F.

Roeser and H.

T.

to

be

Wensel.

published subsequently in this

journal.

Acken]

Properties

of

Platinum-Rhodium Alloys

255

tively

small increases in melting

point.

If the

results are

expressed

in atomic percent,

a smoother

curve

is obtained and

the

rapid

increase

in

melting point with additions of rhodium

up

to

40 percent,

is

less

apparent.

o

.004

5

2

x.003

o

a.

UJ

Qu

o°

a

.00 2

UJ

CL

<n

2

I

O

,001

O

10

1

2

x

O

a.

o

2

1

1

1

r

DENSITY

AT

25°

C

I

1 1 l

i

1

i

r^

RESISTIVITY AT

20°

C

25

20

10

2

u

a

OL

2

<

(X

o

20 40

60 60

COMPOSITION,

PER CENT

RHODIUM

100

Figure

3.

—

Density,

electrical

resistivity,

and

temperature

coefficient

of

resistance

of

platinum-rhodium alloys.

2.

HARDNESS

The

hardness

was

determined

by

means

of

the Baby

Brinell,

Rockwell, and

Vickers

hardness

testers.

The ingots

previously

used

for

the

melting

point

determinations

were

hot forged

to square

bars

and

annealed;

L

at

1,200

C before

the hardness

impressions

were

made.

256 Bureau

of

Standards Journal

of

Research

[Vol. is

The

results on a weight

percent

basis are shown

graphically in

figure

2.

The

10

percent

rhodium

alloy is decidedly

harder than

pure platinum.

With increased

rhodium contents

above 10 percent

the hardness

increases

at

a slower rate, and apparently

reaches

a

maximum

at about

70

percent

of rhodium.

With further increase in

rhodium

content the hardness

decreases slowly, and

approaches

the

hardness

of pure rhodium.

The Rockwell hardness

values

have also

been

plotted on the

basis of atomic percent,

to show that this method

of

presentation

tends

to smooth out the curves particularly in

the

region

of low

rhodium

contents. The values obtained agree

well

with

the Brinell

hardness numbers

reported

by

Carter,

21

on pure

platinum and

on alloys containing

10,

20,

and

50 percent of rhodium.

3.

DENSITY

22

Density

determinations

were

made

on wires

1 mm

in diameter

which

had

been

annealed

at

approximately

1,500

C.

The

values

shown in

figure

3

indicate

that the density of the platinum-rhodium

alloys

decreases regularly

with

increasing

rhodium content.

4. ELECTRICAL RESISTIVITY

23

The

electrical resistivity

was

measured on wires 1 meter

long

by

1

mm in

diameter, annealed

at a temperature of

approximately

1,500

C.

The

results are plotted in figure

3.

The increase

in resistivity

is

fairly

rapid with increasing rhodium content up

to

20

percent;

above

20

percent

of rhodium the resistivity decreases

gradually to

that of pure rhodium.

A slight

irregularity is noticeable

in the

curve

between

50

and

60 weight

percent

of

rhodium content.

Similar

relations are

apparent when the results are plotted

on the basis

of

atomic percent,

but the curve is smoothed out and

becomes

more

symmetrical.

5.

TEMPERATURE

COEFFICIENT OF

ELECTRICAL RESISTANCE

24

The results of the measurements

which

were

made on

wires

0.2

mm in

diameter,

show (fig.

3)

that

the

addition

of rhodium to

plati-

num

causes a

rapid

decrease

in the

coefficients of

resistance

which

reach

a

minimum

value

for alloys

containing 20

to

40

percent

of

rhodium; with higher rhodium contents

the values

again increase

regularly

and

approach

the

value for pure

rhodium.

If

these

results

are plotted on the basis of atomic

percent,

the curve

becomes

smooth

and nearly symmetrical, as would be

expected

for

a

series of

solid

solution alloys.

6. THERMAL ELECTROMOTIVE

FORCE

AGAINST

PURE

PLATINUM

Some

of the alloys

prepared

for this

investigation

were

included

in

a

series of

10

platinum-rhodium

alloys whose

thermoelectric

prop-

erties over the

temperature

range 100 to

1,200

C

have already

been

published.

25

21

See

footnote

11, p.

250.

22

E. L. Peffer,

Chief,

section

of capacity and

density.

23

A. R.

Lindberg,

junior

electrical

engineer, section

of electrical

resistance.

24

F.

R. Caldwell, Assistant

Physicist,

pyrometry section.

2

«

Frank R. Caldwell, Thermoelectric

Properties of

Platinum-Rhodium

Alloys. B. S.

Jour.

Research,

vol.

10,

pp.

373-380,

1933.

.

1

%

~\

.M>^

Acken]

Properties

of

Platinum-Rhodium

Alloys

257

7.

STRUCTURE OF

PLATINUM-RHODIUM

ALLOYS

26

Two

previous

investigators

27

have stated that

platinum and rho-

dium

form

a

continuous

series

of solid

solutions. In

the present

investigation,

slight

irregularities

in

melting point, Brinell

hardness,

electrical

resistivity, and

thermoelectric force of the alloys

containing

about 55

percent of

rhodium suggested the

possibility that there

might be some

departure from a

simple

solid

solution

at

or near

this

composition.

The presence

of impurities, to account for these irreg-

ularities, could

not be

established

by

chemical and spectrographic

analyses.

Examination

of

the

microstructure

failed

to reveal evidence

of

any

phase except a

solid solution in any of the

alloys used in this

investi-

gation.

The specimens used for

the microscopic examination

were

swaged wires,

1 mmin diameter,

which had

been

annealed

at

1,500

C.

Figure

4 shows the microstructure

of the alloy containing 37.5

percent

of rhodium. This was typical of the

structure of the other alloys

of

the series.

X-ray diffraction patterns made

from filings

of each of the alloys

likewise failed

to

reveal any

significant

difference

in

structure to

account

for

the

irregularity in properties of some of

the

alloys.

Evi-

dence

of the

existence of phases other

than

a

simple solid

solution

was

not

obtained.

IV. DISCUSSION

When

the

technic

for

the

production

of

rhodium

wire was devel-

oped

28

it became possible

to use

rhodium or platinum-rhodium

alloys

of

high

rhodium content for

windings

on furnaces which were

to be

operated

at

temperatures higher

than

could

be

reached with

plati-

num. Pure rhodium

and an alloy containing

80

percent of rhodium

and 20 percent of platinum

have

been

successfully used at this

Bureau

to

maintain

furnace

temperatures

above

the melting point

of

plati-

num.

However, the melting point

curve

shows that

but little advan-

tage can

be

gained

by using alloys containing more than

40 or

50

percent of rhodium. The

40

percent

alloy is much easier

to

work than

the

80 percent alloy or

pure rhodium and hence should be cheaper,

at

least at

present prices

for rhodium and platinum.

It

also has greater

resistivity

and

a lower temperature

coefficient

of

resistance (both

measured

at

ordinary

temperatures) than the alloy of

higher rhodium

content.

M

R.

E. Pollard and R.

Q. Kennedy, Jr.,

Junior Metallurgist and

Assistant Metallurgist,

respectively.

»

See footnotes 11 and

13,

p.

250.

«

See

footnote

18, p.

250.

-34

1

258

Bureau

of

Standards Journal

oj Research

[vot. 12

It will

be

noted that

the

temperature

coefficient of

resistance is

at

a

minimum for

alloys

containing

20 to 40 percent of rhodium

and that

the resistivity is at its maximum between 10 and

40 percent.

In

these

respects

an

alloy

containing

about 20 percent of rhodium

is

evidently superior

to

the ordinary platinum

winding.

Such an alloy

can be

drawn into wire

nearly as easily as

platinum

and weighs

about

15 percent less per unit length. Observations of the 10

and 20 per-

cent

alloys in

service indicate that they deteriorate less

rapidly

than

platinum, under comparable conditions. For all these reasons they

are

preferable

to

platinum for

use

in furnace windings

as long as the

cost

of rhodium

does

not rise very

much

above that of platinum.

Only

the requirement of a

higher operating temperature

would appear

to

justify

the use

of

the

less easily worked alloys of

higher

rhodium

content.

Washington, November

10,

1933.