repligen.com

© 2023 Repligen Corporation. All rights reserved. The trademarks mentioned herein

are the property of Repligen Corporation and/or its affiliate(s) or their respective owners.

OPUS Columns RSF-10

OPUS® Pre-packed

Chromatography

Columns

Regulatory Support File

2

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

The information contained in this document is subject to change without notice.

With respect to documentation accompanying Product Repligen makes no warranty, express or implied. Any and all warranties

related to the documentation accompanying Product are expressly disclaimed. Customer shall refer to the terms and conditions of

sale governing the transaction for any and all warranties for the Product.

Repligen Corporation shall not be liable for errors contained herein or for incidental or consequential damages in connection with

the furnishing, performance, or use of this material.

No part of this document may be photocopied, reproduced, or translated to another language without the prior written consent of

Repligen Corporation.

Products are not intended for diagnostic or therapeutic use or for use in vivo with humans or animals.

For further information, please contact Repligen Corporation at www.repligen.com

.

©2023 Repligen Corporation. All rights reserved. The trademarks mentioned herein are the property of Repligen Corporation and/or

its affiliate(s) or their respective owners.

Customer Support

customerserviceUS@repligen.com

+1-781-250-0111

Repligen Corporation

41 Seyon Street

Building #1, Suite 100

Waltham, MA 02453

customerserviceEU@repligen.com

+31-76-5719-419

Repligen Europe B.V.

Hoeksteen 13

4815 PR BREDA

The Netherlands

www.repligen.com

3

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Contents

2.12.1 Mechanical strength: Column hardware pressure rating .............................................................................................. 21

2.12.2 Packed bed integrity: packed column pressure rating ................................................................................................... 23

2.1.3 Thermal stability ............................................................................................................................................................... 24

2.13.1 Mechanical stability ....................................................................................................................................................... 25

2.13.2 Chromatographic performance ...................................................................................................................................... 25

2.13.3 Conclusion and Interpretation of OPUS Pre-packed Chromatography Column shelf-life data ..................................... 27

2.16.1 General warranty ........................................................................................................................................................... 29

3.2.1 Manufacturing Controls and SOP ................................................................................................................................... 30

3.2.2 Manufacturing facilities ................................................................................................................................................. 31

4

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

List of tables

Table 1. Column handling features........................................................................................................................................................ 12

Table 2. Product contact materials of construction .............................................................................................................................. 14

Table 3. OPUS H-Tubing Set Connector and sizing options ................................................................................................................... 20

Table 4. OPUS Column 2.5 cm ID pressure integrity testing ................................................................................................................. 21

Table 5. OPUS Column 8 cm ID pressure integrity testing* .................................................................................................................. 21

Table 6. OPUS Column 12.6 cm ID pressure integrity testing* ............................................................................................................. 22

Table 7. OPUS 80R Pre-packed Chromatography Column pressure integrity testing* ......................................................................... 22

Table 8. OPUS Column Hardware pressure ratings .............................................................................................................................. 23

Table 9. Physical specifications summary: OPUS Columns 2.5 – 30 ...................................................................................................... 23

Table 10. Physical specifications summary: OPUS 36R – 80R Pre-packed Chromatography Columns ................................................... 24

Table 11. Column mass (approximate weight of packed columns in kilograms) .................................................................................... 24

Table 12. Column shelf-life summary ...................................................................................................................................................... 25

Table 13. Stability study schedule and acceptance criteria ..................................................................................................................... 26

Table 14. Mechanical stability test results .............................................................................................................................................. 27

Table 15. Performance stability study results ......................................................................................................................................... 27

Table 16. Results of bioburden and endotoxin testing ........................................................................................................................... 29

Table 17. Water specifications compared with ASTM, USP purified water and water for injection ....................................................... 32

Table 18. Parts cleaning specification ..................................................................................................................................................... 35

Table 19. OPUS Pre-GMP and GMP applications .................................................................................................................................... 37

Table 20. ISTA 2A, 2B, and 3B Testing (OPUS 2.5 – 80R Pre-packed Chromatography Columns) ........................................................... 49

Table 21. OPUS Pre-packed Chromatography Column chromatographic performance data ................................................................. 52

List of figures

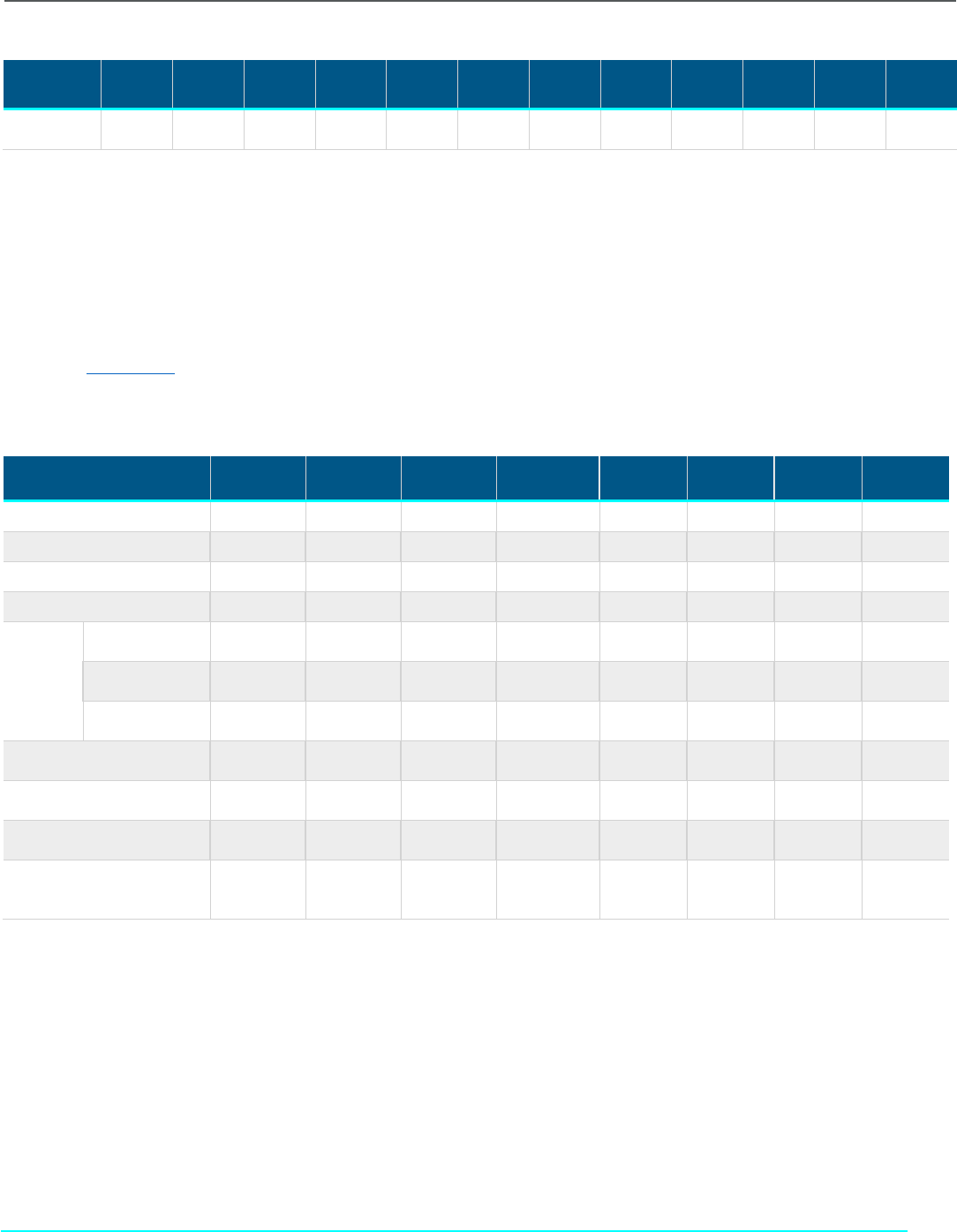

Figure 1. OPUS Column part number format ........................................................................................................................................ 10

Figure 2. OPUS Pre-packed Chromatography Column packaging: Tamper evident clamps ................................................................. 11

Figure 3. OPUS 60R Pre-packed Chromatography Column prepared for shipment ............................................................................. 11

Figure 4. Handles and inlet/outlet ports for OPUS 20 - 30 Pre-packed Chromatography Column ....................................................... 12

Figure 5. Caster detail on an OPUS 36R-80R Pre-packed Column ........................................................................................................ 13

Figure 6. OPUS 2.5 Pre-packed Chromatography Column design ........................................................................................................ 15

Figure 7. OPUS 5 and 8 Pre-packed Chromatography Column design .................................................................................................. 15

Figure 8. OPUS 10 – 30 Pre-packed Chromatography Column design (OPUS 20 shown) ..................................................................... 16

Figure 9. OPUS 45 – 60 Pre-packed Chromatography Column design (no R port) ............................................................................... 17

Figure 10. OPUS 36R – 80R Pre-packed Chromatography Column design (OPUS 80R shown) .............................................................. 18

Figure 11. OPUS R Port design ................................................................................................................................................................ 18

Figure 12. OPUS H-tubing Set Design ...................................................................................................................................................... 19

Figure 13. Example OPUS H-Tubing Set with Aseptic Connectors .......................................................................................................... 20

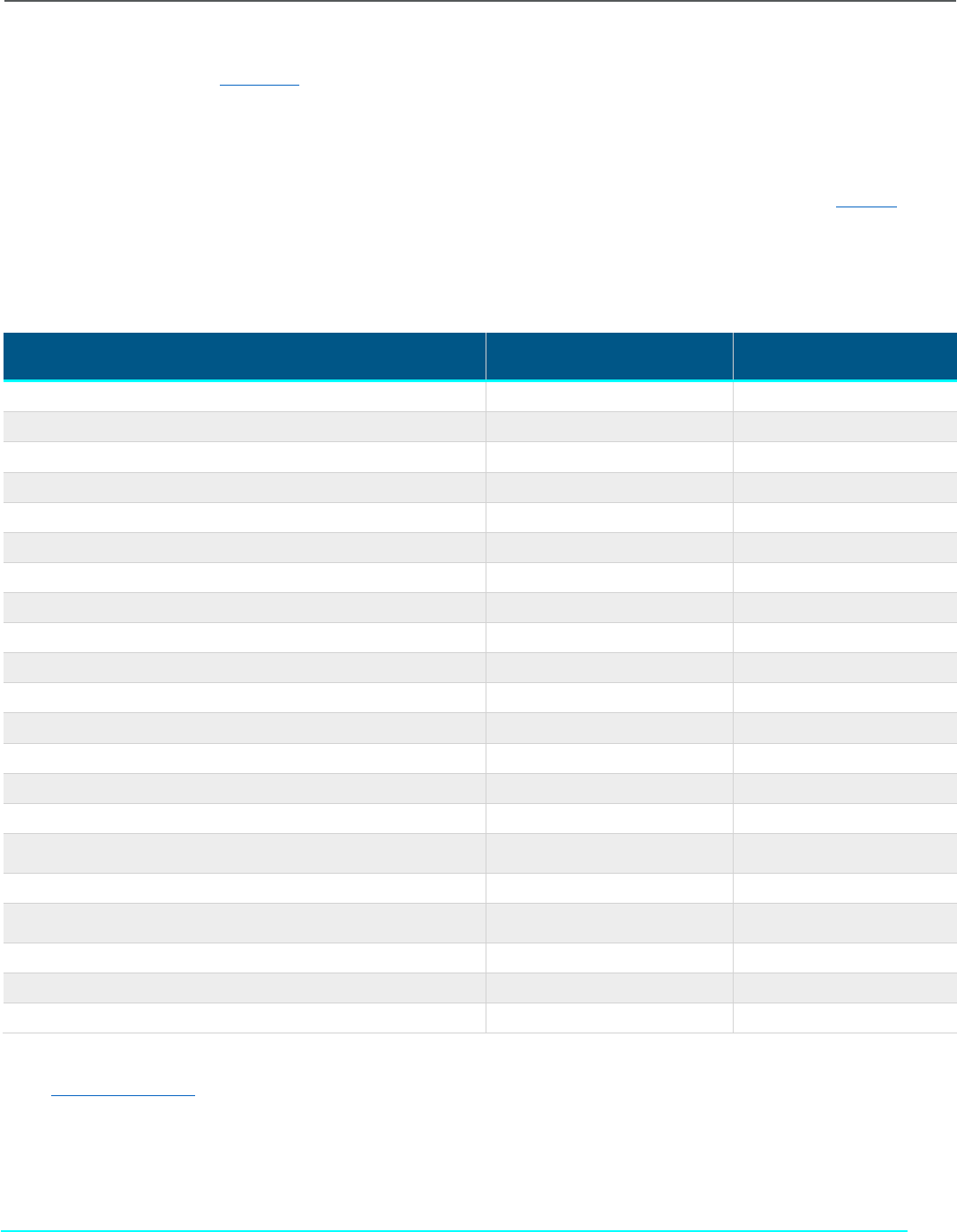

Figure 14. OPUS Column Specification Sheet example ........................................................................................................................... 33

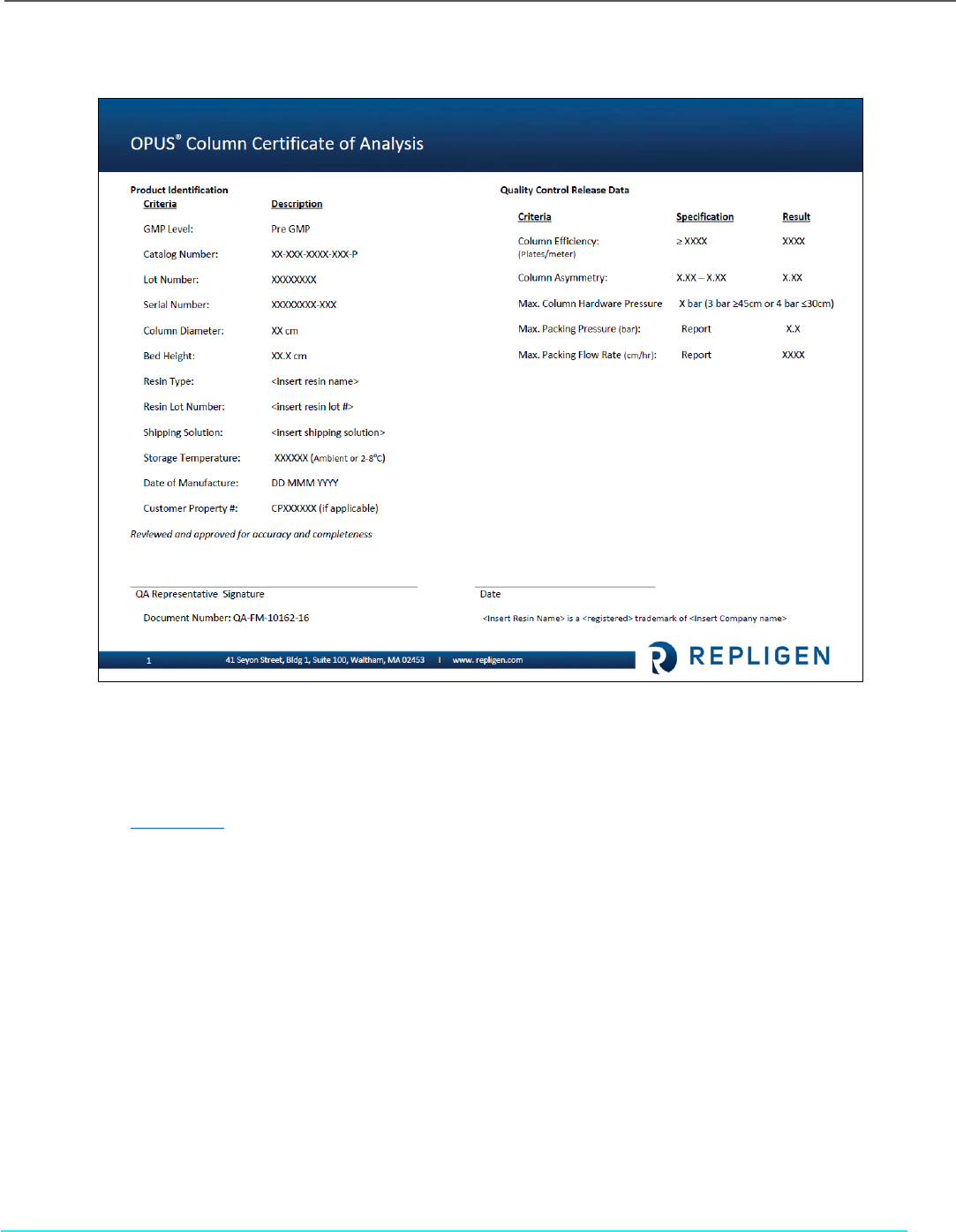

Figure 15. Pre-GMP OPUS CoA: OPUS 8 – 80R Pre-packed Chromatography Columns ......................................................................... 38

Figure 16. GMP Run Ready OPUS Column CoA: OPUS Columns 2.5 – 80R ............................................................................................. 39

Figure 17. OPUS CoA: Testing conditions and chromatograms .............................................................................................................. 40

Figure 18. CoA: Quality Assurance Statements ....................................................................................................................................... 41

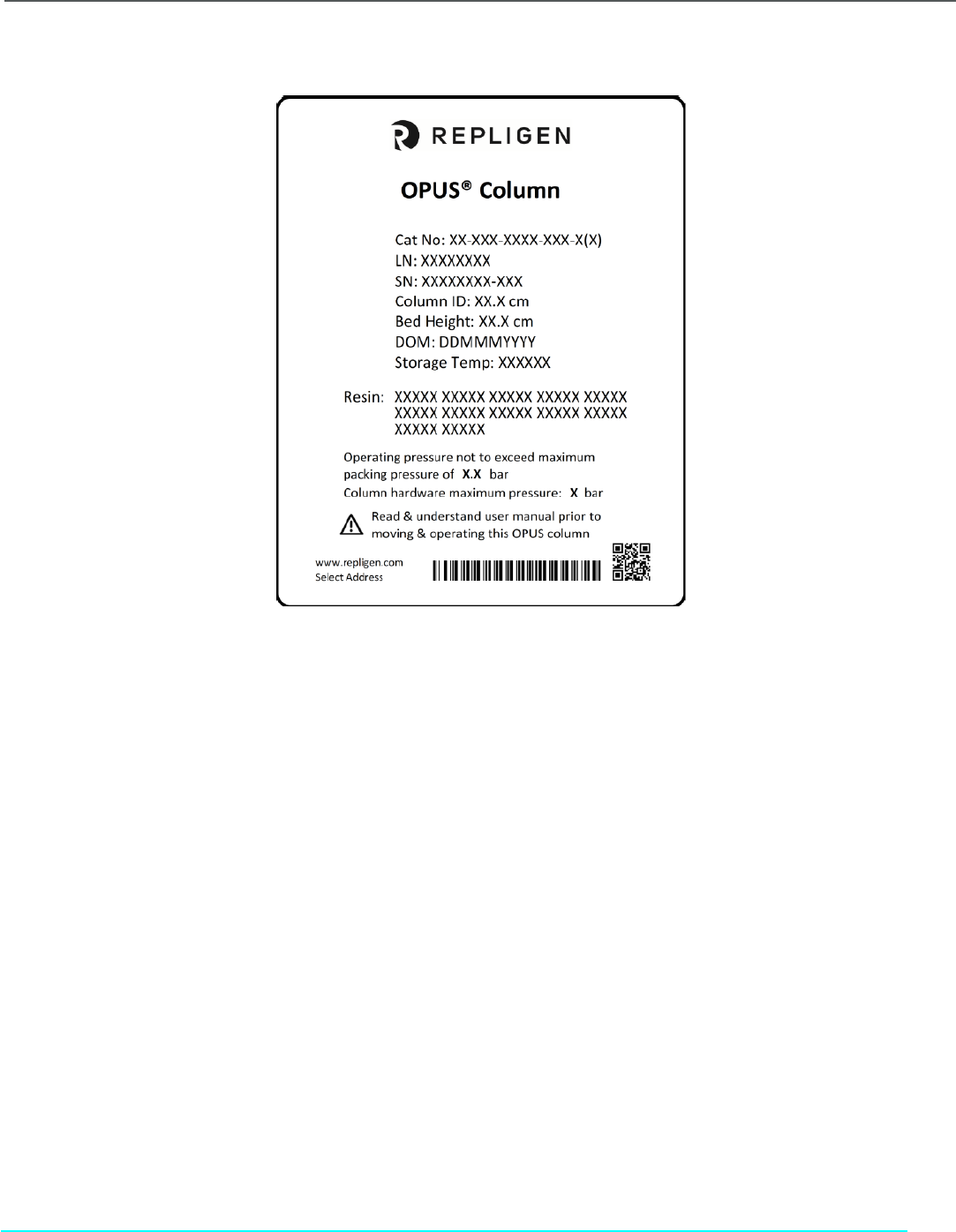

Figure 19. OPUS 10 – 80R cm ID Column label ....................................................................................................................................... 42

Figure 20. OPUS Small Scale (2.5 – 8 cm) Pre-packed Chromatography Column label .......................................................................... 43

Figure 21. OPUS 2.5 cm Pre-packed Chromatography Column supplementary label ............................................................................ 43

Figure 22. OPUS 2.5 – 8 cm Pre-packed Chromatography Columns box label ....................................................................................... 44

Figure 23. OPUS Column Resin sample label .......................................................................................................................................... 44

Figure 24. OPUS 8 Pre-packed Chromatography Column shipping container design ............................................................................. 46

Figure 25. OPUS 10, 12.6, 14, 20, 25, 30 Pre-packed Chromatography Column shipping container ..................................................... 46

Figure 26. OPUS 36R – 45R Pre-packed Chromatography Column non-wood shipping container........................................................ 47

5

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Figure 27. OPUS 45R and 60R Pre-packed Chromatography Column shipping container design .......................................................... 47

Figure 28. OPUS 60R Pre-packed Chromatography Column crate tamper evident banded straps ........................................................ 48

Figure 29. OPUS 80R Pre-packed Chromatography Column shipping container design ........................................................................ 48

Figure 30. OPUS 60R Pre-packed Chromatography Column vibrational, incline impact, drop testing ................................................... 50

Figure 31. OPUS 5 Pre-packed Chromatography Column packaging (Box Design) ................................................................................. 53

Figure 32. OPUS 5 Pre-packed Chromatography Column packaging (Packing inserts)........................................................................... 54

Figure 33. OPUS 8 Pre-packed Chromatography Column packaging ...................................................................................................... 54

Figure 34. OPUS 10 – 14 Pre-packed Chromatography Column packaging ............................................................................................ 55

Figure 35. OPUS 20 – 30 Pre-packed Chromatography Column packaging ............................................................................................ 56

Figure 36. OPUS 36R and 45R Corrugated Pre-packed Chromatography Column packaging................................................................. 57

Figure 37. OPUS 45 and 45R Pre-packed Chromatography Column packaging ...................................................................................... 58

Figure 38. OPUS 60 and 60R Pre-packed Chromatography Column packaging ...................................................................................... 59

Figure 39. OPUS 80R Pre-packed Chromatography Column packaging .................................................................................................. 60

Abbreviations

ABS Acrylonitrile Butadiene Styrene

AGS Associated Global Systems

As asymmetry

BCMS Business Continuity Management System

BSA bovine serum albumin

C Celsius

CE Conformite Europeenne

CF compression factor

CFD computational fluid dynamics

CFU colony forming units

cm centimeter

cm

2

centimeter squared

CMC Chemistry, Manufacturing & Controls

CoA Certificate of Analysis

CP Customer Property

CV column volume

EMA European Medicines Agency

EU endotoxin units

FOS factor of safety

ft

3

cubic feet

FTIR Fourier Transform Infrared Spectroscopy

G acceleration

GMP Good Manufacturing Practice

HCl hydrochloric acid

hr hour

Hz hertz

ID internal diameter

in inches

IPA isopropyl alcohol

IPPC International Plant Protection Committee

ISO International Organization for Standardization

ISPM International Standards for Phytosanitary Measures

6

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

ISTA International Safe Transit Association

kg kilogram

L liter

lb pound

m meter

M molar

m

3

cubic meter

min minute

mL milliliter

mm millimeter

mS milliSiemens

N plates

NaCl sodium chloride

nm nanometer

NVP non-viable particulate

OD optical density

OPUS Open Platform User Specified

PD Process Development

PETG polyethylene terephthalate glycol

PP polypropylene

ppm parts per million

PSD power spectral density

psi pounds per square inch

QA Quality Assurance

QC Quality Control

R&D Research and Development

RODI reverse osmosis deionized water

RSF Regulatory Support File

TNTC too numerous to count

TOC total organic carbons

TSA tryptic soy agar

TSE transmissible spongiform encephalopathy

w/v weight/volume

µm micron

µS microSiemens

7

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

1. Introduction

The Regulatory Support File (RSF) for OPUS® (Open Platform User-Specified) Pre-packed Chromatography Columns is intended to be

used as:

• A guide for appropriate application use in process development, clinical, and commercial purification processes

• A guide to validation in manufacturing processes

• A support reference for chemistry, manufacturing, and control (CMC) drug development submissions for regulatory license

approval

• A guide for supplier audits

• In place of a Drug Master File submission

This Regulatory Support File covers all column sizes including OPUS Pre-packed Chromatography Columns 2.5, 5, 8, 10, 12.6, 14, 20,

25, 30, 36R, 45, 45R, 60, 60R, and 80R. Unless otherwise specified, all information applicable to OPUS Pre-packed Chromatography

Columns 45R and 60R designs is also applicable to OPUS Pre-packed Chromatography Columns 45 and 60 designs.

For more information covering OPUS Gamma Pre-packed Chromatography Columns 2.5, 5, 8, 10, 12.6, 14, 20, 25, and 30, please

refer to the specific Regulatory Support File on this portfolio on repligen.com.

Repligen is committed to providing all relevant technical, manufacturing, and quality information, however, only non-confidential

information is presented in this document. Confidential details may be made available upon request through a formal confidentiality

agreement or as part of a supplier audit.

1.1 Repligen Quality Policy

Copies of the Repligen quality policy, quality manual, and ISO certificate can be found on the following website,

https://www.repligen.com

.

1.2 Safety notices

• Follow all local regulations for safe disposal

• For laboratory and manufacturing production only

1.3 Responsible official

The individual designated responsible for quality and regulatory affairs for Repligen, and to whom all correspondence or requests for

audits should be addressed.

Senior Director of Quality

Telephone: +1-781.250.0111

Email: quality@repligen.com

8

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

2. Product information

2.1 Product overview

OPUS Pre-packed Chromatography Columns are designed to perform chromatographic purification of biological molecules in either

Good Manufacturing Practice (GMP) or non-GMP applications. The OPUS 2.5 – 80R Pre-packed Chromatography Column platform

offers an easy-to-use alternative to traditional self-packed columns with configurable diameter, bed height, and chromatographic

resin. Additional end-user requirements, such as release criteria for plate count, asymmetry, and storage solution, can be specified.

All OPUS 2.5 – 80R Pre-packed Chromatography Columns are built-to-order. Repligen does not maintain stock of standard

configurations. Please consult with Repligen for specific lead time information.

2.2 Quality standards

OPUS 2.5 – 80R Pre-packed Chromatography Columns are manufactured in the Waltham, MA, USA. or Breda, The Netherlands under

the following quality standards for GMP manufacturing:

• Repligen maintains an ISO 9001 compliant Quality Management System. A copy of the current ISO certification can be

downloaded from the following web address, https://www.repligen.com/resources/quality

.

• All materials in direct fluid contact path meet USP Class VI, and USP <88> requirements for In Vivo Biological Reactivity.

• All columns are packed in a controlled, classified clean room that meets ISO Class 7 Non-Viable Particulate (NVP) standards.

• All fluid contact components are free from materials of animal origin or compliant with EMA 410/01 Rev 3.

2.3 OPUS Pre-packed Chromatography Column features overview

Obtaining User Specified Column Inputs

All OPUS Columns are produced based on user specifications, captured from the Repligen internal quote configuration tool.

All specifications are summarized on the OPUS Column Specification Sheet for each column or part number. Available user specified

inputs are summarized below:

• Column details (4 parameters): internal diameter, bed height, resin type, and GMP level

• Resin supply (two options): Repligen-supplied or customer supplied

• Acceptance criteria (two options):

• Repligen recommended:

o Specifications derived based on resin manufacturer recommendations, statistical process control (SPC) OPUS

Columns packing data, and inputs from applications development or historical packing experience.

• Customer specified:

o Chromatographic release criteria: plate count (N/m), asymmetry range, injection volume, injection solution,

Mobile phase solution, and linear velocity (cm/hr)

Application specific (if required):

• Pressure vs. flow requirements

• Maximum working flow rate

• Maximum working pressure to inform maximum packing pressure

• Chromatography resin sanitization method (post packing)

• Storage solution

Some column packing parameters cannot be configured as they are unique to the Repligen OPUS Column hardware, customized

packing techniques, and Standard Operating Procedures (SOP). Examples include:

• Chromatography resin compression or consolidation factor

• Packing solution

• Packing methods

Repligen will make an effort to understand and accommodate all requests. For example, request for packing with a specific flow rate

will initiate a conversation towards understanding the importance of that parameters to the overall process followed by adjustment

of the OPUS Column packing method as appropriate. The OPUS Specification Sheet documents all packing adjustments for each

column or part number.

OPUS Column hardware components, which includes inlet and outlet connection size, are not adjustable. See Figure 6

through

Figure 12 for more information on the OPUS Column hardware design.

9

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

The final OPUS Column configuration, generated by either quote request form or internal configuration tool, is submitted for review

by the Repligen Process Engineering and Manufacturing teams. Approval triggers issue of a quotation and an OPUS Column

Specification Sheet (QA-FM-04-10015), which documents user specified requirements. The Specification Sheet is provided to the

end-user for review and approval with the quotation package. Production of an OPUS Column requires receipt of both a Purchase

Order and an approved OPUS Column Specification Sheet from the end-user.

2.4 Resin supply

Resin used to pack an OPUS Pre-packed Chromatography Column may be procured by the end-user from the manufacturer followed

by drop shipment to Repligen or procured by Repligen directly from the manufacturer. Repligen maintains the following policy on

resin expirations dates for Repligen procured resin:

1. Repligen guarantees ≥12 months remaining resin shelf-life at the time of shipment.

2. For resins with less than 2 years of total shelf-life as stated from the supplier, Repligen will guarantee 50% of the shelf-life

upon column shipment.

3. Packing of resin with shelf-life expiry less than described above to availability requires customer notification and approval

prior to column packing.

End-user procured resin requires completion of the Customer Property Declaration Form (QA-FM-02-10035), which confirms health

and safety as well as customer procured resin tracking information. The unique Customer Property (CP) number assigned to each

OPUS Column Specification Sheet provides traceability of customer procured resin throughout the Repligen facility.

It is the responsibility of our customers to ensure resin delivered to Repligen has the necessary remaining shelf life based on your

project requirements. The Customer Property Declaration Form prompts our customers to agreeing for Repligen to release any resin

delivered to Repligen for column packing. Opting out of this statement on the form may lead to extended lead time of your OPUS

Column(s) based on extended resin lead times for additional resin volumes.

It is Repligen policy to pack no more than three (3) resin vendor lot numbers within a single OPUS Column. Should a customer send

greater than 3 resin vendor lot numbers for a column pack, Repligen requires written approval on official letterhead from the end

user customer to pack the resin.

2.5 OPUS Pre-packed Chromatography Column part numbers

OPUS Pre-packed Chromatography Column part numbers are structured as smart, embedded with select column configuration

information. Figure 1

describes the part number format for OPUS Column larger than 2.5 cm inner diameter.

• Field one (two characters) describes procurement mechanism.

o CC indicates end-user procured resin.

o BC indicates Repligen procured resin.

o CX indicates end-user procured resin and gamma irradiated column.

o BX indicates Repligen procured resin and gamma irradiated column.

• Field two (three characters) describes nominal column diameter in millimeters.

• Field three (four characters) describes the unique resin code (CPRI).

• Field four (three characters) describes the target/nominal bed height in millimeters.

• Field five (up to two characters) describe GMP level (Pre-GMP or GMP Run Ready) as well as if the column configuration

includes an OPUS Resin Recovery port (PR or GR).

• Field six (five characters) describes the optional tubing set for attachment to the OPUS Column prior to release (TSXXX).

10

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Figure 1. OPUS Column part number format

The OPUS Column part number system, governed by QA-FM-10107, does not generate a unique output for all column specifications.

The OPUS Column Specification Sheet (Figure 14

), generated upon initiation of column production serves as a unique identifier, even

if the same column/part number is re-ordered.

For example, an OPUS 45R Pre-packed Chromatography Column with a 15 cm bed height and packed with Repligen-procured

CaptivA® Resin, would be assigned the part number BC-450-CPRI-150-GR. In some cases, customer specific part numbers can be

created upon request to reflect specific end-user requirements.

2.6 Summary of OPUS Pre-packed Chromatography Column production processes

Column components: Incoming raw materials and components prioritized by risk assessment are subject to an inspection

procedure. Parts that comply with the criteria described in the Raw Materials and Component Specifications documents are released

for column assembly and packing.

Resins: Consistent with good documentation practices, Repligen maintains material control of all resins, including assignment of

internal lot numbers, to enable full traceability within batch records. The SOP that govern these procedures include SOP-1094

(Control of Incoming Materials), SOP-10042 (Control of Incoming Components) and SOP-10035 (Customer Property).

Manufacturing qualification: Column assembly processes are qualified and documented with SOP and batch records as specified in

the Repligen ISO 9001 Quality Management Systems.

Preparation of Column Components: Column parts are washed and cleaned, according to qualified and validated protocols, prior to

assembly.

Column packing: All OPUS GMP Run Ready and Pre-GMP Pre-packed Chromatography Column are packed in controlled and

classified clean rooms that meet ISO Class 7 standards.

Note: See Section 3

for more detailed information on the OPUS Column production process.

Quality control and Release: Individual OPUS Columns are individually tested according to the corresponding OPUS Column

Specification Sheet. The specifications and the results of the release tests are documented on the Certificate of Analysis (CoA).

Packaging: Packed columns are secured in qualified shipping containers using foam protective packaging material. All OPUS Columns

ship with tamper evident packaging and all inlets and outlets are secured with tamper evident SaniSure® clamps (Figure 2

).

11

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Figure 2. OPUS Pre-packed Chromatography Column packaging: Tamper evident clamps

OPUS 60R Pre-packed Chromatography Column shipped with tamper evident SaniSure® Clamps on inlet and outlet ports.

Figure 3. OPUS 60R Pre-packed Chromatography Column prepared for shipment

See Section 5

for more information on packaging and shipping qualification.

2.7 Performance

OPUS Pre-packed Chromatography Columns provide chromatographic performance equivalent to or better than traditional self-

packed columns. Performance is attained through a semi-automated packing process and a flow distribution system design.

• Optimal flow distribution is achieved through a flow distributor designed with minimal dead volume. Rigorous

Computational Fluid Dynamics (CFD) model, which was validated through experimental testing, supports the design

elements that meet or exceed traditional column flow distribution uniformity.

• Multi-cycle performance tests document robust and reproducible chromatographic results.

12

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Note: More information on column performance can be found at repligen.com/OPUS.

Ease-of-use

OPUS Pre-packed Chromatography Columns incorporate ease of use features such as lifting handles, casters and industry standard

sanitary tri-clamp flow port connections (Table 1).

Inlet/Outlet port locations

• OPUS Pre-packed Chromatography Columns sized 10 – 80R cm ID: Inlet and outlet ports both are located on the top of the

column. Connection to the column inlet and outlet ports is secured with a tri-clamp fitting, designed by SaniSure to be both

leak-proof and tamper-evident.

• OPUS Pre-packed Chromatography Columns sized 5 and 8 cm ID: Inlet and outlet ports are located at both ends of the

column tube, typical for lab scale self-pack column design.

Table 1. Column handling features

Feature

OPUS Columns

5

8

10

12.6

14

20

25

30

36R

45R

60R

80R

Handles No No No No Yes Yes Yes Yes No No No No

Casters No No No No No No No No Yes Yes Yes Yes

Manually lift Yes Yes Yes Yes Yes Yes Yes Yes No No No No

Lifting handles

Figure 4. Handles and inlet/outlet ports for OPUS 20 - 30 Pre-packed Chromatography Column

OPUS Pre-packed Columns sized 14 – 30 cm ID: Handles are located on adjacent sides on the top of the column (Figure 4).

Please follow all local or regional safety guidelines when lifting columns. See Table 11 for approximate column mass.

1

2

3

1. Inlet

2. Outlet

3. Lifting Handle

13

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Casters

Four twin wheel swivel castors allow movement through a facility. (Figure 5

). Each castor is rated to hold ≥100 kg of weight. A

manually engaged wheel lock can restrict castor movement. The bottom column of the cap is designed with channels to allow lifting

of the column with straps. Please contact Repligen Customer Service for more information on how to utilize straps to lift an OPUS

Column.

Figure 5. Caster detail on an OPUS 36R-80R Pre-packed Column

2.8 Reference documentation

The following documents can be found at repligen.com

.

Quality Documentation: The Repligen ISO 9001 ISO certificate indicating that Repligen follows industry standards for document

control.

Technical specifications: External column dimensions are provided in this Regulatory Support File. All other column packing

specifications and end user specified criteria are documented on the OPUS Columns Specification Sheet.

User Guide: User guides for all OPUS Columns

Unpackaging Guide: Unpackaging guides are available for all OPUS Columns.

Technical Documents: A variety of supporting technical documents, presentations, and videos.

CE-Certificate: EG directive 97/23/EG is not applicable to OPUS Pre-packed Chromatography Columns and therefore columns are not

CE-marked.

2.9 Materials of construction:

OPUS Pre-packed Chromatography Columns from 2.5 to 80 cm ID are designed using plastics best suited for downstream processing

of biologic molecules. These plastics were chosen for performance characteristics including:

• Suitability for pharmaceutical use with process fluid contact

• USP Class VI compatibility

• Low levels of extractables

• Free from materials of animal origin and/or compliant with EMA 410/01

14

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Table 2. Product contact materials of construction

OPUS Column component Material USP <88> Class CFR 21 177 Animal origin

Column Tube (2.5 – 30 cm ID) Polypropylene (PP) Class VI 177.1520 Animal Free

Column Tube (36R – 80R)

70% w/w E-Glass/PP

engineered composite structure

Class VI 177.1520 Animal Free

Flow Distributors Polypropylene Class VI 177.1520 Animal Free

Inlet and Outlet Ports Polypropylene Class VI 177.1520 Animal Free

Bed Support Screens Polypropylene Class VI 177.1520 EMA 410/01

Flow Distributor O-Rings Platinum-cured medical grade silicone Class VI 177.2600 Animal Free

Return Lines

Platinum-cured medical grade silicone,

reinforced with strong polyester fiber

Class VI 177.2600 Animal Free

R Plug and Inside Port Polypropylene Class VI 177.1520 Animal Free

R Inner/Outer Gaskets and Plug O-ring Platinum-cured medical grade silicone Class VI 177.2600 Animal Free

Note: The 12 μm polypropylene bed support screen is ultrasonically welded to the flow distributor.

Non-product contact materials summary

• Top and bottom caps: acrylonitrile butadiene styrene (ABS) co-polymer or high-density polyethylene (HDPE)

• Side guard: ABS (blue)

• Inlet and outlet port grommets: silicone (blue)

• Handles: polyurethane (blue)

• Castors: Polyamide casing with non-marking grey polyurethane tires

• OPUS R outer nut and washer: ABS

• OPUS R Bio Clamp: glass filled nylon

For a signed copy of the OPUS Pre-packed Chromatography Columns BSE/TSE Free Statement, contact Customer Support at

customerserviceUS@repligen.com or customerserviceEU@repligen.com

.

15

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

2.10 Column design

Figure 6. OPUS 2.5 Pre-packed Chromatography Column design

External View Cutaway View

Figure 7. OPUS 5 and 8 Pre-packed Chromatography Column design

External View Cutaway View

1

2

3

4

5

6

7

1. Inlet port

2. Top cap

3. Column tube

4. Bottom cap

5. Outlet port

6. Flow distributor and

bed support mesh

7. O-rings

6

7

1

2

3

4

5

1. Inlet port

2. Top cap

3. Column tube

4. Bottom cap

5. Outlet port

6. Flow distributor and

bed support mesh

7. O-rings

16

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Figure 8. OPUS 10 – 30 Pre-packed Chromatography Column design (OPUS 20 shown)

1

2

3

4

5

6

7

8

9

1. Top cap

2. Outlet

3. Side-guard

4. O-rings

5. Bottom cap

6. Inlet

7. Tube

8. Flow distributor and

support mesh

9. Return line

Flow Distributor

(12 µm mesh size)

17

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Figure 9. OPUS 45 – 60 Pre-packed Chromatography Column design (no R port)

1. Top cap

2. Outlet

3. Side-guard

4. O-rings

5. Bottom cap

6. Casters

7. Inlet

8. Tube

9. Flow distributor and 12 µm mesh

10. Return line

1

2

3

4

5

6

7

8

10

Flow Distributor

(12 µm mesh size)

9

18

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Figure 10. OPUS 36R – 80R Pre-packed Chromatography Column design (OPUS 80R shown)

Figure 11. OPUS R Port design

1. Inside port (Polypropylene)

2. Inner gasket (Silicone)

3 Outer gasket (Silicone)

4 Plug O-ring (Silicone)

5 OPUS® R Plug (Polypropylene)

6 1 inch TC sanitary clamp (Glass Filled Nylon)

1. Outlet

2. Top cap

3. Side-guard

4. Tube

5. R port

6. Return line

7. Casters

8. Inlet

9. O-rings

10. Flow distributor and 12 µm mesh

11. Bottom cap

1

2

3

4

5

6

7

8

11

10

9

Flow Distributor

(12 µm mesh size)

1

2

3

4

5

6

19

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

2.11 OPUS H-Tubing Sets

The H-tubing set utilizes a column bypass mechanism that enables a flush and sanitization of the flow path, eliminates the need for

bulky stainless steel 3- or 4-way valves, and reduces the likelihood of air entering the packed bed.

Figure 12. OPUS H-tubing Set Design

Use Instructions:

• Column is delivered with the tubing filled with storage solution and attached to the inlet and outlet of the column.

Note: All four pinch clamps will be engaged.

• To prime the tubing, connect the inlet line from the pump to the top of the inlet side of the tubing set (above pinch valve 1).

• Open pinch valves 2 and 3 for bypass mode of the tubing set

• Connect the outlet line to the top of the outlet side of the tubing set (pinch valve 4).

• Flush buffer through the tubing set in bypass mode for removal of air and cleaning. Ensure constant flow is exiting the

tubing set and there are no visual bubbles in the tubing

• Close pinch valves 2 and 3

• Open pinch valve 1 and 4 to direct flow through the column.

Note: If removing storage solution, start the operation using a linear velocity of 50 cm/hour. Flow rate can be increased slowly as

long as backpressure does not exceed 80% of the maximum pressure achieved during column packing.

Materials of construction:

• Braided platinum cured silicone tubing

• Polypropylene T-adapters and end-fittings

20

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Tubing sets are also available with aseptic connectors for the OPUS 2.5 – 30 cm ID columns. See below for available tubing sets

based on flow path ID and connector types (Table 3).

Table 3. OPUS H-Tubing Set Connector and sizing options

ID Range Tri-Clamp ReadyMate™ AseptiQuik® Kleenpak™ Presto

OPUS 2.5 ⅛" ID Flow Path (TS024) N/A ⅛" ID Flow Path AQS (TS025) N/A

OPUS 5 – 8

1

⅛" ID Flow Path (TS033) ⅛" ID Flow Path (TS019) ⅛" ID Flow Path AQS (TS023) ⅛" ID Flow Path (TS020)

OPUS 10 – 12.6 ¼" ID Flow Path (TS006) ¼" ID Flow Path (TS018) ¼" ID Flow Path AQG (TS007) ¼" ID Flow Path (TS010)

OPUS 14 – 20 ¼" ID Flow Path (TS001) ¼" ID Flow Path (TS009) ¼" ID Flow Path AQG (TS012) ¼" ID Flow Path (TS011)

OPUS 25 – 30 ⅜" ID Flow Path (TS002) ⅜" ID Flow Path (TS016) ⅜" ID Flow Path AQG (TS015) ⅜" ID Flow Path (TS017)

OPUS 36R ½" ID Flow Path (TS031) N/A N/A N/A

OPUS 45R ½" ID Flow Path (TS003) N/A N/A N/A

OPUS 60R ¾" ID Flow Path (TS004) N/A N/A N/A

OPUS 80R ¾" ID Flow Path (TS013) N/A N/A N/A

1

¼" ID flow path (TS032) with AseptiQuik G also available.

For OPUS H-tubing sets with aseptic connectors, two additional pinch valves are engaged on both the inlet and outlet tubing below

the aseptic connectors. Operation of the tubing set in bypass or flow-through mode be performed with both pinch clamps

disengaged.

Figure 13. Example OPUS H-Tubing Set with Aseptic Connectors

1. Base H-Tubing Set

2. Braided Silicone Tubing

3. Tri-clamp Barb Fitting

4. Aseptic Connector

5. Tri-clamp

6. Oetiker clamp

7. Biovalve pinch clamp

21

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

2.12 OPUS Pre-packed Chromatography Column physical specifications

2.12.1 Mechanical strength: Column hardware pressure rating

All columns were designed and qualified with a factor of safety (FOS) of >2X the maximum operating pressure. Pressure integrity was

established with pressure hold studies on empty columns filled with water. To pass a pressure hold integrity test a column must hold

a designated pressure with minimum decay (e.g., ≤5 psi) over a defined period of time. Ambient, 4°C, and 40°C have been evaluated

with passing results. See below for representative tests and results.

Table 4. OPUS Column 2.5 cm ID pressure integrity testing

Pressure Test Verification Method Acceptance Criteria Results

Temperature: Ambient

Pressure hold test at >1.5x the

recommended operating pressure

(4 bar).

≥6 bar (87 psi) pressure hold for 2 hours in

water. After 30 minutes stabilization column

must have ≤5 psi decay over 90 min, with no

visible water leaking.

Pass

Temperature: 4°C

Incubate water-filled column (no

resin) overnight in 4°C chamber, and

test column integrity at maximum

recommended operating pressure.

Pressure test at ≥6 bar, must be less than 5

psi decay over 90 min after 30 min

stabilization.

Pass

Temperature: 40°C

Incubate water-filled column (no

resin) overnight in 40°C chamber, and

test column integrity at maximum

recommended operating pressure.

Pressure test at ≥6 bar, must be less than 5

psi decay over 90 min after 30 min

stabilization.

Pass

Burst pressure

Destructive test on assembled

column.

Record burst pressure for assembled

column

(no resin)

Pass

Failure at >200 psi (>13 bar).

Table 5. OPUS Column 8 cm ID pressure integrity testing*

Pressure Test Verification Method Acceptance Criteria Results

Temperature: Ambient

Pressure hold test at >1.5x the

recommended operating pressure

(4 bar).

100 psi pressure hold for 2 hours in water.

After 60 minutes stabilization column must

have ≤5 psi decay over 60 min, with no

visible water leaking.

Pass

Temperature: 4°C

Run cooled water through system

(no resin) until equilibrium, and test

column integrity at maximum

recommended operating pressure.

Pressure test at 4 bar, must be less than 5

psi decay over 30 min after 30 min

stabilization.

Pass

Temperature: 40°C

Run heated water through system

(no resin) until equilibrium, and test

column integrity at maximum

recommended operating pressure.

Pressure test at 4 bar, must be less than 5

psi decay over 30 min after 30 min

stabilization.

Pass

Burst pressure

Destructive test on assembled

column.

Record burst pressure for assembled

column(no resin)

Pass

Failure at >500 psi (>34 bar).

*Representative of 5 and 8 cm ID columns.

22

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Table 6. OPUS Column 12.6 cm ID pressure integrity testing*

Pressure Test Verification Method Acceptance Criteria Results

Temperature: Ambient

Pressure hold test at >1.5x the

recommended operating pressure

(4 bar).

100 psi pressure hold for 2 hours in water.

After 60 minutes stabilization column must

have ≤5 psi decay over 60 min, with no

visible water leaking.

Pass

Temperature: 4°C

Run cooled water through system

(no resin) until equilibrium, and test

column integrity at maximum

recommended operating pressure

Pressure test at 4 bar must be less than 5 psi

decay over 30 min after 30 min stabilization.

Pass

Temperature: 40°C

Run heated water through system

(no resin) until equilibrium, and test

column integrity at maximum

recommended operating pressure.

Pressure test at 4 bar must be less than 5 psi

decay over 30 min after 30 min stabilization.

Pass

Burst pressure

Destructive test on assembled

column.

Record burst pressure for assembled

column (no resin).

Pass

Failure at >400 psi (>27 bar).

*Representative of 10 – 30 cm ID columns.

Table 7. OPUS 80R Pre-packed Chromatography Column pressure integrity testing*

Pressure Test Method Acceptance Criteria Results

Temperature: Ambient

Pressure hold test at 2x the

recommended operating pressure

(3 bar).

Pressurize column assembly to 6 bar for 2

hours with water at 22°C ± 3°C. 30 minutes

pressure stabilization, 1.5 hr hold ≤5 psi

decay, no visible water leaking w/ 3

assemblies

Pass

Temperature: 4°C

Fill column with water; Store column

in 2 – 8°C overnight (to equilibrate).

Pressurize assembly to maximum

recommended operating pressure.

Pressurize column assembly to 3 bar for 2

hours with water. 30 minutes pressure

stabilization, 1.5 hr hold ≤5 psi decay, no

visible water leaking.

Pass

Temperature: 40°C

Circulate 40 ±3°C water through

system for 1 hour @ 100 cm/hr.

Pressurize assembly maximum

recommended operating pressure for

2 hours with water.

Pressurize column assembly to 3 bar for 2

hours with water. 30 minutes pressure

stabilization, 1.5 hr hold ≤5 psi decay, no

visible water leaking.

Pass

Burst pressure Due to large size of the column, a suitably safe environment was not available to evaluate for burst pressure.

*Representative of 36R – 80R Columns.

Note: Exceeding the maximum column hardware pressure rating will void the Repligen warranty statement (Section 2.16

).

23

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Table 8. OPUS Column Hardware pressure ratings

Column

ID

OPUS

5

OPUS

8

OPUS

10

OPUS

12.6

OPUS

14

OPUS

20

OPUS

25

OPUS

30

OPUS

36R

OPUS

45R

OPUS

60R

OPUS

80R

Pressure

Rating (bar)

4 4 4 4 4 4 4 4 3 3 3 3

Note: The pressures reported above are the pressure limits of the hardware to prevent leaks, cracks, breaks, and damage to

components. The suggested operating pressure will be based on the packing pressure of the resin, and will be less than the

above pressure limits. Refer to column label and CoA for the column-specific packing pressure.

2.12.2 Packed bed integrity: packed column pressure rating

OPUS Pre-packed Chromatography Columns are packed according to Repligen SOP and end-user specifications. Maximum pressure

achieved during packing is noted on either the column label and/or Certificate of Analysis. Exceeding the maximum packing pressure

stated on the Certificate of Analysis and column label will likely compromise the packed bed integrity and void the Repligen warranty

statement (Section 2.16

). Therefore, Repligen recommends establishing an appropriate margin of safety to the maximum packing

pressure achieved when assigning a maximum operating pressure.

Table 9. Physical specifications summary: OPUS Columns 2.5 – 30

Physical Attributes OPUS 5 OPUS 8 OPUS 10 OPUS 12.6 OPUS 14 OPUS 20 OPUS 25 OPUS 30

Diameter 5.1 cm 8.1 cm 10 cm 12.6 cm 14 cm 20 cm 25 cm 30 cm

Internal cross section 20.4 cm

2

51.5 cm

2

78.5 cm

2

125 cm

2

154 cm

2

314 cm

2

491 cm

2

707 cm

2

Column body pressure rating 4 bar 4 bar 4 bar 4 bar 4 bar 4 bar 4 bar 4 bar

Bed height range 5 – 30 cm 5 – 30 cm 5 – 30 cm 5 – 30 cm 5 – 30 cm 5 – 30 cm 5 – 30 cm 5 – 30 cm

Column

volumes

10 cm

bed height

0.2 L 0.5 L 0.8 L 1.3 L 1.5 L 3.1 L 4.9 L 7.1 L

20 cm

bed height

0.4 L 1 L 1.6 L 2.5 L 3.1 L 6.3 L 9.8 L 14.1 L

30 cm

bed height

0.6 L 1.5 L 2.4 L 3.8 L 4.6 L 9.4 L 14.7 L 21.2 L

Assembled column height

(plus column bed height)

~20 cm ~20 cm ~20 cm ~28 cm ~30 cm ~30 cm ~33 cm ~35 cm

Outer diameter

(cm, including caps)

7 cm 10 cm 16 cm 20 cm 21 cm 27 cm 33 cm 38 cm

Inlet/outlet flow path

internal diameter

3.45 mm

(5/32 in)

4.57 mm

(3/16 in)

6.35 mm

(1/4 in)

6.35 mm

(1/4 in)

6.35 mm

(1/4 in)

6.35 mm

(1/4 in)

9.53 mm

(3/8 in)

9.53 mm

(3/8 in)

Inlet/outlet port connectors

3/4 in mini

tri-clamps

3/4 in mini

tri-clamps

3/4 in mini

tri-clamps

3/4 in mini

tri-clamps

3/4 in

mini

tri-clamps

3/4 in

mini

tri-clamps

3/4 in

mini

tri-clamps

3/4 in

mini

tri-clamps

24

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Table 10. Physical specifications summary: OPUS 36R – 80R Pre-packed Chromatography Columns

Physical Attributes OPUS 36R OPUS 45R OPUS 60R OPUS 80R

Diameter 36 cm 45.7 cm 59.9 cm 79.9 cm

Internal cross-section 1020 cm

2

1640 cm

2

2818 cm

2

5014 cm

2

Column body pressure rating 3 bar 3 bar 3 bar 3 bar

Bed height range

1

10 – 30 cm 10 – 30 cm 10 – 30 cm 10 – 30 cm

Column volumes

10 cm bed height 10 L 16 L 28 L 50 L

20 cm bed height 20 L 33 L 56 L 100 L

30 cm bed height 31 L 49 L 84 L 150 L

Assembled column height

1

≤22 cm bed height ~87 cm ~90 cm ~93 cm ~97 cm

>22 cm bed height ~113 cm ~116 cm ~120 cm ~123 cm

Outer diameter

(including caps)

10 cm bed height 45 cm 54 cm 68 cm 91 cm

Inlet/outlet flow path internal diameter 12.7 mm (1/2 in) 12.7 mm (1/2 in) 19.1 mm (3/4 in) 19.1 mm (3/4 in)

Inlet/outlet port connectors ¾" mini tri-clamps ¾" mini tri-clamps 1" tri-clamps 1" tri-clamps

1

Estimates based on the target bed height.

Note: OPUS 36R – 80R Pre-packed Chromatography Columns have a minimum bed height of 10 cm, OPUS 45 and 60 Pre-packed

Chromatography Columns without an R port have a minimum bed height of 5 cm.

Table 11. Column mass (approximate weight of packed columns in kilograms)

Bed

height

OPUS

5

OPUS

8

OPUS

10

OPUS

12.6

OPUS

14

OPUS

20

OPUS

25

OPUS

30

OPUS

36R

OPUS

45R

OPUS

60R

OPUS

80R

5 cm 0.5 1.0 2.0 4.0 4.0 6.0 10 14 43 69 117 235

10 cm 0.5 1.5 2.5 4.5 5.0 8.0 13 18 48 77 131 260

15 cm 1.0 1.5 3.0 5.5 6.0 10 16 22 54 86 145 285

20 cm 1.0 2.0 3.5 6.0 7.0 12 19 26 59 94 159 310

30 cm 1.5 2.5 4.0 8.0 9.0 16 24 34 69 110 187 335

2.1.3 Thermal stability

Column construction can support a working temperature range of 2°C to 40°C based on the general properties of polypropylene as

well as OPUS Pre-packed Chromatography Column ISTA shipping tests (Section 5.3

).

2.13 Column shelf-life

Repligen conducted four studies to assess shelf-life stability for OPUS Pre-packed Chromatography Columns when stored according

to instructions in the user guide. The rationale for the multi-study approach was to group columns based on their cylindrical tube

design and minimize potential variables during evaluation. The first study evaluated OPUS 10 – 30 Pre-packed Chromatography

Columns over an 18 month period. The second study evaluated OPUS 36R – 80R Pre-packed Chromatography Columns family over a

longer period in response to end-user requests for time points up to 5 years. In this study, the OPUS 80R Pre-packed

Chromatography Column was deemed the worst-case condition for column stability given the high volume of resin and lack of

column wall support for the packed resin beads. The third study qualifies the shelf life of OPUS 5-30 Pre-packed Chromatography

25

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Columns for at least 24 months based on mechanical stability testing within an on-going study. The fourth study qualifies the shelf

life of OPUS 5 – 8 Pre-packed Chromatography Columns for 5 years based on single point retrospective data.

Table 12. Column shelf-life summary

Study Number Column Family Column IDs Tested Tube Materials Time Period Status

1 OPUS 10 –30 Columns OPUS 10, 20, 30 Polypropylene 18 months Complete

2

OPUS 36R – 80R

Columns

OPUS 80R

70% w/w E-Glass/Polypropylene

engineered composite structure

60 months Complete

3 OPUS 5 - 30 OPUS 5, 30 Polypropylene 24 months On-going

4 OPUS 5- 8 OPUS 5, 8 Polypropylene 60 months Complete

For column performance testing, Study 1 –3 used agarose resin type for the packed column aspect of the study. Study 4 used

styrene based resin type for the packed colum aspect of the study. Therefore, this study can serve as general guidance for the >250

types of resins which can be packed into OPUS Columns. All columns were stored cold at 2 – 8°C, which represents most challenging

temperature for the integrity of plastic components, and then allowed to equilibrate to room temperature (25°C) before

experiments were performed.

Note: An additional study has been completed for gamma irradiated OPUS 2.5 – 30 Columns. Details of this study are found within

the OPUS Gamma Regulatory Support File.

2.13.1 Mechanical stability

The mechanical stability assessment looked at column structural integrity at pre-determined time points post-assembly. Columns

were filled with 18.5% ethanol (Study 1) or RODI water (Study 2, 3, and 4) and then were pressurized. Pressure decay was monitored

over a set period. During this pressure hold period, the column was visually inspected for gross failure such as leakage from ports

and/or threads, and general structural integrity. See Table 13

for the mechanical stability test schedule and acceptance criteria and

Table 14 for results.

Note: The OPUS 80R Pre-packed Column exhibited increased pressure drop in the initial 30 minutes of the hold because of the higher

surface area subject to plastic stretching. To confirm the column was not leaking, the OPUS 80R Pre-Packed Chromatography

Column hold time was increased to 120 minutes. Based on the reported pressure trend data for the OPUS 80R Pre-Packed

Chromatography Column, the same conclusion of an integral column design and assembly could be achieved at the 60 minute

data point.

2.13.2 Chromatographic performance

Chromatographic performance was assessed over multiple time points by demonstrating that no significant performance

degradation occurs during time in storage. For Study 1, one column was re-tested at each of the time intervals and compared to the

performance of that specific column at time zero. For Study 2, a single OPUS 80 Pre-Packed Chromatography Column was retested at

each of the time intervals and compared to the performance at time zero. For Study 4, only one testing of columns at 5 year

timepoint is used for comparison against performance at time zero. See Table 13 for acceptance criteria and Table 15

for results.

Note: Study 1 is the only study to sample bioburden and endotoxin data because only a single column was tested at each time point;

the potential for artifact bioburden and endotoxin results due to reuse was probable based on experimental design for Study 2,

3, and 4.

26

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Table 13. Stability study schedule and acceptance criteria

Study

Number

Time Interval

Mechanical Stability Criteria

(Empty Columns)

Performance Stability Criteria

(Packed Columns)

Study 1 T = 0

Testing:

Time at Pressure: 60 minutes

Pressure: 4 bar

Acceptance:

Pressure decay: ≤5 psi

Visual: No gross defects or leaks

Acceptance:

Asymmetry: 0.8 – 1.6

Plate count: >1500 N/m (100 cm/hr)

Endotoxin: ≤1.0 EU/mL

Bioburden: ≤100 CFU/mL

Study 1 T = X months

Acceptance:

Pressure decay: ≤5 psi

Visual: No gross defects or leaks

Acceptance:

Endotoxin: ≤1.0 EU/mL

Bioburden: ≤100 CFU/mL

Comparison to T = 0 time point:

N/m Δ = <15%

A

s

Δ = <15%

Study 2 T = 0

Testing:

Time at Pressure: 120 minutes

Pressure: 3 bar

Acceptance:

Pressure decay: ≤5 psi

Visual: No gross defects or leaks

Acceptance:

Asymmetry: 0.8 – 1.8

Plate count: >2000 N/m (100 cm/hr)

Study 2 T = X months

Acceptance:

Pressure decay: ≤5 psi

Visual: No gross defects or leaks

Acceptance:

Comparison to T = 0 time point:

N/m Δ = <20%

A

s

Δ = <20%

Study 3 T = 0

Testing:

Time at Pressure: 60 minutes

Pressure: 4 bar

Acceptance:

Pressure decay: ≤5 psi

Visual: No gross defects or leaks

N/A

Study 3 T = X months

Acceptance:

Pressure decay: ≤5 psi

Visual: No gross defects or leaks

N/A

Study 4 T = 0

Testing:

Time at Pressure: 60 minutes

Pressure: 4 bar

Acceptance:

Pressure decay: ≤5 psi

Visual: No gross defects or leaks

Acceptance:

Asymmetry: 0.8 – 1.8

Plate count: >4000 N/m (100 cm/hr)

Study 4 T = X months

Acceptance:

Pressure decay: ≤5 psi

Visual: No gross defects or leaks

Acceptance:

Comparison to T = 0 time point:

N/m Δ = <20%

A

s

Δ = <20%

All columns passed acceptance criteria at each interim time point, as well as at the final time point.

27

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Note: At the completion of Study 1 (18 months), bioburden and endotoxin for all columns (serial numbers 0001 – 0004) was

0 CFU/mL and <0.1 EU/mL, respectively.

Table 14. Mechanical stability test results

OPUS

Pre-packed

Column Size

Months

3

6

9

12

18

19

24

30

36

48

60

61

5 x 20 cm Pass Pass

Pass

Pass Pass N/A

Pass

N/A N/A N/A N/A

Pass

10 x 20 cm Pass Pass N/A Pass Pass N/A N/A N/A N/A N/A N/A N/A

20 x 20 cm Pass Pass N/A Pass Pass N/A N/A N/A N/A N/A N/A N/A

30 x 20 cm Pass Pass

Pass

Pass Pass N/A

Pass

N/A N/A N/A N/A N/A

80 x 20 cm Pass

Table 15. Performance stability study results

OPUS

Pre-packed

Column Info

Months

3

6

9

12

18

19

24

30

36

48

60

61

5 x 20 cm

N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

Pass

8 x 20 cm

N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A Pass

20 x 15 cm

Serial number 0001

Pass N/A N/A N/A Pass N/A N/A N/A N/A N/A N/A N/A

20 x 15 cm

Serial number 0002

N/A Pass N/A N/A Pass N/A N/A N/A N/A N/A N/A N/A

20 x 15 cm

Serial number 0003

N/A N/A N/A Pass Pass N/A N/A N/A N/A N/A N/A N/A

20 x 15 cm

Serial number 0004

N/A N/A N/A N/A Pass N/A N/A N/A N/A N/A N/A N/A

80 x 20 cm Pass

1

1

80 cm column Serial number 0001 N/m increased by 23% from t = 0 to t = 3 month testing. Results were deemed satisfactory

because 1) no degradation in column performance was observed relative to t = 0, and 2) the column performance was stable

throughout all subsequent tests after the t = 3 month result.

2.13.3 Conclusion and Interpretation of OPUS Pre-packed Chromatography Column shelf-life data

OPUS Pre-packed Chromatography Columns are designed to enable multi-campaign use over a period of months or years. The data

presented for Study 2 demonstrates OPUS 36R, 45R, 60R, and 80R Pre-packed Chromatography Columns maintain mechanical and

chromatographic performance characteristics over a 61-month period. Therefore, this study confirms a 61-month shelf life for OPUS

36R, 45R, 60R, and 80R Pre-Packed Chromatography Columns, but does not consider the potential impact of process design (e.g.,

flow rates, pressure) or process fluids.

In conjunction with the data from the shelf-life studies, we provide guidance below for the justification of column operation over-

time in a downstream chromatography process: An end user may can justify extending OPUS Column hardware and packed bed

shelf-life by assessing plate count and asymmetry data combined with pressure flow tests (e.g., pressure flow curve). Trending

asymmetry, plate count, and pressure flow data over time allows an end user to confirm the integrity of the column hardware as

well as the integrity of the packed bed. This data can then be used to justify the extension of pre-packed column shelf life. In

addition, resin expiration dates and process qualification data (i.e. cycle stability of the resin), should also be considered when

assessing pre-packed column shelf-life.

28

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Data trending over time of asymmetry, plate count, and pressure flow for pre-packed columns should be similar to how self-packed

column lifetime and hardware integrity is assessed. For example, self-packed columns are tested against specifications prior to use in

purification processes to assess hardware integrity as well as packed bed integrity. A similar approach can be used for OPUS

Columns.

2.14 Solvent compatibility

The solvents listed had no detected effect on the integrity of the plastic. This is equivalent to an A = Excellent rating for chemical

compatibility.

• 20% Acetic acid

• 10% Acetone

• Benzyl alcohol

• Citric acid

• 2% (w/v) Detergents

• 20% Ethanol

• 6 M guanidine HCl

• HCl (< 20%)

• Isopropyl alcohol (IPA)

• Methanol

• Phosphoric acid

• Potassium hydroxide

• 2 M sodium hydroxide

• Sulfuric acid (< 50%)

• 8 M Urea

• Water

2.15 Cleaning

OPUS Pre-packed Chromatography Columns are used for purification of biological products which have specific regulatory

requirements for bioburden and endotoxin levels. Therefore, a quantitative cleaning investigation was performed to demonstrate

the effectiveness of sanitization using sodium hydroxide as a cleaning agent.

Method

Several different OPUS Columns were packed with agarose resin in 20 cm bed heights. Each column was loaded with 1 column

volume of E. coli bacteria at a concentration of 0.1 OD (optical density) at 600 nm. The columns were left to incubate at ambient

temperature overnight, and then flushed with reverse osmosis deionized (RODI) water for 2 – 3 column volumes in downflow.

Samples were collected to measure bioburden and endotoxin.

A sanitization procedure was subsequently used as followed:

• Flush with 1 M sodium hydroxide in upflow at 100 cm/hr for 30 minutes

• Flush with 1 M sodium hydroxide in downflow at 100 cm/hr for 30 minutes

• Recirculation of 1 M sodium hydroxide for 2 hours in upflow at 100 cm/hr

• Incubation of the column in 1 M sodium hydroxide for 1 – 5 hours (static sanitization for compete removal of endotoxins)

• Flush with RODI water at 100 cm/hr until neutral pH is achieved

Each column was then left to incubate at ambient temperature overnight prior to pulling samples for bioburden and endotoxin

testing.

Results

Results for bioburden and endotoxin levels from the microbial challenge are outlined in the table below, which shows the

sanitization procedure completely removed bioburden from millions of CFU to zero CFU in the post-sanitization water rinse. In

addition, endotoxin levels were brought below the limit of detection (0.25 EU/mL) for the assay.

29

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Table 16. Results of bioburden and endotoxin testing

Cleaning Method

Column Diameter

2.5 8 12.6 20 30 36R 45R 60R 80R

0.1 M NaCl effluent after overnight

E. coli incubation

TNTC

1

CFU/mL

>0.25 EU/mL

0.1 M NaCl post sanitization effluent

0 CFU/mL

<0.25 EU/mL

1

Too numerous to count.

Conclusions

In order to test effectiveness of sanitization on an OPUS Column, a worst-case scenario was devised where the column was loaded

with an excess of E. coli culture (a gram-negative, endotoxin producing bacteria). The results of the sanitization protocol

demonstrate the effective removal of bioburden and endotoxin contamination.

2.16 Warranty

2.16.1 General warranty

Repligen aspires to complete customer satisfaction and has implemented the following warranty policy for OPUS Pre-packed

Chromatography Columns.

• If the column arrives at the customer site in damaged condition, Repligen will accept the damage risk and issue a

replacement at no charge

• If the column fails passing specifications as agreed to on the OPUS Column Specification Sheet, Repligen will conduct

troubleshooting efforts and if unsuccessful, will ask for the column to be returned for further evaluation. If the root cause

of the failed test is determined to be a compromised packed bed, Repligen will pack a replacement at no charge

• If the packed bed is compromised (e.g., a channel develops) and the root cause is packing, then Repligen will replace the

column at no charge

Note: If an end-user exceeds the maximum packed bed pressure and/or the maximum hardware pressure as stated on the column

label and/or Certificate of Analysis, warranty is void.

2.17 Use of TempTale® Multi-alarm Temperature Monitors

The addition of a TempTale Multi-Alarm Temperature Monitor is an add-on service Repligen offers at the request of our customers.

• Temperature monitoring data extracted from the monitor is for customer informational purposes only

• Customer cannot reject a shipment based on temperature monitoring data extracted from the monitor

• Customer cannot submit a warranty claim based on temperature monitoring data extracted from the monitor. Repligen will

require column qualification results post-delivery in order to compare a column performance post-delivery with the

chromatographic performance results indicated on the Certificate of Analysis

• Repligen accepts no liability for any claims that losses or damages are based on temperature monitoring data extracted

from the monitor

If customer requires guaranteed temperature control during transit from the Repligen manufacturing location to the delivery

destination, customer shall be invoiced for such service separately.

30

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

2.18 OPUS Gamma Pre-packed Chromatography Column Service Liability Statement

Repligen offers OPUS Pre-packed Columns that are gamma irradiated at the request of the customer. This customer-requested

service is subcontracted by Repligen to a third-party vendor for gamma processing.

Note: Repligen will not guarantee resin chromatographic performance post-gamma irradiation (e.g., capacity, selectivity). It is the

burden of the customer to investigate gamma irradiated resin compatibility and chromatographic performance for the

customer process. OPUS MiniChrom Columns are available to evaluate the impact of gamma irradiation on resin functionality.

This service is only offered for the OPUS 2.5 – 30 column ID size range. Customers must choose this option at the quoting stage. The

option is not available for previously packed OPUS Columns. For more information, please refer to the OPUS Gamma Regulatory

Support File on repligen.com

.

2.19 Safety Data Sheet (SDS)

OPUS Pre-packed Chromatography Columns are made from plastic components only and therefore no Safety Data Sheet (SDS) is

needed. An SDS for the chromatography resin packed into an OPUS Column may be obtained from the resin manufacturer.

3. Manufacturing information

3.1 Introduction

All OPUS 2.5 – 80R Pre-packed Chromatography Columns are manufactured in both the Repligen corporate headquarters, located at

41 Seyon Street, Waltham, Massachusetts 02453, USA and Repligen Europe B.V., Hoeksteen 13, 4815 PR BREDA, The Netherlands.

The Quality Assurance (QA) and Quality Control (QC) operations are also based in the same locations. Neither the facility nor

products manufactured require registration or market approval. Therefore, the Repligen column packing facility and products

manufactured herein are not subject to regulatory review or audit by organizations such as the US Food and Drug Administration or

European Medicines Agency.

3.2 Manufacturing Quality Assurance Standards and Policy

Repligen recognizes the need for high quality standards and has therefore established an ISO 9001 Quality Management System.

Refer to Section 1.1

for the Repligen Quality Policy.

3.2.1 Manufacturing Controls and SOP

Training [SOP-1498]: Manufacturing is performed by qualified and trained operators. Training documentation is maintained by

Quality Assurance.

Process documentation [SOP-1302, SOP-1098]: Repligen manufacturing processes are governed by an ISO 9001 compliant Quality

Management System. All manufacturing work instructions are contained in controlled documents, issued in advance of each

manufacturing batch. Batches and process intermediates are fully traceable through an internal lot numbering system. All

manufacturing data are recorded by operators at the time of manufacturing. Batch records are archived for 3 years on site, and

then stored off site for a minimum of 10 years.

Raw materials [SOP-1094]: Raw materials are controlled with pre-approved specifications. Receipt of material is verified and

released by QA prior to use in manufacturing.

Customer property [SOP-10035]: All customer property, including user supplied resin, is documented, tracked, and released prior to

the start of packing. Customer property is stored in segregated areas within the Repligen warehouse.

Supplier management [SOP-1496]: Repligen assesses critical suppliers of raw materials and components based on the impact to the

quality of the product they are used to manufacture. Critical suppliers are subject to a qualification process, monitored and

routinely audited according to a pre-determined schedule. The supplier audit schedule is established based on a critical supplier

audit cycle, supplier performance, past audit results, and business requirements.

31

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

Components [SOP-10042]: Components are controlled with pre-approved specifications. Receipt of material is verified and released

by QA prior to use in manufacturing. In addition, each OPUS Column component has a pre-approved engineering drawing, and is

subject to incoming QC inspection, which includes review of materials certificates, and verification of critical dimensions.

Process change management [SOP-1447]: Manufacturing process changes are governed by change management procedures that

include provisions for customer notification of major changes.

Product storage control [SOP-1263]: Product is stored either at ambient temperature, or in temperature-controlled units as dictated

by the packed resin. All temperature-controlled storage units have backup power supplies, 24/7 electronic monitoring, and alarms

that are monitored.

Preventive maintenance [SOP-1501] and calibration [SOP-1181]: Equipment and monitoring devices are controlled through the

Repligen Equipment Control process [SOP-1171]. Individual equipment components are uniquely identified and have a preventive

maintenance and/or calibration schedule as necessary.

High purity water [SOP-MFG-1209]: Purified water is supplied to all manufacturing areas from a Reverse Osmosis/Deionization

(RODI) system. The RODI system is fully automated and provides high quality water in a continuously circulating loop. The water

system design performance specifications are ASTM Type I Reagent Grade Water, with the addition of low endotoxin and bioburden

specifications (Table 15, Table16

).

Water quality is monitored continuously using an on-line total organic carbon (TOC) device and is routinely sampled and tested by

Repligen Quality Control.

Business continuity policy [CAP-1006]: The Repligen Corporation Business Continuity Management System (BCMS) is designed to

maintain the continuity of critical business activities in the case of an emergency situation and/or an event that severely impacts

business operations and ultimately the ability to supply product. Such events may include operational incidents, un-forecasted

product demand, man-made or environmental incidents or threats, and natural disasters. Proper maintenance and application of

BCMS processes will allow for the control and restoration of business practices in an acceptable amount of time to maintain product

reliability and mitigate the possibility of a product shortage. For OPUS 2.5 - 80R Pre-packed Chromatography Columns, recovery of

production is assumed to be 24 weeks within the United States.

3.2.2 Manufacturing facilities

An OPUS Pre-packed Chromatography Column packing suite consists of multiple ISO Class 7 column packing rooms and a central ISO

Class 8 prep area. Two airlock entry ways are maintained, one for people and one for materials and equipment. In general, product

contact column parts enter the suite through a validated parts washer and are cleaned with sodium hydroxide-based solutions

followed by a rinse with reverse osmosis deionized (RODI) water. The OPUS Column suite is completely segregated from all other

product manufacturing at Repligen and is a restricted-access area.

The clean-room environment is controlled and monitored as follows:

• Air quality is maintained by 100% HEPA filtered air

• Environmental monitoring is performed to check for viable contamination

• Preparation room air quality is tested to ISO Class 8 standards for non-viable particulates

• Column packing room air quality is tested to ISO Class 7 standards for non-viable particulates

• Room pressure differentials are maintained and monitored according to SOP

• All rooms are on a routine cleaning and disinfection schedule

• Access is restricted to authorized personnel only

• Gowning is required for entry into controlled areas including a secondary gowning procedure for entry into the ISO Class 7

packing rooms

32

OPUS Columns RSF

-10

Regulatory Support File

OPUS® Pre-packed Chromatography Columns

4. OPUS Pre-packed Chromatography Column packing and manufacturing

4.1 Packing environment and environmental controls

All OPUS 2.5 - 80R Pre-packed Chromatography Columns are packed in ISO Class 7 classified clean rooms and buffers prepared in an

ISO 8 classified clean room. The rooms are monitored on a weekly basis for viable contaminants using TSA settle plates. Microbial

contaminants (bacteria) are counted and reported. Counts which exceed an alert or action limit are investigated according to SOP-

MFG-1207.

Viable contamination limits have been set for the ISO 8 rooms as follows:

• Alert Limit: > 20 CFU/plate

• Action Limit: > 35 CFU/plate