Xcentric Crusher

instructions manual

Xcentric ripper international, s.l. / Grado cero sistemas, s.l.u.

Arriurdina, 15 (Pol. Ind. Jundiz) · 01015 Vitoria-Gasteiz (Álava) · Spain

Tel.: +34 945 290 555

www.xcentricripper.com www.gradocero.net

CRUSHER

XCENTRIC CRUSHER

2

INSTRUCTIONS MANUAL

3

INTRODUCTION

The Xcentric Crusher is a sophisticated grinding tool, produced by Xcentric Ripper International / Grado

Cero Sistemas, SLU and developed with the latest advances in systems research in the eld of crushing. It is

designed to produce excellent yields, economization of work and obtaining higher production.

Reading and understanding this manual ensures the correct use of the Crusher and obtaining higher yields

and in turn, achieve a longer lifetime. It also will provide you with important tips on handling so you can take

full advantage of the Xcentric Crusher’s technic virtues.

Xcentric Ripper International / Grado Cero Sistemas, SLU reserves the right to make changes or additions to

this manual.

This document is the original instructions manual of the Xcentric Crusher.

Revision: 00 01-09-2015 Cod. 01-15

01 23-09-2015 Cod. 02-15

02 03-12-2015 Cod. 03-15

03 26-02-2016 Cod. 01-16

04 09-06-2016 Cod. 02-16

05 08-07-2016 Cod. 03-16

06 22-08-2016 Cod. 04-16

07 23-02-2017 Cod. 01-17

08 07-03-2018 Cod. 01-18

- PROLOGUE -

XCENTRIC CRUSHER

4

INDEX

PROLOGUE

- INTRODUCTION

- INDEX

- WARRANTY

· ACCEPTANCE TEST

· MODEL AND EC PLATE

· EC DECLARATION

· WARRANTY REGISTRATION FORM

- TECHNICAL ASSISTANCE

SAFETY

- REQUIREMENTS FOR THE USER COMPANY

- REQUIREMENTS FOR THE WORKER

- GENERAL SAFETY INSTRUCTIONS

- SAFETY INSTRUCTIONS IN MACHINE

- CORRECT AND INCORRECT USE OF THE CRUSHER

· PROPER USE

· MISUSE

- PERSONAL PROTECTION EQUIPMENT (PPE)

- SAFETY INSTRUCTIONS STICKERS

- WORK, INSPECTION AND SAFETY AREAS

· WORKING AREA

· SAFETY AREA

· DANGER AREA DURING EXCAVATOR OPERATION

· DANGER AREA DURING MANTEINANCE, CLEANING, ETC. (EXCAVATOR STOPPED)

· MANTEINANCE AREA

· RESIDUAL RISKS

: HYDRAULIC COMPONENTS

: PROLONGED CONTACT WITH HYDRAULIC OIL

: HOT SURFACES AND HOT HYDRAULIC OIL

: RISK OF HEARING LOSS

: CRUSHING HAZARD

3

3

4

7

8

8

9

10

11

12

12

12

13

15

17

18

18

19

20

21

21

21

21

21

22

22

22

22

22

22

22

INSTRUCTIONS MANUAL

5

OPERATION

- TECHNICAL SPECIFICATIONS

· GENERAL DESCRIPTION

- NAME AND SPECIFICATIONS OF COMPONENTS

· NAMES OF COMPONENTS

· STANDARD SPECIFICATIONS

- TOP BRACKET MOUNTING DIMENTIONS

- INSTALLING AND REMOVING THE CRUSHER

· INSTALLATION

: INSTALLATION ON THE EXCAVATOR

: HYDRAULIC CIRCUIT ADJUSTMENT AND HOSE CONNECTIONS

: EXCAVATOR HYDRAULICS

: START UP AND FIRST USE

: ADJUSTING THE WIDTH OF XCENTRIC CRUSHER

· REMOVAL

: REMOVING THE CRUSHER

- USE

· INSTRUCTIONS FOR USING THE CRUSHER

· PRECAUTIONS WHILE OPERATING THE CRUSHER

· HANDLING THE XCENTRIC CRUSHER

· WHAT TO DO IN CASE OF BLOCKED MATERIAL

· MISUSE OF THE XCENTRIC CRUSHER

· WORK INTERRUPTION

· CLEANING

- TRANSPORT

· LIFTING

· TRANSPORT WITH THE EXCAVATOR

· HOW TO FIX THE CRUSHER IN THE TRUCK

- LONG TERM STORAGE

· BEFORE A LONG TERM STORAGE

· STORAGE CONDITIONS

· HOSE STORAGE

23

23

23

24

24

26

27

32

32

32

32

34

34

35

63

63

64

64

64

64

65

66

66

66

67

67

68

69

70

70

70

70

XCENTRIC CRUSHER

6

- TROUBLESHOOTING

MAINTENANCE

- MAINTENANCE, INSPECTION AND REPAIR

· GENERAL WARNINGS

· CRUSHER BUCKET MAINTENANCE

: DAILY INSPECTION

: PERIODIC INSPECTION

: REPLACING WEARING PARTS

· MAINTENANCE PLAN

- LUBRICANTS AND HYDRAULIC SYSTEM

· HYDRAULIC OIL

: MINERAL OIL

: BIOLOGIC OIL

· HYDRAULIC EXCAVATOR FILTER

· HYDRAULIC MECHANISM LUBRICANT

: AVAILABLE MINERAL GREASES

: AVAILABLE BIODEGRADABLE GREASES

· FILLING ECCENTRIC MECHANISM

· VALVE BLOCK SCHEMATIC DRAWINGS

: SCHEMATIC PLAN CONTROL VALVE BLOCK XC15 - XC17 - XC20 - XC30

: SCHEMATIC PLAN CONTROL VALVE BLOCK XC40 - XC50 - XC60

- BOLT TIGHTENING TORQUES

· MAX. TIGHTENING TORQUE FOR BOLTS STEEL QUALITY 8.8

MANUAL REVISION INDEX

71

72

72

72

74

74

75

75

76

77

77

77

77

78

78

78

78

79

80

80

81

82

82

83

INSTRUCTIONS MANUAL

7

WARRANTY

Warranty conditions

From the date of delivery, the CRUSHER carries a warranty of one year or 1,500 operating hours

(whichever comes rst). For this, the following conditions must be fullled:

1) The warranty duration applies to operation in a single daily shift of eight hours. If the duration of daily

operation is above the given value, the warranty period shortens proportionally.

2) Depending on the case, specic warranty conditions must be established for special uses.

3) Within the warranty period, Xcentric Ripper International/Grado Cero Sistemas, S.L.U. replaces free of

charge all components whose damage or failure Xcentric Ripper International/Grado Cero Sistemas,

S.L.U. acknowledges as being due to defects in material or design.

4) If the installation guidelines for the CRUSHER are not observed, the attachment device’s operational safety

can be considerably affected. This will result in Xcentric Ripper International/Grado Cero Sistemas, S.L.U.

rejecting any sort of warranty claim.

5) Replacement of a component during the warranty period does not cause an extension of the total warranty

period for the unit.

6) For all warranty claims, contact Xcentric Ripper International/Grado Cero Sistemas, S.L.U. with the serial

number found in the data on the model plate.

7) A CRUSHER warranty claim form must be submitted to Xcentric Ripper International/Grado Cero Sistemas,

S.L.U. within seven days from the date of repair. Photographs or video of the failed parts are to be sent with

the claim form and a copy of the sales invoice of the Crusher from the dealer to the end user. This allows

Xcentric Ripper International/Grado Cero Sistemas, S.L.U. to decide whether or not the affected parts are

eligible for warranty.

8) Parts that have been replaced free of charge are the property of Xcentric Ripper International/Grado Cero

Sistemas, S.L.U. and must be retained by the dealer for a period of one year for possible inspection by a

representative of Xcentric Ripper International/Grado Cero Sistemas, S.L.U.

9) During the warranty period, transport costs and installation costs of the replacement parts are born by

Xcentric Ripper International/Grado Cero Sistemas, S.L.U. Any import duties incurred in the supply of the

replacement parts will also be born by Xcentric Ripper International/Grado Cero Sistemas, S.L.U. A copy

of the invoice for the import duties must be sent to Xcentric Ripper International/Grado Cero Sistemas,

S.L.U. before reimbursement can be made.

10) The costs of assembling the parts considered defective will be borne by Xcentric Ripper International /

Grado Cero Sistemas, SLU during the warranty period. The costs corresonding to displacements will be

borne by the customer.

11) The warranty does not apply to parts whose wear, damage or breakages have been caused by faulty

operation and/or faulty maintenance of the Crusher.

12) The warranty does not apply to parts subject to consumption or wear.

13) Only original equipment parts from Xcentric Ripper International/Grado Cero Sistemas, S.L.U. can be

used. Infringement automatically voids this warranty.

14) All modications to the device that are made without the prior approval of Xcentric Ripper International

result in automatic forfeiture of the warranty.

15) The warranty registration must be fully completed during the delivery and installation of Xcentric Crusher

and sent to Xcentric Ripper International/Grado Cero Sistemas, S.L.U. within two weeks after delivery.

Otherwise, the warranty will be automatically canceled.

XCENTRIC CRUSHER

8

___________________________________________________________________________________

# NOTICE

The jaws are not subject to warranty.

_______________________________________________________________________________________

ACCEPTANCE TEST

When taking delivery of the CRUSHER, the receiver must perform an acceptance inspection. If there is any

damage, the transport driver and the transport company must be informed. Furthermore, it is necessary to

inform the manufacturer, Xcentric Ripper International/Grado Cero Sistemas S.L.U., and the CRUSHER dealer.

The following documents are delivered with the CRUSHER:

• Instruction manual

• List of replacement parts

• Warranty registration form

• EC declaration of conformity

The warranty registration form must be fully completed and returned to Xcentric Ripper International /

Grado Cero Sistemas SLU, within a period of two weeks from the installation of the Crusher. Failure to

return this document will imply the loss of warranty.

MODEL AND EC PLATE

The model and EC plate is on the rear upper part of the bucket. This plate contains the following data (Examples

in the illustration).

INSTRUCTIONS MANUAL

9

CRUSHER

EC DECLARATION OF CONFORMITY

SCOPE AND LIMITATIONS OF THIS EC DECLARATION

We, Xcentric Ripper International/Grado Cero Sistemas, S.L.U., declare that the Crusher of the brand and

model provided meets the conditions laid down in the European Machinery Directive 2006/42 / EC and the

noise emission in the environment by equipment for outdoors use 2000/14 / EC.

Make:……………………………………………………………………………………………...XCENTRIC CRUSHER

Accessory:…………………………………………………………………..........……………………………CRUSHER

Model:…………………………………………………………………………………………..................................……

Serial No:……………………………………………………………………………………..................................……..

Year of Manufacture:……………………………………………………………………...............................…....……..

Sound power level:………………………………………………………………………………............……...85 dB(A)

The following harmonised standards are applied:

EN ISO 12100 – Safety of machinery

EN ISO 4413 – Hydraulic transmission.

This EC declaration covers the Crusher when it is mounted on the machine for which it is designed. In addition,

the use of the Crusher must be that anticipated in work for the breakage of materials. It must not be used as a

crane for handling loads or for inappropriate work.

Any modication made to this assembly or to any of its components, without express authorisation in writing

from XCENTRIC RIPPER INTERNATIONAL/GRADO CERO SISTEMAS, S.L.U., invalidates this EC certication

and, therefore, the use in service of the Crusher.

Place and date of issue:……………………………………………………………………............................ Vitoria

Authorised by:……………………………………………………………………………………….....Javier Aracama

Signature:

File:

Original for the CUSTOMER

The person authorised to compile the technical le:

Javier Aracama (Manager of the Company)

Xcentric Ripper International/Grado Cero Sistemas, S.L.U

Arriurdina, 15. 01015 Vitoria-Gasteiz (Alava), Spain.

Manufacturer:

Grado Cero Sistemas, S.L.U

Arriurdina, 15. 01015 Vitoria-Gasteiz (Alava), Spain.

XCENTRIC CRUSHER

10

XCENTRIC RIPPER INTERNATIONAL, S.L.

GRADO CERO SISTEMAS, S.L.U · ARRIURDINA N° 15

01015 VITORIA (ALAVA) – Spain

Tel. +34 945 290 555 www.gradocero.net

www.xcentricripper.com

CRUSHER

Warranty registration form

customer details

* Name: .......................................................................………………….…..………………

* Address: …………...…………………………………………………………………………..…

City: ……………………………………..….. Country:…………………………….......….

Installation date: .........../.........../............... Excavator model:........................................................

Hour meter: …………………………………………………………………………………………..

installation details

Preset pressure relief valve: .................................................................................

Preset oil ow: ............... at........................

Working return back pressure: .........….………………………………………………..

Working drain back pressure: …………………………………………………...……..

Have you made the presetting by using the compulsory owmeter? Yes No

pre-operation details

Was the end user given instructions in the safety and operation of the Crusher?:

Was the end user given instructions in the maintenance and service of the Crusher?:

Did the end user receive a Parts List?:

Did the end user receive an Instruction Manual?:

End user Dealer

Installed by:

Trained by:

Date: ......../........../................

Signature end user: Signature dealer:

This form must be returned to Xcentric Ripper International/Grado Cero Sistemas within 30

days of the installation date. Send to [email protected]

Original: End user First copy: Xcentric Ripper International Second copy: Dealer

Model:..................

(* If possible)

(Mark with x)

(Mark with x)

Serial number:............................... Delivery date:......./......../...........

MPa

psi

MPa

psi

MPa

psi

MPa

Yes No

psi

L/min

US gal/min

INSTRUCTIONS MANUAL

11

TECHNICAL ASSISTANCE

For any needs related to employment, maintenance or replacement request, customer please apply directly to

the nearer authorized dealer, specifying the identifying information of your machine, listed on the nameplate.

We do not recommend any repair or handling not indicated in this manual. All operations requiring disassembly

of components, especially the jaw changing operation, must be carried out only by authorized technicians

from Xcentric Ripper International / Grado Cero Sistemas, SLU staff.

Only technical staff of the company Xcentric Ripper International / Grado Cero Sistemas, SLU, or formed by

them, has the necessary knowledge of the machine and special mechanisms, and the expertise to execute

properly and economically any operation.

Warranty registration form

XCENTRIC CRUSHER

12

- SAFETY -

REQUIREMENTS FOR THE USER COMPANY

The user company will give his staff training on operating and maintenance including specic management

practice of the machine.

The user company will give its staff specic training on labour risk prevention.

For the operator is recommended the regulatory training for the basic machine operators, e.g.

according to: Resolution of 16 October 2014, from the Directorate General for Energy and Mines

Policy, by which is modied the technical specication number 08/01/2001 “preventive Training for the

job performance of the operator of extracting/loading/roads machines, shovel loaders and crawler

hydraulic excavator, in outdoors extractive activities”, from the complementary technical instruction

01.02.02 “preventive Training for job performance”, from the General Regulation of Mine Safety Basic

Standards.

The user company will prepare campaigns to raise awareness among staff of their responsibilities, their risks

and their securities.

The user company will make the necessary personal protective equipment available to workers to make use

of them.

The user company should establish programs for periodic checks to ensure that the hazards control measures

remain effective.

The user company will organize the construction site so as to prevent uncontrolled access to the work area.

REQUIREMENTS FOR THE WORKER

Note that the default / failure to observe the safety rules and regulations may have legal consequences of labor

law.

In addition to the instructions in this Manual all existing legislation in the prevention of occupational risks and

environmental protection must be complied.

Works on the machine shall only be performed by personnel who have received proper training and have

proven their competence.

Work only with the Xcentric Crusher in perfect condition.

Do not try to exceed the speeds and reasonable progress; It will not work faster and can cause breakage of

the XC causing additional unnecessary dangers to yourself and others.

Use the Xcentric Crusher according to the purpose for which it was designed. Any use beyond the stablished

contravenes the provisions, and not the manufacturer, importer or supplier shall be liable for consequential

damages. The risk is assumed solely by the user. (Read misuse of XC p. 50)

Before activating any movement and during normal operation of the XC, the operator must ensure that there is

nobody within the danger zone of the machine.

INSTRUCTIONS MANUAL

13

GENERAL SAFETY INSTRUCTIONS

Before beginning work with or on the CRUSHER, it is compulsory reading and understanding this manual

before proceeding to work or perform any operation on the Crusher. We decline all liability in case of misuse.

Xcentric Ripper International / Grado Cero Sistemas, SLU assumes no liability if the owner of the Crusher,

without the prior written consent from Xcentric Ripper International / Grado Cero Sistemas, SLU, undertakes

any modications to the devise or uses it in violation of the instructions in this manual. In both cases the

warranty is void.

Place this manual or a copy of it in the excavator’s operator cab, so that it is always on hand as a reference for

questions and problems. Observe all local laws and regulations applicable to the use and operation of your

work equipment.

Because there are various models of the Crusher, it is possible that some illustrations in this manual will not

correspond to your attachment device. These illustrations are merely to be taken as examples.

The activities described in the following sections require no special skills; personnel performing them must

merely be familiar with the handling of the device.

This instruction manual must be read and understood to ensure that the Crusher is correctly used and provides

peak performance and a long life. You will also nd important advice on correct handling of the attachment

device, so that you can make maximum use of your Crusher’s technical advantages.

If the manual is lost or damaged order a new one from your local Xcentric Ripper International distributor.

Observe all relevant safety standards and use your device accordingly.

In order to ensure maximum reliability and safety of operation, Xcentric Ripper International / Grado Cero

Sistemas SLU. has made a careful choice of materials and components used in the manufacture of the

machine, subjecting it to regular testing before delivery.

The good performance of the machine over time also depends on the proper use and proper maintenance

according to the instructions in this manual.

It is necessary that trained service staff regularly perform the prescribed maintenance, inspection and review,

to avoid damage.

The malfunctions are due in most cases, to improper maintenance.

If in doubt about the operation, immediately stop the machine!

XCENTRIC CRUSHER

14

The machine is built to the current technical level and the existing safety technical rules known.

Failure to follow directions on safety by the operator and recklessness in the use of the machine can cause

serious injury to the operator himself or to other people or animals, and can cause damage to the machine or

other property.

In this regard we must always remember that the machine is provided with safety devises, to ensure protection

against accidents, but if used correctly and according to the safety instructions described in this manual.

BEFORE USING THE MACHINE IT IS COMPULSORY TO READ CAREFULLY THE SAFETY INDICATIONS

AND OPERATING INSTRUCTIONS, MAINTENANCE AND OPERATIONS IN THE MACHINE TO SAFEGUARD

EVERYONE’S INTEGRITY.

DANGER!

Use the machine with the utmost care and caution, as recklessness is the most frequent cause of

accidents. The use of the machine must be performed by an adult and competent person.

ATTENTION!

Before attaching the bucket crusher to the machine, make sure that this is adequate to support all the

caracteristics and functions for the use expected.

Pay special attention at all times to the safe operation of the machine. Here are some factors listed, important

to be taken into account:

- Follow all applicable standards of personal security and re safety. Do not perform the operations

described below without the use of appropriate personal protective equipment (PPE): safety boots, safety

glasses, appropriate gloves and ear protection.

- There is a risk of overturning when the Crusher is disengaged during stowing or transportation operations.

Deposit always the Crusher on a horizontal surface, level, hard, able to bear weight on their footholds.

- There is a risk of entrapment during handling, transport, assembly and disassembly of Crusher when

disengaged, so you should keep a distance considered this.

- You must ensure that the Crusher is installed and properly engaged on the excavator.

- Defective or worn material should always be replaced by another original and new supply.

- The use of spare parts in disrepair, worn, deformed, galling, etc, is not allowed.

- Any operation, inspection, cleaning, repair or inspection shall not be performed while the engine of the

excavator is running.

- Do not use tools (hammers, wrenches, etc.) in poor condition that could cause an accident.

- Stay at least 20 meters from the site of action of Crusher while working due to risk of ejection of particles

and fragments.

INSTRUCTIONS MANUAL

15

- When opening the hydraulic connections every precaution must be taken. Gloves and goggles are needed

since it is possible that the connections are under pressure even with the excavator engine stopped.

- Avoid prolonged, excessive or repeated contact of oil in your skin.

+ Protect your skin with proper protective gloves or protective products.

+ Clean the skin areas that are soiled with oil:

· Wash thoroughly with soap and water.

· A nail brush is an effective aid.

· The special hands cleaning means facilitates the proper cleaning of dirty hands.

· Do not use gasoline, diesel, diluent or solvent.

+ After cleaning, protect your skin with fat cream.

- Some pieces of the Crusher become very hot during operation, especially the jaws. There is high risk of

burns.

- Check the maximum allowable pressure in the hydraulic hoses and proper connection and tightening.

- Wear ear protection while the Crusher is operating.

- Do not wear jewelry or work with long hair undone. The moving parts of the machine could snag hair or

jewelry producing serious injury.

- The use of non-original spare parts can cause danger.

SAFETY INSTRUCTIONS IN MACHINE

Before connecting the crusher bucket to the operating machine and start it, it is advisable to check that this

machine has all the basic requirements listed below to operate in safety, and protecting the health of people.

- The end user must ensure that the weight at full load (bucket weight + loaded material+ Coupling +

various accessories) does not exceed the capacity of the operating machine’s raised arm specied in the

manual; it is necessary to control all positions with which you can work.

- The end user must verify that the capability to overturn of the operating machine is the ideal to the use of

the equipment. It is necessary to control all positions with which you can work.

- Respect the applicability of Xcentric Crusher with the operating machine, it is advisable and very important

to contact the dealer / seller.

- Only adult and competent personal, trained to work using machines can handle the operating machine

for the commissioning of the equipment.

- The Crusher is designed for industrial use and must be used by personnel who have no limited tness.

- The command to start the Xcentric Crusher must be the ON / OFF type, either switch or pedal type;

to launch the bucket is mandatory to have the command pressed, to turn off the bucket releasing the

command is sufcient.

- The machine must be equipped with an emergency stop switch capable of stopping the movement of the

crusher bucket in the shortest time possible.

- Ensure that the operator has understood the meaning of all controls and operation.

XCENTRIC CRUSHER

16

- The operator must know and apply security conditions for the use of the machine in the workplace,

according to the law laid down in the country of use.

- When we speak of right, left, front and rear of the machine, it refers to the view from the driving place of

the excavator.

- The operator must know and correctly interpret all instructions in this manual and signs placed on the

machine: this will help prevent damage to persons, things and to the operating machine.

- Observe mandatoryly instructions in the following document and adhere to the rules of EC general

accident prevention and the applicable regulations in the country of the user.

- Always use the means of individual protection under the EEC 89/686 and 89/656 EEC directives and

everything stated in this manual; also use rules of general accident prevention regulations of the country

of the user.

- Carefully read all indications about safety of adhesive labels attached to the machine.

- The operator should avoid using the Xcentric Crusher in unsuitable conditions or under the inuence of

alcohol or drugs.

- The organization of the work is important to make the fewest transactions based on the work to be

performed.

- For safety and health protection is desirable to

organize the construction site so that you can position

the excavator (with bucket as pictured right), raised

regarding the material for grinding, thus reducing the

loading radius and prevents fullling the maximum

opening of the arm.

- For the use of excavators, it is not recommended to perform the phase bucket load with truck placed at

90 ° (see picture below right), this position allows less stability respect to the positioning of the trolley in

direct position (see the drawing below left).

INSTRUCTIONS MANUAL

17

- For installation in wheels excavators it is mandatory to set the stabilizers on the ground before connecting

and lifting the equipment.

- For installation on operating machines other than wheeled, or tracked, all the above instructions must be

taken into account and also those described below for the correct operation, safety, and protection of

health.

ATTENTION!

Before starting the machine to operate with, make sure there are no people in its surroundings or in its

range of action.

- Keep away people and animals during the use of Xcentric Crusher.

- Do not use the machine to transport people, animals and things.

- It is forbidden to climb on the structure of the machine.

- It is absolutely forbidden to approach the machine during operation.

ATTENTION!

It is forbidden the use of the machine in case of anomalies. The company is not liable for damage to

people and / or things in case of use of the machine by the operator, when the machine malfunctions.

- The control system of the excavator will have the necessary elements to avoid spontaneous start-up of

the Xcentric Crusher when reseting the power supply after an interruption.

- Before dismantling, decommissioning and removal of safety, all pipes and hoses will be drained.

- When hydraulic uids and lubricants are removed during maintenance operations, decommissioning,

dismantling and removal of security, they will be treated as specied in the corresponding safety sheets.

- The user company should establish programs for periodic checks to ensure that the hazards control

measures remain effective.

XCENTRIC CRUSHER

18

CORRECT AND INCORRECT USE CRUSHER

PROPER USE

The Crusher is an interchangeable equipment that modies the function of a machine, provided they meet the

minimum requirements of weight and characteristics regarding the hydraulic system.

The equipment, to operate, does not need the presence and / or assistance from other different persons other

than the operator of the main operating machine. As far as maintenance is concerned, it must be carried out

by authorized personnel, as described in this manual.

The Crusher is designed to crush and crumble stone, concrete, asphalt, etc...

Crushing hard materials like granite or porphyry is permitted, provided they are maximum 90% of the inlet of

the jaws. Keep in mind that this entry mouth may be modied by means of regulators the machine is provided

with. For demolition of high hardness materials, material with a maximum size of 60% of the inlet of the jaws is

recommended.

It can also be used to remove the shredded material, and clean the work area.

MISUSE

Any use for which the Crusher was not designed, will be considered misuse. The hydraulic Crusher should not

be used exceeding his hydraulic limits.

Any action that goes against personal security measures or legislation on safety and re, will be considered

misuse.

The shredded will always be done with the jaws in good condition.

Please read the section Use of Crusher for its correct use.

Do not use the Crusher in a greater excavator than what is due. You could damage its structure or mechanisms.

Do not use the Crusher on a smaller excavator than what it designed for, there is great danger of tipping. See

the manual for the excavator to verify it can operate with the weight of your Crusher.

Do not use the Crusher:

- For excavation or direct extraction.

- As support for positioning the carrier.

- For crushing with temperatures above 100 ° C or below -20 C.

- For the transport of persons, animals and things.

- In the presence of ammable or explosive materials or materials that may generate ammable, explosive,

toxic or harmful dust.

- As a lifting tool.

INSTRUCTIONS MANUAL

19

It is also prohibited:

- Approaching the Crusher while operating.

- Climbing on the structure of the machine.

- Carrying out any operation on the crusher bucket while it is running.

- Carry out any operation which affects operator safety or the safety of things or people.

- The use of the crusher bucket in environments with potentially explosive atmospheres.

- Breaking rocks and various materials with the outside of the machine, hammer type use.

- Use the crusher submerged in liquids.

- The use of the Crusher bucket to move material with the outer parts of the bucket, instead of the front.

- The use of the crusher to lever through the arm for the lateral movement of the excavator.

- The use of the crusher bucket with carrier machines which dont have the minimum hydraulic parameters

for the correct operation, hydraulic parameters described in the following manual.

- The use of the Xcentric Crusher with the position of the crushing bucket different from the vertical.

- To operate the Xcentric Crusher from outside the cab of the main operating machine.

ATTENTION!

The company Xcentric Ripper International / Grado Cero Sistemas SLU assumes no liability for damages

to persons and / or things derived of misuse of the Xcentric Crusher by the customer or third parties.

PERSONAL PROTECTIVE EQUIPMENT (PPE)

The operator proposed by the client to operate this machine, prior to starting operations, use, maintenance

or other interventions on the machine, must use all personal protective equipment (PPE) required to ensure

the protection of the operator itself as provided in the rules of general accident prevention regulations of the

country where the machine is put into operation. The personal protective items operators must use are listed

below:

ATTENTION!

The company Xcentric Ripper International / Grado Cero Sistemas SLU can not be held responsible

for accidents caused by the operator due to lack of use of personal protective equipment.

USE PROTECTIVE CLOTHING USE PROTECTIVE GLASSES

USE SAFETY SHOES USE EARS PROTECTIONS

USE PROTECTIVE GLOVES USE PROTECTIVE HELMET

XCENTRIC CRUSHER

20

SAFETY INSTRUCTIONS STICKERS

Safety stickers are applied on the crusher bucket. All stickers referring to security listed here, should always

be in optimum condition and be clearly visible.

1. Attention! Read this manual completely. it is mandatory that all the information is understood.

2. Noise level: 85 dB (A9). Use ears protection.

3. During use, keep at least 20m away from the crusher. Beware of fragments projection.

4. Danger! High pressure system.

5. During commissioning operations there is a risk of crushing between moving parts (jaw) if untimely

movements.

6. Risk by which a person or part of it gets caught or trapped by machines mechanisms or between objects,

parts or materials.

7. Some component parts of the crusher have high temperatures after working with it. Risk of minor burns exist.

8. In operations of coupling and uncoupling of the hoses could be uid projection.

1

2

3 4

76

5

8

INSTRUCTIONS MANUAL

21

WORK, INSPECTION AND SAFETY AREAS

WORKING AREA

The Crusher can only be controlled from the excavator’s operator cab. Always remain outside the working

area.

SAFETY ZONE

When the Crusher is operating, maintain at least a 20 m safety distance. When working in high places, the work

area expands in relation to the height.

DANGER ZONE DURING EXCAVATOR OPERATION

This includes all distances closer than the safety distance mentioned above. For work in high places, a rollover

protection structure and/or protection structure (ROPS/FOPS) may be required.

DANGER ZONE DURING MAINTENANCE, CLEANING, ETC.

(EXCAVATOR STOPPED)

The area under the Crusher, when it is still connected to the excavator.

The area in the immediate vicinity of the excavator when it is disconnected from the Crusher, because there

is a tilting hazard. Always set the Crusher on a rm, even, horizontal surface that can bear the weight at the

support points.

Some of the Crusher’s surfaces and components may be very hot after use. Therefore take protective measures

to prevent burning.

Crusher

working area

(minimum 20 m)

(check excavator

manual)

Excavator

working area

Safety zone working with

the Crusher

XCENTRIC CRUSHER

22

MAINTENANCE AREA

- The jaws, the mobile support and its mechanism.

- The bucket: the hydraulic block, the top bracket, and turnbuckles or blade.

- Hydraulic hoses.

- Fastening the Crusher to the machine. The Crusher produces vibrations that can loosen or move the bolts

or quick-connect coupling, if the machine is equipped with one. Make a regular visual check of that area.

Sudden, unintentional or accidental release of the attachment device poses a crushing hazard. Keep the

quick-connect coupling system in perfect operating condition, and nd out from the manufacturer if the

coupling is capable of supporting the Crusher.

RESIDUAL RISKS

The continuous movement that the pivot arms cause in the Crusher can throw pieces, fragments or particles

around.

During operation, the machine operator must make sure that no danger is posed to people or materials that

are within the safety zone around the machine.

Use personal protective equipment (PPE).

: Hydraulic components

Broken or leaky hydraulic hoses pose a hazard.

Use extra caution when handing all hydraulic connections. Make sure that the machine’s engine is

stopped and that there is no hydraulic pressure within the system.

: Prolonged contact with hydraulic oil

Prolonged or repeated skin contact with any kind of hydraulic oil leads to loss of fat content in the

skin. That can lead to dryness, irritation or skin inammations. Hydraulic oil also contains dangerous

substances that can cause skin cancer. If the basic safety and hygiene standards are observed during

work, handling hydraulic oil should not cause health problems.

: Hot surfaces and hot hydraulic oil

Be aware that the hydraulic circuit can get very hot.

After working, some of the Crusher’s components get very hot. There is a risk of minor burns.

: Risk of hearing loss

It is mandatory to wear ear protection.

: Crushing hazard

Be especially cautious when installing, removing and handling the Crusher, to prevent it from tipping or

falling over.

Not following the instructions can result in an increased risk of trapment.

INSTRUCTIONS MANUAL

23

- OPERATION -

TECHNICAL SPECIFICATIONS

GENERAL DESCRIPTION

The Xcentric Crusher is a milling attachment for excavators developed by Xcentric Ripper International /

Grado Cero Sistemas SLU, built entirely of wear-resistant steel.

This is a crusher bucket which, by the hydraulic action breaks and crushes any demolition material.

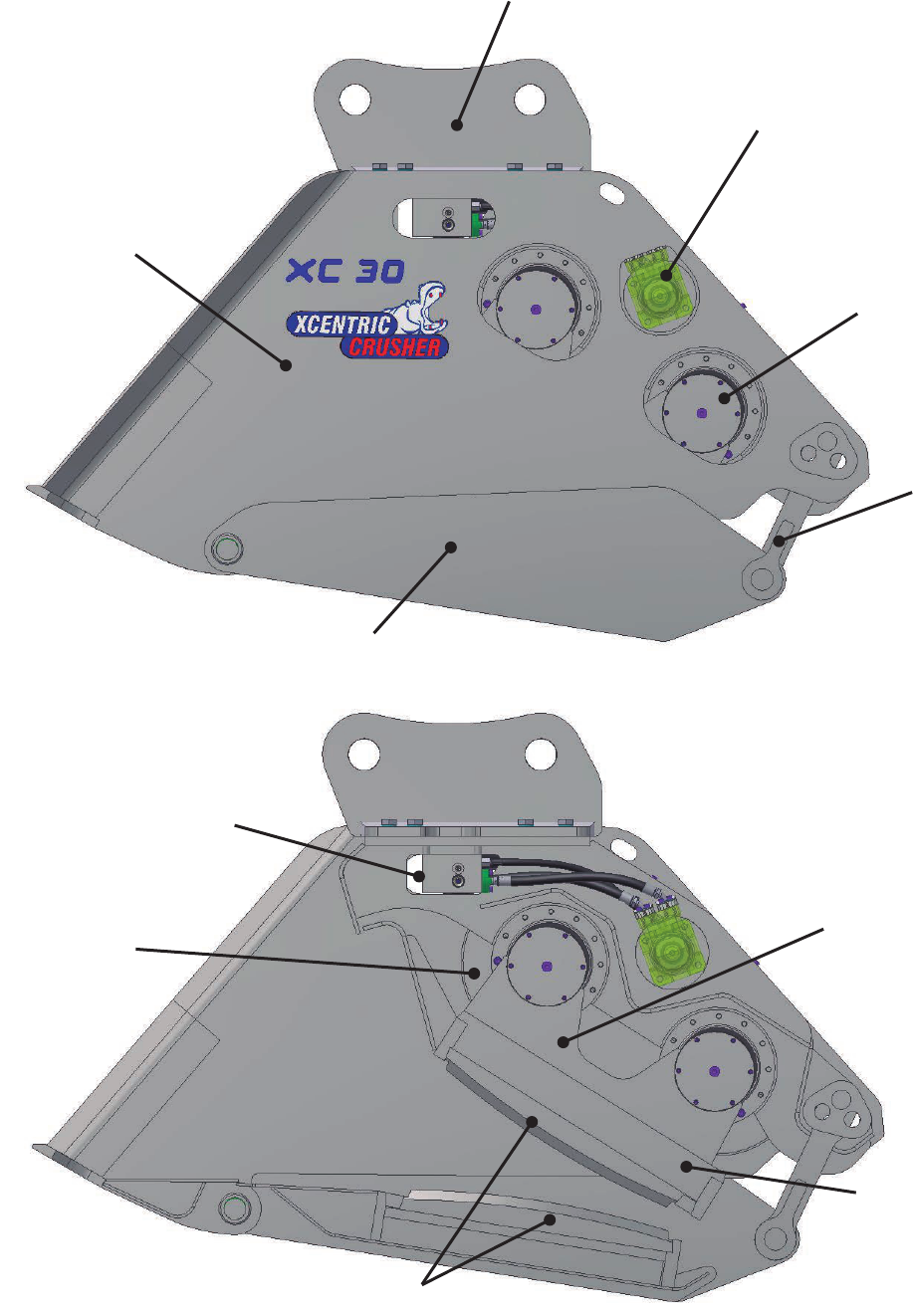

It consists of the following parts:

Top bracket

Mobile support

Bucket

Lower mouth

Tensioner

XCENTRIC CRUSHER

24

NAME AND SPECIFICATIONS OF COMPONENTS

NAME OF COMPONENTS

3

2

1

9

7

11

10

6

5

4

8

INSTRUCTIONS MANUAL

25

1) Bucket

Covers the whole set of units in the mobile support: shaft-pulleys, crankcase, bridge and jaw. Also has threaded

holes where the top bracket it is xed.

2) Hydraulic motor

Bent-Axis Motor, which provides movement to the movable support.

3) Top bracket

It is the element that bolted to the Xcentric Crusher bucket, sets it to the excavator.

4) Mobile Support

Mobile unit composed of the upper jaw, bridges, pins and crankcase. Is the element that receives the movement

from the motors for crushing the material.

5) Bridges

Parts joining the axes to the upper jaw.

6) Crankcase

The crankcase is a metal box that houses and protects the engine operating mechanisms.

7) Axis-pulleys

Set which purpose is to transmit the motion from the motor to the mobile support. Comprises two eccentric

pins and a set of pulleys.

8) Jaws

Casting pieces, whose physical properties and geometry are conducive to crushing the material.

9) Lower mouth

Plate where the lower jaw is xed. It is attached to the bucket by two pins and two adjustable turnbuckles in

order to be able to modify the opening of the bucket.

10) Control block

Hydraulic unit that protects and controls the start and stop, and also the motors direction shift.

11) Tensioner fork

Adjustable parts that attach the lower mouth to the bucket. Depending on the setting of these elements, a

bigger or smaller opening of the bucket exit can be obtained.

XCENTRIC CRUSHER

26

STANDARD SPECIFICATIONS

H

LW

technical specifications

XC30 XC40 XC50 XC60

Excavator size

Tons 24 to 35 32 to 45 45 to 60 60 to 85

Weight (without top plate)

kg 3.750 5.300 6.250 10.500

Operating pressure

MPa 25 32 32 25

Operating Flow

L/min 180 – 200 300 340 500

Max. drain pressure

MPa 0,4 0,4 0,4 0,4

Hydraulic circuit

Double effect Double effect Double effect Double effect

Loading capacity

m

3

1 1,20 1,5 2

External width

mm 1.070 1.280 1.280 1.535

Internal width

mm 900 1.100 1.100 1.310

Length

mm 2.575 2.840 3.270 3.440

Height

mm 1.400 1.450 1.560 1.900

Crushing size

mm 20 – 140 20 – 140 20 – 210 20 – 210

Jaw opening

mm 420 465 500 500

technical specifications

XC15 XC17 XC20

Excavator size

Tons 13 to 15 16 to 20 20 to 25

Weight (without top plate)

kg 2.000 2.000 2.500

Operating pressure

MPa 32 25 25

Operating Flow

L/min 100 - 120 140 - 160 160 - 180

Max. drain pressure

MPa 0,4 0,4 0,4

Hydraulic circuit

Double effect Double effect Double effect

Loading capacity

m

3

0,5 0,5 0,8

External width

mm 930 930 930

Internal width

mm 730 730 730

Length

mm 2.050 2.050 2.465

Height

mm 1.200 1.200 1.300

Crushing size

mm 20 – 90 20 – 90 20 – 140

Jaw opening

mm 400 400 420

INSTRUCTIONS MANUAL

27

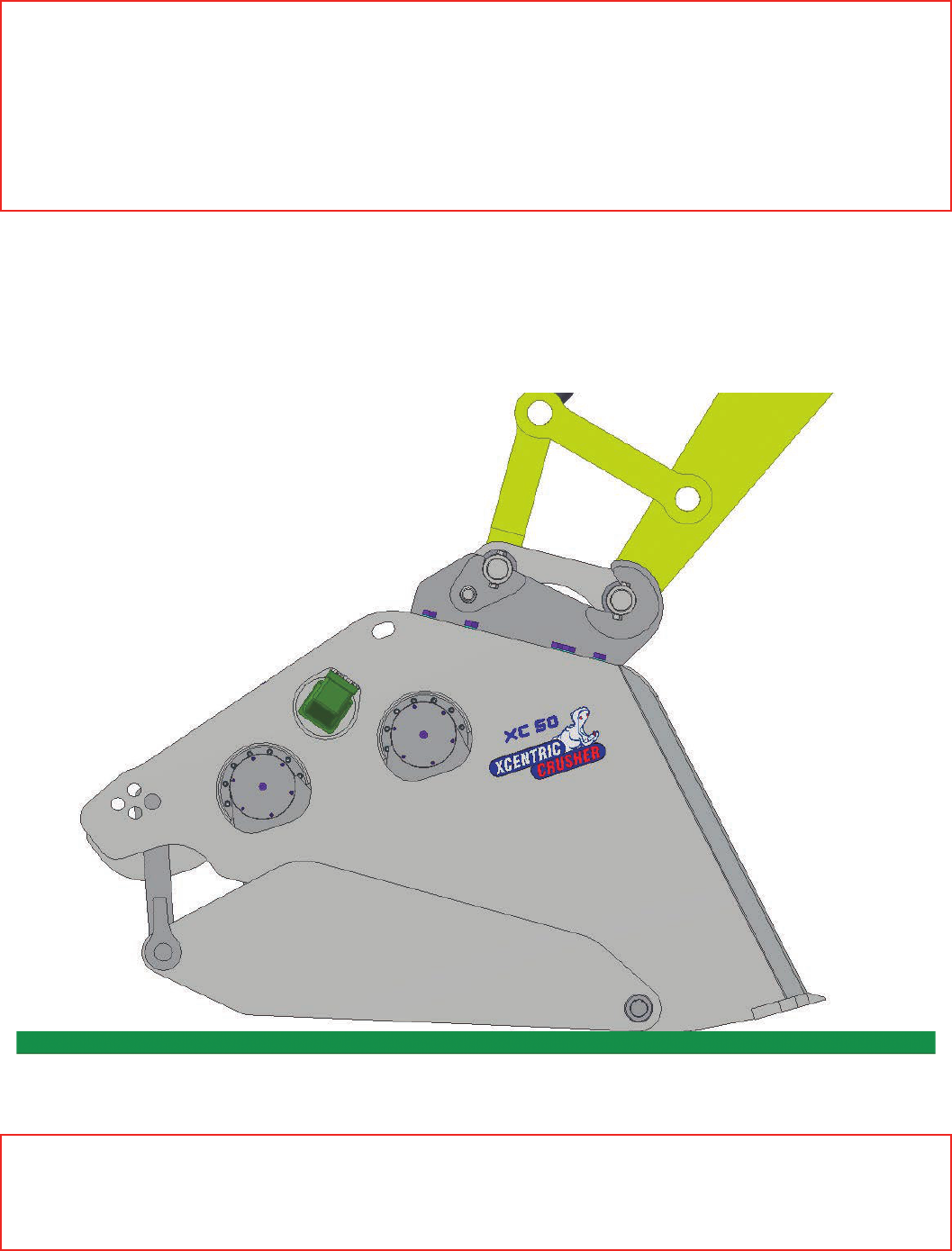

TOP BRACKET DIMENSIONS

When installing an Xcentric Crusher on a base machine such as a hydraulic excavator, backhoe loader, etc.

a top bracket will be required to connect the Crusher to the base machine. This can be ordered from Xcentric

Ripper International/Grado Cero Sistemas S.L.U. at the time the Xcentric Crusher is ordered. Details of the type

and model of the base machine will be required and if the base machine is equipped with a quick coupler,

details of the manufacturer and model number will also be required.

If a top bracket is not ordered or if the Xcentric Crusher is to be mounted on a different base machine than the

previous installation, a top bracket will have to be ordered separately from Xcentric Ripper International/Grado

Cero Sistemas S.L.U. or manufactured locally.

IMPORTANT!

When manufacturing a top bracket to mount an Xcentric Crusher on an excavator it is very important to

follow the guidelines listed below:

1. Cut the plates for the top bracket to the dimensions given in the following drawings.

2. Weld on to the top plate the mounting ears required to mount the Xcentric Crusher on the specic

excavator to be used for this Crusher.

3. After the above operations have been carried out the surface of the top bracket plates which will

be in contact with the Xcentric Crusher must be milled perfectly at across the whole of both of the

surfaces.

4. Drill the required mounting bolt holes to the dimensions given in the drawings. They must be

drilled and use at least the indicated ones for each model.

It is not allowed to use a top bracket where the mounting surfaces have not been milled perfectly at.

XCENTRIC CRUSHER

28

XC15 - XC17 TOP BRACKET DIMENSIONS

THICKNESS 25mm

EXCAVATOR SIDE

Minimum number of holes 12

Screws dimensions M27 x 65

Torque 1050 Nm

INSTRUCTIONS MANUAL

29

XC20 TOP BRACKET DIMENSIONS

THICKNESS 30mm

EXCAVATOR SIDE

Minimum number of holes 12

Screws dimensions M30 x 65

Torque 1420 Nm

XCENTRIC CRUSHER

30

XC30 TOP BRACKET DIMENSIONS

THICKNESS 30mm

EXCAVATOR SIDE

Minimum number of holes 12

Screws dimensions M30 x 65

Torque 1420 Nm

INSTRUCTIONS MANUAL

31

XC40 & XC50 TOP BRACKET DIMENSIONS

THICKNESS 40mm

EXCAVATOR SIDE

1050

850

35 150 190 300 190 150 35

40

140

440

190

40

R20

n

38

230

390

230

145

221

R20

205

Minimum number of holes 20

Screws dimensions M36 x 90

Torque 2400 Nm

XCENTRIC CRUSHER

32

XC60 TOP BRACKET DIMENSIONS

THICKNESS 40mm

EXCAVATOR SIDE

Minimum number of holes 34

Screws dimensions M36 x 90

Torque 2400 Nm

INSTRUCTIONS MANUAL

33

INSTALLING AND REMOVING THE CRUSHER

INSTALLATION

• The operations of assembly and disassembly of the Xcentric Crusher on the base machine should be

performed by qualied and prepared for it personnel.

• Only qualied staff who has read carefully the instructions for assembly and disassembly of the

Xcentricr Crusher on the base machine, as described in the instruction manual, can perform these

operations.

• User companies will prepare specic safe work instructions to be observed by its staff.

• The operator of the machine will be personnel who have received proper training and have

demonstrated competence.

• Refer to the excavator manual to locate the valves of control at the end of the pressure line and return

line on the arm of the base machine.

• Access to the machine will be restricted to authorized personnel while bringing out the assembly,

installation and commissioning.

• Personnel in charge of the movements will control that nobody will be affected by the moving element.

: Installation on the excavator

Check to see that the top bracket and the excavator arm t together. Position the Crusher according to the

illustration.

Install the Crusher only on an even surface with the elements to be connected standing across from each

other.

Additional adapters or mounting brackets must not be welded to the Crusher. This will void both the

warranty and the EC declaration of conformity.

: Hydraulic circuit adjustment and hose connections

Before installing the hoses between the Crusher and the excavator the hydraulic circuit pressures and ow

must be set as follows:

1. Install pressure gauges at the end of the pressure and return lines on the excavator arm.

2. Make sure that the excavator circuit is in the “double effect” position (shear or cramp).

XCENTRIC CRUSHER

34

WARNING!

The above relief valve pressure settings must never be exceeded. Operating a Crusher with excessive

pressure can possibly lead to serious damage to the hydraulic motor and control valve block cartridge

elements.

CAUTION!

The hydraulic hoses are not delivered with the Crusher. Do not use hydraulic quick-connect couplings

on the hoses as these can reduce the Crusher’s performance and damage the hydraulic motor. Make

sure that the bends in the hydraulic hoses in all positions exceed the minimum radius specied by the

manufacturer and that the hoses have no contact with other components.

6. Stop the engine. Remove the plugs (or caps) from the shut-off valves and install a ow meter. Open the

shut-off valves.

7. With he excavator at working regime, ensure that the maximum ow never exceeds these values:

XC 15 - 100-120 l/min / XC 17 - 140-160 l/min / XC 20 - 160-180 l/min

to 4MPa to 4MPa to 4MPa

XC 30 - 180-200 l/min / XC 40 - 300 l/min / XC 50 - 340 l/min / XC 60 - 500 l/min

to 4MPa to 4MPa to 4MPa to 4MPa

8. After ensuring the oil ow is correct, stop the engine, close the shut-off valves and remove the ow meter

and hoses.

9. A total of three hoses must be connected from the Crusher to the excavator. The rst two hoses, pressure

and return, must be designed for a continuous pressure of at least 300 bars and withstand additional

pressure peaks. We recommend the use of a 4SH hose for the pressure hoses, and a 2 wire hose for the

drain hose. The connections to the Crusher must be of the type SAE 6000 1” for the pressure and return;

SAE 6000 ½” for the drenage. It is mandatory the hoses to be sealed with appropriate accessories when

the Crusher is not operating.

10. Connect the hydraulic hoses between the excavator and the Crusher. The hydraulic hoses are

connected as follows:

• Remove the plugs.

• Before connecting the hoses, make sure that the connections and hoses are clean.

• Connect Crusher hoses to the shutoff valves on the arm of the excavator.

• Connect the XC drain hose to the drain line of the excavator.

3. Ensure that the shut-off valves at the end of the pressure and return lines on the excavator arm are in the

closed position, to prevent hydraulic ow from reaching the Xcentric Crusher.

4. Start the engine and raise the hydraulic oil temperature to a minimum of 40ºC.

5. Operate the Crusher control valve with the engine running at full r.p.m. and read the pressure on the

gauge on both lines. This pressure is the excavator circuit relief valve setting and should be set at the

pressure for your specic model of Crusher as listed in the following table:

XC30

XC15

XC40

XC17

XC50

XC20

XC60

Work line

Work line 25 MPa (250 bar)

32 MPa (320 bar)

32 MPa (320 bar)

25 MPa (250 bar)

32 MPa (320 bar)

25 MPa (250 bar)

25 MPa (250 bar)

150 to 250 bar

150 to 250 bar

150 to 250 bar

150 to 250 bar

150 to 250 bar

150 to 250 bar

150 to 250 bar

Return line / unlock

Return line / unlock

INSTRUCTIONS MANUAL

35

CAUTION!

To avoid or reduce damage to the hydraulic motor or its seals, it is mandatory to always install the case

drain line from the case drain line connection on the Crusher directly to the hydraulic tank or lter just

before the hydraulic tank. Under no circumstances is the drain line of the Crusher to be connected to

other case drain lines on the excavator as this can lead to excessive back pressure in the Crusher case

drain line.

11. Install a pressure gauge in the case drain line.

12. Open the oil shut-off keys on the excavator towards the bucket. Start with the return line (normally on

the right side of the excavator arm but this can differ depending on the excavator’s manufacturer, so

check which side is the return side before opening) and then open the pressure line.

13. Start the excavator engine.

14. Lift the Crusher off the ground, idle or run the engine at a low RPM and press the Crusher’s pedal for

about 2 minutes to let the air out of the hydraulic system and at the same time check the system for

leaks. If leaks occur, seal them right away.

15. Check the drain line pressure. This pressure should never exceed 0.4 MPa (4 bar) in any case.

16. Stop operating the Crusher.

17. Again check the drain line pressure. This should be at zero. If there is a pressure this is caused by

pressure coming back from the excavator circuit. The cause of this has to be found and rectied (check

to see if the bucket’s drain line is connected to other drain lines from elements on the excavator such

as the swing motor or travel motors, if so the bucket’s drain line must be connected directly to the tank

or lter just before the tank).

18. If the bucket’s drain pressure is correct lift the Crusher up and set it in the rest position. Then stop the

engine.

19. Remove the pressure gauges tted in the pressure, return and bucket’s drain lines.

: Excavator hydraulics

Check to make sure that the quality of the hydraulic oil and the excavator’s lter comply with the manufacturer’s

specied requirements. (ISO 4406 purity class 20/18/13).

: Start-up and rst use

Start-up and rst operation of the Crusher are always performed by a technician authorized by Xcentric Ripper

International/Grado Cero Sistemas, S.L.U.

After all of the previously described tasks have been performed, the Crusher is put into operation as follows:

• Before starting work, you should leave the engine running for a few minutes. If you are going to work

in cold climates, it is advisable to leave the Crusher running until a temperature of approximately 40°

C (104° F) is reached.

• When the machine is ready, start lling the bucket. After lling the bucket, turn the Crusher to reach

the best position to help extraction. Then activate the mechanism slowly and gradually until the

maximum number of revolutions are reached.

• When nished shredding the material, repeat the above operation.

XCENTRIC CRUSHER

36

: Adjusting the width of Xcentric Crusher

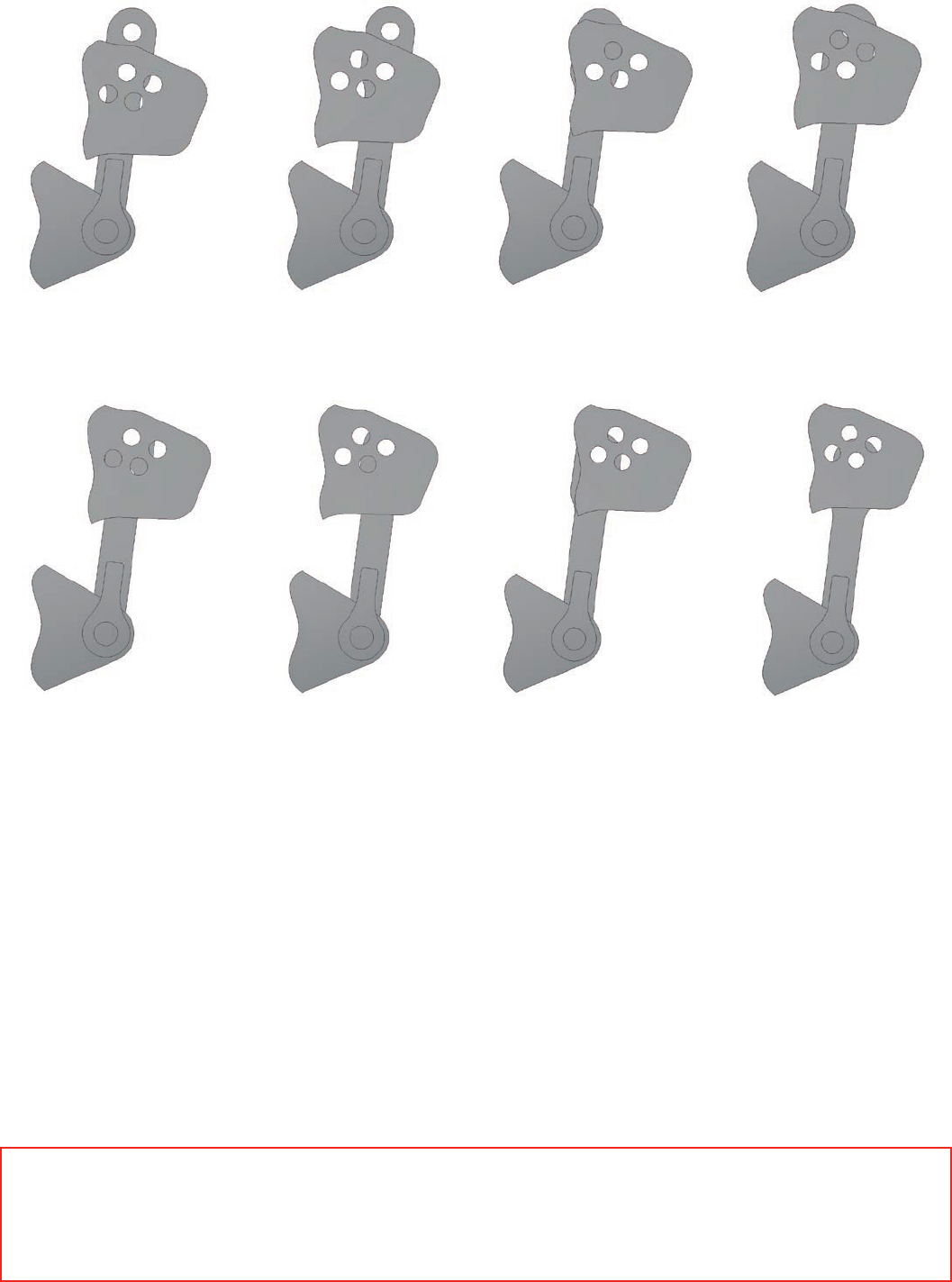

Opening System Bucket XC15 - XC17

The XC15 and XC17 buckets are designed in a simple but effective and resilient way, so that it has a system

of opening and closing jaws to obtain a nal product according to the required demands.

It is based on a union of the jaw and the bucket by means of a through-pin, which varies the opening of the

jaw, depending on the combination of holes used.

Below cuting of the system shown:

Hexagonal screw

Washer

Self-locking

nut

Bucket

A

B

C

D

1

2

3

4

Lower support

Adjusting pin

INSTRUCTIONS MANUAL

37

ATTENTION!

All these operations will be held by ONE SINGLE operator and carrying out a number of safety guidelines:

- Mandatory use of Personal Protective Equipments (PPE): boots, gloves, goggles, etc.

- Eliminate any possible start / accidental operation of the excavator.

- Eliminate the possibility that someone else starts / operates the excavator while performing the

regulation.

ATTENTION!

Block the excavator and stop the engine by following the instructions in the manual of the excavator

itself, prior to the removal of the pin of regulation.

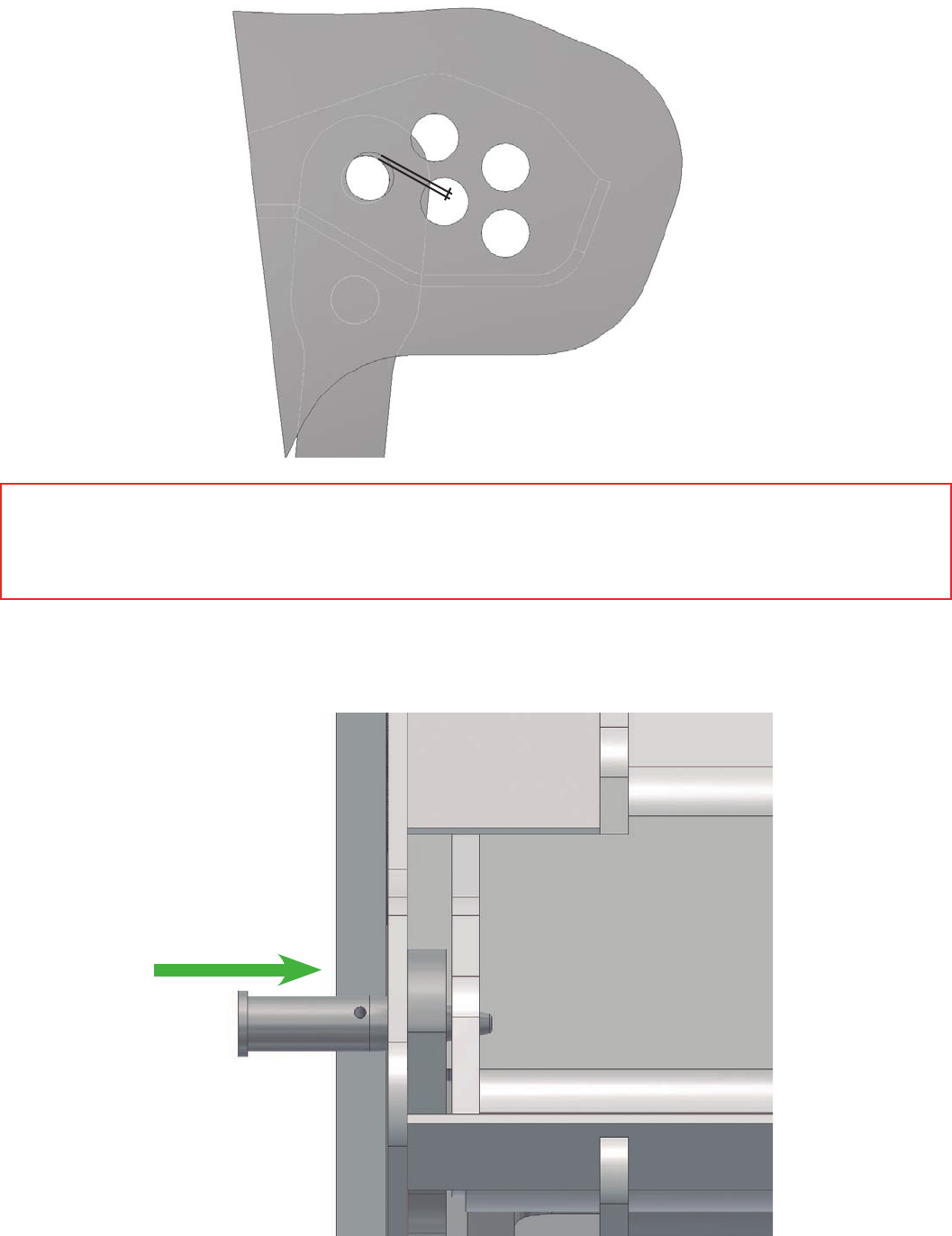

1.- Lean the bucket slightly on a at, stable surface. Avoid pressure against the surface on the back of the

bucket, so that pins can be extracted without difculty.

Opening regulation

XCENTRIC CRUSHER

38

2. Remove the screw-nut system. 3. Remove the washer.

4. Remove the pin.

INSTRUCTIONS MANUAL

39

5. After removing the pin of regulation, get into and the excavator and through the arm movement, open or

close the jaw to the desired opening. Lock and stop the excavator again.

6. Visually inspect which opening correction you will need to do, in order to install again the pin of regulation.

XCENTRIC CRUSHER

40

7. Introduce the pin of regulation, with the help of a mallet if necessary, having previously cleaned it. Light

greasing of the diameter of the pin will facilitate insertion.

Get into the excavator and make the correction through the arm movement. Lock and stop the engine of the

excavator.

Repeat this step as often as necessary until the alignment of selected holes is within an error less than 3 mm.

ATTENTION!

This operation must be carried out by the operator of the excavator without the help of another person.

There is high risk of unintended entrapment.

3 mm

INSTRUCTIONS MANUAL

41

8. Install the screw-nut properly.

ATTENTION!

The opening regulation with the bucket suspended in the air is totally prohibited, it exists high risk of

entrapment by droping or involuntary movement.

XCENTRIC CRUSHER

42

REMOVAL

: Removing the Crusher

Remove the Crusher as follows:

• Close the valve of the pressure line.

• Close the return line valve.

• Disconnect all hydraulic hoses.

• Attach the appropriate sealing plugs on the Crusher as well as on the excavator hoses.

• Position the Crusher on a horizontal surface to prevent tipping over and to ease subsequent removal.

• Remove the Crusher.

NOTICE

When detaching the Crusher from the excavator, close the hydraulic hoses and connections with plugs

to prevent oil from dripping out and dirt from getting into the hydraulic system.

XC15 - XC17

A 1

≤ 20 mm.

C 3

≤ 60 mm.

B 2

≤ 40 mm.

D 4

≤ 90 mm.

OUTPUT SIZE

OUTPUT SIZE

INSTRUCTIONS MANUAL

43

: Adjusting the width of Xcentric Crusher

Opening System Bucket XC20, XC30 & XC40

The XC20, XC30 and XC40 buckets are designed in a simple but effective and resilient way, so that they have

a system of opening and closing jaws to obtain a nal product according to the required demands.

It is based on a bracket attached to the bucket and a movable lower jaw by bolt-fastening pin, varying the

opening of the jaw, according to the combination of holes used.

Below cuting of the system shown:

Adjustment pin

Lower pin

Bucket

A

B

C

1

2

Lower support

Screwed

washer

Tensioner

Allen Screw

Nord-Lock

washer

Locking pin

XCENTRIC CRUSHER

44

ATTENTION!

All these operations will be held by ONE SINGLE operator and carrying out a number of safety guidelines:

- Mandatory use of Personal Protective Equipments (PPE): boots, gloves, goggles, etc.

- Eliminate any possible start / accidental operation of the excavator.

- Eliminate the possibility that someone else starts / operates the excavator while performing the

regulation.

ATTENTION!

Block the excavator and stop the engine by following the instructions in the manual of the excavator

itself, prior to the removal of pins of regulation.

1.- Lean the bucket slightly on a at, stable surface. Avoid pressure against the surface on the back of the

bucket, so that pins can be extracted without difculty.

Opening regulation

INSTRUCTIONS MANUAL

45

CAUTION!

Caution when removing pins of regulation, because there is a risk of movement of the rods.

2. Remove the retaining pins.

3. Remove pins of regulation, helped by a mallet if necessary.

XCENTRIC CRUSHER

46

4. After removing the pins of regulation, get into and the excavator and through the arm movement, open or

close the jaw to the desired opening. Lock and stop the excavator again.

5. Visually inspect which opening correction you will need to do, in order to install again the pins of regulation.

INSTRUCTIONS MANUAL

47

6. Introduce the pins of regulation, with the help of a mallet if necessary, having previously cleaned them. Light

greasing of the diameter of the pin will facilitate insertion.

Get into the excavator and make the correction through the arm movement. Lock and stop the engine of the

excavator.

Repeat this step as often as necessary until the alignment of selected holes is within an error less than 3 mm.

ATTENTION!

This operation must be carried out by the operator of the excavator without the help of another person.

There is high risk of unintended entrapment.

3 mm

XCENTRIC CRUSHER

48

7. Install the locking pins correctly.

ATTENTION!

The opening regulation with the bucket suspended in the air is totally prohibited, it exists high risk of

entrapment by droping or involuntary movement.

INSTRUCTIONS MANUAL

49

REMOVAL

: Removing the Crusher

Remove the Crusher as follows:

• Close the valve of the pressure line.

• Close the return line valve.

• Disconnect all hydraulic hoses.

• Attach the appropriate sealing plugs on the Crusher as well as on the excavator hoses.

• Position the Crusher on a horizontal surface to prevent tipping over and to ease subsequent removal.

• Remove the Crusher.

NOTICE

When detaching the Crusher from the excavator, close the hydraulic hoses and connections with plugs

to prevent oil from dripping out and dirt from getting into the hydraulic system.

1 A

≤ 20 mm.

2 A

≤ 95 mm.

1 B

≤ 45 mm.

2 B

≤ 125 mm.

1 C

≤ 70 mm.

2 C

≤ 150 mm.

OUTPUT SIZE

OUTPUT SIZE

XC20 - XC30 - XC40

XCENTRIC CRUSHER

50

: Adjusting the width of Xcentric Crusher

Opening System Bucket XC50

The XC50 buckets are designed in a simple but effective and resilient way, so that they have a system of

opening and closing jaws to obtain a nal product according to the required demands.

It is based on a bracket attached to the bucket and a movable lower jaw by bolt-fastening pin, varying the

opening of the jaw, according to the combination of holes used.

Below cuting of the system shown:

Adjustment pin

Lower pin

Bucket

A

B

C

D

1

2

Lower support

Screwed

washer

Tensioner

Allen Screw

Nord-Lock

washer

Locking pin

INSTRUCTIONS MANUAL

51

ATTENTION!

All these operations will be held by ONE SINGLE operator and carrying out a number of safety guidelines:

- Mandatory use of Personal Protective Equipments (PPE): boots, gloves, goggles, etc.

- Eliminate any possible start / accidental operation of the excavator.

- Eliminate the possibility that someone else starts / operates the excavator while performing the

regulation.

ATTENTION!

Block the excavator and stop the engine by following the instructions in the manual of the excavator

itself, prior to the removal of pins of regulation.

1.- Lean the bucket slightly on a at, stable surface. Avoid pressure against the surface on the back of the

bucket, so that pins can be extracted without difculty.

Opening regulation

XCENTRIC CRUSHER

52

CAUTION!

Caution when removing pins of regulation, because there is a risk of movement of the rods.

2. Remove the retaining pins.

3. Remove pins of regulation, helped by a mallet if necessary.

INSTRUCTIONS MANUAL

53

4. After removing the pins of regulation, get into and the excavator and through the arm movement, open or

close the jaw to the desired opening. Lock and stop the excavator again.

5. Visually inspect which opening correction you will need to do, in order to install again the pins of regulation.

XCENTRIC CRUSHER

54

6. Introduce the pins of regulation, with the help of a mallet if necessary, having previously cleaned them. Light

greasing of the diameter of the pin will facilitate insertion.

Get into the excavator and make the correction through the arm movement. Lock and stop the engine of the

excavator.

Repeat this step as often as necessary until the alignment of selected holes is within an error less than 3 mm.

ATTENTION!

This operation must be carried out by the operator of the excavator without the help of another person.

There is high risk of unintended entrapment.

3 mm

INSTRUCTIONS MANUAL

55

7. Install the locking pins correctly.

ATTENTION!

The opening regulation with the bucket suspended in the air is totally prohibited, it exists high risk of

entrapment by droping or involuntary movement.

XCENTRIC CRUSHER

56

REMOVAL

: Removing the Crusher

Remove the Crusher as follows:

• Close the valve of the pressure line.

• Close the return line valve.

• Disconnect all hydraulic hoses.

• Attach the appropriate sealing plugs on the Crusher as well as on the excavator hoses.

• Position the Crusher on a horizontal surface to prevent tipping over and to ease subsequent removal.

• Remove the Crusher.

NOTICE

When detaching the Crusher from the excavator, close the hydraulic hoses and connections with plugs

to prevent oil from dripping out and dirt from getting into the hydraulic system.

1 A

≤ 20 mm.

2 A

≤ 125 mm.

1 B

≤ 50 mm.

2 B

≤ 150 mm.

1 C

≤ 75 mm.

2 C

≤ 175 mm.

1 D

≤ 100 mm.

2 D

≤ 210 mm.

OUTPUT

SIZE

OUTPUT

SIZE

XC50

INSTRUCTIONS MANUAL

57

: Adjusting the width of Xcentric Crusher

Opening System Bucket XC60

The XC60 buckets are designed in a simple but effective and resilient way, so that they have a system of

opening and closing jaws to obtain a nal product according to the required demands.

It is based on a bracket attached to the bucket and a movable lower jaw by bolt-fastening pin, varying the

opening of the jaw, according to the combination of holes used.

Below cuting of the system shown:

Adjustment pin

Lower pin

Bucket

1

2

Lower support

Screwed

washer

Tensioner

Allen Screw

Nord-Lock

washer

Locking pin

A

B

C

D

E

XCENTRIC CRUSHER

58

ATTENTION!

All these operations will be held by ONE SINGLE operator and carrying out a number of safety guidelines:

- Mandatory use of Personal Protective Equipments (PPE): boots, gloves, goggles, etc.

- Eliminate any possible start / accidental operation of the excavator.

- Eliminate the possibility that someone else starts / operates the excavator while performing the

regulation.

ATTENTION!

Block the excavator and stop the engine by following the instructions in the manual of the excavator

itself, prior to the removal of pins of regulation.

1.- Lean the bucket slightly on a at, stable surface. Avoid pressure against the surface on the back of the

bucket, so that pins can be extracted without difculty.

Opening regulation

INSTRUCTIONS MANUAL

59

CAUTION!

Caution when removing pins of regulation, because there is a risk of movement of the rods.

2. Remove the retaining pins.

3. Remove pins of regulation, helped by a mallet if necessary.

XCENTRIC CRUSHER

60

4. After removing the pins of regulation, get into and the excavator and through the arm movement, open or

close the jaw to the desired opening. Lock and stop the excavator again.

5. Visually inspect which opening correction you will need to do, in order to install again the pins of regulation.

INSTRUCTIONS MANUAL

61

6. Introduce the pins of regulation, with the help of a mallet if necessary, having previously cleaned them. Light

greasing of the diameter of the pin will facilitate insertion.

Get into the excavator and make the correction through the arm movement. Lock and stop the engine of the

excavator.

Repeat this step as often as necessary until the alignment of selected holes is within an error less than 3 mm.

ATTENTION!

This operation must be carried out by the operator of the excavator without the help of another person.

There is high risk of unintended entrapment.

3 mm

XCENTRIC CRUSHER

62

7. Install the locking pins correctly.

ATTENTION!

The opening regulation with the bucket suspended in the air is totally prohibited, it exists high risk of

entrapment by droping or involuntary movement.

INSTRUCTIONS MANUAL

63

REMOVAL

: Removing the Crusher

Remove the Crusher as follows:

• Close the valve of the pressure line.

• Close the return line valve.

• Disconnect all hydraulic hoses.

• Attach the appropriate sealing plugs on the Crusher as well as on the excavator hoses.

• Position the Crusher on a horizontal surface to prevent tipping over and to ease subsequent removal.

• Remove the Crusher.

NOTICE

When detaching the Crusher from the excavator, close the hydraulic hoses and connections with plugs

to prevent oil from dripping out and dirt from getting into the hydraulic system.

1 A

≤ 20 mm.

2 A

≤ 150 mm.

1 B

≤ 45 mm.

2 B

≤ 180 mm.

1 C

≤ 65 mm.

2 C

≤ 180 mm.

1 D

≤ 90 mm.

2 D

≤ 215 mm.

1 E

≤ 120 mm.

2 E

≤ 250 mm.

OUTPUT

SIZE

OUTPUT

SIZE

XC60

XCENTRIC CRUSHER

64

USE

INSTRUCTIONS FOR USING THE XCENTRIC CRUSHER

Even though the Crusher requires no daily maintenance, for a long lasting life it must be kept clean and shock

free Before starting work with the Crusher, a daily visual inspection must be made.

PRECAUTIONS WHEN OPERATING THE CRUSHER

The Xcentric Crusher is intended for crushing and demolition materials reduction, so it is possible that a small

part of the material to crush is projected during use. It is therefore advisable to respect the safety distance.

Pay attention to the material to be crushed, large portions are not recommended, as they could get stuck in

the mouth of the bucket.

The operator in charge of the base machine will control that nobody can be affected by the movements of the

Xcentric Crusher.

Only qualied staff who has carefully read the instructions for use of Xcentricr Crusher described in the

instruction manual can perform such operations.

User companies will prepare specic safe work instructions to be observed by its staff.

User companies, will instruct and observe all mandatory regulations of law enforcement and those relevant to

the prevention of occupational risks and environmental protection.

The operator of the machine will be personnel who have received proper training and have demonstrated

competence.

The operator of the main operating machine will always remain inside the cab while the Xcentric Crusher is

working and being handled by the operator.

HANDLING THE XCENTRIC CRUSHER

The best way to learn to handle the Crusher is to operate it, although the use of it doesn’t differ much from a

normal crusher, therefore its handling is simple.

The way to use it is as follows:

• Fill the Xcentric Crusher with the material to be

ground.

• Rotate the bucket so that the opening of the material

outlet is at the bottom.

• Operate the Xcentric Crusher.

• Once you have completely crushed the material

deposited in the bucket, repeat the operation.

• The Xcentric Crusher should always run with the

crusher bucket upright.

• In the event that the Xcentric Crusher can not begin

to process the material in an upright position, the

amount of charge to be processed must be reduced.

INSTRUCTIONS MANUAL

65

WHAT TO DO IN CASE OF BLOCKED MATERIAL?

In the case the Crusher is blocked, it is strictly forbidden to remove the obstacle manually.

To unlock the jaws:

• Stop the Xcentric Crusher.

• Change the direction of movement of the jaws.

• If the jaws are still blocked, place the bucket with the loading mouth looking down and operate the

bucket in both directions until it is released.

• If necessary, lightly shake the Crusher.

NOTE

In no case hit the Xcentric Crusher against the ground or any other element in order to unlock it.

ATTENTION!

In case you have to gure out the cause of the machine blockage, it is strictly forbidden to hit the bucket

on the oor or against things horizontally. In case of damage caused by this operation the manufacturer

is exempt from any liability.

The XC has two rotation directions, one

for working and one for unlocking. In the

working direction, the jaw pushes the

material towards the outlet. In the sense of

release, the jaw pushes the material into

the inlet making it easier the unlocking

operation.

XCENTRIC CRUSHER

66

MISUSE OF THE XCENTRIC CRUSHER

The Xcentric Crusher is designed for crushing and reduction of demolition material, so is not authorized for use

in performing other tasks such as:

• Excavation or direct removal.

• Lifting Tool.

• Transportation of persons, animals, or any type of object.

• Support to maneuver or position the machine that is coupled to.

• Works with ammable materials, explosives, toxic and / or harmful.

• Work under water or moist material (reduces the life of the jaw).

• Above 100 ° C or below -20 ° C temperatures.

Also prohibited:

• Climb to the machine structure.

• Carry out any type of work on the machine with the Xcentric Crusher operating.

• Perform any operation that impairs the safety of the operator and bystanders.

• Breaking or removing material as if it were a hammer.

• The use of the bucket as a lever for lateral movement of the excavator.

• The use of Xcentric Crusher on machines whose hydraulic installation is not compatible with the

minimum requirements described in this manual.

• To use the Xcentric Crusher with the position of the crushing bucket different from the vertical.

• To operate the Xcentric Crusher from outside the cab of the main operating machine.

WORK INTERRUPTION

When interrupting work, place the Crusher on its lower mouth in a horizontal surface. Make the recommended

visual inspection. Keep in mind that there are areas that are very hot.

CLEANING

Clean the Xcentric Crusher after operation. Avoid directing the high-pressure water jet from a short distance at

the more sensitive parts as hydraulic hoses, seals, and other components, as this may damage them.

INSTRUCTIONS MANUAL

67

TRANSPORT

LIFTING

The lifting, securing, loading and unloading manipulations must be performed by qualied personnel prepared

for this purposes.

It is recommended to follow a few guidelines:

• Check the lifting elements to be inserted for their maximum allowable load.

• Follow the advice and recommendations of chains and straps manufacturer and ensure the correct

labeling of these, as well as having the certicate.

• For lifting the Xcentric Crusher use the lifting eyes provided, which are specically designed for this

purpose.

• The machine is designed so that its geometry allows it to be manipulated using standard lift ttings.

• If you are making a long-distance transport lubricate all machined exposed surfaces.

• Secure properly all loose parts to the machine.

• Before handling parts or items of equipment, check weights and note that transportation and handling

are adequate to support the weight of the machine.

• NEVER should attach any sling or strap directly to the moving parts of machines.

• The machine must be properly secured to prevent it from being damaged, tip over or fall of the

conveyance during transport.

• The equipment and auxiliary materials, such as cables, chains, shackles, eyebolts, slings, beams,

etc., will be selected based on the loads to be lifted, their centers of gravity, pulling angles and forms

of the equipment and materials to be lifted.

• The lifting equipment must not carry higher loads than its design.

• The cables, chains, straps, etc. they will only be tied to the points of the equipment specically

provided for this purpose.

• No lifting lugs will be welded to the equipment without the approval of the manufacturer or its

representative on site.

• The lifting equipment and auxiliary materials will be veried prior to use to check their perfect state.

• Mooring on axes or axes ends of the Xcentric Crusher for hoisting is not allowed.

• Contact between bare parts of wires with machined surfaces will be absolutely prohibited.

• During the displacement of the machine by mechanical handling equipment, the existence of people

in the equipment operating range and displacement area are not allowed.

• Passing the burden above the staff or passageways will be avoided

• Do not allow anyone to perch on the Xcentric Crusher during lifting operations.

• Do not leave the lifting equipment with Xcentric Crusher suspended.

• During lifting, xing any of the moving parts of the machine it is not necessary.

XCENTRIC CRUSHER

68

TRANSPORT WITH THE EXCAVATOR

The Crusher can be transported while attached to an excavator if the weight and dimensions of the machine

and attachment device are considered and applicable regulations are observed.

Ensure that the carrier excavator can support the load.

If the excavator is higher, there is a risk of mechanical stress in the XC.

The excavator must be stable at all times.

Read the operation and safety manual of the excavator before attaching the bucket.

Lifting eye

Lifting eye

ATTENTION!

It is strictly forbidden to stand under the load once it is suspended, and in the area of load balancing.