8

ASSEMBLY

NOTE: This Operator’s Manual covers several models. Tractor

features may vary by model. Not all features in this manual are

applicable to all tractor models and the tractor depicted may

differ from yours.

NOTE: All references in this manual to the left or right side and

front or back of the tractor are from the operating position only.

Exceptions, if any, will be specified.

Preparation

MANUALLY MOVING THE TRACTOR

1. Engage the transmission bypass rod to move the tractor

manually without starting it. The transmission bypass rod is

located on the rear of the tractor, on the frame. Engage the

bypass rod by pulling out. See Figure 1.

Figure 1

NOTE: If the tractor will not move or does not move freely when

pushing check if the hydrostatic bypass rod is fully open or the

brake is engaged.

NOTE: The transmission will NOT engage when the hydrostatic

bypass rod is pulled out. Return the rod to its disengaged

position prior to operating the tractor.

2. Disengage the transmission bypass rod by pushing the rod

back in after moving the tractor. See Figure 1.

INSTALL OPERATOR’S SEAT (IF NECESSARY)

To install the seat proceed as follows:

NOTE: The seat is shipped with the seat switch and seat

pan attached.

1. Cut any straps securing the seat assembly to the tractor.

Remove any packing material.

NOTE: Be careful not to cut the wiring harness connecting the

seat and the seat switch.

2. Remove the two shoulder bolts (a) and flange lock nuts (b) in

the seat pan as shown in Figure 2.

(a)

(a)

(b)

(b)

Figure 2

3. Rotate the seat into position and slide a Phillips screwdriver

through one of the seat-securing holes and seat bracket

for alignment.

4. With the previously removed shoulder bolts (a) and flange

lock nuts (b) secure one side of the seat and seat bracket.

While supporting the seat, remove the Phillips screwdriver

and secure the other side of the seat. Be careful not to crimp

or damage the wire harness while installing the seat. See

Figure 3. Torque to 84-103 in-lbs (9.5-11.6 N-m).

(a)

(b)

(a)

(b)

Figure 3

5. Using the harness clip attached to the harness, secure the

excess wire to the fender by snapping the harness clip in place

as shown in Figure 4.

Figure 4

9

ASSEMBLY

INSTALLING THE HOOD COLLAR (IF NECESSARY)

There are three (3) alignment posts (a) on the hood collar (b) that

line up with corresponding alignment holes (c) in the hood (d).

See Figure 5.

(a)

(a)

(a)

(a)

(b)

(c)

(c)

(c)

(d)

Figure 5

Use these alignment points to properly position the hood collar

(a), then secure it in place with the six hex bolts (b) provided in

the hardware bag. Tighten the hex bolts to 102-124 in-lbs (11.5-

14 N-m). See Figure 6.

bb

aa

bb

bb

bb

Figure 6

INSTALLING THE SNAP-ON HOOD TOPPER (IF NECESSARY)

1. To install the snap-on hood topper (a), line up the holes on

the hood topper (a) with the tabs (b) in the hood frame as

shown in Figure 7.

(a)

(b)

(b)

(b)

(b)

Figure 7

2. Insert the tabs into the hood topper and pull back to lock

into place.

3. Once the hood topper is in place, the two locking tabs near

the rear of the hood need to be pushed upward to lock the

hood topper in place. See Figure 8.

Hood Topper Not Shown for Clarity

Figure 8

INSTALLING THE SCREW-ON HOOD TOPPER

(IF NECESSARY)

NOTE: Be careful not to damage the headlight harness when

installing the screw-on hood topper.

1. Set the hood topper up against the top of the hood with the

hood open, and align the holes on the hood.

2. Secure the screw-on hood topper (a) from below, hand-

tighten the screws (b) on the rear half of the hood and then

snug them. See Figure 9.

3. With the rear screws in place, align the holes in the hood

topper (a) with the holes in the hood (c) and secure in place

with remaining two screws (d). See Figure 9.

(a)

(b)

(b)

(d)

(c)

(d)

Figure 9

4. Tighten all four screws to 16-24 in-lbs (1.8-2.7 N-m).

INSTALLING THE PLENUM (IF NECESSARY)

NOTE: Be careful not to damage the headlight harness when

installing the plenum.

To install the plenum (a) onto the hood (b):

1. Insert the rear tabs (c) as shown in Figure 10.

(b)

(a)

(c)

Figure 10

10

ASSEMBLY

2. With the rear tabs installed, insert the front tabs (a) on the

plenum (b) as shown in Figure 11.

(a)

(a)(a)

(b)

(a)(a)

Figure 11

NOTE: The rear tabs fit into a recessed area on the top of

the hood. They slide up from under the hood and into these

recessed areas.

3. Push up on the bottom of the plenum to make sure that the

plenum is securely in place.

4. Secure the headlight harness (a) into the two guides (b) on

the front of the plenum. Figure 12.

(a)

(b)

(b)

Figure 12

INSTALLING THE DASH CAP (IF NECESSARY)

To install the dash cap (a), line up the tabs (b) on the dash cap (a)

with the holes in the upper dash as shown in Figure 13. Slide the

tabs (b) into the holes in the upper dash and push forward on the

dash cap to lock into place.

(a)

(b)

Figure 13

NOTE: Be sure to press on the lower part of the dash cap (a)

facing the operator position to ensure the lower tabs on the dash

cap are in place. See Figure 13.

INSTALLING THE STEERING WHEEL (IF NECESSARY)

The hardware for attaching the steering wheel has been packed

within the steering wheel, beneath the steering wheel cap.

Carefully remove the cover by inserting a small flat screwdriver

into one of the three snap locations, while slowly prying up on

the steering wheel cap to remove the hardware.

IMPORTANT! Do not use impact tools to install or remove

the steering wheel. Doing so can over-torque and damage

the fastener.

1. With the wheels of the tractor pointing straight forward,

align the steering wheel (a) by using the center-line (b) on

the front of the steering wheel (a) pointing straight ahead

and the flat section (c) of the steering wheel (a) facing toward

the seat, place the steering wheel (a) over the steering shaft

(d). See Figure 14.

(e)

(f)

(c)

(a)

(b)

(d)

Figure 14

2. Secure the steering wheel (a) with the hex bolt (e) from

under the steering wheel cap (f) and torque to 18-22 ft-lbs

(24.4-29.8 N-m). See Figure 14.

3. Place the steering wheel cap (f) over the center of the

steering wheel (a) and push downward until it “clicks”

into place.

NOTE: The hex bolt (e) securing the steering wheel (a) has thread

locker applied to it, so if it is removed, it is recommended that the

hex bolt (e) be replaced or thread lock re-applied. See Figure 14.

INSTALLING THE FRONT BUMPER (IF EQUIPPED)

WARNING

Disengage the PTO, engage the brake lock, and stop

the tractor engine before performing any preparation

procedures. Place the tractor on a firm and level surface

before beginning installation or removal procedures.

The exhaust system and surrounding areas are HOT. To avoid

personal injury, allow the tractor to cool before beginning

any installation or removal procedures.

11

ASSEMBLY

The hardware for attaching the front bumper is shipped installed

into the bumper.

1. Remove the four hex screws (a) from the bumper (b). See

Figure 15.

2. Position the bumper brackets to the inside of the tractor’s

frame and secure it in place with the four hex screws (a). See

Figure 15.

(a) (a)

(b)

Figure 15

INSTALLING THE FASTATTACH™ BRUSH GUARD

(IF EQUIPPED)

1. Align the brush guard assembly with the FastAttach™

brackets and push assembly together. See Figure 16.

Figure 16

2. Install the pins on the right and left side of brush guard and

then secure with two cotter pins found in the hardware pack.

See Figure 17.

NOTE: Pulling up lightly on the brush guard may make

installation of the pins easier.

1

2

Figure 17

LOWER DECK DISCHARGE CHUTE DEFLECTOR

WARNING

Never operate the mower deck without the chute deflector

installed and in the down position.

For 46” deck models:

1. Remove the keys attached with a zip tie to the chute bracket.

2. Remove the flange lock nut and hex screw from the deck.

3. Place the chute deflector on the deck, be sure to insert the

tabs on the chute deflector into the holes on the deck. See

Figure 18.

4. Slide the chute deflector toward the rear of the tractor until

the bolt hole in the chute deflector aligns with the hole in the

deck. See Figure 18.

3

4

5

5

4

Figure 18

5. Secure the chute deflector in place with the flange lock nut

and hex screw removed in Step 2. Tighten to 102-124 in-lbs

(11.5-14 N-m). See Figure 18. Skip ahead to Setting the

Deck Wheels.

12

ASSEMBLY

For 42”/50”/54” deck models:

1. Check the tractor deck for a shipping brace that may be

holding the chute deflector upward for shipment. If the

brace is present, it must be removed before operating the

tractor. Holding the chute deflector fully upward, remove the

shipping brace. Lower the chute deflector and discard the

shipping brace. See Figure 19.

Figure 19

SETTING THE DECK WHEELS

NOTE: The deck wheels are an anti-scalp feature of the deck and

are not designed to support the weight of the cutting deck.

1. Move the tractor to a level surface, preferably pavement.

2. Check the tire pressure, adjust, if necessary. See tire sidewall

for proper tire pressure.

3. Make sure the deck is level side-to-side and properly pitched.

See the Service and Maintenance section for deck leveling

information and instructions.

4. Place deck lift lever in the desired mowing height position.

5. Check the wheels for contact or excessive clearance with the

surface below.

NOTE: The deck wheels should have between 1/4”-1/2” (6.35-

12.7 mm) clearance above the ground. Proceed as follows to

adjust the wheels:

a. Raise the deck lift handle to its highest setting.

b. Remove the front (a) and rear (b) deck wheels by

removing the flange lock nuts (c) and shoulder bolts (d)

that secure them to the deck. See Figure 20.

(a)

(b)

(c)

(d)

(d)

(c)

Figure 20

c. Place the deck lift lever in the desired mowing

height setting.

d. Reinsert the shoulder bolt (with each deck wheel) into

the index hole that leaves approximately 1/2” (12.7 mm)

between the bottom of the wheel and the pavement.

Tighten the flange lock nut and shoulder bolt to between

25-30 ft-lbs (33.9-40.7 N-m) using a torque wrench.

Battery Information

WARNING

California Proposition 65 Warning: Battery posts,

terminals, and related accessories contain lead and lead

compounds, chemicals known to the State of California

to cause cancer and reproductive harm. Wash hands

after handling.

WARNING

Should battery acid accidentally splatter into the eyes or

onto the skin, rinse the affected area immediately with

clean cold water. Seek prompt medical attention.

If acid spills on clothing, first dilute it with clean water,

then neutralize with a solution of ammonia/water or

baking soda/water.

NEVER connect (or disconnect) battery charger clips to the

battery while the charger is turned on, as it can cause sparks.

Keep all sources of ignition (cigarettes, matches, lighters)

away from the battery. The gas generated during charging

can be combustible.

As a further precaution, only charge the battery in a well

ventilated area.

Always shield eyes and protect skin and clothing when

working near batteries.

Batteries contain sulfuric acid and may emit explosive

gases. Use extreme caution when handling batteries. Keep

batteries out of the reach of children.

The battery may present a risk of fire or chemical burn if

misused. Do NOT open, disassemble, overheat, or incinerate

the battery.

13

ASSEMBLY

CAUTION

When attaching battery cables, always connect the POSITIVE

(Red) wire to terminal first, followed by the NEGATIVE

(Black) wire.

NOTE: The positive battery terminal is marked Pos. (+). The

negative battery terminal is marked Neg. (–).

CONNECTING THE BATTERY CABLES

WARNING

Always connect the positive lead to the battery before

connecting the negative lead. This will prevent sparking or

possible injury from an electrical short caused by contacting

the tractor body with tools being used to connect cables.

For shipping reasons the factory may leave both battery cables

disconnected from the terminals. To connect the battery cables,

proceed as follows:

NOTE: Wiring harness should lay on top of battery hold down

rod, otherwise damage to the wiring harness may result. See

Figure 22 on page 14.

1. Remove the factory installed hex screws (a) and square

nuts (b) located either on the end of the wiring harness or

in the bag with this manual. Retain the hardware for later

instructions. See Figure 21.

2. Remove the plastic cover (c), if present, from the positive

battery terminal (d) and attach the red cable (e) to the

positive battery terminal (d) with one of the hex screws (a)

and square nuts (b), from Step 1. Use a Philips screw driver.

See Figure 21.

3. Remove the plastic cover (c), if present, from the negative

battery terminal (f) and attach the black cable (g) to the

negative battery terminal (f) with the remaining hex screw

(a) and square nut (b). See Figure 21.

4. Position the red rubber boot over the positive battery

terminal to help protect it from corrosion. See inset in

Figure 21.

NOTE: If the battery is put into service after the date shown

on top/side of battery, charge the battery as instructed in the

Charging the Battery section prior to operating the tractor.

(c)

(c)

(a)

(d)

(e)

(f)

(b)

(a)

(g)

(b)

Figure 21

BATTERY MAINTENANCE

• Some batteries are filled with battery acid and then sealed

at the factory. However, even a “maintenance free” battery

requires some maintenance to ensure its proper life cycle.

• Spray the terminals and exposed wire with a battery

terminal sealer, or coat the terminals with a thin coat of

grease or petroleum jelly, to protect against corrosion.

• Always keep the battery cables and terminals clean and

free of corrosion.

• Some models are equipped with a battery containing a

liquid electrolyte. Handle the battery with care and avoid

tipping to prevent leakage.

BATTERY STORAGE

• When storing the tractor for extended periods, disconnect

the negative battery cable. It is not necessary to remove

the battery.

• All batteries discharge during storage. Keep the exterior

of the battery clean, especially the top. A dirty battery will

discharge more rapidly.

• The battery must be stored with a full charge. A discharged

battery can freeze sooner than a charged battery. A fully

charged battery will store longer in cold temperatures

than hot.

• Recharge the battery before returning to service. Although

the tractor may start, the engine charging system may not

fully recharge the battery.

14

ASSEMBLY

BATTERY REMOVAL

WARNING

Battery posts, terminals, and related accessories contain

lead and lead compounds. Wash hands after handling.

The battery is located beneath the seat frame. To remove

the battery:

1. Remove the hex screw and square nut securing the black

negative battery lead to the negative battery post (marked

NEG (-)). Move the cable away from the negative battery post.

2. Remove the hex screw and square nut securing the red

positive battery lead to the positive battery post (marked

POS (+)).

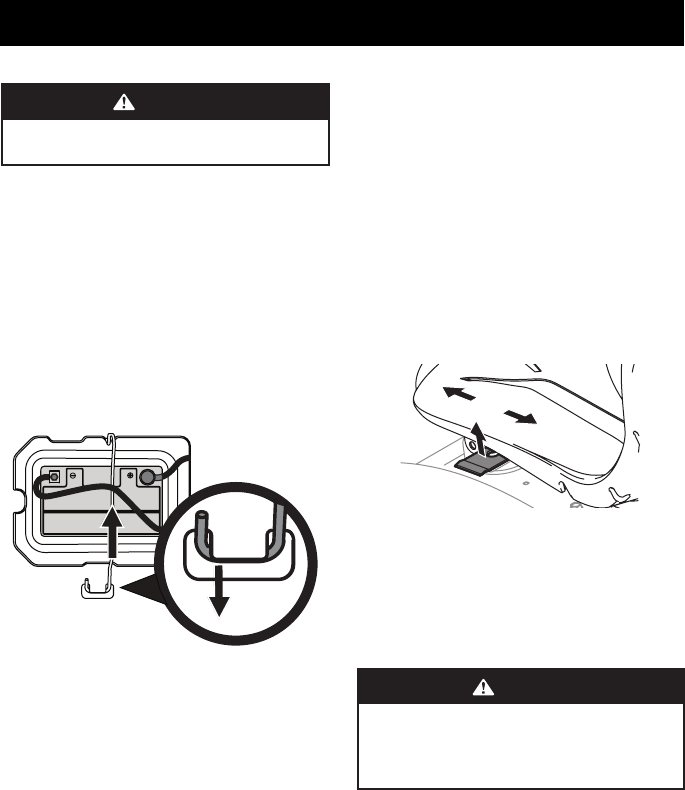

3. Remove the battery hold down rod by pushing the hooked

end out of the tab on the fender to the right side of the

battery. Then flip the battery hold down rod up to free the

battery. See Figure 22.

Figure 22

4. Carefully lift the battery out of the tractor.

5. Install the battery by repeating the above steps in the

reverse order.

CHARGING THE BATTERY

Test and, if necessary, recharge the battery after the tractor has

been stored for a period of time.

Models with Lead-Acid Battery

• A voltmeter or load tester reading of 12.4 volts (DC) or lower

across the battery terminals indicates that the battery

needs to be charged.

• A lead-acid battery charger should be used. Recommended

charge rate is 4A/14.7V.

• If your battery charger is automatic, charge the battery

until the charger indicates that charging is complete. If the

charger is not automatic, charge for no fewer than eight

(8) hours.

Models with AGM Battery

• An AGM battery charger should be used. Recommended

charge rate is 1.1A/14.8V.

IMPORTANT! Do NOT use an automotive charger.

• If your battery charger is automatic, charge the battery

until the charger indicates that charging is complete. If the

charger is not automatic, charge for no fewer than eight

(8) hours.

Adjusting the Seat

To adjust the position of the seat, lift the seat adjustment lever

up. Slide the seat forward or rearward to the desired position;

then release the adjustment lever. Make sure seat is locked into

position before operating the tractor. See Figure 23.

Figure 23

Oil

NOTE: Your tractor is shipped with oil in the engine. However,

you MUST check the oil level before operating. See the Engine

Operator’s Manual for instructions on checking, adding and

changing oil.

CAUTION

Always check the engine oil level before each use as

instructed in the Engine Operator’s Manual. Add oil as

necessary. Failure to do so may result in serious damage to

your engine.