Effect of drying methods on the physical properties and microstructures

of mango (Philippine ‘Carabao’ var.) powder

O.A. Caparino

a

, J. Tang

a,

⇑

, C.I. Nindo

b

, S.S. Sablani

a

, J.R. Powers

c

, J.K. Fellman

d

a

Biological Systems Engineering Department, Washington State University, P.O. Box, Pullman, WA 99164-6120, USA

b

School of Food Science, University of Idaho, Moscow, ID 83844-2312, USA

c

School of Food Science, Washington State University, P.O. Box, Pullman, WA 99164-6120, USA

d

Horticulture and Landscape Architecture, Washington State University, P.O. Box, Pullman, WA 99164-6120, USA

article info

Article history:

Received 9 November 2011

Received in revised form 3 January 2012

Accepted 5 January 2012

Available online 4 February 2012

Keywords:

Drum drying

Freeze drying

Glass transition temperature

Microstructure

Physical properties

Refractance Window

Ò

drying

Spray drying

X-ray diffraction

abstract

Mango powders were obtained at water content below 0.05 kg water/kg dry solids using Refractance

Window

Ò

(RW) drying, freeze drying (FD), drum drying (DD), and spray drying (SD). The spray-dried

powder was produced with the aid of maltodextrin (DE = 10). The chosen drying methods provided wide

variations in residence time, from seconds (in SD) to over 30 h (in FD), and in product temperatures, from

20 °C (in FD) to 105 °C (in DD). The colors of RW-dried mango powder and reconstituted mango puree

were comparable to the freeze-dried products, but were significantly different from drum-dried (darker),

and spray-dried (lighter) counterparts. The bulk densities of drum and RW-dried mango powders were

higher than freeze-dried and spray-dried powders. There were no significant differences (P 6 0.05)

between RW and freeze-dried powders in terms of solubility and hygroscopicity. The glass transition

temperature of RW-, freeze-, drum- and spray-dried mango powders were not significantly different

(P 6 0.05). The dried powders exhibited amorphous structures as evidenced by the X-ray diffractograms.

The microstructure of RW-dried mango powder was smooth and flaky with uniform thickness. Particles

of freeze-dried mango powder were more porous compared to the other three products. Drum-dried

material exhibited irregular morphology with sharp edges, while spray-dried mango powder had a spher-

ical shape. The study concludes that RW drying can produce mango powder with quality comparable to

that obtained via freeze drying, and better than the drum and spray-dried mango powders.

Ó 2012 Elsevier Ltd. All rights reserved.

1. Introduction

Mango (Mangifera indica L.) is one of the most appreciated fruits

in the world. The 2005 world production of mango was estimated

at 28.5 million metric tons, of which 85% was produced in the fol-

lowing 10 countries: India (37.9%), China (12.9%), Thailand (6.3%),

Mexico (5.9%), Indonesia (5.2%), Pakistan (5.9%), Brazil (3.5%),

Philippines (3.5%), Nigeria (2.6%), and Egypt (1.3%) (Evans, 2008).

In the Philippines, mango ranks third among fruit crops next to

banana and pineapple in terms of export volume and value, with

a total of metric tons harvested in 2007. The Carabao variety pop-

ularly known as ‘‘Philippine Super Mango’’ accounts for 73% of the

country’s production (BAS, 2009). This variety is acclaimed as one

of the best in the world due to its sweetness and non-fibrous flesh.

Fresh mangoes are perishable and may deteriorate in a short

period of time if improperly handled, resulting in large physical

damage and quality loss, ranging from 5% to 87% (Serrano, 2005).

Gonzalez-Aguilar et al. (2007) reported that 100% of untreated ripe

mango fruits of the ‘Hadin’ variety showed fungal infection and se-

vere decay damage by the end of 18 days of storage at 25 °C. In or-

der to take advantage of the potential health benefits of mango and

add value to the commodity with lesser handling and transport

costs, there is a need to develop mango products in forms of mango

powders that not only have desired functionality but also are sta-

ble over a longer storage time. Mango powder offers several advan-

tages over other forms of processed mango products like puree,

juice and concentrate. Besides having a much longer shelf life

due to considerable reduction in water content, the transport cost

is also significantly reduced. Mango powders may also offer the

flexibility for innovative formulations and new markets. For exam-

ple, mango powders can be used as a convenient replacement for

juice concentrates or purees, and as shelf-stable ingredients for

health drinks, baby foods, sauces, marinades, confections, yogurt,

ice cream, nutrition bars, baked goods and cereals (Rajkumar

et al., 2007). Development of high quality mango powder may

match the increasing worldwide demand for more natural man-

go-flavored beverages either singly flavored or in multi-flavored

products (FAO, 2007), and meet the great demand for natural fruit

powders by the pharmaceutical and cosmetic industries.

0260-8774/$ - see front matter Ó 2012 Elsevier Ltd. All rights reserved.

doi:10.1016/j.jfoodeng.2012.01.010

⇑

Corresponding author. Address: 208 LJ Smith Hall, Pullman, WA 99164-6120,

USA. Tel.: +1 509 335 2140; fax: +1 509 335 2722.

Journal of Food Engineering 111 (2012) 135–148

Contents lists available at SciVerse ScienceDirect

Journal of Food Engineering

journal homepage: www.elsevier.com/locate/jfoodeng

Several drying technologies can be viable commercial options

for manufacture of mango powders, including freeze drying, drum

drying, spray drying and Refractance Window

Ò

drying. Each has its

own advantages and limitations. The final product obtained from

these methods may differ in physicochemical or nutritional prop-

erties and microstructures. Freeze drying, also known as lyophili-

zation, is a drying process in which the food is first frozen then

dried by direct sublimation of the ice under reduced pressure (Oet-

jen and Haseley, 2004; Barbosa-Cánovas, 1996). To carry out a suc-

cessful freeze drying operation, the pressure in the drying chamber

must be maintained at an absolute pressure of at least 620 Pa (To-

ledo, 2007). Freeze drying is generally considered as the best meth-

od for production of high quality dried products (Ratti, 2001). But,

it suffers from high production costs, high energy consumptions,

and low throughputs (Ratti, 2001; Hsu et al., 2003; Caparino,

2000).

Drum drying is commonly used in production of low moisture

baby foods and fruit powders (Kalogiannia et al., 2002; Moore,

2005). A drum dryer consists of two hollow cylinder drums rotat-

ing in opposite directions. The drums are heated with saturated

high temperature (120–170 °C) steam inside the drums. Raw mate-

rials are spread in thin layers on the outer drum surface and dry

rapidly. The product is scraped from the drum in the form of dried

flakes (Kalogiannia et al., 2002; Saravacos and Kostaropoulos,

2002). A major likely drawback is undesirable cooked aromas

and other severe quality losses in the final products caused by

the high temperature used in the drying process (Nindo and Tang,

2007).

Spray drying is widely used in commercial production of milk

powders, fruits and vegetables (Kim et al., 2009; Kha et al.,

2010). This method has several advantages, including rapid drying,

large throughput and continuous operation (Duffie and Marshall,

1953). During the drying process, the feed solution is sprayed in

droplets in a stream of hot air (Saravacos and Kostaropoulos,

2002). The liquid droplets are dried in seconds as a result of the

highly efficient heat and mass transfers (Toledo, 2007). The fin-

ished product can be made in the form of powder, granules or

agglomerates (Nindo and Tang, 2007). Spray drying processes can

be controlled to produce relatively free flowing and uniform spher-

ical particles with distinct particle size distribution (Barbosa-Cano-

vas et al., 2005; Duffie and Marshall, 1953). However, due to the

relatively high temperatures involved in spray-drying processes,

this drying technique may cause loses of certain quality and sen-

sory attributes, especially vitamin C, b-carotene, flavors and aroma

(Dziezak, 1988). In addition, it is difficult to directly spray dry su-

gar-rich materials such as mango, because they tend to stick to the

walls of the dryer (Bhandari et al., 1997a,b; Masters, 1985). Drying

aids, such as maltodextrin, are widely added to the feed to increase

glass transition temperature of the dried product and hence over-

come the problem of stickiness during spray drying.

Refractance Window

Ò

(RW™) is a novel drying technique de-

signed mainly to convert fruit puree into powder, flakes, or concen-

trates. The technology utilizes circulating hot water (95–97 °C) to

transfer thermal energy to a thinly spread liquid material placed

on a polyester conveyor belt that moves at a predetermined speed

while in direct contact with hot water. During drying, the thermal

energy from hot water is transmitted to foods through the plastic

conveyor by conduction and radiation. Water vapor from foods is

carried away by a flow of filtered air over the thin layer. This technol-

ogy offers several benefits when applied to fruits and vegetables. For

example, good retention of nutritional (vitamins), health-promoting

(antioxidants) and sensory (color, aroma) attributes were reported

for dried carrots, strawberries and squash (Nindo and Tang, 2007).

The bright green color of pureed asparagus remained virtually un-

changed when dried in the RW dryer, and was comparable to the

quality of freeze-dried product (Abonyi et al., 2002). In addition,

energy efficiency of RW drying method compares favorably with

other conventional dryers (Nindo and Tang, 2007).

Studies were reported that compared the influence of different

drying methods on various quality attributes of fruits and vegeta-

bles, including the color of dehydrated apple, banana, carrots and

potatoes (Krokida et al., 2001), b-carotene and ascorbic acid reten-

tion in carrots and strawberry (Abonyi et al., 2002), antioxidants

and color of yam flours (Hsu et al., 2003), asparagus (Nindo et al.,

2003), and antioxidant activities in soybean (Niamnuy et al.,

2011), encapsulated b-carotene (Desobry et al., 1997), and color

and antioxidant of beetroots (Figiel, 2010). However, no studies

have been conducted to evaluate the effect of drying methods on

mango powders in terms of color, bulk density, porosity, hygro-

scopicity, solubility, and microstructures. Thus, the objective of

this work was to investigate the influence of four drying methods

(Refractance Window

Ò

drying, freeze drying, drum drying and

spray drying) on the physical properties and microstructures of

resulting mango powders to provide better understanding in

selecting drying techniques that can be applied toward the manu-

facture of high quality mango powder.

2. Materials and methods

2.1. Preparation of mango puree

Frozen mango puree (Philippine ‘Carabao’ var.) was acquired

from Ramar Foods International (Pittsburg, CA). The puree was

produced following the manufacturer’s standard process that in-

volved selection of ripened mangoes (95–100% ripeness), washing

using chlorinated water, manual trimming, removal of any black

portions of the peel and separation of stone/peel. The cleaned man-

go fruits went through a pulping machine that separated the pulp

and discarded excess fibers. A buffer tank was used to standardize

the puree at 14–15 °Brix. The mango puree was pasteurized,

packed in 5 kg polyethylene (PE) bags, sealed and blast frozen at

35 °C. Bags of puree were placed in carton boxes and stored at

18 °C. The frozen mango puree was kept at constant temperature

while in transit from the Philippines to California and finally to

Washington State University (Pullman, WA). This frozen mango

was stored at 35 °C until it was ready for drying. The average

moisture content of the mango puree was 6.5 ± 0.1 kg water/kg

dry solids determined using standard oven method (AOAC, 1998).

2.2. Drying experiment

Frozen mango puree was thawed overnight at room tempera-

ture (23 °C), and afterward blended for 5 min to a uniform consis-

tency using a bench top blender (Oster Osterizer, Mexico) with

lowest speed setting. The puree was dried to below 0.05 kg

water/kg dry solids by Refractance Window

Ò

drying, freeze drying,

drum drying, or spray drying. Due to difficulty in spray drying of

this sugar-rich material, maltodextrin (DE = 10) (Grains Processing

Corporation, Muscatine, IA) was added to mango puree before

spray drying. No addition of carrier was used for the other three

drying systems. Detailed procedures for each drying method are

described below:

2.2.1. Refractance Window

Ò

drying

A pilot scale Refractance Window

Ò

dryer at MCD Technologies,

Inc. (Tacoma, WA) was used for drying mango puree. The dryer has

an effective surface drying area of 1.10 m

2

and length of 1.83 m in

the direction of belt movement. The main components of the dryer

included a conveyor belt made of ‘‘Mylar

Ò

’’ (polyethylene tere-

phthalate) plastic, a water pump, a hot water tank, a heating unit,

two water flumes, a hood with suction blowers and exhaust fans, a

136 O.A. Caparino et al. / Journal of Food Engineering 111 (2012) 135–148

spreader, and a scraper (Fig. 1). The drying was accomplished by

spreading homogenized mango puree on the plastic conveyor belt

that moves over the surface of circulating hot water. The thickness

of the puree on the belt was 0.5–0.7 mm and was controlled using

a spreader bar. The thermal energy from the circulating hot water

(transferred to the puree through the belt) was used to remove

moisture from the product (Nindo et al., 2003). Previous studies re-

ported that the temperature of the product during drying rarely ex-

ceeded 80 °C(Abonyi et al., 2002). During drying operation, the

temperature of circulating hot water was maintained between 95

and 97 °C similar to that reported by Abonyi et al. (2002) and

Nindo and Tang (2007). The temperature of the circulating hot

water was continuously monitored at the flume inlet and outlet

section using pre-calibrated Type T thermocouple sensors. The sen-

sors were connected to a data acquisition unit equipped with mon-

itoring software. Water vapor removal from the samples was

facilitated by forcing the suction air (22 °C) with relative humidity

(50–52%) over the puree at an average air velocity of 0.7 m/s (Abo-

nyi et al., 2002). The residence time to dry the mango puree into

flakes or powder was determined by monitoring the time travelled

by the thinly spread mango puree from inlet to the outlet section of

the plastic conveyor belt. Measurement of the residence time was

performed in triplicate.

2.2.2. Freeze drying

Freeze drying was carried out using a laboratory freeze dryer

(Freeze Mobile 24, Virtis Company, Inc., Gardiner, NY). The thawed

mango puree was poured into a stainless pan to form a layer of

15 mm. The samples were placed at 25 °C for 24 h before trans-

ferring to the freeze dryer. The vacuum pressure of the dryer was

set at 20 Pa, the plate temperature was 20 °C, and the condenser

was at 60 °C. The residence time needed to dry the mango puree

to below 0.05 kg water/kg dry solids was determined when the

vacuum pressure had dropped to 30 mTorr (4 Pa).

2.2.3. Drum drying

A laboratory atmospheric double drum dryer (Model no. ALC-5,

Blaw-Knox Co., Buffalo, NY) was utilized in this experiment. The

dryer has two hollow metal drums with 0.15 m external diameter

and 0.19 m length. The drums were internally heated by steam at

379.2 ± 7 kPa producing a temperature of 152 ± 2 °C. Preliminary

experiments were conducted at different rotational speed settings

in order to obtain dried sheets of below 0.05 kg water/kg dry solids.

The clearance between the two drums was fixed at 0.01 mm allow-

ing the puree to flow (forced by rotary action) into a thin layer as it

passed through the gap. The drum temperature was allowed to

stabilize before feeding the puree. This prepared puree was poured

evenly over the hot pool area between the two drums. After trav-

eling approximately three fourths of the revolution of the drums

or 15 cm distance, the dried product was scraped from the drum

surface by doctor blades. The residence time for drying was re-

corded by taking three fourths of the time measured for one com-

plete revolution of the drum. Due to stickiness of mango, the dried

product at the exit section of the dryer tended to roll and build up

while the drum was rotating forming an extruded-like product and

not the expected thin flakes. Thin sheet or flakes of dried product

was obtained by carefully pulling the dried product as it goes out

of the exit section of the dryer. The dried product removed from

the two drums was mixed together for analysis because their

appearance and moisture content were generally similar.

2.2.4. Spray drying

The thawed mango puree was spray-dried in a pilot scale S-1

spray dryer (Anhydro Attleboro Falls, MA). Before starting the

experiment, the dryer was conditioned for 20 min by pumping

de-ionized water through the atomizer with the dryer inlet and

outlet temperatures set at 180 and 80 °C, respectively (Shrestha

et al., 2007). The mango puree was pumped into the spray dryer

chamber at a flow rate of 50 ± 2 g/min using Masterflex pump

(Cole-Parmer Instruments Co., Chicago, IL). The air temperature

was maintained at 190 ± 2 °

C (dryer inlet) and 90 ± 2 °C (dryer out-

let) during drying. These air inlet and outlet conditions are within

the recommended temperatures of 180–220 and 90–110 °C,

respectively, for spray drying of heat sensitive products at atmo-

spheric pressure (Filkova and Mujumdar, 1995; Kim et al., 2009).

The outlet temperature determines the thermal exposure of the

sample during spray drying. It was observed during preliminary

experiments that spray drying of mango puree without any carrier

was not possible due to the high content of low molecular weight

sugars (e.g. fructose, glucose, sucrose), similar to what had been re-

ported by other authors (Abonyi et al., 2002; Bhandari et al.,

1997a,b). Maltodextrin (DE = 10) having a median glass transition

temperature of T

gm

= 139.7 °C(Jakubczyk et al., 2010) was added

to produce a non-sticky and free flowing powder (Bhandari et al.,

1997a,b). Preliminary experiments were carried out to obtain dried

product that has better appearance and throughput. Three malto-

dextrin concentrations of 0.25, 0.35 and 0.45 kg/kg dried mango

solids were tested for this purpose (Jaya et al., 2006; Nindo and

Tang, 2007; Sablani et al., 2008). By visual examination, the color

and appearance of the dried mango powder from the three treat-

ments showed very little variation. Hence, the spray-dried mango

powder with the lowest maltodextrin concentration of 0.25 kg/kg

dried mango solids was selected for comparison with other dried

powders. The actual residence time to obtain mango powder with

Fig. 1. Schematic layout of Refractance Window

Ò

dryer (adapted from Nindo and Tang (2007) and Abonyi et al. (2002)).

O.A. Caparino et al. / Journal of Food Engineering 111 (2012) 135–148

137

a moisture content below 0.05 kg water/kg dry solids was not mea-

sured, but the information from previous studies on spray drying of

sugar-rich material was used to approximate the time.

2.3. Handling and packaging of samples

The product from each drying process had unique geometries at

the exit point, so different handling procedures were employed.

Rectangular cake-like dried products obtained from the freeze dry-

ing process were collected and sliced into smaller pieces using a

clean stainless steel knife and packed in leak-proof Ziploc

Ò

plastic

bags. The spray-dried material, which appeared like agglomerated

spherical shapes, was immediately packed in the same type of

plastic bags after coming out from the dryer. The dried thin sheets

collected from the drum and RW drying processes were handled in

a similar manner. All the samples sealed in Ziploc

Ò

bags were

placed inside aluminum-coated polyethylene bags. To prevent oxi-

dation, all the packaged samples were flushed with nitrogen gas,

heat sealed and stored at 35 °C until further analyses.

2.4. Grinding and sieving

One hundred grams each of dried flakes or sheets obtained from

different drying processes were ground using mortar and pestle.

Sieving analysis was carried out by stacking and vibrating the

sieves in ascending order of mesh sizes of 35, 45, 60 and 80 (Amer-

ican Society for Testing and Materials, ASTM) to obtain particle

sizes of 500, 350, 250 and 180

l

m (International Standard for

Organization, ISO), respectively (Barbosa-Canovas et al., 2005).

Those with particle sizes ranging between 180–500

l

m and flakes

or sheets were evaluated in terms of color, bulk density and bulk

porosity, while particle sizes of 180–250

l

m were analyzed for sol-

ubility, hygroscopicity and microstructures.

2.5. Water content

The water content of mango puree and dried flakes/powders

made from RW, freeze, drum and spray drying methods was deter-

mined using the standard oven method at 70 °C and 13.3 kPa for

24 h (AOAC, 1998). The drying, cooling and weighing of samples

was continued until the difference between two successive weigh-

ing was less than 1 mg.

2.6. Water activity

Water activity of the RW-, freeze-, drum-, and spray-dried man-

go powders was measured using water activity meter (Aqualab 3TE

series, Decagon Devises, Pullman, WA). Duplicate samples were

measured at 24.7 ± 1 °C.

2.7. Physical properties of mango powders

2.7.1. Color analysis

The dried mango in flakes or sheet forms and four different par-

ticle sizes of 500, 350, 250 and 180

l

m were evaluated for color

comparison. Mango powders or flakes were poured into Petri

dishes, slightly shaken to form a layer of 10 mm thickness and cov-

ered with transparent film (Saran™ Wrap, SC Johnson, Racine, WI).

The International Commission on Illumination (CIE) parameters L,

a

⁄

and b

⁄

were measured with a Minolta Chroma CR-200 color me-

ter (Minolta Co., Osaka, Japan). The colorimeter was calibrated with

a standard white ceramic plate (L = 95.97, a = 0.13, b = 0.30)

prior to reading. Corresponding L value (lightness of color from

zero (black) to 100 (white); a

⁄

value (degree of redness (0–60) or

greenness (0 to 60); and b

⁄

values (yellowness (0–60) or blueness

(0 to 60) were measured for all the samples. The average L, a

⁄

and

b

⁄

values were obtained from six readings taken from each of five

locations. The hue angle, H

⁄

and chroma, C

⁄

expressed as H

¼

tan

1

b

a

and C

¼

ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

a

2

þ b

2

p

, respectively were also calculated (Abo-

nyi et al., 2002). Hue is a color attribute by which red, yellow, green

and blue are identified, while chroma distinguishes between vivid

and dull colors.

For color comparison with the original mango puree, 2 g each of

RW-, freeze-, drum-, and spray-dried mango powders (250

l

m)

with water content of 0.017 ± 0.001, 0.023 ± 0.002, 0.013 ± 0.001

and 0.043 ± 0.003 kg water/kg dry solids were reconstituted by

adding an amount of 12.10, 12.04, 11.96 and 11.70 g of distilled

water, respectively using material balance. The reconstituted man-

go powders produced slurries with moisture content of 6.143 kg

water/kg dry solids similar as the original mango puree. The recon-

stitution of mango powder was carried out by mixing the powder

and water at 23 °C while vortexing (Fisher Scientific mini vortexer,

USA) until the powder was completely dissolved. The L

⁄

, a

⁄

and b

⁄

,

H

⁄

and C

⁄

values were immediately measured and calculated fol-

lowing the same procedure employed for mango flakes and pow-

ders. The total change in color of the reconstituted mango

powders with reference to the original puree were computed as:

D

E ¼

ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

ðL

0

L

Þ

2

þða

0

a

Þ

2

þðb

0

b

Þ

2

q

where, subscript ‘‘o’’ de-

notes the color of original puree (Jaya and Das, 2004; Nindo

et al., 2003).

2.7.2. Bulk density

The bulk density of the mango powder obtained from different

drying processes and particle sizes was measured following the

procedure described in previous studies with modification (Barb-

osa-Canovas et al., 2005; Goula and Adamopoulus, 2008). Approx-

imately 5 g of mango powder was freely poured into a 25 ml glass

graduated cylinder (readable at 1 ml) and the samples were

repeatedly tapped manually by lifting and dropping the cylinder

under its own weight at a vertical distance of 14 ± 2 mm high until

negligible difference in volume between succeeding measure-

ments was observed. Given the mass m and the apparent (tapped)

volume V of the powder, the powder bulk density was computed as

m/V (kg/m

3

). The measurements were carried out at room temper-

ature in three replicates for all samples.

2.7.3. Particle density and bulk porosity

The particle densities of mango powders obtained by different

drying methods were calculated by adopting the pycnometer

method. A 2.5 ± 0.04 g of each of the RW-, freeze-, drum-, and

spray-dried mango powders (180–250

l

m) was placed in an

empty liquid pycnometer (25 ml), and filled with measured vol-

ume of toluene. Toluene was used because of its ability to pene-

trate the finest external pores connected to surface of the

material without dissolving the material. Bulk porosity (

e

b

) was

calculated by determining the ratio of particle density (

q

p

) and

bulk density (

q

b

) using the Eqs. (1)–(3) as (Krokida and Maroulis,

1997):

q

b

¼

m

s

V

t

ð1Þ

q

p

¼

m

s

V

s

ð2Þ

e

b

¼ 1

q

b

q

p

ð3Þ

where

q

b

is the bulk density of mango solids,

q

p

is the particle den-

sity of the solids, m

s

is the mass of mango solids, V

t

and V

s

is the to-

tal and volume of the dry solids, respectively.

138 O.A. Caparino et al. / Journal of Food Engineering 111 (2012) 135–148

2.7.4. Solubility

Solubility of mango powder was determined using the procedure

developed by Eastman and Moore (1984) as adopted by Cano-Chau-

ca et al. (2005). One gram of the powder (dry basis) was dispersed in

100 ml distilled water by blending at high speed (13,000 rpm) for

5 min using an Osterizer blender (Oster, Mexico). The dispersed

mango powder was then centrifuged at 3000g for 5 min. A 25 ml ali-

quot of the supernatant was carefully pipetted and transferred to a

pre-weighed aluminum dish and then oven-dried at 105 °C for 5 h.

Drying was continued and weighed every hour for 2 h. The solubility

of the powder (%) was determined by taking the weight difference.

2.7.5. Hygroscopicity

Ten grams each of RW-, freeze-, drum- and spray-dried mango

powders with particle sizes of 180–250

l

m and moisture content

below 0.05 kg H

2

O/kg mango solids were placed in an open glass

container. Three replicate samples for each product were put sep-

arately in three sealed humidity jars containing NaCl saturated

solution (75.5% humidity) and stored at 25 °C for 7 days. Samples

were prepared at 20 °C. Hygroscopicity, HG (%) or 1 g of adsorbed

moisture per 100 g dry solids (g/100 g) was calculated using the

following equation:

HG ¼

D

m=ðM þ M

i

Þ

1 þ

D

m=M

ð4Þ

where

D

m (g) is the increase in weight of powder after equilibrium,

M is the initial mass of powder and M

i

(% wb) is the free water con-

tents of the powder before exposing to the humid air environment

(Jaya and Das, 2004; Sablani et al., 2008; Tonon et al., 2008).

2.8. Glass transition temperature

Glass transition temperature (T

g

) of mango powders with water

activity below 0.2 was measured using differential scanning

calorimeter (DSC, Q2000, TA Instruments, New Castle, DE), follow-

ing the procedure described by Syamaladevi et al. (2009). The

calorimeter was calibrated for heat flow and temperature using

standard indium and sapphire. Twelve to sixteen milligrams of

each mango powder sample was sealed in an aluminum pan

(volume of 30

l

l), cooled down from 25 to 90 °C using liquid

nitrogen and then equilibrated for 10 min. The samples at 90 °C

were scanned to 90 °C then cooled down to 25 °C. Scanning of all

samples was carried out using the same heating and cooling rate

of 5 °C/min. To avoid condensation on the surface of the powder

particles, a nitrogen carrier gas was purged at a flow rate of

50 ml/min. The onset- (T

gi

), mid- (T

gm

) and end-point (T

ge

) values

of the mango powders were determined by finding the vertical

shift in the heat flow-temperature diagram. All measurements

were performed in duplicate.

2.9. X-ray diffraction

X-ray diffraction (XRD) characteristics of mango powders

obtained from different drying processes were investigated using

a Siemens D-500 diffractometer (Bruker, Karlsruhe, Germany).

The powder samples (180–250

l

m) were placed and slightly

pressed in an aluminum holder using a glass slide. The diffractom-

eter was operated at a wavelength of 0.15 nm and the input energy

was set at 30 mA and 35 kV. Diffractograms were taken between 5°

and 50° (2h) with a step angle of 0.02° and scan rate of 1 s per step.

The XRD patterns of all the samples were plotted for comparison.

2.10. Microstructure analyses

A small quantity of mango powders (180–250

l

m) from differ-

ent drying systems were mounted on aluminum stubs and coated

with a fine layer of gold (15 nm) using a Sputter gold coater (Tech-

nics Hummer V, Anatech, San José, CA). All powder samples were

examined by Scanning Electron Microscopy using SEM Hitachi S-

570 camera (Hitachi Ltd., Tokyo, Japan) operated at an accelerating

voltage of 20 kV. Micrographs were photographed at a magnifica-

tion of 100, 300 and 1000 at scale bar of 0.30 mm, 100

l

m

and 30

l

m.

The microstructure of samples prepared for hygroscopicity

experiments were also analyzed to identify possible relationships

between the obtained hygroscopicity values for each mango pow-

der sample using a Quanta 200F Environmental Scanning Electron

Microscope (FEI, Field Emission Instruments, Hillsboro, Oregon,

USA). The low vacuum mode (200 Pa) was used during scanning

to allow measurement of samples at their native state. Observa-

tions were carried out with an accelerated voltage of 30 kV and

magnification of 700 at a scale of 100

l

m.

2.11. Statistical analysis

All experiments were carried out at least in duplicate, the re-

sults analyzed using the general linear model procedure of SAS

(SAS Institute Inc., Cary, NC), and the means separated by Tukey-

honest significant difference test with a confidence interval of

95% used to compare the means. Mean standard deviations are pre-

sented in the results.

3. Results and discussion

3.1. Residence time, water content and product temperature

The residence time during drying of mango puree from the ini-

tial moisture content of 6.52 kg water/kg mango solids to below

0.05 kg water/kg mango solids was accomplished in 180 ± 0.15,

111,600 ± 5100 and 54 ± 0.2 s for RW, FD and FD, respectively,

and less than 3 s with SD (Table 1). It should be noted here that

the residence time used for SD was only an approximation based

on the data reported by Desobry et al. (1997) and Jayasundera

et al. (2011b). The actual residence time during spray drying of

mango powder in our study might be higher than 3 s because of

the difference in drying conditions and specifications of the spray

dryer used as compared from the literature. Nevertheless, the esti-

mated residence time for SD is definitely much smaller than for

RW, freeze and drum drying. The product temperatures measured

for each drying process was 74 ± 2 °C (RW), 20 ± 0.5 °C (FD),

105 ± 5 °C (DD) and 90 ± 2 °C (SD).

3.2. Physical properties of mango powder

3.2.1. Color analysis

The color of the dried product (mango flakes/sheet) or powders

of different particle sizes were affected by the drying methods.

Table 1

Drying conditions for production of mango powders using different methods.

Product Product

temperature (°C)

Residence

time (s)

Water content

(kg water/kg dry solids)

Fresh puree – – 6.518 ± 0.123

RW 74 ± 2 180 ± 0.15 0.017 ± 0.001

FD 20 ± 0.5 111,600 ± 5091 0.023 ± 0.002

DD 105 ± 5 54 ± 0.2 0.013 ± 0.001

SD 90 ± 2 1–3

a

0.043 ± 0.003

Standard deviation from the average value of at least two replicates.

a

The residence time was an approximate value, based on information given in

Desobry et al. (1997) and Jayasundera et al. (2011a,b,c).

O.A. Caparino et al. / Journal of Food Engineering 111 (2012) 135–148

139

Visual examination showed that spray-dried (agglomerate powder

particles) and drum-dried mango powder had the lightest and

darkest color, respectively. The color difference between mango

powder obtained using RW and FD was not significantly different

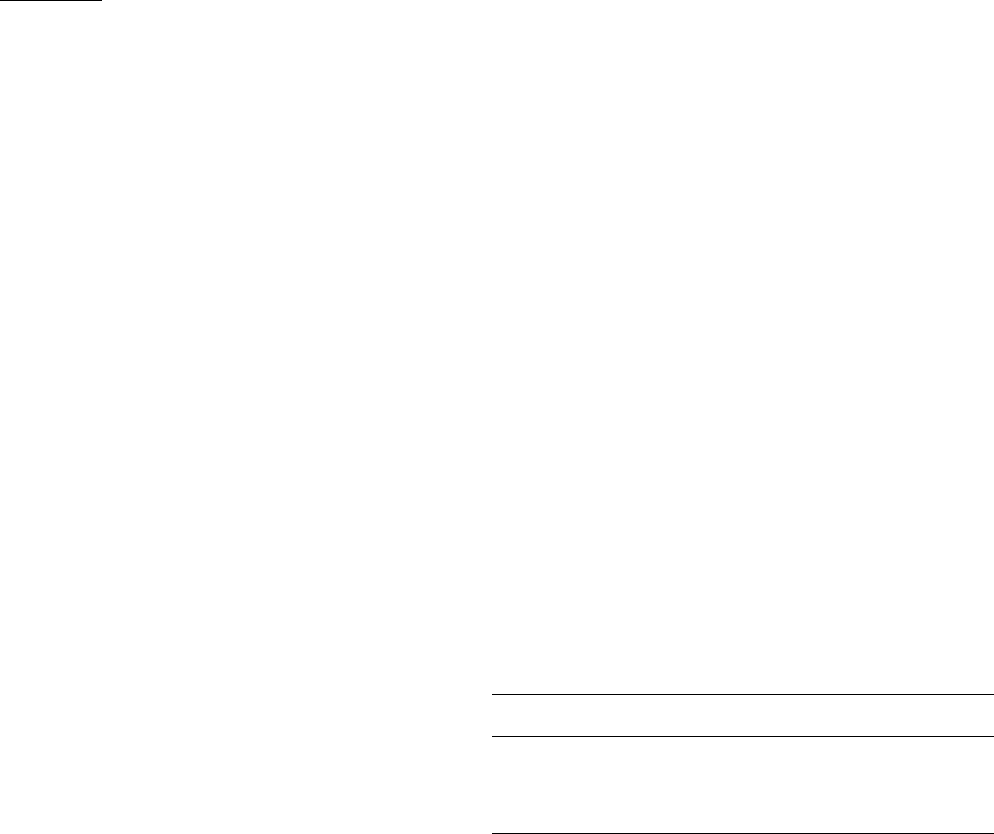

(P 6 0.05) (Fig. 2). Hunter color tristimulus values for mango pow-

der of different particle sizes are presented in Fig. 3. Overall, the

product (flakes) at exit had a significant difference in the L value

(lightness) among the RW-, freeze-, drum-, and spray-dried mango

flakes or powders, except for the RW and freeze-dried powder with

particle size of 500 and 350

l

m which showed no significant vari-

ation (P 6 0.05) (Fig. 3a). The similarity in L-value for RW, FD and

DD powders of the smallest particle size (180

l

m) may be attrib-

uted to negligible effect on reflectance.

The mango powder produced by spray drying had the highest L

value, while the drum-dried mango powder appeared to have the

lowest L value (indicating darkest color). The lighter color in spray

drying was due to the addition of maltodextrin carrier which was

necessary to reduce the stickiness of the mango to allow the spray

drying process to be effective (Abonyi et al., 2002; Jaya et al., 2006).

While the outlet temperature during spray drying reached

90 ± 2 °C, the drying time was very short (l–3 s) as reported by

Desobry et al. (1997). Hence the color degradation was limited.

On the other hand, the darker color of the drum-dried mango

powder can be attributed to high drying temperature. Such effect

confirmed previous studies on strawberry puree (Abonyi et al.,

2002) wherein color degradation was greatly influenced by high

processing temperatures. The dark color in drum-dried mango

flakes or powder can be characterized by browning reaction or

Maillard reaction caused by the chemical reactions between sugars

and proteins (Potter and Hotchkiss, 1995). Moreover, carameliza-

tion of sugars in mango can occur due to high temperature contrib-

uting to darkening during drying. The dominant color in mango

puree is yellow and hence can be best represented by Hunter color

b

⁄

(yellowness) to distinguish the color difference of the resulting

mango powders as affected by the drying process. No significant

difference was observed in b

⁄

value (yellowness) between RW

and freeze-dried mango powder while there was a highly signifi-

cant difference between spray and drum-dried product (P 6 0.05)

(Fig. 3b). Chroma value or vividness in yellow color of 250

l

m

particle size RW and freeze dried mango flakes and powders

showed no significant difference, but RW-dried mango powder

with particle size 350–500

l

m were of a more vivid yellow color

than freeze dried mango powder having obtained the highest chro-

ma value (Fig. 3c). The hue angle value in spray-dried mango pow-

der was the highest but its chroma value is very low indicating a

dull color (Fig. 3d). RW dried mango flakes or powder at all particle

sizes obtained a higher hue angle compared to freeze and drum-

dried mango powders suggesting that RW-dried mango powder is

more vivid in its yellow color implying that it will be more attrac-

tive and appealing to consumers. The overall distinct vivid yellow

color of the RW-dried mango may be indicative of high b-carotene

retention. Abonyi et al. (2002) reported that b-carotene in RW and

freeze-dried carrot puree was 53% and 55% higher compared to

drum-dried products, respectively. Wagner and Warthesen (1995)

reported that the yellow and red color of carrot slices is attributed

to the presence of carotenes. Also, the b

⁄

(yellow) values for raw and

puree sweet potato were highly correlated with b-carotene content

(Ameny and Wilson, 1997). The minimal color change of product

produced by RW and freeze drying suggests the appropriateness

of these processes to produce high quality products. The compara-

ble yellow color of RW and freeze-dried mango powder can also be

attributed to low product temperature for RW (74 ± 2 °C) and

freeze-dried (20 ± 0.5 °C), compared to spray-dried (90 ± 2 °C) and

drum-dried (105 ± 5 °C) mango powder.

The reconstituted mango powder was prepared by adding water

to achieve the same solid contents as the original mango puree.

Visual examination of the color of the reconstituted RW-, freeze-,

drum-, and spray-dried mango powders showed variations in com-

parison with the original mango puree (Fig. 4). Luminosity (L

⁄

) val-

ues as presented in Table 2 showed no significant difference

between reconstituted RW- and freeze-dried mango puree and

both are similar in luminosity to the original puree. Reconstituted

drum-dried mango puree was darker as expected because of the

darker powder. The result is in agreement with the work of Abonyi

et al. (2002) wherein a drum-dried carrot puree was perceived as

darker in comparison with powders produced by spray, freeze

Fig. 2. Photograph of mango flakes or powders at different particle sizes obtained from Refractance Window

Ò

(RW) drying, freeze drying (FD), drum drying (DD), and spray

drying (SD).

140 O.A. Caparino et al. / Journal of Food Engineering 111 (2012) 135–148

and RW drying methods. Spray-dried mango powder was darker

than RW- and freeze-dried but lighter than reconstituted drum

dried mango puree. The original mango puree and reconstituted

RW and freeze-dried mango powders are significantly different

but comparable in terms of vividness and saturation of yellow

color. On the other hand, the reconstituted drum-dried and

spray-dried mango puree had lower chroma values indicating less

saturation and dull yellow appearance. A comparable result was

also observed for hue angle among the original puree, reconstituted

RW- and freeze-dried mango puree while reconstituted drum-dried

mango puree had a low hue angle value, which indicates a dull

yellow color. The reconstituted spray-dried mango puree had the

highest hue angle value but because of its low lightness and chroma

values, it produced a grayish pale color. The reconstituted mango

powder from drum drying process showed the highest deviation

in color with respect to the original mango puree having a

D

E value

of 9.22 ± 0.01 followed by the reconstituted spray-dried mango

puree with

D

E value of 6.23 ± 0.02 (e.g. lightest). The reconstituted

RW-dried mango puree had the lowest color difference with

D

E va-

lue = 1.22 ± 0.02, a value very close to reconstituted freeze-dried

mango puree with

D

E value = 1.57 ± 0.02. The distinct superiority

of RW drying process against drum and spray drying processes in

producing mango powder in the present experiment is in corrobo-

ration with previous studies for asparagus (Nindo et al., 2003), and

carrots and strawberry (Abonyi et al., 2002).

3.2.2. Bulk density and porosity

For all drying methods, the bulk density of mango powders in-

creased and their porosity decreased with decreasing particle size

(Figs. 5 and 6). These results may be attributed to the decrease in

the inter-particle voids of smaller sized particles with larger

contact surface areas per unit volume. Similar observation was re-

ported for bulk density of ginger powder at different particle sizes

(Xiaoyan, 2008). It was also consistent with the explanation by

other authors that powder characteristics such as particle size

may result in significant changes in bulk density and porosity

(Barbosa-Canovas et al., 2005).

Freeze- and spray-dried mango powders had significantly lower

bulk densities and higher porosities compared to drum- and RW-

dried products (P 6 0.05) (Figs 5 and 6). It is well recognized that

in freeze drying of foods in the form of either puree or as a whole,

the material is first frozen allowing it to maintain its structure fol-

lowing sublimation of ice under high vacuum (Oetjen and Haseley,

2004). Since liquid phase in the material is not present during this

process, there is no transfer of liquid water to the surface, but in-

stead the ice changes to vapor below the collapse temperature

without passing the liquid state (Krokida and Maroulis, 1997). In

effect the collapse and shrinkage of the product is prevented there-

by resulting in a porous dried material (Karel, 1975).

The higher porosity or lower bulk density in spray-dried mango

powder was due to the addition of maltodextrin (Fig. 6). Shrestha

et al. (2007) demonstrated that increasing maltodextrin concentra-

tion in tomato pulps led to the decrease in bulk density. Goula and

Adamopoulus (2008) also explained that maltodextrin is consid-

ered a skin-forming material and by using it as carrier can induce

accumulation and trapping of air inside the particle causing it to

become less dense and porous.

On the other hand, the bulk porosity and density of RW- and

drum-dried mango powder were significantly lower and higher

than freeze and spray dried product, respectively with drum dried

product exhibited the lowest porosity (P 6 0.05) (Figs. 5 and 6).

During drum drying, the mango puree poured inside a pool

between the two drums has vapor bubbles bursting at the free sur-

face and spattered along side of the two drum surfaces as triggered

by high temperature (above boiling). The high temperature used in

Fig. 3. Lightness (a), yellowness (b), chroma (c) and hue angle (d) of mango flakes

or powders at different particle sizes obtained from Refractance Window

Ò

(RW),

freeze drying (FD), drum drying (DD), and spray drying (SD).

O.A. Caparino et al. / Journal of Food Engineering 111 (2012) 135–148

141

drum drying may have caused collapse which resulted in more

compact and rigid product. These characteristics resulted in lower

porosity when compared to freeze- or spray-dried mango powder.

RW-dried mango powder exhibited low porosity compared to

freeze- and spray-dried mango powder but significantly higher

than drum-dried powder (P 6 0.05) (Figs. 5 and 6). RW is catego-

rized as a direct drying technique similar to drum-drying (Nindo

and Tang, 2007), except that the energy is indirectly transferred

via plastic film instead of steel as in drum drying. Apparently, both

drying processes seem to produce a similar form of end product.

3.2.3. Solubility

Solubility is the most reliable criterion to evaluate the behavior

of powder in aqueous solution. This parameter is attained after the

powder undergoes dissolution steps of sinkability, dispersability

and wettability (Chen and Patel, 2008). There was no significant

difference in the solubility between spray and drum-dried mango

powder, while both were significantly higher compared to RW

and freeze-dried product (P 6 0.05) (Table 3). The high solubility

of spray-dried mango powder can be attributed to the addition of

maltodextrin (DE = 10). This result was in agreement with the

study reported by Cano-Chauca et al. (2005) where they concluded

that solubility of mango powders increased when maltodextrin

was added during spray-drying. Maltodextrin is a material that

serves as coating agent as the particle crust is developed during

spray drying resulting in a product that is highly soluble (Desai

and Park, 2004). Cai and Corke (2000) also confirmed that malto-

dextrin as a carrier and coating agent increased the solubility of

spray-dried betacyanins. The atomization of mango puree during

spray drying may also contribute to solubility of spray-dried prod-

uct. Fibers present in mango might have been broken into tiny

pieces as a result of high atomization of the material resulting in

increased solubility. From the above observations, maltodextrin

was proven effective in increasing solubility of spray-dried mango

powder. However, spray drying of mango puree containing

25 kg/kg dried mango solids significantly altered the total color

change of the resulting mango powder as earlier discussed. Like-

wise, the cyclone recovery of mango powder at this maltodextrin

concentration was only 37.8 ± 1.8% (data not shown), far below

the >50% benchmark cyclone recovery for a marginally successful

spray drying process of sugar-rich material (Bhandari et al.,

Fig. 4. Photograph of reconstituted mango powders obtained from Refractance Window

Ò

(RW), freeze drying (FD), drum drying (DD), and spray drying (SD).

Table 2

Hunter color measurements of reconstituted mango powders obtained from different drying processes.

Drying method L

⁄

a

⁄

b

⁄

C

⁄

Hue angle b

⁄

/a

⁄

D

E

Original puree 45.12 ± 0.02

a

4.65 ± 0.01

c

41.52 ± 0.03

a

41.78 ± 0.03

c

83.61 ± 0.01

a

8.93 ± 0.01

c

–

RW 43.95 ± 0.02

b

4.40 ± 0.01

d

41.79 ± 0.03

a

42.02 ± 0.03

b

83.99 ± 0.01

a

9.50 ± 0.02

b

1.22 ± 0.02

d

FD 43.74 ± 0.06

c

4.69 ± 0.01

b

40.99 ± 0.23

b

41.26 ± 0.23

d

83.47 ± 0.04

b

8.73 ± 0.06

d

1.57 ± 0.03

c

DD 37.73 ± 0.01

d

6.92 ± 0.02

a

36.48 ± 0.02

c

37.13 ± 0.02

e

79.27 ± 0.03

c

5.28 ± 0.03

e

9.22 ± 0.01

a

SD 41.59 ± 0.07

e

3.05 ± 0.01

e

36.64 ± 0.02

c

36.77 ± 0.03

a

85.24 ± 0.02

d

12.00 ± 0.05

a

6.23 ± 0.02

b

D

E is calculated using the original mango puree as reference.

a–e

Means with the same superscript letters within a column indicate no significant differences (P 6 0.05).

0

200

400

600

800

1000

RW FD DD SD

Bulk Density,k g/m3

Drying method

500 350 250 180

µm µm µm µm

Fig. 5. Bulk density of mango powders obtained from Refractance Window

Ò

(RW)

drying, freeze drying (FD), drum drying (DD), and spray drying (SD).

0.00

0.10

0.20

0.30

0.40

0.50

0.60

RW FD DD SD

Porosity

Drying method

500 350 250 180

µm µm µm µm

Fig. 6. Porosity of mango powders obtained from Refractance Window

Ò

(RW)

drying, freeze drying (FD), drum drying (DD), and spray drying (SD).

142 O.A. Caparino et al. / Journal of Food Engineering 111 (2012) 135–148

1997a,b; Jayasundera et al., 2011a,b). The application of alternative

drying aids such as proteins and low molecular surfactants may

improve the recovery and quality of spray-dried mango powders

and help in maintaining higher solubility (Jayasundera et al.,

2011a,b,c; Adhikari et al., 2009a,b). Recently, a type of protein

called ‘‘Protein X’’ developed at the University of Sydney, was

found to increase the recovery of sugar-rich material of up to

80% by just adding a small amount (<5%) to the sticky fruit juice

or puree (Wang et al., 2011).

Drum dried mango powder also had a high solubility value that

was not significantly different from spray-dried mango powder.

The higher solubility of drum-dried samples could be attributed

to a higher degree of macromolecular disorganization of the mate-

rial as affected by drying process and condition. However, its infe-

rior dark color may restrict consumer acceptance even though its

solubility is high.

The solubilities of freeze- and RW-dried mango powders were

similar and significantly lower than that of spray- and drum-dried

mango powders. Both drying methods are gentle in terms of prod-

uct temperature (Table 1). One possible reason for the lower solu-

bility of those samples is that the cell structure of mango puree

was not disrupted and smaller amounts of solids were dissolved

to become part of the supernatant.

3.2.4. Hygroscopicity

A demarcation or cut-off values for hygroscopicity (HG) of man-

go powder ranging from 5.13% to 9.38% were considered as the ba-

sis for comparing the results in our study. These figures were based

on the average range of hygroscopicity values of instant coffee

(lower HG) and tomato soup powder (higher HG) as calculated

by Jaya and Das (2004). Table 3 shows the hygroscopicity of mango

powders made from Refractance Window, freeze, drum and spray

drying. The drum-dried mango powder exhibited the highest

hygroscopicity (20.1 ± 0.88%), 74% higher than the higher limit

cut-off HG, indicating its strong capacity to attract water molecules

when in contact with the surrounding air. Mujumdar (2007) ex-

plained that drum drying of sugar-rich fruits requires high temper-

ature and usually a dry to very low moisture thin sheet product.

This drying condition usually causes the product to be very hygro-

scopic and often other quality attributes are degraded. The lower

hygroscopicity value obtained for spray drying (16.5 ± 0.06) or

68.91% higher than the benchmark HG can be attributed to the

addition of maltodextrin in the mango puree before drying. Tonon

et al. (2008) demonstrated that the hygroscopicity of spray-dried

acai powder gets lower as the concentration of maltodextrin was

increased. Similar observation was confirmed during spray drying

of cactus pear juice (Rodríguez-Hernández et al., 2005), sweet po-

tato powder (Ahmed et al., 2009) and betacyanin pigments (Cai

and Corke, 2000), suggesting that maltodextrin is an efficient car-

rier agent in lowering hygroscopicity of dried material. Conse-

quently, when this carrier is added, other quality attributes of

the mango powder such as color and b-carotene (data not shown)

were found inferior. There was no significant difference in the

hygroscopicity between RW- (18.0 ± 0.36%) and freeze-dried

(18.0 ± 0.19%) mango powder (P 6 0.05) obtaining a similar in-

crease of 71.50% based on the higher limit cut-off HG, suggesting

the superiority of RW over drum and spray-dried mango powder.

The small variation of moisture content of the different samples

may have direct relationship with the hygroscopicity as shown in

Table 3. Tonon et al. (2008) expound that the low moisture

spray-dried acai has the greater capacity to absorb water from

the surrounding air and hence is more hygroscopic. However, his

findings on the moisture–hygroscopicity relationship cannot be

generalized for all commodities. Ahmed et al. (2009) reported that

hygroscopicity of spray-dried sweet potato was greatly affected by

carrier agents with no direct relationship to varying moisture

content. The present study was in agreement with his findings

wherein maltodextrin greatly influenced the hygroscopicity of

the spray-dried mango powder.

3.3. Glass transition temperature

The glass transition temperatures of RW-, freeze-, drum- and

spray-dried mango powders were determined in the water activity

range from 0.169 to 0.177 and water content below 0.05 kg water/

kg mango solids (Table 4

). The onset of T

g

(T

gi

) values of mango

powders were slightly lower than the room temperature (25 °C)

normally used for long-term storage of food powders. Adhikari

et al. (2009a) reported that water activity below 0.2 is the value

commonly applied for processing of spray-dried powders in a com-

mercial scale. The T

gi

values of mango powders ranged from

18.7 ± 0.2 to 26.1 ± 0.8 with RW-dried mango powder displaying

the lowest T

gi

and being significantly different from spray-dried

product having the highest T

gi

value (P < 0.05). The higher T

g

value

of spray-dried product may be attributed to the addition of higher

T

g

maltodextrin before spray drying. Maltodextrin has high molec-

ular weight and adding this amorphous material to low molecular

weight sugar-rich material such as mango will cause it to increase

the glass transition temperature of the product (Jaya and Das,

2004). The glass transition temperature of RW- freeze- and

drum-dried mango powder produced without the drying aids

showed no significant differences among each other (P < 0.05). It

can also be seen from the data that the glass transition

Table 3

Solubility and hygroscopicity of RW-, freeze-, drum-, and spray-dried mango powders with particle size 180–250

l

m.

Drying methods Particle size (

l

m) Moisture content (kg water/

kg mango solids)

Solubility

A

(%) Hygroscopicity

B

(%)

RW 180–250 0.017 ± 0.001 90.79 ± (0.394)

*,a

18.0 ± 0.36

a

FD 180–250 0.023 ± 0.002 89.70 ± 0.631

a

18.0 ± 0.19

a

DD 180–250 0.013 ± 0.001 94.38 ± 0.431

b

20.1 ± 0.88

b

SD 180–250 0.043 ± 0.003 95.31 ± 0.112

b

16.5 ± 0.06

c

*

Standard deviation from the average value.

a,b

Means with the same superscript letters within a column indicate no significant differences (P 6 0.05).

A

Measurement was done at 23 °C.

B

Samples were exposed to 75 ± 1% RH at 25 °C for 7 days.

Table 4

Glass transition temperatures and water activity of RW-, freeze-, drum-, and spray-

dried mango powders.

Drying methods Glass transition temperatures Water activity

T

gi

T

gm

T

gi

RW 18.7 ± 0.2

b

23.1 ± 0.7

a

24.6 ± 0.5

a

0.177 ± 0.001

a

FD 20.1 ± 0.8

ab

25.8 ± 2.7

a

27.6 ± 1.8

ab

0.174 ± 0.001

a

DD 22.4 ± 1.1

ab

27.6 ± 1.3

a

30.3 ± 1.1

ab

0.169 ± 0.002

a

SD 24.4 ± 0.8

a

28.8 ± 4.3

a

31.5 ± 0.7

a

0.173 ± 0.006

a

Means with the same superscript letters within a column indicate no significant

differences (P < 0.05). T

gi

, T

gm

and T

ge

represent the onset, mid- and end-point glass

transition temperatures of mango powders (180–250

l

m).

O.A. Caparino et al. / Journal of Food Engineering 111 (2012) 135–148

143

temperature of mango powder with water activity <0.2 was not af-

fected by the drying process and condition.

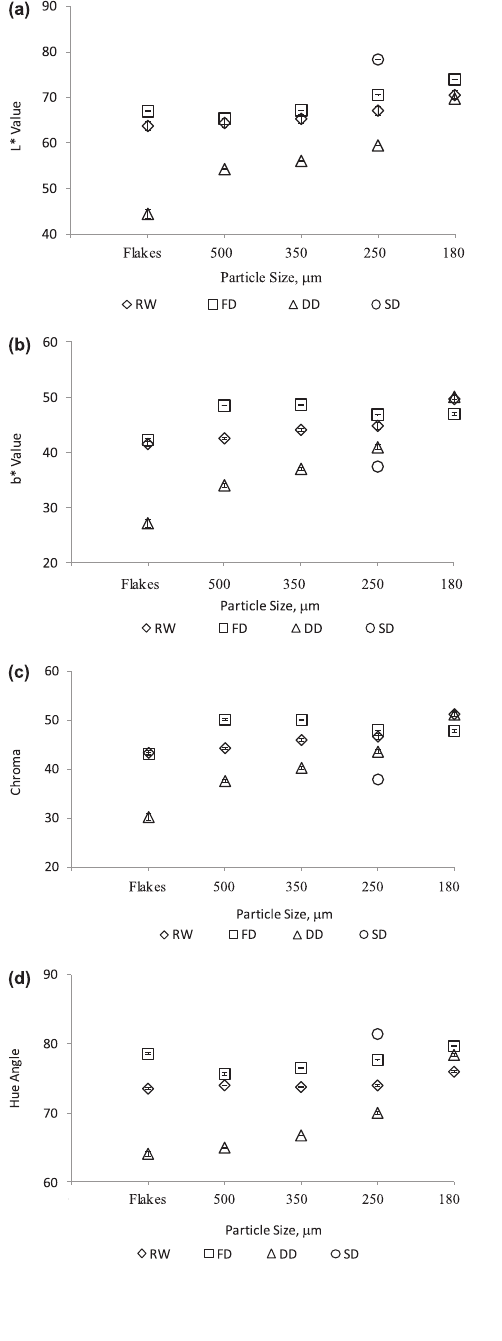

3.4. X-ray diffraction

X-ray diffraction is a common technique used to confirm the

crystalline–amorphous state of dried products in a powder form.

In general, crystalline material shows a series of sharp peaks, while

amorphous product produces a broad background pattern. The X-

ray diffraction patterns of RW-, freeze-, drum- and spray-dried

mango powders at a

w

< 0.2 clearly exhibited amorphous character-

istics and showed no crystalline peak formation (Fig. 7). The rapid

drying of low molecular weight sugars present in mango (sucrose,

fructose and glucose) and organic acids that happened under RW,

drum and spray drying processes tend to produce amorphous

metastable state dried products because of insufficient time to

crystallize (Jayasundera et al., 2011a,b). The diffractogram of

freeze-dried mango powder obtained in this study was similar to

the one reported by Harnkarnsujarit and Charoenrein (2011) and

Haque and Roos (2005).

The X-ray patterns and shapes for all the mango powders tested

were similar to spray-dried sucrose indicating the dominance of

sucrose sugars present in mango (Adhikari et al. (2009a). However,

it is interesting to note that the intensity count for drum-dried

mango powder as shown in the diffractograms was significantly

lower compared to the other three powder products. This could

be due to puree gelatinization that occurred before the actual drum

drying, resulting in the disorganization of intra- and intermolecu-

lar hydrogen bonding between water and starch molecules (Gavri-

elidou et al., 2002). Anastasiades et al. (2002) confirmed that

gelatinization process causes irreversible changes in the physical

structure of starch, which is present in mango resulting in degrada-

tion of molecular structure and loss of crystallinity. The absence of

crystalline peaks confirmed that no substantial changes occurred

on the hygroscopicity of RW-, freeze-, drum- and spray-dried man-

go powders as earlier discussed.

3.5. Microstructure

Scanning electron micrographic studies of mango powders

(180–250

l

m) obtained by different drying processes are shown

in Figs. 8–10. The microstructure of RW-dried mango powder

was smooth, and flaky with uniform thickness (Fig. 8a and b).

The uniformity of the flake thickness was the result of a controlled

feeding of mango puree using a spreader bar at the inlet section of

the RW dryer. During dying, the thinly spread mango puree on the

surface of the plastic film conveyor is undisturbed, except for re-

moval of moisture, as it moves toward the other end of the dryer,

hence producing a continuous sheet with thickness nearly equal.

Crushing the RW-dried mango flakes into powder form produced

irregularly shaped particles while maintaining its thickness. The

two sides of a single particle were smooth indicating more flow-

ability and less susceptibility to oxidation because of lesser surface

area. Freeze-dried mango powder (Fig. 8c and d), showed a skele-

tal-like structure and was more porous than the other mango pow-

ders. This result happens because the ice in the material during

freeze drying helps prevent shrinkage and collapse of the structure

and shape resulting in an insignificant change in volume (Ratti,

2001). The microstructure of drum-dried mango powder (Fig. 8e

and f) was compact and exhibited irregular particles with sharp

edges and considerable indentation as a result of crushing into

powder. Caric and Kalab (1987) reported similar structure for

drum-dried milk powder. They explained that the compactness

of drum-dried milk powder was due to deaeration of raw milk dur-

ing drum drying. It is also evident that the drum dried sheets are

smooth on one side that is in direct contact with the drum surface,

while visible corrugation and crinkle was observed on the other

side. These observations are in agreement with the microstructure

of drum-dried pre-gelatinized maize starches as described by

Anastasiades et al. (2002). Spray-dried mango powder (Fig. 8g

and h) has spherical or oval shape and smooth surface particles

due to effect of spray-drying condition, which was maintained at

inlet temperature of 190 ± 2 °C during drying. Nijdam and Langrish

(2005) demonstrated that milk powders spray-dried at inlet tem-

perature of 200 °C have spherical, smooth and larger particles,

while particles were smaller and shriveled when the inlet temper-

ature was reduced to 120 °C. The smooth spherical-shaped mango

powder contributed to its high porosity compared to the other

three drying methods.

Individual particles of mango powders obtained from different

drying processes were further examined (Fig. 9). The RW-dried

mango powder clearly showed a composite sheet with distinguish-

able internal pores within the particle indicating that some emp-

tied space during evaporation is not replaced as the mango puree

0

50

100

150

200

250

01020304050

Intensity (Counts)

2 Theta (Deg)

d

a

b

c

Fig. 7. X-ray diffraction patterns of Refractance Window

Ò

-dried (a), freeze-dried (b), drum-dried (c) and spray-dried (d) mango powders with particle size 180–250

l

m and

a

w

< 0.2.

144 O.A. Caparino et al. / Journal of Food Engineering 111 (2012) 135–148

Fig. 8. Scanning electron micrographs (SEM) of mango powders (180–250

l

m) dried using Refractance Window

Ò

drying (a and b), freeze drying (c and d), drum drying (e and

f) and spray drying (g and h) (magnification of 100 (a, c, e and g) and 300 (b, d, f and h), 20 kV).

Fig. 9. Scanning electron micrographs (SEM) of individual mango powder particles (180–250

l

m) dried using Refractance Window

Ò

drying (a), freeze drying (b), drum drying

(c) and spray drying (d) (magnification of 1000, 20 kV).

O.A. Caparino et al. / Journal of Food Engineering 111 (2012) 135–148

145

is dried. These pores might have contributed to the higher porosity

of RW-dried compared to drum-dried mango powder. Drum-dried

mango powder developed a fine particle surface allowing it to be

more compact and rigid. Spray-dried mango powder particle

showed a very fine and smooth surface, but it may not be indica-

tive of being rigid and compact as it contains vacuoles forming a

hollow spherical shape (Cai and Corke, 2000). Apparently, external

pores were developed within the internal pores of a single particle

freeze-dried mango powder. This further explains why the porosity

of freeze-dried materials always is higher in comparison with other

drying methods.

The microstructures of mango powders (180–25

l

m) exposed

at 23 °C for 7 days at high relative humidity (75.5%) showed differ-

ent water adsorption behavior (Fig. 10). The particle surfaces and

edges of RW- and freeze-, and spray-dried mango powders were

still visible indicating that the materials adsorbed less when com-

pared to drum-dried mango powder wherein its particles were

nearly dissolved with water. This result confirmed the higher

hygroscopicity value obtained for drum-dried mango powder

compared to the other three powder products.

4. Conclusions

The physical properties and microstructures of mango powders

were significantly affected by drying methods applied. Drying of

mango puree to below 0.05 kg/kg dry mango solids was accom-

plished in 180 ± 0.15, 111,600 ± 5100 and 54 ± 0.2 s for RW, FD

and FD, respectively, and less than 3 s with SD. The color of

drum-dried mango powder was severely degraded because of high

processing temperature, while the spray-dried powder became

lighter due to the addition of maltodextrin. On the other hand,

the color of RW- and freeze-dried mango powder was comparable

at different particle sizes. The reconstituted RW-dried mango

puree showed a slight deviation in comparison with the original

puree and was very close to reconstituted freeze-dried mango

puree. Reconstituted drum- and spray-dried mango puree suffered

discoloration and were respectively darker and lighter than the ori-

ginal puree. Both the drum- and RW-dried mango powders were

significantly denser compared to freeze- and spray-dried. Regard-

less of the particle size and shape, freeze-dried mango powder

had the highest bulk porosity compared to the other three drying

methods. Drum-dried mango powder was the most hygroscopic

while spray-dried was the least hygroscopic. There was no signifi-

cant difference in hygroscopicity and solubility between RW and

freeze-dried material. The glass transition temperatures of RW-,

freeze-, drum- and spray-dried powders were not significantly dif-

ferent at water activity just below 0.2. The X-ray diffraction pat-

terns of RW-, freeze-, drum- and spray-dried mango powders

(a

w

< 0.2) clearly exhibited amorphous characteristics and showed

no crystalline peak formation. The microstructure analysis verified

the variations in bulk density, porosity, solubility and hygroscopic-

ity of mango powders. Also, the microstructures of individual par-

ticles played an important role in analyzing the physical properties

of mango powders. Overall, our study concludes that the RW dry-

ing method can produce superior quality mango powder compared

to drum and spray drying, while it is highly comparable to freeze

drying. The study provides an opportunity to the powder process-

ing industry in selecting a better drying technique that can be uti-

lized for the manufacture of high quality mango powder.

Acknowledgments

We thank the Ford Foundation International Fellowship Pro-

gram (IFP)/Institute of International Education (IIE)-New York

Fig. 10. Field emission scanning electron micrographs (FESEM) of Refractance Window

Ò

-dried (a), freeze-dried (b), drum-dried (c) and spray-dried (d) mango powders (180–

250

l

m) stored for 7 days at 25 °C with RH = 75.5% (magnification of 300, 30 kV).

146 O.A. Caparino et al. / Journal of Food Engineering 111 (2012) 135–148

through IFP-Philippine Social Science Council (IFP-PSCC) for pro-

viding the financial support, and the Philippine Center for Posthar-

vest Development and Mechanization (PhilMech) for granting

study leave to Ofero Caparino. Special thanks to Richard E. Magoon

and Karin M. Bolland of MCD Technologies, Inc (Tacoma, WA) for

allowing the use of their RW drying facilities, and for their assis-

tance in doing the experiments; Eng. Frank Younce and Ms. Galina

Mikhaylenko for assisting with the drying and physical analysis

experiments, respectively, Roopesh Syamaladevi for assisting in

X-ray diffraction, and Dr. Valerie Lynch-Holm for helping with

the SEM and FESEM imaging.

References

Abonyi, B.I., Feng, B.I., Edwards, C.G., Tang, J., 2002. Quality retention in strawberry

and carrot purees dried with Refractance Window system. Journal of Food

Science 67, 1051–1056.

Adhikari, B., Howes, T., Bhandari, B., Langrish, T.G., 2009a. Effect of addition of

proteins on the production of amorphous sucrose powder through spray drying.

Journal of Food Engineering 94 (2), 144–153.

Adhikari, B., Howes, T., Wood, B.J., Bhandari, B.R., 2009b. The effect of low molecular

weight surfactants and proteins on surface stickiness of sucrose during powder

formation through spray drying. Journal of Food Engineering 94, 135–143.

Ahmed, M., Akter, M.S., Eun, J.-B., 2010. Impact of alpha-amylase and maltodextrin

on physicochemical, functional and antioxidant capacity of spray-dried purple

sweet potato flour. Journal of Food Agriculture 90, 494–502.

Ameny, M.A., Wilson, P.W., 1997. Relationship between hunter color values and b-

carotene contents in white-fleshed African sweet potatoes (Ipomoea batatas

Lam). Journal of the Science of Food and Agriculture 73, 301–306.

Anastasiades, A., Thanou, S., Loulis, D., Stapatoris, A., Karapantsios, T.D., 2002.

Rheological and physical characterization of pregelatinized maize starches.

Journal of Food Engineering 52, 57–66.

AOAC, 1998. Official Methods of Analysis. Association of Official Analytical

Chemists, Washington, DC, USA.

Barbosa-Cánovas, G.V., 1996. Dehydration of Foods. Chapman and Hall, New York.

Barbosa-Canovas, G.V., Ortega-Rivas, E., Juliano, P., Yan, H., 2005. Food Powders:

Physical Properties, Processing, and Functionality. Kluwer Academic/Plenum

Publishers, New York.

BAS, 2009. Situation Report on Selected Fruit Crops. Retrieved March 1, 2011, from

<http://www.bas.gov.ph>.

Bhandari, B.R., Datta, N., Howes, T., 1997a. Problems associated with spray drying of

sugar-rich foods. Drying Technology 15 (2), 671–684.

Bhandari, B.R., Datta, N., Crooks, R., Howes, T., Rigby, S., 1997b. A semi-empirical

approach to optimize the quantity of drying aids required to spray dry sugar-

rich foods. Drying Technology 15 (10), 2509–2525.

Cai, Y.Z., Corke, H., 2000. Production and properties of spray-dried amaranthus

betacyanin pigments. Journal of Food Science 65 (6), 1248–1252.

Cano-Chauca, M., Stringheta, P.C., Ramos, A.M., Cal-Vidal, C., 2005. Effect of the

carriers on the microstructure of mango powder obtained by spray drying and

its functional characterization. Innovative Food Science and Emerging

Technologies 6, 420–428.

Caparino, O.A., 2000. Characteristics and quality of freeze-dried mango powder pre-

frozen at different temperatures. Philippine Agricultural Scientist Journal 83 (4),

338–343.

Caric, M., Kalab, M., 1987. Effects of drying techniques on milk powder quality and

microstructure: a review. Food Microstructure 6, 171–180.

Chen, X.D., Patel, K.C., 2008. Manufacturing better quality food powders from spray

drying and subsequent treatments. Drying Technology 26, 1313–1318.

Desai, K.G., Park, H.J., 2004. Solubility studies of valdecoxib in the presence of

carriers, co-solvent and surfactants. Drug Development Research 62, 41–48.

Desobry, S.A., Netto, F.M., Labuza, T.P., 1997. Comparison of spray-drying, drum-

drying and freeze-drying for b-carotene encapsulation and preservation. Journal

of Food Science 62 (6), 1158–1162.

Duffie, J., Marshall, W., 1953. Factors influencing the properties of spray-dried

materials. Chemical Engineering and Processing 49, 417–423.

Dziezak, 1988. Microencapsulation and encapsulated ingredients. Food Technology

42, 136–148.

Eastman, J.E., Moore, C.O., 1984. Cold Water Soluble Granular Starch for Gelled Food

Composition. U.S. Patent 4465702.

Evans, E.A., 2008. Recent Trends in World and US Mango Production Trade, and

Consumption. University of Florida. Food and Resource Economics Department,

Gainesville, Florida.

FAO, 2007. FAOSTAT Database Collections, Agricultural Data, Food and Agriculture

Organization of the United Nations. Retrieved 10.03.11, from <http://

www.faostat.org>.

Figiel, A., 2010. Drying kinetics and quality of beetroots dehydrated by combination

of convective and vacuum-microwave methods. Journal of Food Engineering 98,

461–470.

Filkova, I., Mujumdar, A.S., 1995. Industrial spray drying systems. In: Mujumdar,

A.S. (Ed.), Handbook of Industrial Drying. Marcel Dekker, New York, pp. 263–

307.

Gavrielidou, M.A., Vallous, N.A., Karapantsios, T.D., Raphaelides, S.N., 2002. Heat

transport to a starch slurry gelatinizing between the drums of a double drum

dryer. Journal of Food Engineering 54, 45–58.

Gonzalez-Aguilar, G.A., Zavaleta-Gatica, R., Tiznado-Hernandez, M., 2007.

Improving postharvest quality of mango ‘Haden’ by UV-C treatment.

Postharvest Biology and Technology 45, 108–116.

Goula, A.M., Adamopoulus, K.G., 2008. Effect of maltodextrin addition during spray

drying of tomato pulp in dehumidified air: II. Powder properties. Drying Journal

26, 726–737.

Haque, M., Roos, Y., 2005. Crystallization and X-ray diffraction of spray-dried and

freeze-dried amorphous lactose. Carbohydrate Research 340, 293–301.

Harnkarnsujarit, N., Charoenrein, S., 2011. Effect of water activity on sugar

crystallization and beta-carotene stability of freeze-dried mango powder.

Journal of Food Engineering 105, 592–598.

Hsu, C.L., Chen, W., Weng, Y.M., Tseng, C.Y., 2003. Chemical composition, physical

properties, and antioxidant activities of yam flours as affected by different

drying methods. Food Chemistry 83, 85–92.

Jakubczyk, E., Ostrowska-Ligeza, E., Gonde, E., 2010. Moisture sorption

characteristics and glass transition temperature apple puree powder.

International Journal of Food Science and Technology 45, 2515–2523.

Jaya, S., Das, H., 2004. Effect of maltodextrin, glycerol monostearate and tricalcium

phosphate on vacuum dried mango powder properties. Journal of Food

Engineering 63, 125–134.

Jaya, S., Das, H., Mani, S., 2006. Optimization of maltodextrin and tricalcium

phosphate for producing vacuum dried mango powder. International Journal of

Food Properties 9, 13–24.

Jayasundera, M., Adhikari, B., Adhikari, R., Aldred, P., 2011a. The effect of protein

types and low molecular weight surfactants on spray drying of sugar-rich foods.

Food Hydrocolloids 25 (3), 459–469.

Jayasundera, M., Adhikari, B., Adhikari, R., Aldred, P., 2011b. The effects of proteins

and low molecular weight surfactants on spray drying of model sugar-rich

foods: powder production and characterisation. Journal of Food Engineering