Standards Research and Development Branch

Motor Vehicle Safety Directorate

TRANSPORT CANADA

Ottawa, Ontario

K1A 0N5

TECHNICAL STANDARDS DOCUMENT

No. 108, Revision 7

Lamps, Reective Devices, and

Associated Equipment

The text of this document is based on Federal Motor Vehicle Safety Standard No.

108,

Lamps, Reective Devices, and Associated Equipment, as published in the U.S. Code of

Federal Regulations, Title

49, Chapter V, Part

571, as it read on February 8, 2016.

Publication Date:

Effective Date:

Mandatory Compliance Date:

February

04, 2021

February

04, 2021

February 04, 2021

i

Effective:

February 04, 2021

Technical Standards Document

Number 108, Revision 7

Lamps, Reective Devices, and

Associated Equipment

(Ce document est aussi disponible en français.)

Introduction

As dened by section 12 of the

Motor Vehicle Safety Act, a Technical Standards Document

(TSD) is a document that reproduces an enactment of a foreign government (e.g. a Federal

Motor Vehicle Safety Standard issued by the U.S. National Highway Trafc Safety

Administration). According to the Act, the

Motor Vehicle Safety Regulations

may alter or

override some provisions contained in a TSD or specify additional requirements; consequently,

it is advisable to read a TSD in conjunction with the Act and its counterpart Regulation. As a

guide, where the corresponding Regulation contains additional requirements, footnotes indicate

the amending subsection number.

TSDs are revised from time to time in order to incorporate amendments made to the reference

document, at which time a Notice of Revision is published in the

Canada Gazette

Part

I. All

TSDs are assigned a revision number, with “Revision

0” designating the original version.

Identication of Changes

In order to facilitate the incorporation of a TSD, certain non-technical changes may be made to

the foreign enactment. These may include the deletion of words, phrases, gures, or sections

that do not apply under the Act or Regulations, the conversion of imperial to metric units,

the deletion of superseded dates, and minor changes of an editorial nature. Additions are

underlined, and provisions that do not apply are

stroked through. Where an entire section has

been deleted, it is replaced by: “[CONTENT NOT REPRODUCED]”. Changes are also made

where there is a reporting requirement or reference in the foreign enactment that does not apply

in Canada. For example, the name and address of the U.S. Department of Transportation are

replaced by those of the Department of Transport.

Effective Dates

The effective date of a TSD is the date of publication of its incorporating regulation or of

the notice of revision in the Canada Gazette, and the date as of which voluntary compliance

is permitted. The mandatory compliance date is the date upon which compliance with the

requirements of the TSD is obligatory. If the effective date and mandatory compliance date are

different, manufacturers may follow the requirements that were in force before the effective

date, or those of this TSD, until the mandatory compliance date.

Lamps, Reective Devices, and Associated Equipment

ii

In the case of an initial TSD, or when a TSD is revised and incorporated by reference by

an amendment to the Regulations, the mandatory compliance date is as specied in the

Regulations, and it may be the same as the effective date. When a TSD is revised with no

corresponding changes to the incorporating Regulations, the mandatory compliance date is six

months after the effective date.

Ofcial Version of Technical Standards Documents

Technical Standards Documents may be consulted electronically in both HTML and Portable

Document Format (PDF) on the Department of Transport’s Web site at http://www.tc.gc.ca/

eng/acts-regulations/regulations-crc-c1038.htm. The PDF version is a replica of the TSD as

published by the Department and is to be used for the purposes of legal interpretation and

application. The HTML version is provided for information purposes only.

(Original signed by)

Director, Standards Research and Development

for the Minister of Transport,

Ottawa, Ontario

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

iii

Table of Contents

Introduction .......................................................................................................................... i

Identication of Changes

..................................................................................................... i

Effective Dates ...................................................................................................................... i

Ofcial Version of Technical Standards Documents ........................................................ ii

S1 Scope. ........................................................................................................................... 1

S2 Purpose. ....................................................................................................................... 1

S3 Application.................................................................................................................... 1

S4 Denitions. ................................................................................................................... 1

S5 References to SAE publications. ................................................................................ 7

S6 Vehicle requirements. ................................................................................................ 8

S6.1 Required lamps, reective devices, and associated equipment by vehicle type. .. 8

S6.2 Impairment. ......................................................................................................... 10

S6.3 Equipment combinations. ....................................................................................11

S6.4 Lens area, visibility and school bus signal lamp aiming. ....................................11

S6.5 Marking. .............................................................................................................. 12

S6.6 Associated equipment. ......................................................................................... 14

S6.7 Replacement equipment. ...................................................................................... 14

S7 Signal lamp requirements. ....................................................................................... 14

S7.1 Turn signal lamps. ................................................................................................ 14

S7.2 Taillamps . ............................................................................................................ 19

S7.3 Stop lamps. .......................................................................................................... 20

S7.4 Side marker lamps. ............................................................................................. 22

S7.5 Clearance and identication lamps. .................................................................... 23

S7.6 Backup lamps. ..................................................................................................... 24

S7.7 License plate lamps. ............................................................................................ 24

S7.8 Parking lamps. .................................................................................................... 26

S7.9 High-mounted stop lamps. .................................................................................. 26

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

iv

S7.10 Daytime running lamps (DRLs). ....................................................................... 27

S7.11 School bus signal lamps. ................................................................................... 28

S8 Reective device requirements. .............................................................................. 29

S8.1 Reex reectors. ................................................................................................. 29

S8.2 Conspicuity systems. ........................................................................................... 30

S9 Associated equipment requirements. ..................................................................... 34

S9.1 Turn signal operating unit. .................................................................................. 34

S9.2 Turn signal asher. .............................................................................................. 34

S9.3 Turn signal pilot indicator tell-tale. .................................................................... 34

S9.4 Headlamp beam switching device. ...................................................................... 35

S9.5 Upper beam headlamp indicator tell-tale. ........................................................... 35

S9.6 Vehicular hazard warning signal operating unit. ................................................ 36

S9.7 Vehicular hazard warning signal asher. ............................................................ 36

S9.8 Vehicular hazard warning signal pilot indicator tell-tale. ................................... 36

S10 Headlighting system requirements. ...................................................................... 37

S10.1 Vehicle headlighting systems. ........................................................................... 37

S10.2 [Reserved] ....................................................................................................... 37

S10.3 Number. See Tables I-a and I-c. ........................................................................ 37

S10.4 Color of light. See Tables I-a and I-c. ................................................................ 37

S10.5 Mounting location. See Tables I-a and I-c and S6.1.3.5. ................................... 37

S10.6 Mounting height. See Tables I-a and I-c. ........................................................... 37

S10.7 Activation. See Tables I-a and I-c, Table II, and S6.1.5. ................................... 37

S10.8 Effective projected luminous lens area. No requirement. .................................. 37

S10.9 Visibility. No requirement. ................................................................................. 37

S10.10 Indicator Tell-tale. See S9.5. ............................................................................ 37

S10.11 Markings. See S6.5. ......................................................................................... 37

S10.12 Spacing to other lamps. See S6.1.3.5. .............................................................. 37

S10.13 Sealed beam headlighting systems. ................................................................ 37

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

v

S10.14 Integral beam headlighting systems. ............................................................... 38

S10.15 Replaceable bulb headlighting systems. ......................................................... 40

S10.16 Combination headlighting systems. ................................................................ 41

S10.17 Motorcycle headlighting systems. .................................................................. 42

S10.18 Headlamp aimability performance requirements (except for motorcycles) .... 44

S11 Replaceable light source requirements. ............................................................... 50

S11.1 Markings. .......................................................................................................... 50

S11.2 Ballast markings. .............................................................................................. 50

S11.3 Gas discharge laboratory life. ........................................................................... 51

S11.4 Physical tests. .................................................................................................... 51

S12 Headlamp concealment device requirements. ..................................................... 51

S13 Replaceable headlamp lens requirements. .......................................................... 52

S14 Physical and photometry test procedures and performance requirements. ..... 52

S14.1 General test procedures and performance requirements. .................................. 52

S14.2 Photometric test procedures. ............................................................................. 53

S14.3 Motorcycle headlamp out of focus test procedure and performance

requirements. .....................................................................................................59

S14.4 General test procedures and performance requirements. .................................. 60

S14.5 Signal lamp and reective device physical test procedures and performance

requirements. .....................................................................................................64

S14.6 Headlamp physical test procedures and performance requirements. ................ 65

S14.7 Replaceable light source physical test procedures and performance

requirements. ......................................................................................................76

S14.8 Vehicle headlamp aiming devices (VHAD) physical test procedures and

performance requirements. ................................................................................78

S14.9 Associated equipment physical test procedures and performance

requirements. ......................................................................................................79

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

vi

LIST OF TABLES

Table I-a—Required Lamps and Reective Devices...................................................... 92

Table I-b—Required Lamps and Reective Devices

..................................................... 99

Table I-c—Required Lamps and Reective Devices .................................................... 103

Table II-a—Headlighting Systems - Sealed Beams ...................................................... 106

Table II-b—Headlighting Systems - Combination ...................................................... 107

Table II-c—Headlighting Systems - Integral Beams ................................................... 108

Table II-d—Headlighting Systems - Replaceable Bulb ............................................... 109

Table III—Marking Requirements Location

................................................................110

Table IV-a—Effective Projected Luminous Lens Area Requirements ........................112

Table IV-b—Effective Projected Luminous Lens Area Requirements .......................113

Table IV-c—Effective Projected Luminous Lens Area Requirements

........................113

Table V-a—Visibility Requirements of Installed Lighting Devices .............................113

Table V-b—Visibility Requirements of Installed Lighting Devices - Lens Area

Visibility Option

...............................................................................................................114

Table V-c—Visibility Requirements of Installed Lighting Devices - Luminous

Intensity Visibility Option ...............................................................................................115

Table V-d—Visibility Requirements of Installed Lighting Devices

(Legacy Visibility Alternative)

........................................................................................116

Table VI-a—Front Turn Signal Lamp Photometry Requirements .............................117

Table VI-b—Front Turn Signal Lamp Photometry Requirements

.............................118

Table VII—Rear Turn Signal Lamp Photometry Requirements ................................119

Table VIII—Taillamp Photometry Requirements ....................................................... 120

Table IX—Stop Lamp Photometry Requirements....................................................... 121

Table X—Side Marker Lamp Photometry Requirements

.......................................... 122

Table XI—Clearance and Identication Lamps Photometry Requirements ............ 123

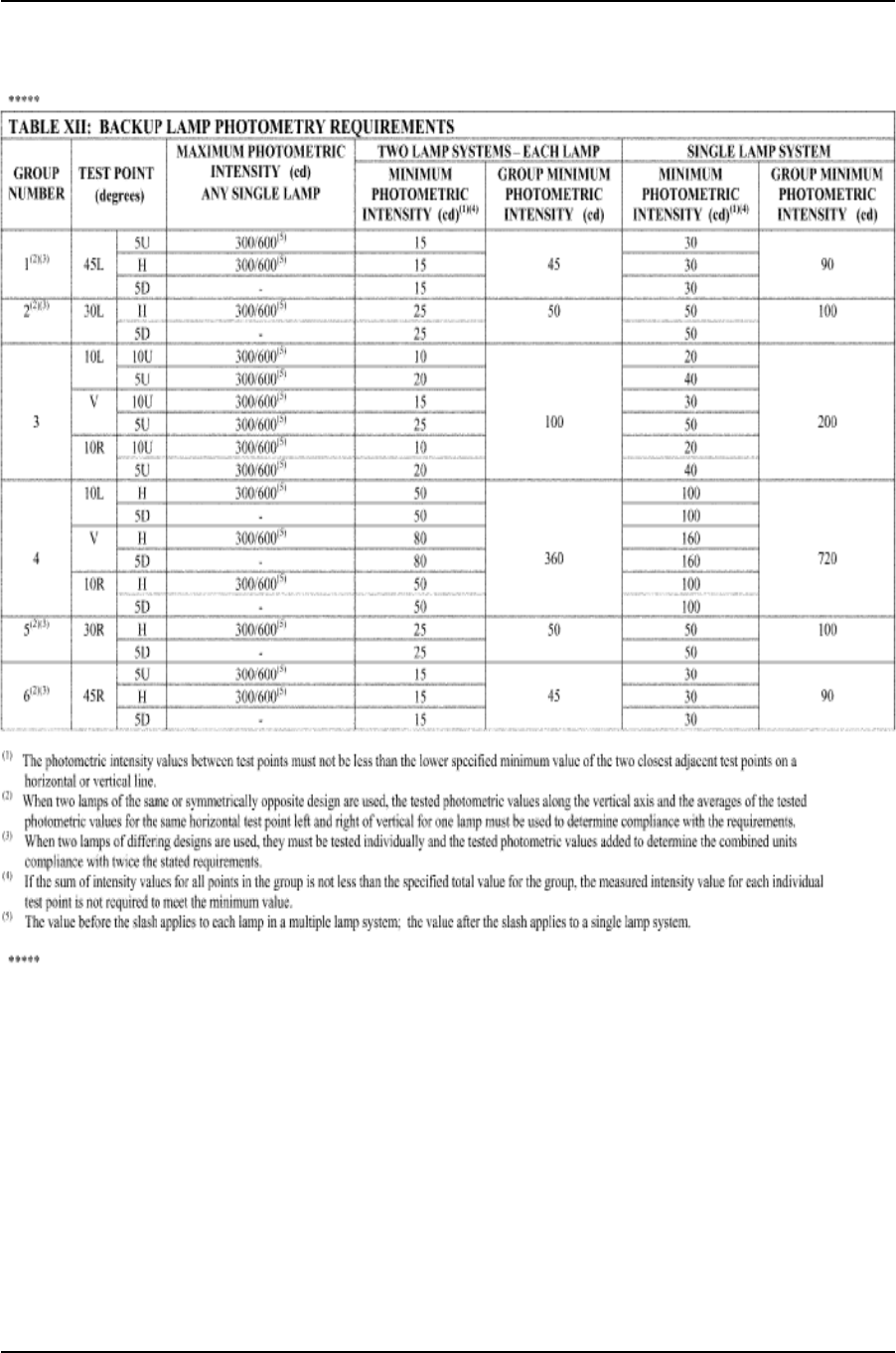

Table XII—Backup Lamp Photometry Requirements

................................................ 124

Table XIII-a—Motorcycle Turn Signal Lamp Alternative Photometry

Requirements

................................................................................................................... 125

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

vii

Table XIII-b—Motor Driven Cycle Limited Speed Motorcycle Stop Lamp

Alternative Photometry Requirements ......................................................................... 126

Table XIV—Parking Lamp Photometry Requirements .............................................. 127

Table XV—High Mounted Stop Lamp Photometry Requirements

........................... 128

Table XVI-a—Reex Reector Photometry Requirements ........................................ 129

Table XVI-b—Additional Photometry Requirements for Conspicuity

Reex Reectors

............................................................................................................. 129

Table XVI-c—Retroreective Sheeting Photometry Requirements ........................... 130

Table XVII—School Bus Signal Lamp Photometry Requirements ........................... 131

Table XVIII—Headlamp Upper Beam Photometry Requirements

........................... 132

Table XIX-a—Headlamp Lower Beam Photometry Requirements ........................... 133

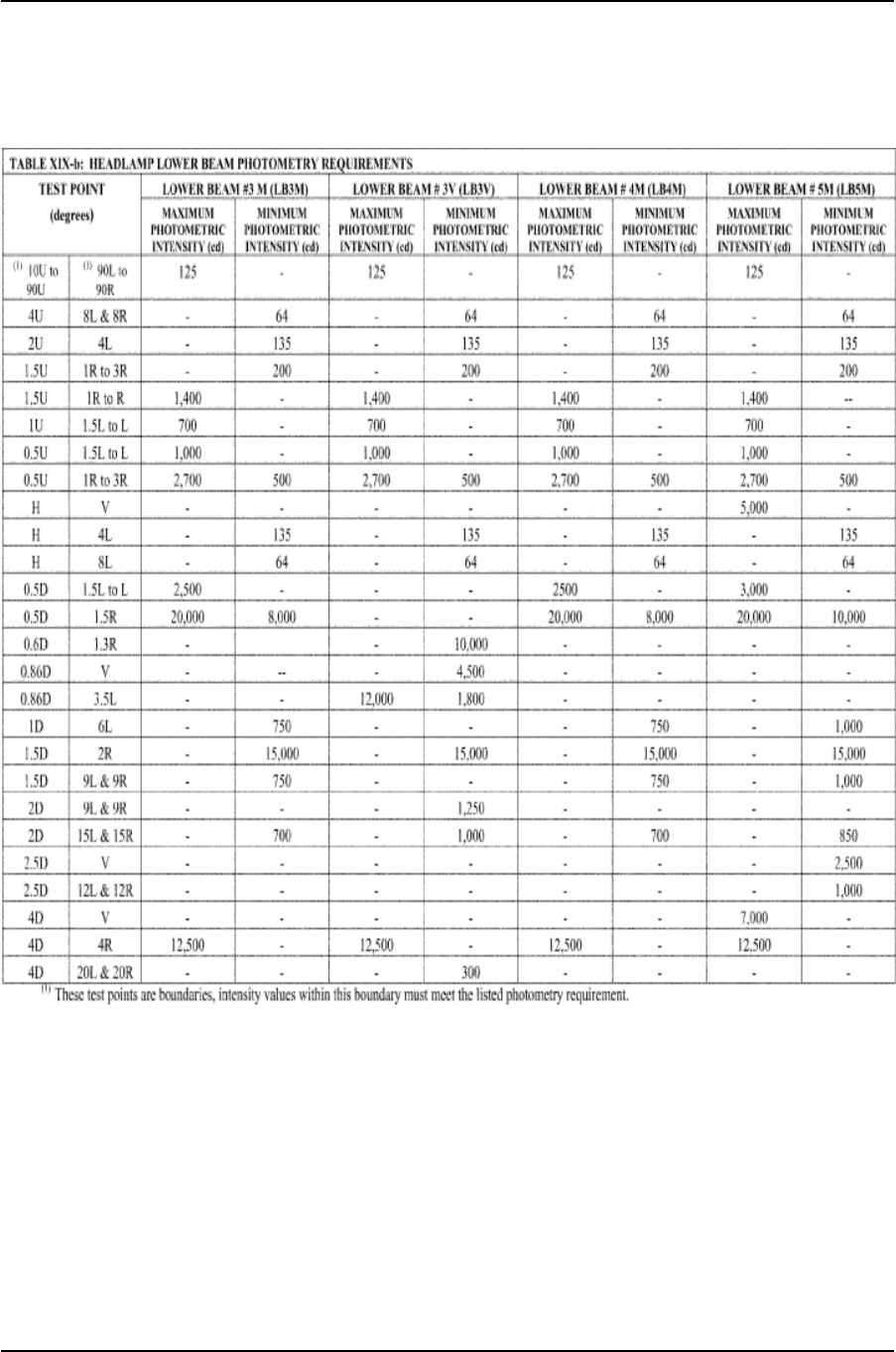

Table XIX-b—Headlamp Lower Beam Photometry Requirements........................... 134

Table XIX-c—Headlamp Lower Beam Photometry Requirements

........................... 135

Table XX—Motorcycle and Motor Driven Cycle Limited Speed Motorcycle

Photometry Requirements ............................................................................................. 136

LIST OF FIGURES

Figure 1—Chromaticity Diagram ................................................................................. 137

Figure 2—Flasher Performance Chart ......................................................................... 138

Figure 3—Replaceable Bulb Headlamp Aim Pads ...................................................... 139

Figure 4—Headlamp Connector Test Setup

................................................................. 140

Figure 5—Headlamp Abrasion Test Fixture ................................................................ 141

Figure 6—Thermal Cycle Prole ................................................................................... 142

Figure 7—Dirt / Ambient Test Setup

............................................................................. 143

Figure 8—Replaceable Light Source Deection Test Setup ........................................ 144

Figure 9—Environmental Test Prole .......................................................................... 145

Figure 10—Replaceable Light Source Pressure Test Setup

........................................ 146

Figure 11—Trailer Conspicuity Treatment Examples ................................................. 147

Figure 12-1—Trailer Conspicuity Detail I

.................................................................... 148

Figure 12-2—Trailer Conspicuity Detail II

.................................................................. 149

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

viii

Figure 13—Tractor Conspicuity Treatment Examples ............................................... 150

Figure 14 — Type F: Headlamp Aim Deection Test Setup........................................ 151

Figure 15 — Types G and H: Headlamp Aim Deection Test Setup .......................... 151

Figure 16 — Types A and E: Headlamp Aim Deection Test Setup

........................... 151

Figure 17 — Type B: Headlamp Aim Deection Test Setup ....................................... 151

Figure 18 — Types C and D: Headlamp Aim Deection Test Setup .......................... 151

Figure 19—License Plate Lamp Target Locations

....................................................... 152

Figure 20—License Plate Lamp Measurement of Incident Light Angle ................... 153

Figure 21—Vibration Test Machine .............................................................................. 154

Figure 22—Flasher Standard Test Circuit

................................................................... 155

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

1

1 For applicability, see Schedule III and section 108 of Schedule IV of the Motor Vehicle Safety Regulations

(MVSR).

Effective:

February 04, 2021

TSD No. 108, Revision 7

Technical Standards Document

Number 108, Revision 7

Lamps, Reflective Devices, and

Associated Equipment

S1

Scope.

This

Technical Standards Document (TSD)

standard

species requirements for original

and

replacement

lamps, reective devices, and associated equipment.

S2

Purpose.

The purpose of this

TSD

standard

is to reduce trafc accidents and deaths and injuries resulting

from trafc accidents, by providing adequate illumination of the roadway, and by enhancing the

conspicuity of motor vehicles on the public roads so that their

presence is perceived and their

signals understood, both in daylight and in darkness or other conditions of reduced visibility.

S3

Application.

1

[CONTENT NOT REPRODUCED]

S4

Denitions.

Aiming plane

means a plane dened by the surface of the three aiming pads on the lens.

(plan

d’orientation)

Aiming reference plane

means a plane which is perpendicular to the longitudinal axis

of the

vehicle and tangent to the forwardmost aiming pad on the headlamp.

(plan d’orientation repère)

Aiming screws

are the horizontal and vertical adjusting screws with self-locking features used to

aim and retain a headlamp unit in the proper position.

(vis d’orientation)

Lamps, Reective Devices, and Associated Equipment

2

Axis of reference means the characteristic axis of the lamp for use as the direction of reference

(H = 0°, V = 0°) for angles of eld for photometric measurements and for installing the lamp on

the vehicle.

(axe de référence)

Backup lamp means a lamp or lamps which illuminate the road to the rear of a vehicle and

provide a warning signal to pedestrians and other drivers when the vehicle is backing up or is

about to back up. (feu de recul)

Beam contributor means an indivisible optical assembly including a lens, reector, and light

source, that is part of an integral beam headlighting system and contributes only a portion of a

headlamp beam. (projecteur contribuant)

Cargo lamp is a lamp that is mounted on a multipurpose passenger vehicle, truck, or bus

for the purpose of providing illumination to load or unload cargo. (dispositif d’éclairage du

compartiment de charge)

Clearance lamps are lamps which show to the front or rear of the vehicle, mounted on the

permanent structure of the vehicle as near as practicable to the upper left and right extreme

edges to indicate the overall width and height of the vehicle. (feux de gabarit)

Coated materials means a material which has a coating applied to the surface of the nished

sample to impart some protective properties. Coating identication means a mark of the

manufacturer’s name, formulation designation number, and recommendations for application.

(matériaux enrobés)

Color Fundamental denitions of color are expressed by Chromaticity Coordinates according

to the CIE 1931 Standard Colorimetric System, as described in the CIE 1931 Chromaticity

Diagram (

incorporated by reference, see § 571.5). (couleur)

Color bleeding means the migration of color out of a plastic part onto the surrounding surface.

(saignement)

Combination clearance and side marker lamps are single lamps which simultaneously fulll the

requirements of clearance and side marker lamps. (combinaison feu de gabarit et feu de position)

Combination headlamp means a headlamp that is a combination of two different headlamp

types chosen from a type F sealed beam headlamp, an integral beam headlamp, or a replaceable

bulb headlamp. (combinaison de projecteurs)

Cracking means a separation of adjacent sections of a plastic material with penetration into the

specimen. (craquelage)

Crazing means a network of apparent ne cracks on or beneath the surface of materials.

(ssuration)

Cutoff means a generally horizontal, visual/optical aiming cue in the lower beam that marks a

separation between areas of higher and lower luminance. (coupure)

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

3

2

Daytime running lamps (DRLs) are steady burning lamps that are used to improve the

conspicuity of a vehicle from the front and front sides when the regular headlamps are not

required for driving. (Feux de jour (FDJ))

Delamination means a separation of the layers of a material including coatings. (délamination)

Design voltage means the voltage used for design purposes. (tension de calcul)

Direct reading indicator means a device that is mounted in its entirety on a headlamp or

headlamp aiming or headlamp mounting equipment, is part of a VHAD, and provides

information about headlamp aim in an analog or digital format. (indicateur à lecture directe)

Effective light-emitting surface means that portion of a lamp that directs light to the

photometric test pattern, and does not include transparent lenses, mounting hole bosses,

reex reector area, beads or rims that may glow or produce small areas of increased

intensity as a result of uncontrolled light from an area of

1

⁄

2

° radius around a test point.

(surface de sortie efcace de la lumière)

Effective projected luminous lens area means the area of the orthogonal projection of the

effective light-emitting surface of a lamp on a plane perpendicular to a dened direction relative

to the axis of reference. Unless otherwise specied, the direction is coincident with the axis of

reference. (surface lumineuse efcace projetée d’une lentille)

Exposed means material used in lenses or optical devices exposed to direct sunlight as installed

on the vehicle. (exposé)

Filament means that part of the light source or light emitting element(s), such as a resistive

element, the excited portion of a specic mixture of gases under pressure, or any part of other

energy conversion sources, that generates radiant energy which can be seen. (lament)

2

Flash means a cycle of activation and deactivation of a lamp by automatic means continuing

until stopped either automatically or manually. (clignotement)

Fully opened means the position of the headlamp concealment device in which the headlamp is

in the design open operating position. (entièrement ouvert)

H-V axis means the line from the center of the principal lament of a lamp to the intersection of

the horizontal (H) and vertical (V) lines of a photometric test screen. (axe H-V)

Haze means the cloudy or turbid appearance of an otherwise transparent specimen caused by

light scattered from within the specimen or from its surface. (obscurcissement)

2

Headlamp means a lighting device providing an upper and/or a lower beam used for providing

illumination forward of the vehicle. (projecteur)

Headlamp concealment device means a device, with its operating system and components, that

provides concealment of the headlamp when it is not in use, including a movable headlamp

2 See the Motor Vehicle Safety Regulations (MVSR), subsection 2(1), for the applicable denition

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

4

cover and a headlamp that displaces for concealment purposes. (dispositif de dissimulation de

projecteur)

Headlamp mechanical axis means the line formed by the intersection of a horizontal and a

vertical plane through the light source parallel to the longitudinal axis of the vehicle. If the

mechanical axis of the headlamp is not at the geometric center of the lens, then the location will

be indicated by the manufacturer on the headlamp. (axe mécanique du projecteur)

Headlamp test xture means a device designed to support a headlamp or headlamp assembly in

the test position specied in the laboratory tests and whose mounting hardware and components

are those necessary to operate the headlamp as installed in a motor vehicle. (appareil d’essai de

projecteur)

High-mounted stop lamp means a lamp mounted high and possibly forward of the tail, stop, and

rear turn signal lamps intended to give a steady stop warning through intervening vehicles to

operators of following vehicles. (feu de freinage surélevé)

Identification lamps are lamps used in groups of three, in a horizontal row, which show to the

front or rear or both, having lamp centers spaced not less than [6 in] 152 mm nor more than

[12 in] 304 mm apart, mounted on the permanent structure as near as practicable to the vertical

centerline and the top of the vehicle to identify certain types of vehicles. (feux d’identication)

Integral beam headlamp means a headlamp (other than a standardized sealed beam headlamp

designed to conform to paragraph S10.13 or a replaceable bulb headlamp designed to conform

to paragraph S10.15) comprising an integral and indivisible optical assembly including lens,

reector, and light source, except that a headlamp conforming to paragraph S10.18.8 or

paragraph S10.18.9 may have a lens designed to be replaceable. (projecteur à faisceau intégré)

License plate lamp means a lamp used to illuminate the license plate on the rear of a vehicle.

(lampe de plaque d’immatriculation)

2

Lower beam means a beam intended to illuminate the road and its environs ahead of the

vehicle when meeting or closely following another vehicle. (faisceau-de croisement)

Material means the type and grade of plastics, composition, and manufacturer’s designation

number and color. (matériau)

Mechanically aimable headlamp means a headlamp having three pads on the lens, forming an

aiming plane used for laboratory photometric testing and for adjusting and inspecting the aim of

the headlamp when installed on the vehicle. (projecteur orientable de façon mécanique)

3

Motor driven cycle means every motorcycle, including every motor scooter, with a motor

which produces not more than 5 horsepower, and every bicycle with motor attached.

(cyclomoteur)

3 See the Motor Vehicle Safety Regulations (MVSR), subsection 2(1), for the applicable definition of limited-

speed motorcycle.

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

5

Motorcycle or motor driven cycle limited speed motorcycle headlamp means a major lighting

device used to produce general illumination ahead of the vehicle. (projecteur de motocyclette

ou de cyclomoteur motocyclette à vitesse limitée)

Mounting ring means the adjustable ring upon which a sealed beam unit is mounted. (anneau

de montage)

Mounting ring (type F sealed beam) means the adjustable ring upon which a sealed beam unit is

mounted and which forces the sealed beam unit to seat against the aiming ring when assembled

into a sealed beam assembly. (anneau de retenue (projecteur scellé de type F))

Multiple compartment lamp means a device which gives its indication by two or more

separately lighted areas which are joined by one or more common parts, such as a housing or

lens. (feu à compartiments multiples)

Multiple lamp arrangement means an array of two or more separate lamps on each side of the

vehicle which operate together to give a signal. (arrangement à feux multiples)

Optically combined means a lamp having a single or two lament light source or two or more

separate light sources that operate in different ways, and has its optically functional lens area

wholly or partially common to two or more lamp functions. (combiné optiquement)

Overall width means the nominal design dimension of the widest part of the vehicle, exclusive

of signal lamps, marker lamps, outside rearview mirrors, exible fender extensions, mud aps,

and outside door handles determined with doors and windows closed, and the wheels in the

straight-ahead position. Running boards may also be excluded from the determination of overall

width if they do not extend beyond the width as determined by the other items excluded by this

denition. (largeur hors tout)

Parking lamps are lamps on both the left and right of the vehicle which show to the front and

are intended to mark the vehicle when parked or serve as a reserve front position indicating

system in the event of headlamp failure. (feux de stationnement)

Protected means material used in inner lenses for optical devices where such lenses are

protected from exposure to the sun by an outer lens made of materials meeting the requirements

for exposed plastics. (Protégé)

Rated voltage means the nominal circuit or vehicle electrical system voltage classication.

(tension nominale)

2

Reex reectors are devices used on vehicles to give an indication to approaching drivers

using reected light from the lamps of the approaching vehicle. (cataphotes)

Remote reading indicator means a device that is not mounted in its entirety on a headlamp or

headlamp aiming or headlamp mounting equipment, but otherwise meets the denition of a

direct reading indicator. (téléindicateur)

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

6

Replaceable bulb headlamp means a headlamp comprising a bonded lens and reector

assembly and one or two replaceable light sources, except that a headlamp conforming to

paragraph S10.18.8 or paragraph S10.18.9 may have a lens designed to be replaceable.

(projecteur à ampoule remplaçable)

Replaceable light source means an assembly of a capsule, base, and terminals that is designed

to conform to the requirements of appendix A or appendix B

of

49 part 564 Replaceable Light

Source Information of this Chapter V of title 49 of the U.S. Code of Federal Regulations (CFR)

(hereinafter referred to as part 564). (source lumineuse remplaçable)

Retaining ring means the clamping ring that holds a sealed beam unit against a mounting ring.

(anneau de retenue)

Retaining ring (type F sealed beam) means the clamping ring that holds a sealed beam unit

against a mounting ring, and that provides an interface between the unit’s aiming/seating pads

and the headlamp aimer adapter (locating plate). (anneau de retenue (projecteur scellé de

type F))

School bus signal lamps are alternately ashing lamps mounted horizontally both front and rear,

intended to identify a vehicle as a school bus and to inform other users of the highway that such

vehicle is stopped on the highway to take on or discharge school children. (feux de signalisation

d’autobus scolaire)

Sealed beam headlamp means an integral and indivisible optical assembly including the light

source with “SEALED BEAM” molded in the lens. (projecteur scellé)

Sealed beam headlamp assembly means a major lighting assembly which includes one or

more sealed beam units used to provide general illumination ahead of the vehicle. (montage de

projecteur scellé)

Seasoning means the process of energizing the lament of a headlamp at design voltage for a

period of time equal to 1% of design life, or other equivalent method. (vieillissement)

Semiautomatic headlamp beam switching device is one which provides either automatic or

manual control of beam switching at the option of the driver. When the control is automatic the

headlamps switch from the upper beam to the lower beam when illuminated by the headlamps

on an approaching vehicle and switch back to the upper beam when the road ahead is dark.

When the control is manual, the driver may obtain either beam manually regardless of the

conditions ahead of the vehicle. (dispositif de commutation de faisceau de projecteur semi-

automatique)

Side marker lamps are lamps which show to the side of the vehicle, mounted on the permanent

structure of the vehicle as near as practicable to the front and rear edges to indicate the overall

length of the vehicle. Additional lamps may also be mounted at intermediate locations on the

sides of the vehicle. (feux de position latéraux)

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

7

Stop lamps are lamps giving a steady light to the rear of a vehicle to indicate a vehicle is

stopping or diminishing speed by braking. (feux de freinage)

Taillamps are steady burning low intensity lamps used to designate the rear of a vehicle. (feux

arrière)

Test voltage means the specied voltage and tolerance to be used when conducting a test.

(tension d’essai)

Turn signal lamps are the signaling element of a turn signal system which indicates the

intention to turn or change direction by giving a ashing light on the side toward which the turn

will be made. (feux de changement de direction)

Turn signal asher means a device which causes a turn signal lamp to ash as long as it is

turned on. (clignotant des feux de changement de direction)

Turn signal operating unit means an operating unit that is part of a turn signal system by which

the operator of a vehicle causes the signal units to function. (dispositif activant les feux de

changement de direction)

2

Upper beam means a beam intended primarily for distance illumination and for use when not

meeting or closely following other vehicles. (faisceau-de route)

Vehicle headlamp aiming device or VHAD means motor vehicle equipment, installed either on

a vehicle or headlamp, which is used for determining the horizontal or vertical aim, or both the

vertical and horizontal aim of the headlamp. (dispositif d’orientation intégré du véhicule ou

DOIV)

Vehicular hazard warning signal asher means a device which, as long as it is turned on, causes

all the required turn signal lamps to ash. (clignotant des signaux de détresse du véhicule)

Vehicular hazard warning signal operating unit means a driver controlled device which causes

all required turn signal lamps to ash simultaneously to indicate to approaching drivers the

presence of a vehicular hazard. (dispositif activant les signaux de détresse du véhicule)

Visually/optically aimable headlamp means a headlamp which is designed to be visually/

optically aimable in accordance with the requirements of paragraph S10.18.9 of this TSD

standard. (projecteur orientable visuellement/optiquement)

S5 References to SAE publications.

Each required lamp, reective device, and item of associated equipment must be designed to

conform to the requirements of applicable SAE publications as referenced and subreferenced

in this TSD standard. The words “it is recommended that,” “recommendations,” or “should be”

appearing in any SAE publication referenced or subreferenced in this TSD standard must be

read as setting forth mandatory requirements.

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

8

S6 Vehicle requirements.

S6.1 Required lamps, reective devices, and associated

equipment by vehicle type.

S6.1.1 Quantity. Except as provided in succeeding paragraphs of this S6.1.1 each vehicle

must be equipped with at least the number of lamps, reective devices, and items of associated

equipment specied for that vehicle type and size in Table I and Section 6.6, designed to

conform to the requirements of this TSD standard. Multiple license plate lamps and backup

lamps may be used to fulll photometric requirements for those functions.

S6.1.1.1 Conspicuity systems. Each trailer of 2032 mm or more in overall width, and with

a GVWR over 4,536 kg (10,000 lb.), except a trailer designed exclusively for living or ofce

use, and each truck tractor must be equipped with retroreective sheeting, reex reectors, or a

combination of retroreective sheeting and reex reectors as specied in S8.2.

S6.1.1.2 High-mounted stop lamps. Each multipurpose passenger vehicle, truck, and bus

required by this TSD standard to be equipped with a high-mounted stop lamp, whose vertical

centerline, when the vehicle is viewed from the rear, is not located on a xed body panel but

separates one or two moveable body sections, such as doors, which lacks sufcient space to

install a single high-mounted stop lamp on the centerline above such body sections, must have

two high-mounted stop lamps identical in size and shape.

S6.1.1.2.1 The two lamps must be located at the same height, with one vertical edge of each

lamp on the vertical edge of the body section nearest the vehicle centerline.

S6.1.1.3 Truck tractor rear turn signal lamps. A truck tractor need not be equipped with turn

signal lamps mounted on the rear if the turn signal lamps installed at or near the front are of

double face construction and are located such that they meet the photometric requirements for

double faced turn signal lamps specied in Footnote 6 of Table VII.

S6.1.1.3.1 The ashing signal from a double faced signal lamp must not be obliterated when

subjected to external light rays from either in front or behind, at any and all angles.

S6.1.1.4

4

Daytime running lamps. Any pair of lamps on the front of a passenger car,

multipurpose passenger vehicle, truck, or bus, whether or not required by this TSD standard,

other than parking lamps or fog lamps, may be wired to be automatically activated, as

determined by the manufacturer of the vehicle, in a steady burning state as daytime running

lamps (DRLs) in accordance with S7.10.5.

S6.1.2 Color. The color in all lamps and reective devices to which this TSD standard applies

must be as specied in Table I. The color identied as amber is identical to the color identied

as yellow.

4 See Schedule IV of the MVSR, subsections 108(25) to 108(30) for daytime running lamps requirements.

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

9

S6.1.3 Mounting location.

S6.1.3.1 Each lamp, reective device, and item of associated equipment must be securely

mounted on a rigid part of the vehicle, other than glazing, that is not designed to be removed

except for repair, within the mounting location and height limits as specied in Table I, and in

a location where it complies with all applicable photometric requirements, effective projected

luminous lens area requirements, and visibility requirements with all obstructions considered.

S6.1.3.2 When multiple lamp arrangements for rear turn signal lamps, stop lamps, or taillamps

are used, with only a portion of the lamps installed on a xed part of the vehicle, the lamp or

lamps that are installed to the non-xed part of the vehicle will be considered auxiliary lamps.

S6.1.3.3 License plate lamp. The license plate lamp or lamps installed on vehicles other

than motorcycles and motor driven cycles limited speed motorcycles must be mounted so

as to illuminate the license plate without obstruction from any designed feature unless the

lamp or lamps is (are) designed to comply with all the photometric requirements with these

obstructions considered.

S6.1.3.4 High-mounted stop lamps.

S6.1.3.4.1 Interior mounting. A high-mounted stop lamp mounted inside the vehicle

must have means provided to minimize reections from the light of the lamp upon the rear

window glazing that might be visible to the driver when viewed directly, or indirectly in

the rearview mirror.

S6.1.3.4.2 Accessibility. Each high-mounted stop lamp must provide access for convenient

replacement of bulbs without special tools.

S6.1.3.5 Headlamp beam mounting.

S6.1.3.5.1

5

Vertical headlamp arrangement.

S6.1.3.5.1.1 Where multiple headlamps with single light sources are installed in a vertical

orientation the lower beam must be provided by the uppermost headlamp.

S6.1.3.5.1.2 Where headlamps with two vertically oriented light sources are installed the

lower beam must be provided by the uppermost light source or by all light sources.

S6.1.3.5.2 Horizontal headlamp arrangement.

S6.1.3.5.2.1 Where multiple headlamps with single light sources are installed in a horizontal

orientation the lower beam must be provided by the most outboard headlamp.

S6.1.3.5.2.2 Where headlamps with two horizontally oriented light sources are installed the

lower beam must be provided by the outboard light source or by all light sources.

5 The requirements of S6.1.3.5.1, Vertical headlamp arrangement, do not apply with regard to headlamps

mounted on a motorcycle or motor tricycle, as specied in subparagraphs 108(10)(a) and 108(11)(a)(i) of

Schedule IV of the MVSR.

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

10

S6.1.3.6 Auxiliary lamps mounted near identication lamps. Each auxiliary lamp must be

located at least twice the distance from any required identication lamp as the distance between

two adjacent required identication lamps.

S6.1.4 Mounting height. The mounting height of each lamp and reective device must be

measured from the center of the item, as mounted on the vehicle at curb weight, to the road

surface.

S6.1.4.1 High-mounted stop lamps.

S6.1.4.1.1 A high-mounted stop lamp mounted below the rear window must have no lens

portion lower than 153 mm [6 in] below the lower edge of the rear glazing on convertibles, or

77 mm [3 in] on other passenger cars.

S6.1.5 Activation. Each lamp must be activated as specied, in the combinations specied,

and in response to the inputs specied in Table I and Table II.

S6.1.5.1 Hazard warning signal. In all passenger cars, multipurpose passenger vehicles,

trucks, and buses, the activation of the vehicular hazard warning signal operating unit must

cause to ash simultaneously sufcient turn signal lamps to meet, as a minimum, the turn signal

photometric requirements of this TSD standard.

S6.1.5.2 Simultaneous beam activation.

S6.1.5.2.1 On any vehicle to which this TSD standard applies where the headlighting system

is designed to conform to the photometric requirements of UB1 of Table XVIII and LB1M or

LB1V of Table XIX-a, the lamps marked “L” or “LF” may remain permanently activated when

the lamps marked “U” or “UF” are activated.

S6.1.5.2.2 On any vehicle to which this TSD standard applies where an integral beam

headlighting system is designed to conform to the photometric requirements of UB6 of Table

XVIII and LB5M of Table XIX-b or LB4V of Table XIX-c, the lower beam headlamps must

remain permanently activated when the upper beam headlamps are activated.

S6.1.5.2.3 On any vehicle to which this TSD section applies where the headlighting system

is designed to conform to the photometric requirements of UB2 of Table XVIII and LB2M or

LB2V of Table XIX-a, a lower beam light source may remain permanently activated when an

upper beam light source is activated if the lower beam light source contributes to the upper

beam photometric compliance of the headlighting system.

S6.2 Impairment.

S6.2.1 No additional lamp, reflective device, or other motor vehicle equipment is permitted to

be installed that impairs the effectiveness of lighting equipment required by this TSD standard.

S6.2.2 If any required lamp or reective device is obstructed by motor vehicle equipment

(e.g., mirrors, snow plows, wrecker booms, backhoes, winches, etc.) including dealer installed

equipment, and cannot meet the applicable photometry and visibility requirements, the vehicle

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

11

must be equipped with an additional lamp or device of the same type which meet all applicable

requirements of this TSD standard, including photometry and visibility.

S6.2.3 Headlamp obstructions.

S6.2.3.1 When activated in the steady burning state, headlamps (excluding headlamps

mounted on motorcycles) must not have any styling ornament or other feature, such as a

translucent cover or grill, in front of the lens

S6.2.3.2 Headlamp wipers may be used in front of the lens provided that the headlamp system

is designed to conform with all applicable photometric requirements with the wiper stopped in

any position in front of the lens.

S6.3 Equipment combinations.

Two or more lamps, reective devices, or items of associated equipment may be combined if

the requirements for each lamp, reective device, and item of associated equipment are met

with the following exceptions:

S6.3.1 No high-mounted stop lamp is permitted to be combined with any other lamp or

reective device, other than with a cargo lamp.

S6.3.2 No high-mounted stop lamp is permitted to be optically combined with any cargo lamp.

S6.3.3 No clearance lamp is permitted to be optically combined with any taillamp.

S6.4 Lens area, visibility and school bus signal lamp aiming.

S6.4.1 Effective projected luminous lens area. Each turn signal lamp, stop lamp, high-

mounted stop lamp, and school bus signal lamp must meet the applicable effective projected

luminous lens area requirement specied in Tables IV-a, IV-b, and IV-c.

S6.4.2 Visibility. Each backup lamp, single or combination of dual high-mounted stop

lamp(s), and school bus signal lamp must meet the applicable visibility requirement specied in

Table V-a.

S6.4.3 Visibility options. A manufacturer must certify compliance of each lamp function to

one of the following visibility requirement options, and it may not thereafter choose a different

option for that vehicle:

(a) Lens area option. When a vehicle is equipped with any lamp listed in Table V-b each such

lamp must provide not less than 1250 sq mm of unobstructed effective projected luminous lens

area in any direction throughout the pattern dened by the corner points specied in Table V-b

for each such lamp; or

(b) Luminous intensity option. When a vehicle is equipped with any lamp listed in Table V-c

each such lamp must provide a luminous intensity of not less than that specied in Table V-c in

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

12

any direction throughout the pattern dened by the corner points specied in Table V-c for each

such lamp when measured in accordance with the photometry test requirements of this TSD

standard.

S6.4.4 Legacy visibility alternative. As an alternative to S6.4.3, each passenger car and

motorcycle, and each multipurpose passenger vehicle, truck, trailer, and bus that is of less

than 2032 mm overall width, that is manufactured on or before September 1, 2011, and each

multipurpose passenger vehicle, truck, trailer, and bus that is of 2032 mm or more overall

width, that is manufactured on or before September 1, 2014, must have each lamp located so

that it meets the visibility requirements specied in Table V-d.

S6.4.5 School bus signal lamp aiming. Each school bus signal lamp must be mounted on

the vehicle with its aiming plane vertical and normal to the vehicle longitudinal axis. Aim

tolerance must be no more than 127 mm (5 in.) vertically and 254 mm (10 in.) horizontally at

7.6 m (25 ft.) from the lamp. If the lamps are aimed or inspected by use of SAE Recommended

Practice J602-1963 (incorporated by reference, see § 571.5), the graduation settings for aim

must be 2° D and 0° sideways for aiming and the limits must be 3° U to 7° D and from 10° R to

10° L for inspection.

S6.5 Marking.

A summary of the marking requirements of this TSD standard and their location in the

TSDstandard is contained in Table III.

S6.5.1 DOT marking. The lens of each original equipment and replacement headlamp, and

of each original equipment and replacement beam contributor, and each replacement headlamp

lens for an integral beam or replaceable bulb headlamp, must be marked with the symbol

“DOT” either horizontally or vertically to indicate certication under 49 U.S.C. 30115.

S6.5.1.1 The DOT marking requirements for conspicuity materials are specied in S8.2 of this

TSD standard.

S6.5.1.2 Each original equipment or replacement lamp or reective device specied in Table I,

except for a headlamp, or an item of associated equipment specied in S9 may be marked with

the symbol “DOT” which constitutes a certication that it conforms to the requirements of this

TSD standard.

S6.5.2 DRL marking. Each original equipment and replacement lamp used as a daytime

running lamp (DRL), unless optically combined with a headlamp, must be permanently marked

“DRL” on its lens in letters not less than 3 mm high.

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

13

S6.5.3 Headlamp markings.

S6.5.3.1 Trademark. The lens of each original and replacement equipment headlamp, and

of each original and replacement equipment beam contributor must be marked with the name

and/or trademark registered with the U.S. Patent and Trademark Ofce of the manufacturer

of such headlamp or beam contributor, of its importer, or any manufacturer of a vehicle

equipped with such headlamp or beam contributor. Nothing in this TSD standard authorizes

the marking of any such name and/or trademark by one who is not the owner, unless the

owner has consented to it.

S6.5.3.2 Voltage and trade number. Each original and replacement equipment headlamp, and

each original and replacement equipment beam contributor must be marked with its voltage and

with its part or trade number.

S6.5.3.3 Sealed beam headlamp markings.

S6.5.3.3.1 Each sealed beam headlamp lens must be molded with “sealed beam” and the

appropriate designation code as shown in Table II in characters no less than 6.35 mm in size.

S6.5.3.3.2 The face of any character molded on the surface of the lens must not be raised more

than 0.5 mm above the lens surface.

S6.5.3.3.3 Type 1C1, 2C1, and 2D1 headlamps must have no raised markings on the outside

surface of the lens between the diameters of 40 mm and 90 mm about the lens center.

S6.5.3.3.4 Type 1A1, 2A1, 2B1, and 2E1 headlamps must have no raised markings on the

outside surface of the lens within a diameter of 70 mm about the lens center.

S6.5.3.3.5 Type LF, UF, 1G1, 2G1, and 2H1 headlamps must have no raised markings on the

outside surface of the lens within a diameter of 35 mm about the lens center.

S6.5.3.3.6 [CONTENT NOT REPRODUCED]”.

S6.5.3.4 Replaceable bulb headlamp markings.

S6.5.3.4.1 The lens of each replaceable bulb headlamp must bear permanent marking in front

of each replaceable light source with which it is equipped that states either: The HB Type, if

the light source conforms to S11 of this TSD standard for lament light sources, or the bulb

marking/designation provided in compliance with Section VIII of appendix A of 49 CFR Part

564 (if the light source conforms to S11 of this TSD standard for discharge light sources).

S6.5.3.4.1.1 No marking need be provided if the only replaceable light source in the headlamp

is type HB1.

S6.5.3.5 Additional headlamp markings. Additional marking requirements for headlamps are

found in, S10.14.4, S10.15.4, S10.17.2, S10.18.5, S10.18.7, and S10.18.9 of this TSD standard.

S6.5.3.6 [CONTENT NOT REPRODUCED]

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

14

S6.6 Associated equipment.

S6.6.1 All vehicles to which this TSD standard applies, except trailers, must be equipped

with a turn signal operating unit, a turn signal asher, a turn signal pilot indicator tell-tale, a

headlamp beam switching device, and an upper beam headlamp indicator tell-tale meeting the

requirements of S9.

S6.6.2 All vehicles to which this TSD standard applies except trailers and motorcycles must

be equipped with a vehicular hazard warning operating unit, a vehicular hazard warning signal

asher, and a vehicular hazard warning signal pilot indicator tell-tale meeting the requirements

of S9.

S6.6.3 License plate holder. Each rear license plate holder must be designed and constructed to

provide a substantial plane surface on which to mount the plate.

S6.6.3.1 For motor vehicle on which the license plate is designed to be mounted on the vehicle

such that the upper edge of the license plate is 1.2 m or less from the ground, the plane of the

license plate mounting surface and the plane on which the vehicle stands must be perpendicular

within 30 degrees upward (an installed plate will face above the horizon) and 15 degrees

downward (an installed plate will face below the horizon).

S6.6.3.2 For motor vehicles on which the license plate is designed to be mounted on the

vehicle such that the upper edge of the license plate is more than 1.2m from the ground, the

plane of the license plate mounting surface and the plane on which the vehicle stands must be

perpendicular within +/-15 degrees.

S6.7 Replacement equipment.

[CONTENT NOT REPRODUCED]

S7 Signal lamp requirements.

S7.1 Turn signal lamps.

S7.1.1 Front turn signal lamps.

S7.1.1.1 Number . See Tables I-a and I-c.

S7.1.1.2 Color of light . See Tables I-a and I-c.

S7.1.1.3 Mounting location . See Tables I-a and I-c.

S7.1.1.4 Mounting height . See Tables I-a and I-c.

S7.1.1.5 Activation . See Tables I-a and I-c.

S7.1.1.6 Effective projected luminous lens area . See Table IV-a.

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

15

S7.1.1.7 Visibility . See S6.4.

S7.1.1.8 Indicator Tell-tale. See S9.3.

S7.1.1.9 Markings. See S6.5.1.2.

S7.1.1.10 Spacing to other lamps .

S7.1.1.10.1 Each front turn signal lamp must also be designed to comply with any additional

photometry requirements based on its installed spacing to other lamps as specied by this TSD

section. Where more than one spacing relationship exists for a turn signal lamp the requirement

must be the one that species the highest luminous intensity multiplier of Tables VI-a and VI-b.

S7.1.1.10.2 Spacing measurement for non-reector lamps . For any front turn signal lamp that

does not employ a reector to meet photometric requirements, the spacing must be measured

from the light source of the turn signal lamp to the lighted edge of any lower beam headlamp,

or any lamp such as an auxiliary lower beam headlamp or fog lamp used to supplement the

lower beam headlamp.

S7.1.1.10.3 Spacing measurement for lamps with reectors . For any front turn signal lamp

which employs a reector, such as a parabolic reector, to meet photometric requirements,

the spacing must be measured from the geometric centroid of the turn signal lamp effective

projected luminous lens area to the lighted edge of any lower beam headlamp, or any lamp

such as an auxiliary lower beam headlamp or fog lamp used to supplement the lower beam

headlamp.

S7.1.1.10.4 Spacing based photometric multipliers .

(a) where the spacing measurement of S7.1.1.10.2 or S7.1.1.10.3 between a turn signal

lamp and the lighted edge of any lower beam headlamp is less than 100 mm the photometric

multiplier must be 2.5.

(b) where the spacing measurement of S7.1.1.10.2 or S7.1.1.10.3 between a turn signal lamp

and the lighted edge of any lamp such as an auxiliary lower beam headlamp or fog lamp used to

supplement the lower beam headlamp is at least 75 mm but less than 100 mm the photometric

multiplier of Table VI must be 1.5.

(c) where the spacing measurement of S7.1.1.10.2 or S7.1.1.10.3 between a turn signal lamp

and the lighted edge of any lamp such as an auxiliary lower beam headlamp or fog lamp used

to supplement the lower beam headlamp is at least 60 mm but less than 75 mm the photometric

multiplier must be 2.0.

(d) where the spacing measurement of S7.1.1.10.2 or S7.1.1.10.3 between a turn signal

lamp and the lighted edge of any lamp such as an auxiliary lower beam headlamp or fog

lamp used to supplement the lower beam headlamp is less than 60 mm the photometric

multiplier must be 2.5.

S7.1.1.11 Multiple compartment lamps and multiple lamps.

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

16

S7.1.1.11.1 A multiple compartment lamp or multiple lamps may be used to meet the

photometric requirements of a front turn signal lamp provided the requirements of S6.1.3.2

are met.

S7.1.1.11.2 If a multiple compartment lamp or multiple lamps are used on a passenger car or

on a multipurpose passenger vehicle, truck, bus, or trailer of less than 2032 mm in overall width,

and the distance between adjacent light sources does not exceed 560 mm for two compartment or

lamp arrangements and does not exceed 410 mm for three compartments or lamp arrangements,

then the combination of the compartments or lamps must be used to meet the photometric

requirements for the corresponding number of lighted sections specied in Tables VI-a or VI-b.

S7.1.1.11.3 If the distance between adjacent light sources exceeds the previously stated

dimensions, each compartment or lamp must comply with the photometric requirements for one

lighted section specified in Tables VI-a or VI-b.

S7.1.1.11.4 Lamps installed on vehicles 2032 mm or more in overall width . Multiple

compartment front turn signal lamps installed on multipurpose passenger vehicles, trucks, and

buses 2032 mm or more in overall width require measurement of the photometrics for the entire

lamp and not for individual compartments.

S7.1.1.12 Ratio to parking lamps and clearance lamps .

S7.1.1.12.1 When a parking lamp, or a clearance lamp on a multipurpose passenger vehicle,

truck, trailer, or bus of 2032 mm or more in overall width, is combined with a front turn signal

lamp, the luminous intensity of the front turn signal lamp at each identied test point must not

be less than the luminous intensity of the parking lamp or clearance lamp at that same test point

times the multiplier shown for that test point in Tables VI-a or VI-b.

S7.1.1.12.2 If a multiple compartment or multiple lamp arrangement is used on a passenger

car or on a multipurpose passenger vehicle, truck, bus, or trailer of less than 2032 mm in

overall width, and the distance between the optical axes for both the parking lamp and turn

signal lamp is within 560 mm for two compartment or lamp arrangements or 410 mm for three

compartment or lamp arrangements, then the ratio must be computed with all compartments or

lamps lighted.

S7.1.1.12.3 If a multiple compartment or multiple lamp arrangement is used and the distance

between optical axes for one of the functions exceeds 560 mm for two compartment or lamp

arrangements or 410 mm for three compartments or lamp arrangements, then the ratio must be

computed for only those compartments or lamps where the parking lamp and turn signal lamp

are optically combined.

S7.1.1.12.4 Where the clearance lamp is combined with the turn signal lamp, and the

maximum luminous intensity of the clearance lamp is located below horizontal and within

an area generated by a 1.0 degree radius around a test point, the ratio for the test point may

be computed using the lowest value of the clearance lamp luminous intensity within the

generated area.

S7.1.1.13 Photometry.

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

17

S7.1.1.13.1 When tested according to the procedure of S14.2.1, each front turn signal

lamp must be designed to conform to the base photometry requirements plus any applicable

multipliers as shown in Tables VI-a and VI-b for the number of lamp compartments or

individual lamps and the type of vehicle it is installed on.

S7.1.1.13.2 As an alternative to S7.1.1.13.1, a front turn signal lamp installed on a motorcycle

may be designed to conform to the photometry requirements of Table XIII-a when tested

according to the procedure of S14.2.1.

S7.1.1.14 Physical tests . Each front turn signal lamp must be designed to conform to the

performance requirements of the vibration test, moisture test, dust test, and corrosion test of

S14.5, and the color test and plastic optical material test of S14.4.

S7.1.2 Rear turn signal lamps .

S7.1.2.1 Number . See Tables I-a, I-b, and I-c.

S7.1.2.2 Color of light . See Tables I-a, I-b, and I-c.

S7.1.2.3 Mounting location . See Tables I-a, I-b, and I-c and S6.1.3.2.

S7.1.2.4 Mounting height . See Tables I-a, I-b, and I-c.

S7.1.2.5 Activation . See Tables I-a, I-b, and I-c.

S7.1.2.6 Effective projected luminous lens area . See Table IV-a.

S7.1.2.7 Visibility . See S6.4.

S7.1.2.8 Indicator Tell-tale. See S9.3.

S7.1.2.9 Markings. See S6.5.1.2.

S7.1.2.10 Spacing to other lamps . No requirement.

S7.1.2.11 Multiple compartments and multiple lamps .

S7.1.2.11.1 A multiple compartment lamp or multiple lamps may be used to meet the

photometric requirements of a rear turn signal lamp provided the requirements of

S6.1.3.2 are met.

S7.1.2.11.2 If a multiple compartment lamp or multiple lamps are used on a passenger car

or on a multipurpose passenger vehicle, truck, bus, or trailer of less than 2032 mm in overall

width, and the distance between adjacent light sources does not exceed 560 mm for two

compartment or lamp arrangements and does not exceed 410 mm for three compartment or

lamp arrangements, then the combination of the compartments or lamps must be used to meet

the photometric requirements for the corresponding number of lighted sections specied in

Table VII.

S7.1.2.11.3 If the distance between adjacent light sources exceeds the previously stated

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

18

dimensions, each compartment or lamp must comply with the photometric requirements for one

lighted section specied in Table VII.

S7.1.2.11.4 Lamps installed on vehicles 2032 mm or more in overall width . Multiple

compartment rear turn signal lamps installed on multipurpose passenger vehicles, trucks, and

buses 2032 mm or more in overall width require measurement of the photometrics for the entire

lamp and not for individual compartments.

S7.1.2.12 Ratio to taillamps and clearance lamps.

S7.1.2.12.1 When a taillamp, or a clearance lamp on a multipurpose passenger vehicle, truck,

trailer, or bus of 2032 mm or more in overall width, is combined with a rear turn signal lamp,

the luminous intensity of the rear turn signal lamp at each identied test point must not be less

than the luminous intensity of the taillamp or clearance lamp at that same test point times the

multiplier shown for that test point in Table VII.

S7.1.2.12.2 If a multiple compartment or multiple lamp arrangement is used on a passenger

car or on a multipurpose passenger vehicle, truck, bus, or trailer of less than 2032 mm in overall

width, and the distance between the optical axes for both the taillamp and turn signal lamp is

within 560 mm for two compartment or lamp arrangement or 410 mm for three compartments

or lamp arrangements, then the ratio must be computed with all compartments or lamps lighted.

S7.1.2.12.3 If a multiple compartment or multiple lamp arrangement is used and the distance

between optical axes for one of the functions exceeds 560 mm for two compartment or lamp

arrangements or 410 mm for three compartment or lamp arrangements, then the ratio must be

computed for only those compartments or lamps where the taillamp and turn signal lamp are

optically combined.

S7.1.2.12.4 Where the taillamp or clearance lamp is combined with the turn signal lamp, and

the maximum luminous intensity of the taillamp or clearance lamp is located below horizontal

and within an area generated by a 0.5 ° radius around a test point for a taillamp on a passenger

car or on a multipurpose passenger vehicle, truck, bus, or trailer of less than 2032 mm in overall

width, or by a 1.0 ° radius around a test point for a taillamp or clearance lamp on a vehicle 2032

mm or more in overall width, the ratio for the test point may be computed using the lowest

value of the taillamp or clearance lamp luminous intensity within the generated area.

S7.1.2.13 Photometry.

S7.1.2.13.1 Each rear turn signal lamp must be designed to conform to the photometry

requirements of Table VII, when tested according to the procedure of S14.2.1, for the number of

lamp compartments or individual lamps, the type of vehicle it is installed on, and the lamp color

as specied by this TSD section.

S7.1.2.13.2 As an alternative to S7.1.2.13.1, a rear turn signal lamp installed on a motorcycle

may be designed to conform to the photometry requirements of Table XIII-a when tested

according to the procedure of S14.2.1.

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

19

S7.1.2.14 Physical tests . Each rear turn signal lamp must be designed to conform to the

performance requirements of the vibration test, moisture test, dust test, and corrosion test of

S14.5, and the color test and plastic optical material test of S14.4.

S7.1.3 Combined lamp bulb indexing .

S7.1.3.1 Each turn signal lamp optically combined with a taillamp or a parking lamp, or

clearance lamp where installed on a vehicle 2032 mm or more in overall width, where a two-

lament bulb is used must have a bulb with an indexing base and a socket designed so that

bulbs with non-indexing bases cannot be used.

S7.1.3.2 Removable sockets must have an indexing feature so that they cannot be re-inserted

into lamp housings in random positions, unless the lamp will perform its intended function with

random light source orientation.

S7.2 Taillamps .

S7.2.1 Number . See Tables I-a, I-b, and I-c.

S7.2.2 Color of light . See Tables I-a, I-b, and I-c.

S7.2.3 Mounting location . See Tables I-a, I-b, and I-c and S6.1.3.2.

S7.2.4 Mounting height . See Tables I-a, I-b, and I-c.

S7.2.5 Activation . See Tables I-a, I-b, and I-c.

S7.2.6 Effective projected luminous lens area . No requirement.

S7.2.7 Visibility . See S6.4.

S7.2.8 Indicator Tell-tale. No requirement.

S7.2.9 Markings. See S6.5.1.2.

S7.2.10 Spacing to other lamps . No requirement.

S7.2.11 Multiple compartments and multiple lamps .

S7.2.11.1 A multiple compartment lamp or multiple lamps may be used to meet the

photometric requirements of a taillamp provided the requirements of S6.1.3.2 are met.

S7.2.11.2 If a multiple compartment lamp or multiple lamps are used and the distance between

the optical axes does not exceed 560 mm for two compartment or lamp arrangements and

does not exceed 410 mm for three compartment or lamp arrangements, then the combination

of the compartments or lamps must be used to meet the photometric requirements for the

corresponding number of lighted sections specied in Table VIII.

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

20

S7.2.11.3 If the distance between optical axes exceeds the previously stated dimensions, each

compartment or lamp must comply with the photometric requirements for one lighted section

specied in Table VIII.

S7.2.11.4 Taillamps installed on vehicles 2032 mm or more in overall width . A maximum

of two taillamps and/or two compartments per side may be mounted closer together than 560

mm providing that each compartment and/or lamp meets the single lighted section photometric

requirements specied in Table VIII. Each lamp and/or compartment utilized in this manner

must meet the single lighted section requirements for all functions for which it is designed.

S7.2.12 Ratio . See S7.1.2.12 for rear turn signal lamps and S7.3.12 for stop lamps.

S7.2.13 Photometry . Each taillamp must be designed to conform to the photometry

requirements of Table VIII, when tested according to the procedure of S14.2.1, for the number

of lamp compartments or individual lamps and the type of vehicle it is installed on.

S7.2.14 Physical tests . Each taillamp must be designed to conform to the performance

requirements of the vibration test, moisture test, dust test, and corrosion test of S14.5, and the

color test and plastic optical material test of S14.4.

S7.3 Stop lamps.

S7.3.1 Number . See Tables I-a, I-b, and I-c.

S7.3.2 Color of light . See Tables I-a, I-b, and I-c.

S7.3.3 Mounting location . See Tables I-a, I-b, and I-c and S6.1.3.2.

S7.3.4 Mounting height . See Tables I-a, I-b, and I-c.

S7.3.5 Activation . See Tables I-a, I-b, and I-c.

S7.3.6 Effective projected luminous lens area . See Table IV-a.

S7.3.7 Visibility . See S6.4.

S7.3.8 Indicator Tell-tale. No requirement.

S7.3.9 Markings. See S6.5.1.2.

S7.3.10 Spacing to other lamps . No requirement.

S7.3.11 Multiple compartments and multiple lamps .

S7.3.11.1 A multiple compartment lamp or multiple lamps may be used to meet the

photometric requirements of a stop lamp provided the requirements of S6.1.3.2 are met.

S7.3.11.2 If a multiple compartment lamp or multiple lamps are used on a passenger car or

on a multipurpose passenger vehicle, truck, bus, or trailer of less than 2032 mm in overall

Effective:

February 04, 2021

TSD No. 108, Revision 7

Lamps, Reective Devices, and Associated Equipment

21

width, and the distance between adjacent light sources does not exceed 560 mm for two

compartment or lamp arrangements and does not exceed 410 mm for three compartment or

lamp arrangements, then the combination of the compartments or lamps must be used to meet

the photometric requirements for the corresponding number of lighted sections specied in

Table IX.

S7.3.11.3 If the distance between adjacent light sources exceeds the previously stated

dimensions, each compartment or lamp must comply with the photometric requirements for one

lighted section specied in Table IX.