Marketing and

Regulatory

Programs

Agricultural

Marketing

Service

Federal Grain

Inspection

Service

Washington, DC

August 2020

Rice

Inspection

Handbook

Distribution: FGIS, OSP, Industry

Originating Office: FMD, PPMAB

United States Department of Agriculture

Agricultural Marketing Service

Federal Grain Inspection Service

Program Handbook August 20, 2020

Rice Inspection Handbook

Foreword

The Rice Inspection Handbook sets forth the policies and procedures for sampling,

inspecting, and certifying rice in accordance with the regulations under the Agricultural

Marketing Act (AMA) of 1946, as amended. These regulations establish the basic

guidelines for inspecting rice and authorize the issuance of such additional guidelines

as may be necessary for the interpretation and application of the United States

Standards for Rice.

The information contained in this handbook is applicable to official rice inspection

services performed by the Federal Grain Inspection Service (FGIS)—a program under

the Agricultural Marketing Service (AMS)—an agency or department of the Federal

Government that has an interagency agreement, a State Agency, or other entity that

has an agreement with FGIS to conduct commodity inspection services under the AMA.

Persons interested in obtaining official services may contact any FGIS field office or

cooperator.

Trade names are used solely to provide specific information. The mention of trade

names does not constitute a guarantee or warranty of the product by the U.S.

Department of Agriculture or an endorsement by the Department over other products

not mentioned.

In accordance with Federal civil rights law and U.S. Department of Agriculture (USDA) civil rights regulations and

policies, the USDA, its agencies, offices, and employees and institutions participating in or administering USDA

programs are prohibited from discriminating based on race, color, national origin, religion, sex, gender identity

(including gender expression), sexual orientation, disability, age, marital status, family/parental status, income derived

from a public assistance program, political beliefs, or reprisal or retaliation for prior civil rights activity in any program

or activity conducted or funded by USDA (not all bases apply to all programs). Remedies and complaint filing

deadlines vary by program or incident.

Persons with disabilities who require alternative means of communication for program information (e.g., Braille, large

print, audiotape, American Sign Language, etc.) should contact the responsible agency or USDA’s TARGET Center

at (202) 720-2600 (voice and TTY) or contact USDA through the Federal Relay Service at (800) 877-8339.

Additionally, program information may be made available in languages other than English.

To file a program discrimination complaint, complete the USDA Program Discrimination Complaint Form, AD-3027,

found online at How to File a Program Discrimination Complaint and at any USDA office, or write a letter addressed

to USDA and provide in the letter all of the information requested in the form. To request a copy of the complaint

form, call (866) 632-9992. Submit your completed form or letter to USDA by: (1) mail: U.S. Department of

Agriculture, Office of the Assistant Secretary for Civil Rights, 1400 Independence Avenue, SW, Washington, DC

20250-9410; (2) fax: (202) 690-7442; or (3) email: [email protected].

USDA is an equal opportunity provider, employer, and lender.

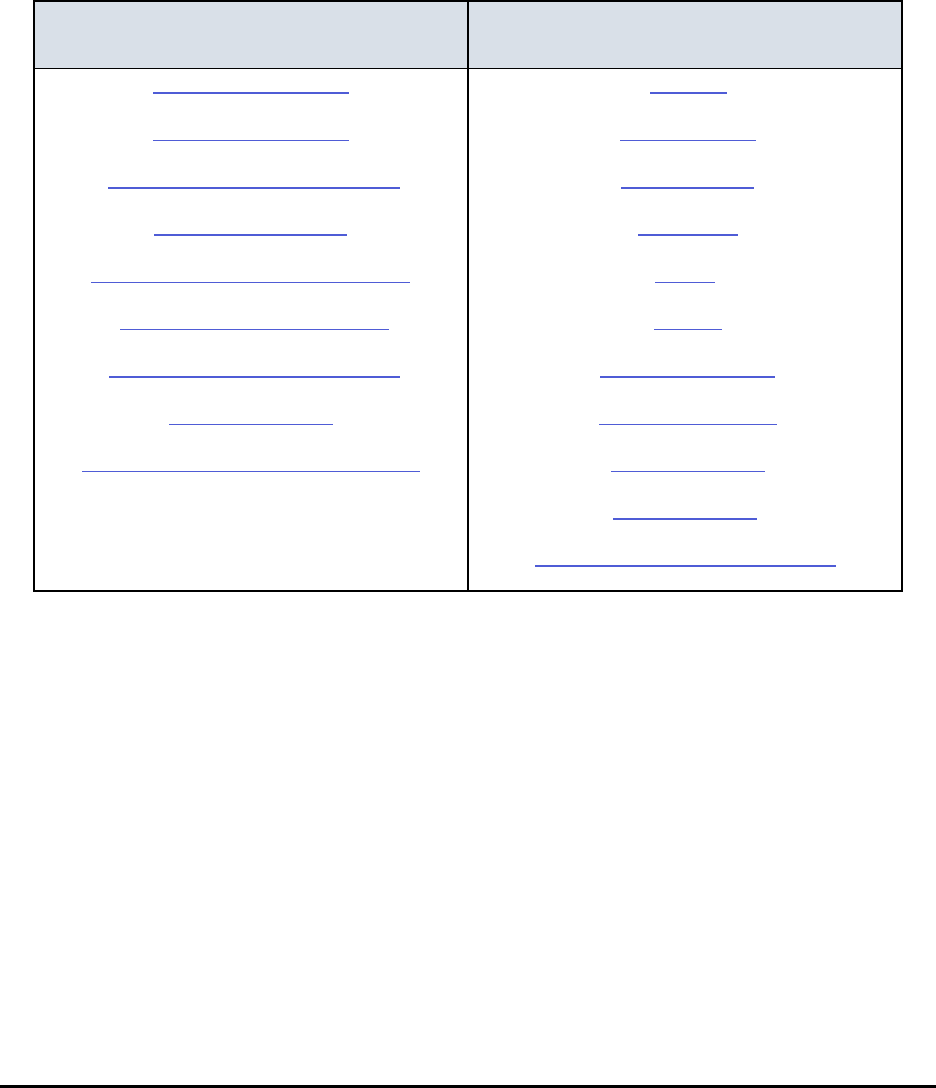

TABLE OF CONTENTS

CHAPTER 1: GENERAL INFORMATION

CHAPTER 2: SAMPLING

CHAPTER 3: ROUGH RICE

CHAPTER 4: BROWN RICE FOR PROCESSING

CHAPTER 5: MILLED RICE

CHAPTER 6: CERTIFICATION

CHAPTER 7: ROUND-LOT INSPECTION PLAN

CHAPTER 8: IDENTITY-PRESERVED INSPECTION PLAN

CHAPTER 9: WAREHOUSE-LOT INSPECTION PLAN

CHAPTER 10: COMMODITY PROCUREMENT LOT INSPECTIONS

CHAPTER 11: REVISION HISTORY

APPENDIX 1 - OFFICIAL COMMERCIAL INSPECTION SERVICES

APPENDIX 2 - ROUGH RICE INSPECTIONS FOR

CHICAGO BOARD OF TRADE (CBOT)

APPENDIX 3 - UNIFORMITY TOLERANCE TABLES

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-1

CHAPTER 1:

GENERAL INFORMATION

CONTENTS

1.1 INTRODUCTION ........................................................................................... 1-2

1.2 DEFINITIONS ............................................................................................... 1-2

1.3 ABBREVIATIONS ......................................................................................... 1-6

1.4 ORIGINAL INSPECTION SERVICES ........................................................... 1-9

1.5 RETEST INSPECTION SERVICES ............................................................ 1-10

1.6 APPEAL INSPECTION SERVICES ............................................................ 1-12

1.7 BOARD APPEAL INSPECTION SERVICES ............................................... 1-15

1.8 NEW ORIGINAL INSPECTIONS ................................................................. 1-16

1.9 CONTRACT SERVICE AGREEMENTS ...................................................... 1-17

1.10 REGISTERED TYPE AND TYPE SAMPLE INSPECTIONS ....................... 1-19

1.11 GRADE OPTIONS ...................................................................................... 1-22

1.12 OTHERWISE GRADE INSPECTIONS ........................................................ 1-22

1.13 ORIGIN INSPECTIONS .............................................................................. 1-24

1.14 COMBINED-LOT INSPECTIONS ............................................................... 1-25

1.15 FACTOR ONLY INSPECTIONS ................................................................. 1-28

1.16 WITHHOLDING AND WITHDRAWAL OF

AMA INSPECTION SERVICES ................................................................... 1-29

1.17 WEIGHTS, MEASURES, AND CONVERSION FACTORS ......................... 1-32

1.18 RICE INSPECTION SURFACES ................................................................ 1-33

ATTACHMENT 1: [BLANK] FGIS-983, “CONTRACT SERVICE AGREEMENT” ....... 1-34

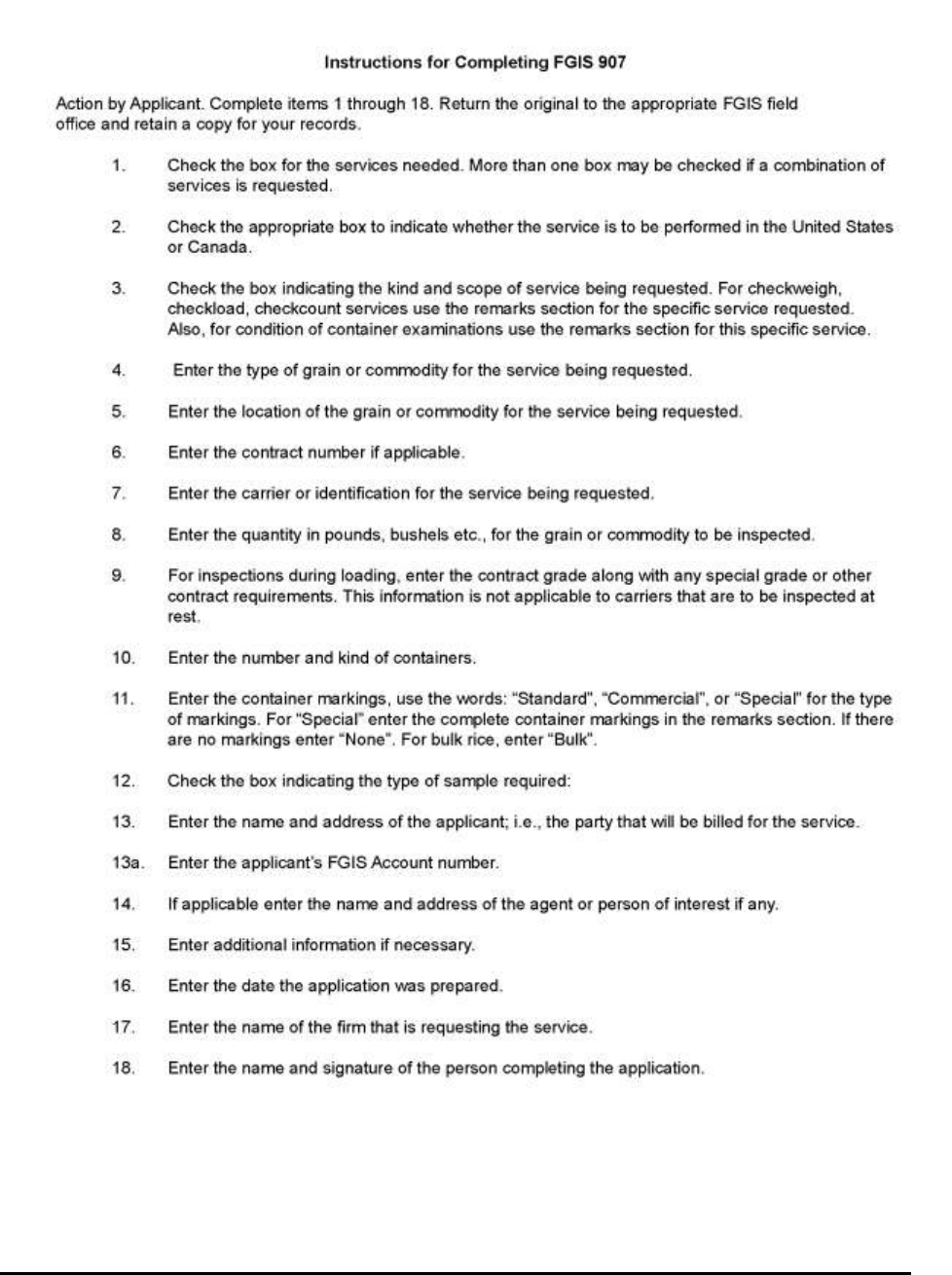

ATTACHMENT 2: [EXAMPLE] FGIS-907 APPLICATION FOR INSPECTION .......... 1-36

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-2

1.1 INTRODUCTION

The inspection of rice is a service provided under the United States Agricultural

Marketing Act (AMA) of 1946, as amended. Service is provided by either a

Federal Grain Inspection Service (FGIS) field office or a cooperator upon request

depending upon the location of the lot and the type of inspection requested.

1.2 DEFINITIONS

Appeal Inspection. A review by FGIS of the result(s) of an original inspection or

retest inspection service.

Board Appeal Inspection. A review by the FGIS - Board of Appeals and Review

of the result(s) of an original inspection or appeal inspection service on graded

commodities.

Cargo Shipment. Bulk or bagged rice that is loaded directly aboard waterborne

carrier for shipment. Rice loaded aboard a land carrier for shipment aboard a

waterborne carrier must not be considered a cargo shipment.

Carrier. A truck, trailer, truck/trailer(s) combination, railroad car, shipping

container, barge, ship, or other container used to transport bulk, sacked, or

packaged commodity.

Certification. The process of issuing an official certificate that indicates the

quality of a lot or sample of rice or the results of some other official service.

Checkcounting. The process of determining the total number of filled outer

containers in a lot in order to determine that the number of containers shown by

the applicant is correct and certifying the results.

Checkloading. The process of performing a stowage examination on a carrier,

computing the number of filled rice containers loaded aboard the carrier,

observing the condition of the rice containers loaded aboard the carrier, sealing

the carrier, if practicable, and certifying the results.

Checkweighing. The process of weighing a selected number of containers from

a rice lot, determining the estimated total gross, tare, and net weight, or the

estimated average gross or net weight per filled container, and certifying the

results.

Composite Sample. A single sample composed of small portions (component

samples) taken throughout a lot. A composite sample may be inspected as a

sublot or a single lot.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-3

Condition Inspection. The process of determining whether an identifiable rice lot

is water damaged, fire damaged, or has rodent or bird contamination, insect

infestation, or any other deteriorating condition and certifying the results.

Container. A carrier (e.g., trucks, railcars, barges, ships, and shipping

containers) or a bin, other storage space, bag, box, or other receptacle for rice.

Cooperator. An agency or department of the Federal Government that has an

interagency agreement or State agency that has a reimbursable agreement with

FGIS.

Interested Person. Any person having a contract or other financial interest in a

commodity as the owner, seller, purchaser, warehouseman, carrier, or otherwise.

Lot. Any identified amount of rice offered by an applicant for inspection.

Lot (Quality) Inspection. The process of obtaining a representative sample(s) of

an identified rice lot, examining or testing the sample(s), examining relevant

records of the lot, and certifying the results.

Not Standardized Rice. A lot/sample offered for inspection that does not meet

the U.S. Standards for Rough Rice, Brown Rice for Processing, or Milled Rice.

Observation of Loading. The process of determining that an identified lot has

been moved from a warehouse or carrier and loaded into another warehouse or

carrier and certifying the results.

Official Personnel. Any authorized Department employee or person licensed by

FGIS to perform all or specified functions under the AMA.

Official Sample. A representative sample drawn by official personnel licensed or

authorized by FGIS.

Plant Examination. The process of performing a facility examination according to

the Food and Drug Administration requirements found in the FGIS Sanitation and

Food Defense Handbook.

Plate. An approved laboratory device with a perforated tray and a fixed back

plate mounted on a frame for use in separating particles of various sizes.

a. 5 Plate. A laminated metal plate 0.142-inch thick, with a top lamina,

0.051-inch thick, perforated with rows of round holes 0.0781 (5⁄64) inch in

diameter, 5⁄32-inch from center to center, with each row staggered in

relation to the adjacent rows, and a bottom lamina 0.091-inch thick,

without perforations.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-4

b. 6 Plate. A laminated metal plate 0.142-inch thick, with a top lamina 0.051-

inch thick, perforated with rows of round holes 0.0938 (6/64) inch in

diameter, 5/32-inch from center to center, with each row staggered in

relation to the adjacent rows, and a bottom lamina 0.091inch thick, without

perforations.

Representative Sample. A sample that has been (1) obtained by official

personnel, (2) has been obtained, handled, and submitted in accordance with the

instructions and (3) is of the size prescribed in the instructions.

Sampling. The process of drawing a sample from a lot of rice.

Security Container. A locked container in which official personnel store rice

samples, supplies, and equipment.

Sieve. Approved laboratory device with perforations for use in separating

particles of various sizes.

a. 2 ½ Sieve. A metal sieve 0.032-inch thick, perforated with rows of round

holes 0.0391 (2 ½ /64) inch in diameter, 0.075-inch from center to center,

with each row staggered in relation to the adjacent rows.

b. 4 Sieve. A metal sieve 0.032-inch thick, perforated with rows of round

holes 0.0625 (4/64) inch in diameter, 1⁄8 inch from center to center, with

each row staggered in relation to the adjacent rows.

c. 5 Sieve. A metal sieve 0.032-inch thick, perforated with rows of round

holes 0.0781 (5⁄64) inch in diameter, 5⁄32 inch from center to center, with

each row staggered in relation to the adjacent rows.

d. 5 ½ Sieve. A metal sieve 0.032-inch thick, perforated with rows of round

holes 0.0859 (5 ½ /64) inch in diameter, 9⁄64 inch from center to center,

with each row staggered in relation to the adjacent rows.

e. 6 Sieve. A metal sieve 0.032-inch thick, perforated with rows of round

holes 0.0938 (6/64) inch in diameter, 5/32 inch from center to center, with

each row staggered in relation to the adjacent rows.

f. 6 ½ Sieve. A metal sieve 0.032-inch thick, perforated with rows of round

holes 0.1016 (6 ½ /64) inch in diameter, 5/32 inch from center to center,

with each row staggered in relation to the adjacent rows.

g. 30 Sieve. A woven wire cloth sieve having 0.0234-inch openings, with a

wire diameter of 0.0153 inch, and meeting the specifications of American

Society for Testing and Materials Designation E-11-61, prescribed in FGIS

instructions.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-5

Southern Production. Rice grown in Arkansas, Louisiana, Mississippi, Missouri,

Texas, or the surrounding areas.

Stowage Examination. The process of visually determining if an identified carrier

or container is clean; dry; free of live infestation, rodents, toxic substances, and

foreign odors; and suitable to store or carry rice, then certifying the results.

Submitted Sample. A sample that has been provided by the applicant and/or a

sample that does not meet the criteria of a representative sample.

Submitted Sample Inspection. The process of grading or testing a sample of rice

submitted by an applicant and certifying the results.

Type Sample. Samples of rice (not officially sampled) obtained by an applicant

and sent to prospective buyers to demonstrate product quality or analyze for

conformance to a prospective buyer’s standards. The quantity is identified as the

entire lot.

Western Production. Rice grown in California and surrounding areas.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-6

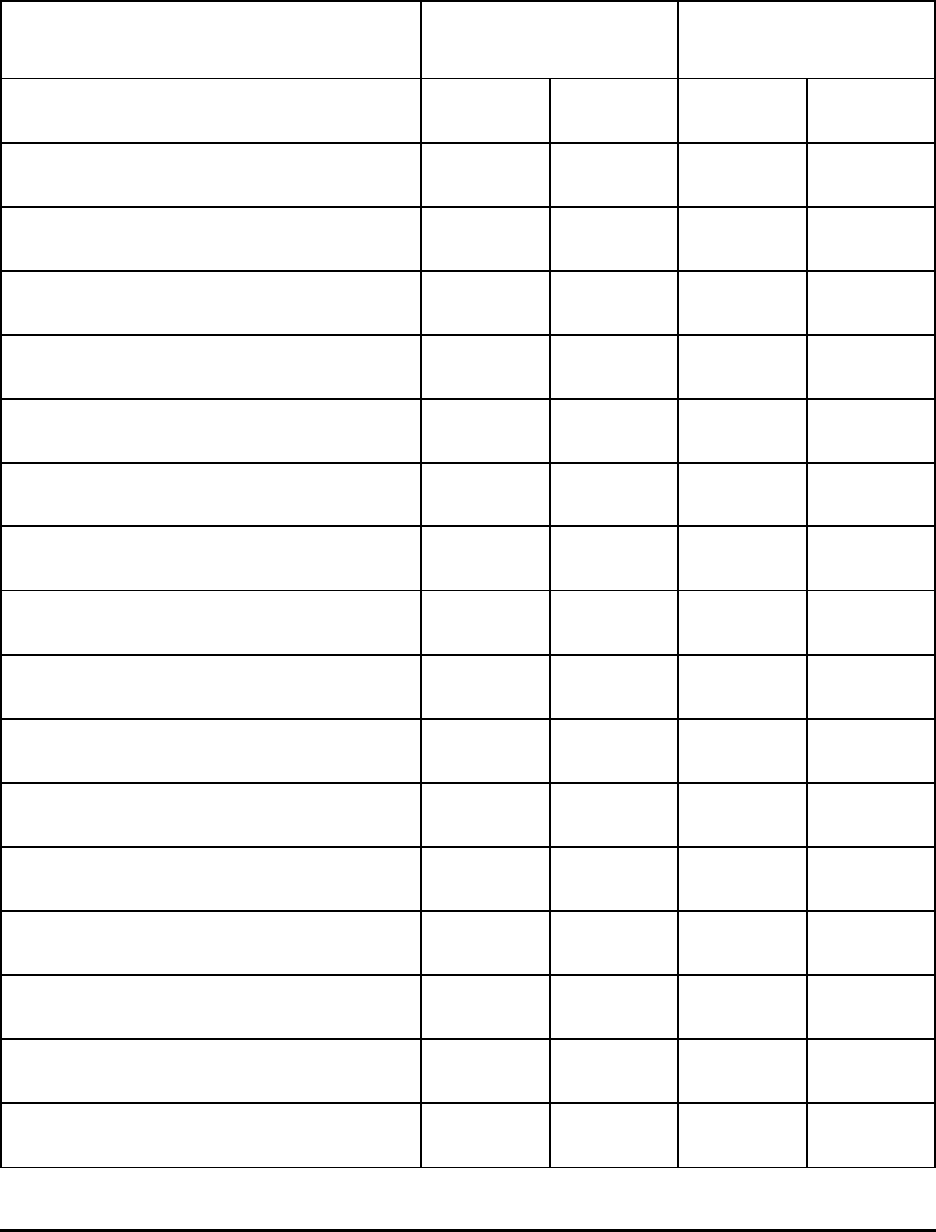

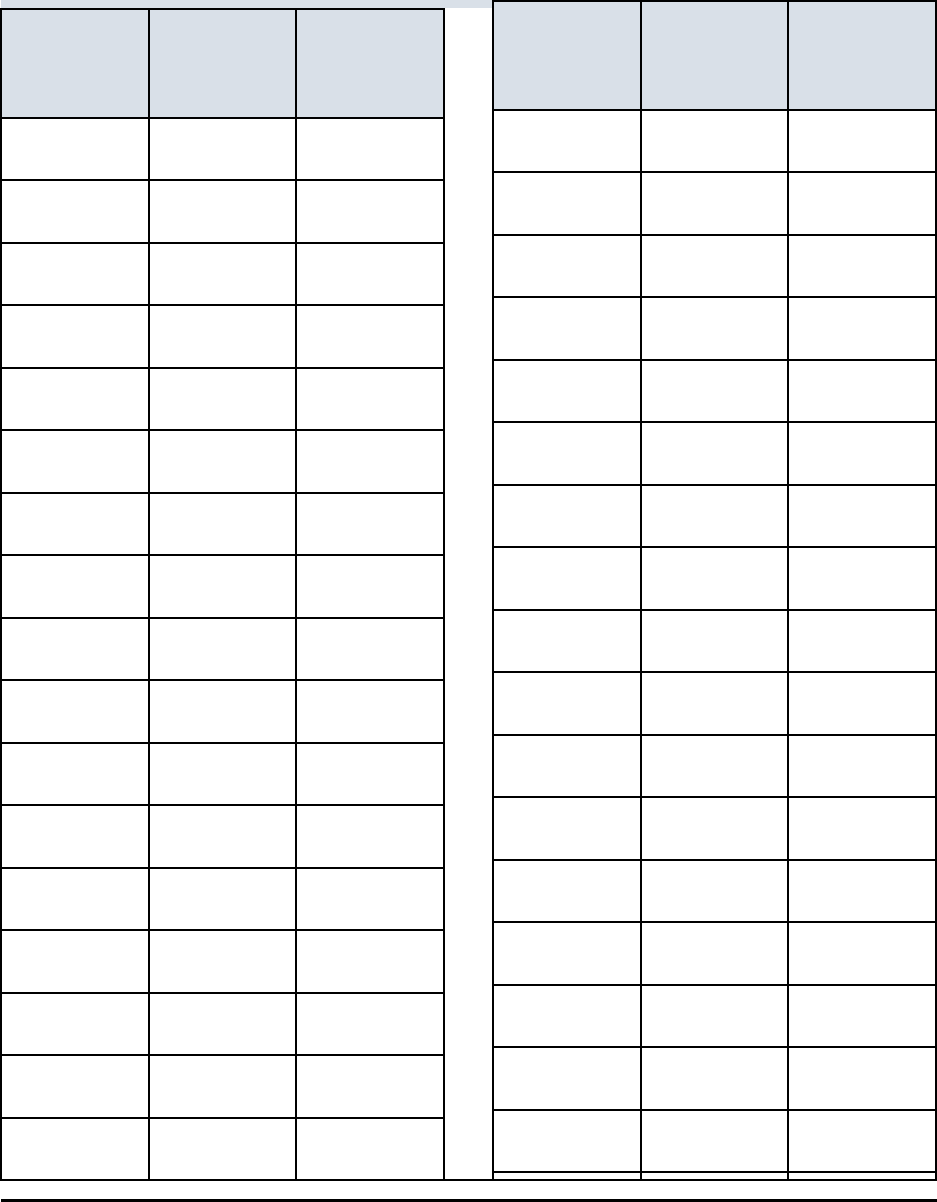

1.3 ABBREVIATIONS

The following abbreviations may be shown on work records.

AV

Average

LBK

Large broken

kernels

RUF

Rough rice

B

Brewers

LG

Long grain

RWM

Reasonably

well-milled

BDA

Badly-

damaged

appearance

LGBR

Long Grain

Brown Rice for

Processing

s

Sampling

BK

Broken kernels

LGMR

Long Grain

Milled Rice

S

Sieve

BMR

Brewers Milled

Rice

LGRU

F

Long Grain

Rough Rice

SC

Screenings

BRK

Brown rice

kernels

LIG

Light gray

SD

Seeds

C

Color

LIM

Lightly milled

SG

Sample grade

CC

Checkcounting

LS

Lightly stained

SH

Second head

CE

Condition

examination

LW

Live weevils

SHG

Short grain

CH

Chalky kernels

M

Moisture

SGBR

Short Grain

Brown Rice for

Processing

CL

Class

m

meter(s)

SGMR

Short Grain

Milled Rice

CLO

Checkloading

MD

Milling degree

SRUF

Short Grain

Rough Rice

cm

Centimeter(s)

MG

Medium grain

SHMR

Second Head

Milled Rice

COFO

Commercially

objectionable

foreign odor

MGBR

Medium Grain

Brown Rice for

Processing

SLG

Slightly gray

CR

Creamy

MGMR

Medium Grain

Milled Rice

SLRO

Slightly rosy

CT

Count

MRUF

Medium Grain

Rough Rice

SMR

Screenings

Milled Rice

CTD

Coated

ml

Milliliter(s)

SK

Smutty

CW

Checkweighing

mm

Millimeter

SOUR

Sour

DG

Dark gray

MOTH

Angoumois

moth

SR

See reverse

DHT

Damaged by

heat

MR

Milled rice

STE

Stowage

examination

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-7

DK

Damaged

kernels

MREQ

Milling

requirement

TBK

Total broken

kernels

DKG

Dockage

MUST

Musty

TR

Total rice

DLQ

Distinctly low

quality

MY

Milling yield

TS

Total seeds

DW

Dead weevils

NOBS

Non-

objectionable

seeds

TW

Test weight per

bushel

ENR

Enriched milled

rice

NPB

Nonparboiled

rice

UGK

Ungelatinized

kernels

ERA

Extremely red

appearance

NSR

Not

standardized

rice

UM

Under milled

FE

Facility

examination

O

Odor

URM

Unrelated

material

FM

Foreign

material

OB

Observing of

loading

V

Variety

FORT

Fortified milled

rice

OBS

Objectionable

seeds

VR

Very rosy

FSUB

Unknown

foreign

substance

ODI

Other dead

insects

WH

White

ft

Foot (Feet)

OLI

Other live

insects

WF

Witness of

fumigation

g

Gram(s)

OT

Other types

WK

Whole kernels

GRL

Granulated

P

Paddy Kernels

WLBK

Whole and

large broken

kernels

HDP

Heat-damaged

kernels,

kernels

damaged by

heat, or

parboiled

kernels in non

parboiled rice

PL

Plate

WM

Well milled

HP

Handpicked

PB

Parboiled

WMK

Well milled

kernels

HT

Heat-damaged

kernels

PBD

Parboiled dark

WVLY

Weevily

HTG

Heating

PBL

Parboiled light

XBR

Mixed Brown

Rice for

Processing

INR

Insect refuse

RLSR

Roundlot-see

reverse

XMR

Mixed Milled

Rice

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-8

INW

Insect webbing

RO

Rosy

XRUF

Mixed Rough

Rice

kg

Kilogram(s)

RM

Related

material

#

U.S. No.

lb

Pound(s)

RR

Red rice

#SG

U.S. Sample

grade

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-9

1.4 ORIGINAL INSPECTION SERVICES

a. Any interested person may request an original inspection.

b. Requests may be made verbally, in writing, or electronically, using FGIS-

907, “Application for Inspection and Weighing Services.” Cooperators

must use a similar form.

(1) Verbal requests must be confirmed, in writing. All written requests

must be made in English and include the following:

(a) The identification, quantity, and location of the rice;

(b) The type of service(s) requested;

(c) The applicant account number;

(d) Names and mailing addresses/email addresses of interested

persons; and

(e) Any other relevant information that official personnel require.

c. Copies of FGIS-907, “Application for Inspection and Weighing Services,”

can be found at the link provided here, or may be obtained from any FGIS

field office. Contact the cooperator to request copies of similar forms. If

all required documentation is not available when the request is made, it

must be provided as soon as it is available. At their discretion, official

personnel may withhold inspection service pending receipt of the required

documentation.

d. Requests for services, other than submitted sample inspections, must be

made with the FGIS field office or cooperator responsible for the area in

which the service will be provided.

e. Requests for submitted sample inspections may be made with any FGIS

field office or cooperator that provides original rice inspection services.

f. Requests for services to be performed during loading, unloading,

handling, or processing must be submitted far enough in advance so

official personnel can be present.

Note: Only Appeal and Board Appeal Inspections are available after

an original inspection for rice, there is no reinspection. The

applicant, however, may request to bypass an Appeal inspection and

go directly to a Board Appeal.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-10

1.5 RETEST INSPECTION SERVICES

a. Any interested person may request a retest inspection service on

chemically tested (nongrade) factors (e.g., Total Oil and Free Fatty Acid,

enrichment, and aflatoxin). When more than one interested person

requests a retest inspection, the first interested person to file is the

applicant of record.

b. Requests may be made verbally or in writing.

(1) Verbal requests must be confirmed in writing. All written requests

must be made in English and include the following:

(a) The identification, quantity, and location of the rice;

(b) The type of service(s) requested;

(c) The applicant account number;

(d) Names and mailing addresses/email addresses of interested

persons; and

(e) Any other relevant information that official personnel require.

(2) Requests must be filed with the FGIS field office responsible for the

area in which the original inspection was performed.

(3) Copies of request forms may be obtained from any FGIS field office

or cooperator. If all required documentation is not available when

the request is made, it must be provided as soon as it is available.

At their discretion, official personnel may withhold inspection

service pending receipt of the required documentation.

c. A retest inspection must only be performed by an authorized person.

Official personnel must not perform, participate in performing, or issue a

certificate if they participated in a previous inspection or certification of the

lot unless there is only one authorized person available at the time and

place of the requested retest inspection.

d. Only one retest inspection may be obtained from any original inspection.

e. The scope of a retest inspection may be requested for any or all quality

factors tested. If the request specifies a different scope, the request must

be dismissed.

f. A retest inspection must be limited to an analysis of the file sample.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-11

g. A retest inspection certificate supersedes the original inspection

certificate. The superseded certificate will be considered null and void as

of the date of the retest inspection certificate.

h. A retest inspection certificate must be issued before the close of business

on the business day following the date the retest inspection is completed.

A complete list of approved statements for retest inspections can be found

in section 6.18(f) of this handbook.

i. A request for a retest inspection must be dismissed when one of the

following occurs:

(1) The scope is different from the scope of the original inspection;

(2) The condition of the rice has undergone a material change;

(3) A representative file sample is not available;

(4) The applicant requests a new sample; or

(5) The reasons for the retest are frivolous.

j. Official personnel must notify the applicant of the proposed dismissal of

service. The applicant must then be afforded reasonable time to take

corrective action or to demonstrate there is no basis for the dismissal. If

the corrective action has not been adequate, the applicant must be

notified of the decision to dismiss the request for service; and any results

of service must not be released.

k. An applicant may withdraw a request for retest inspection any time before

official personnel release results, either verbally or in writing. Verbal

requests must be confirmed, in writing. All written requests must be made

in English

Note: Applicants who withdraw a request for service may be billed

for all expenses incurred prior to withdrawal.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-12

1.6 APPEAL INSPECTION SERVICES

a. Any interested person may request an appeal inspection. When more

than one interested person requests an appeal inspection, the first

interested person to file is the applicant of record.

b. Requests may be made verbally or in writing.

(1) Verbal requests must be confirmed, in writing. All written requests

must be made in English and include the following:

(a) The identification, quantity, and location of the rice;

(b) The type of service(s) requested;

(c) The applicant account number;

(d) Names and mailing addresses/email addresses of interested

persons; and

(e) Any other relevant information that official personnel require.

(2) Requests for appeal inspection services on quality (grade) factors

must be filed with the FGIS field office responsible for the area in

which the original inspection was performed. Requests for appeal

inspection services on chemically-tested (nongrade) factors must

also be filed with the FGIS field office responsible for the area in

which the original inspection was performed. This office must then

forward the request, with the file sample(s), to the appropriate

office.

(3) Requests for appeal inspection services must be made before the

rice has left the place where the inspection being appealed was

performed and not later than the close of business on the second

business day following the date of the inspection being appealed.

However, the AMS FGIS Deputy Administrator may extend the time

requirement, as deemed necessary.

(4) Copies of request forms may be obtained from the cooperator or

FGIS field office. If all required documentation is not available

when the request is made, it must be provided as soon as it is

available. At their discretion, official personnel may withhold

inspection service pending receipt of the required documentation.

c. An appeal inspection must only be performed by an authorized person.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-13

d. Official personnel must not perform, participate in performing, or issue a

certificate if they participated in a previous inspection or certification of the

lot, unless there is only one authorized person available at the time and

place of the requested appeal inspection.

e. Only one appeal inspection may be obtained from any original or retest

inspection service.

f. The scope of an appeal inspection is limited to the scope of the original

inspection. If the request specifies a different scope, the request will be

dismissed. When chemically tested factors are appealed, all chemically

tested factors must be tested and certified.

g. An applicant for service may request an appeal or Board appeal

inspection of a specific factor(s) or official grade and factors. Appeal and

Board appeal inspection for grade may include a review of any pertinent

factor(s), as deemed necessary by official personnel.

h. The applicant may request that an appeal inspection be based on the file

sample or the results based on a new sample. However, an appeal

inspection must be based on a new sample only if the lot can positively be

identified by official personnel as the lot that was previously inspected,

and the entire lot is available and accessible for sampling and inspection.

i. An appeal inspection is limited to a review of the sampling procedures and

an analysis of the file sample when, as a result of the original inspection,

the rice is found to be contaminated with filth or to contain a deleterious

substance. If it is determined that the sampling procedures were

improper, a new sample will be obtained if the lot can be positively

identified as the lot which was previously inspected, and the entire lot is

available and accessible for sampling and inspection.

j. An appeal inspection certificate supersedes the original inspection

certificate. The superseded certificate will be considered null and void as

of the date of the appeal inspection certificate.

k. An appeal inspection certificate must be issued before the close of

business on the business day following the date the appeal inspection is

completed. A complete list of approved statements for appeal inspections

can be found in section 6.18(f) of this handbook.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-14

l. A request for an appeal inspection must be dismissed when one of the

following occurs:

(1) The scope is different from the scope of the original inspection;

(2) The condition of the rice has undergone a material change;

(3) The request specifies a file sample and a representative file sample

is not available;

(4) The applicant requests that a new sample be obtained and a new

sample cannot be obtained; or

(5) The reasons for the appeal inspection are frivolous.

m. Official personnel must notify the applicant of the proposed dismissal of

service. The applicant will then be afforded reasonable time to take

corrective action or to demonstrate there is no basis for the dismissal. If

the corrective action has not been adequate, the applicant must be

notified of the decision to dismiss the request for service, and any results

of service must not be released.

n. An applicant may withdraw a request for appeal inspection any time

before official personnel release results, either verbally or in writing.

Verbal requests must be confirmed, in writing. All written requests must be

made in English

Note: Applicants who withdraw a request for service may be billed

for all expenses incurred prior to withdrawal.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-15

1.7 BOARD APPEAL INSPECTION SERVICES

a. Any interested person who is dissatisfied with the original or appeal

inspection results may appeal to the FGIS Board of Appeals and Review

(BAR). However, if the applicant elects to forgo the appeal and requests a

Board Appeal, no further appeal may be made.

b. The Board appeal inspection must only be performed for physically

determined quality (grade) factors and must be limited to an analysis of

the file sample.

(1) When a request for a Board appeal inspection is filed, the file

sample(s) and all other pertinent information must be immediately

submitted to the BAR.

(2) The FGIS field office must act as a liaison between the BAR and

the applicant.

(3) The Board appeal certificate must supersede any certificate

previously issued and will be the final appeal inspection service.

c. A complete list of approved statements for board appeal inspections can

be found in section 6.18(f) of this handbook.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-16

1.8 NEW ORIGINAL INSPECTIONS

a. When the identity of the lot has been lost and /or circumstances prevent a

retest, an appeal, or a Board appeal inspection, an applicant may request

a new original inspection on any previously inspected lot. However, a new

original inspection must not be performed on an identifiable rice lot that, as

a result of a previous inspection, was found to be contaminated with filth

or to contain a deleterious substance.

Note: Identity is not lost if the identity of the rice, carrier, or

container is not lost. A new original inspection cannot be performed

on the same identified lot of rice, carrier, or container in the same

assigned area of responsibility within 5 business days after the last

official inspection.

b. A certificate issued as a result of a new original inspection is, in fact, an

original inspection certificate. It must be based on a new sample and

must not be restricted to the scope of any previous inspection.

Subsequently, the applicant for a new original inspection may request any

or all of the inspection services provided for by the regulations.

c. A new original inspection certificate must not supersede any previously

issued certificate.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-17

1.9 CONTRACT SERVICE AGREEMENTS

a. Applicants for rice inspection services in areas served by an FGIS field

office, may enter into a contract service agreement with the field office in

order to ensure timely services and to obtain lower inspection charges.

(1) A contract service agreement is an agreement whereby the

applicant agrees to pay contract rates for 8 hours of service per day

for a predetermined number of official personnel, for at least 5

consecutive days per week.

(2) In turn, FGIS agrees to make official personnel available to the

applicant for the specified period and to perform all requested

services at reduced hourly rates.

(3) All hours of service worked in excess of the service agreement are

charged at the noncontract rate.

(4) Service charges are not assessed under the service agreement for

recognized federal holidays when, upon request of the applicant,

service is not performed. The applicant should make this request

not later than 2 p.m. the preceding business day.

b. To enter into a contract service agreement, the applicant must provide the

appropriate FGIS field office with 60 days written notice specifying the

proposed effective date of the service agreement. A service agreement

may become effective prior to the proposed effective date with the consent

of both parties.

If official grading and/or quality inspections are required onsite, the

applicant must provide lab space for official inspections in accordance with

FGIS Directive 9160.5, “Official Inspection Laboratory Location, Design

and Maintenance Requirements.”

c. To terminate a contract service agreement, the applicant must provide the

appropriate FGIS field office with 60 days written notice specifying the

date of termination. However, a service agreement may be terminated at

any time by mutual consent of both parties.

d. FGIS reserves the right to the following:

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-18

(1) Determine the number of official personnel needed to perform the

service for the contracted applicant, which may be different than the

number of official personnel under contract;

(2) Terminate a contract service agreement by giving the applicant 60

days written notice specifying the date of termination; and

(3) Temporarily reassign official personnel from a contracted applicant

when, in the opinion of FGIS, the official personnel are not needed

to perform service for the contracted applicant.

Note: Charges will be assessed in accordance with Section

868.91, “Fees for certain Federal rice inspection services,” of

the regulations under the AMA.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-19

1.10 REGISTERED TYPE AND TYPE SAMPLE INSPECTIONS

Registered Type Sample Inspections.

a. Applicants may request that the quality of rice in a lot be compared with

the quality of an identified rice type sample that has been registered with

an FGIS field office or cooperator.

When a registered type sample inspection is requested, the applicant

must follow the below procedure:

(1) Submit a clearly identified rice sample for an inspection for quality

or other criteria:

(a) The sample must not be less than 1,200 grams for milled

rice, 1,800 grams for brown rice for processing, and 2,300

grams for rough rice.

(b) Official personnel may require a larger sample if portions are

to be sent to other offices, or if the applicant requests that

the sample be divided into several portions for submission to

prospective buyers or brokers.

(2) If FGIS is requested to forward registered type sample(s) to

prospective buyers or brokers, the applicant must supply the

necessary containers and labels for samples to be shipped.

(3) Specify, in writing, all pertinent information, including the following:

(a) Identification of the type sample (e.g., Corkin Rice Mills type

“Aunt Carolina Brand” or Duncan Rice Mill type 311); and

(b) Quality factor information or any other criteria information

that is desired.

b. Official personnel must follow the below procedure:

(1) Perform a quality inspection as specified by the applicant and

approved by the FGIS field office or cooperator;

(2) Issue a submitted sample inspection certificate;

(3) Register the type sample in the field office or office of the

cooperator; and

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-20

(4) Retain a representative portion of the type sample, under

refrigeration, for comparison with the sample(s) obtained from

identified lot(s).

(a) Because of limited refrigerated storage and file space, and

the possibility of quality factor change due to prolonged

storage, type samples will not be retained for more than 1

year from the submitted sample inspection certificate

issuance date.

(b) Notify the applicant of record at least 30 days prior to the

expiration date of the type sample; and

(c) Destroy the type sample on the expiration date.

(5) When requested by the applicant, send a copy of the submitted

sample inspection certificate and a sample of the rice to the BAR,

other FGIS field offices, or cooperator offices that have been

requested to compare the quality of an identified lot of rice against

the type sample.

(6) If the applicant requests that one or more representative portions

be divided out from the type sample for submission to prospective

buyers or brokers, securely seal each representative portion in a

plastic bag that has a label affixed.

Show the following information on the label:

(a) The statement, “This representative portion of rice was taken

from type sample (sample identification) and was inspected,

registered, and sealed by the (USDA, FGIS, or name of

cooperator).”

(b) Office of inspection (city and state).

(c) Applicant (name, city, and state).

(d) Registration date (date).

(e) Expiration date (date).

(f) Submitted sample inspection certificate issued

(identification).

(g) Name and signature of FGIS field office inspector or

cooperator.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-21

(7) Issue a lot inspection certificate when the quality of an identified lot

of rice is compared against the type sample. State that the quality

of the rice in the lot was either “equal to or better than” or “not equal

to” the type sample.

For Example: “(Type of rice/grade and kind of rice). (Quality

equal to or better than/Quality not equal to)

(name of registered type sample).”

Type Sample Inspections. “Type” samples are samples of rice (not officially

sampled) obtained by an applicant and sent to prospective buyers to

demonstrate product quality or analyze for conformance to a prospective buyer’s

standards. The quantity is identified as the entire lot.

For Example: A 5-pound bag of Long Grain Milled Rice represents itself, a

5-pound bag of Long Grain Milled Rice.

Issuing Certificates. Issue an appropriate Submitted Sample Inspection

Certificate as follows:

a. “Identification” section, show the identification of the sample provided by

the applicant;

b. “Quantity” section, enter total weight (grams/pounds) of type sample; and

c. “REMARKS” section, identify the sample as a “Type” sample.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-22

1.11 GRADE OPTIONS

a. Applicants for inspection may obtain “Option 1” or “Option 2” certification

by requesting it on the application for inspection. The request must be

filed prior to the beginning of the inspection.

(1) Under “Option 1,” rice offered for inspection is certified as a specific

grade (e.g., “U.S. No. 2 Long Grain Rough Rice”).

(2) Under “Option 2,” rice offered for inspection would be certified as

being a specific grade “or better” (e.g., “U.S. No. 3 or better Long

Grain Rough Rice”). (Not available for submitted samples.)

Note: If no request for either option is submitted prior to the

beginning of inspection, certification must be “Option 1.”

1.12 OTHERWISE GRADE INSPECTIONS

a. Applicants may request information as to what the quality of rice in a lot or

sample would “otherwise grade” if the results of one or more factors were

not considered.

b. When requested, official personnel must follow the below procedure:

(1) Determine and show the actual grade of the lot or sample in the

space provided for the grade designation; or determine requested

factors only and show the type or class of the rice on the grade line

(e.g., “Milled Rice”).

(2) Show the grade determining factor results and the results of other

analyses in the factor information space.

(3) Show the following statement in the “REMARKS” section of the

certificate:

“(Desired grade and kind) except for (factor(s) that prevent

the lot or sample from being assigned the desired grade).”

c. The following are examples of otherwise grade designations:

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-23

EXAMPLE 1: An application is received to inspect a lot of U.S. No.

3 Long Grain Milled Rice. The inspection determines

that the rice is U.S. No. 4 Long Grain Milled Rice

because of 17.0 percent total broken kernels.

Grade Designation. “U.S. No. 4 Long Grain Milled Rice.”

Statement. “U.S. No. 3 Long Grain Milled Rice except for total broken

kernels.”

EXAMPLE 2: An application is received to inspect a lot of U.S. No.

3 Long Grain Milled Rice. The inspection determines

that the rice is of the class Mixed Milled Rice because

of 18.9 percent other types.

Grade Designation. “U.S. No. 3 Mixed Milled Rice. Long grain whole

kernels 72.0 percent, medium grain whole kernels 12.9 percent, long grain

broken kernels 9.0 percent, medium or short grain broken kernels 6.0

percent, and seeds 0.1 percent.”

Statement. “U.S. No. 3 Long Grain Milled Rice except for other types.”

EXAMPLE 3: An application is received to inspect a lot of U.S. No.

5 Long Grain Milled Rice. The inspection determines

that the rice is U.S. Sample Grade Long Grain Milled

Rice because of 57.4 percent total broken kernels.

The applicant does not want U.S. Sample Grade to be

shown on the grade line. The factor results meet the

grade limits for U.S. No. 3 Second Head Milled Rice.

Grade Designation. “Milled Rice.”

Statement. “U.S. No. 3 Second Head Milled Rice except for whole

kernels.”

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-24

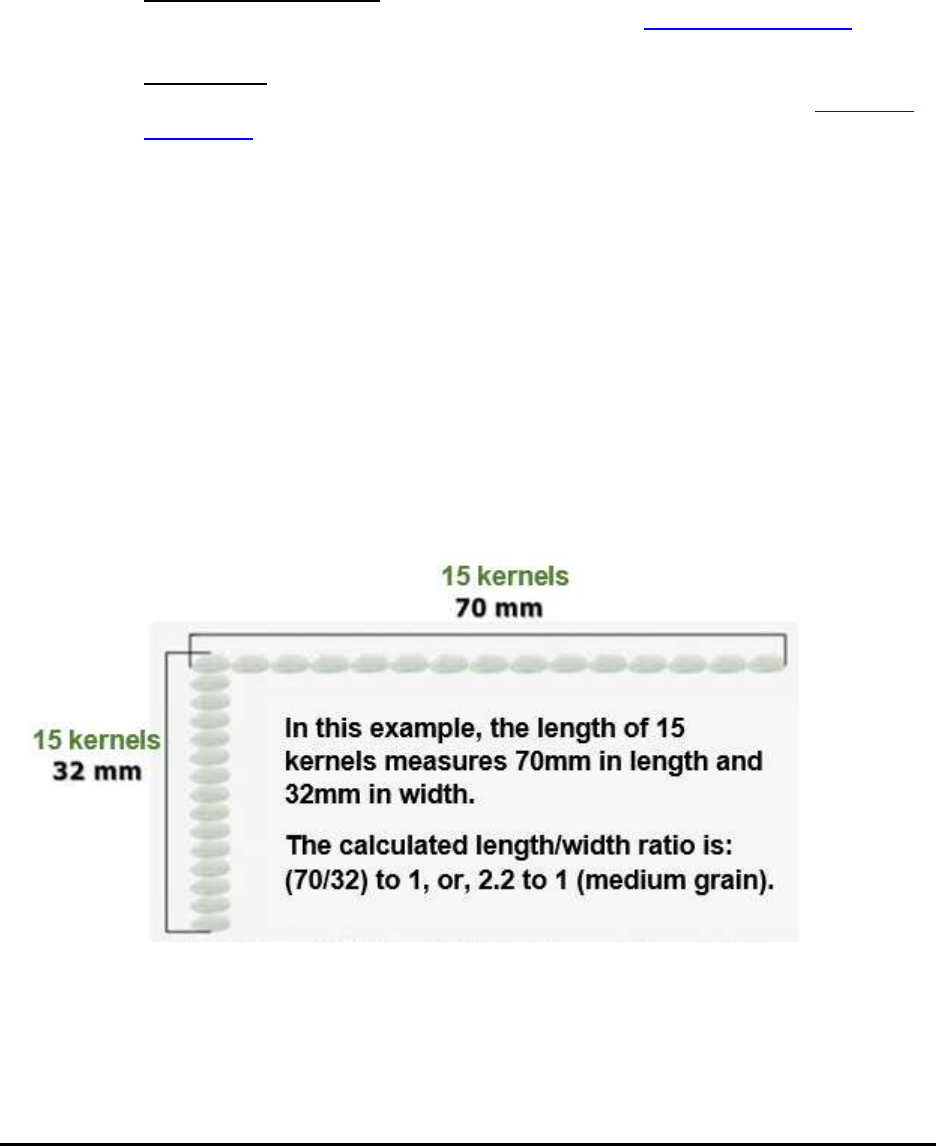

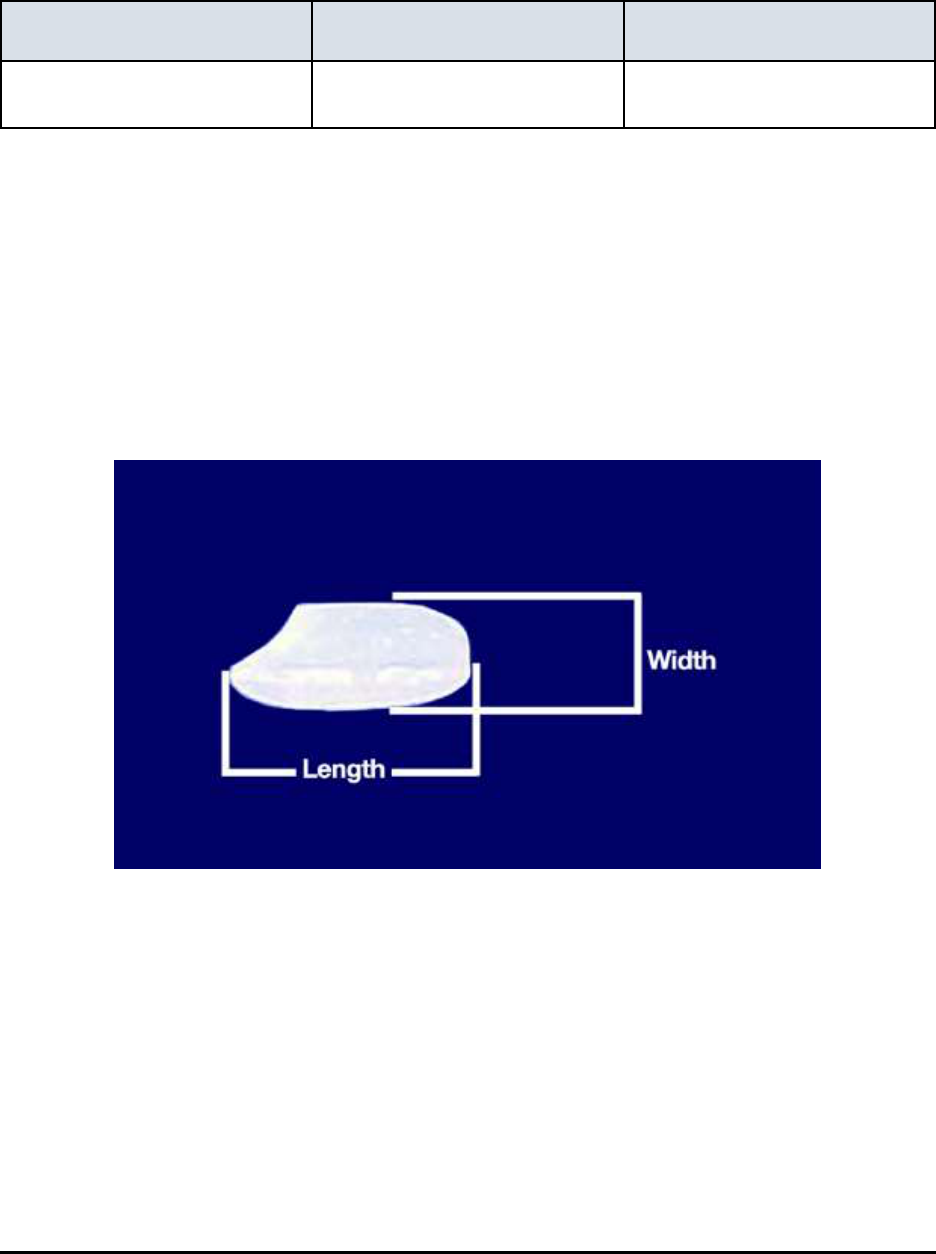

1.13 ORIGIN INSPECTIONS

a. Applicants may request that origin inspection certificates be issued which

show that their rice is a product of the soil and industry of the United

States.

b. When an origin inspection is requested, official personnel must follow the

below procedure:

(1) Request from the applicant all relevant records that may indicate

the origin of the rice;

(2) Obtain a representative sample; and

(3) Analyze the sample to verify that the rice compares favorably with

types of rice known to be grown in the United States. The

length/width ratios, size, shape, and other kernel characteristics

should be considered in making this determination.

c. If after reviewing the relevant records and analyzing the rice, there is no

indication that the rice is not a product of the soil and industry of the

United States, show the following statement on the certificate:

“The rice described herein and relevant records indicating the origin

of the rice have been examined, and the rice is found to be a

product of the soil and industry of the United States.”

d. When records are not available or if the records are not sufficient to

substantiate that the rice is a product of the soil and industry of the United

States, but the representative sample appears to be of a type of rice

common to the United States, the following statement may be shown on

the certificate:

“Applicant states that this rice is a product of the soil and industry of

the United States.”

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-25

1.14 COMBINED-LOT INSPECTIONS

a. Applicants may request a combined-lot inspection to be performed on

single lots of rice during loading, unloading, at rest, or after officially

inspecting and certifying rice as two or more single lots.

b. Requests for service must be in writing and include the following:

(1) The estimated quantity of rice that is to be certified as one lot;

(2) The contract grade, if applicable;

(3) The identity of each carrier into which the rice is being loaded or

from which the rice is being unloaded; and

(4) Any other relevant information that official personnel require.

Note: For recertification of single lots as a combined-lot, the

request for service must be filed no later than two business

days after the latest inspection date of the single lots.

c. Rice in two or more carriers that are to be officially inspected as a

combined-lot must be sampled in a reasonably continuous operation.

Representative samples must be obtained from the rice in each individual

carrier and inspected in accordance with the procedures as prescribed in

Chapter 2, Sampling, of this handbook.

d. Rice that has been officially inspected and certified as two or more single

lots may be recertified as a combined-lot if the following criteria is met:

(1) The rice in each single lot was sampled in a reasonably continuous

operation;

(2) The original inspection certificates issued for the single lots have

been voided by official personnel;

(3) Representative file samples of the single lots are available;

(4) The rice in the single lots is of one grade and quality;

(5) Official personnel who performed the inspection service for the

single lots and those who are to recertify the rice as a combined-lot,

determine that the samples used as a basis for the inspection of the

rice in the single lots were representative at the time of sampling

and have not changed in quality or condition; and

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-26

(6) The quality or condition of the rice meets uniformity requirements

established by Chapter 2, Sampling, of this handbook.

e. Official factor and official criteria information shown on a certificate for rice

in a combined-lot must be based on the weighted or mathematical

averages of the analysis of the sublots in the lot and must be determined

in accordance with the procedures shown in Chapter 7, Round-Lot

Inspection Plan, of this handbook.

f. If rice in a combined-lot is offered for official inspection as it is being

loaded aboard a carrier and the rice, or a portion of the rice, in a lot is

found to be infested, the applicant must be notified and given one of the

following options:

(1) Removing the infested rice from the lot;

(2) Receiving a grade certificate with a special grade or sample grade

designation, as appropriate, indicating that the entire lot is infested;

or

(3) For rough rice, fumigating the rice in accordance with FGIS

instructions and receiving a grade certificate without the special

grade designation.

g. Samples obtained from rice officially inspected as a combined-lot must be

examined for uniformity of quality. If the rice in the samples is found to be

uniform in quality and the rice is loaded aboard or is unloaded from the

carriers in a reasonably continuous operation, the rice in the combined-lot

must be officially inspected and certified as one lot. The requirements of

this paragraph, with respect to reasonably continuous loading or

unloading, do not apply to rice which is at rest in carriers when the rice is

offered for inspection.

h. When rice officially inspected as a combined-lot is found to be not uniform

in quality or if the rice is not loaded or unloaded in a reasonably

continuous operation, the rice in each portion, and any rice which is

loaded or unloaded at different times, must be officially sampled,

inspected, graded, and certified as single lots.

i. Each official certificate for a combined-lot inspection service must show

the identification for the “combined-lot” or, at the request of the applicant,

the identification of each carrier in the combined-lot.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-27

If the identification of each carrier is not shown, the following statement

must be shown on the inspection certificate, in the space provided for

“REMARKS”:

“Carrier identification available on official inspection log.”

j. If a request for a combined-lot inspection service is filed after the rice has

been officially inspected and certified as single lots, the combined-lot

inspection certificate must show the following:

(1) The date of inspection of the rice in the combined-lot (if the single

lots were inspected on different dates, the latest of the dates must

be shown);

(2) The location of the rice, if at rest, or the name of the facility from

which or into which the rice in the combined-lot was loaded or

unloaded;

(3) A statement showing the approximate quantity of rice in a

combined-lot;

(4) A completed statement showing the identification of any

superseded certificates; and

(5) A statement indicating that the superseded certificates have not

been surrendered must be clearly shown in the “REMARKS”

section of the certificate.

“This certificate supersedes Certificate No. , dated

. The superseded certificate has not been

surrendered and is no longer valid for commerce.”

k. After a combined-lot inspection certificate has been issued, there must be

no further combining and no dividing of the certificate.

l. Combined-lot inspection certificates must not be issued for the following:

(1) For any official inspection service other than as described in this

handbook; or

(2) Which shows a quantity of rice in excess of the quantity in the

single lots.

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-28

1.15 FACTOR ONLY INSPECTIONS

a. Applicants may request a factor only inspection to be performed on any lot

or sample of rice.

b. Requests for service must specify the factor(s) or other criteria for which

analysis is required. “Other criteria” includes, but is not limited to,

dockage, test weight per bushel, milling analysis, quantitative analysis,

and specifications prescribed by federal agencies, trade associations, and

contracts.

c. When requested, official personnel must follow the below procedures:

(1) Determine the factors results according to the procedures in

Chapter 3, Rough Rice; Chapter 4, Brown Rice for Processing; and

Chapter 5, Milled Rice, of this handbook, or as approved in specific

cases by the FGIS Deputy Administrator;

(2) Show the factor results on the inspection certificate according to the

procedures in Chapter 6, Certification, of this handbook; and

(3) The class of rice must be recorded on the grade line of the work

record and the official certificate. The type may be recorded on the

grade line upon request. (e.g., “Milled Rice” or “Long Grain Milled

Rice.”) A numerical grade will not be assigned on the grade line of

the certificate. Factors must be recorded on the work record and in

the “RESULTS” section on the official certificate.

Note: If a Submitted Sample does not contain a sufficient

amount of rice to perform an accurate and complete analysis

for an official grade, the request will be dismissed or a factor

only inspection may be performed upon request.

Note: Upon request, also show the following statement in the

“REMARKS” section:

“The quality of this rice, (show factor results that meet

or exceed the desired rice grade), are equal to or better

than the grade requirements of (desired grade).”

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-29

1.16 WITHHOLDING AND WITHDRAWAL OF AMA INSPECTION SERVICES

Procedures. Section 868.24 of the regulations under the AMA, provides for the

conditional withholding of inspection service for correctable causes, which can be

found in section 868.21, such as (1) failure to pay bills for inspection services, (2)

unsanitary plant conditions, or (3) plant conditions which would subject the

inspector to unusual hazard or discomfort.

a. Inspectors at the plant must report any such conditions to the field office or

cooperator as soon as possible.

(1) The final decision to withhold service must be made by the field

office manager or the cooperator manager.

(2) The field office manager or the cooperator manager may

conditionally withhold service upon notification to the applicant.

b. Section 868.25 of the regulations provides for the denial or withdrawal of

service due to (1) a willful violation of the AMA, regulations, or directives;

or (2) intimidation, threat, assault, or other improper action that interferes

with or obstructs official personnel in the performance of their duties.

(1) Denial or withdrawal of service requires that the applicant be

accorded due process and must, therefore be conducted by FGIS

headquarters in accordance with the Rules of Practice Governing

Formal Adjudicatory Proceedings Instituted by the Secretary of

Agriculture under Various Statutes (7 CFR Part 1, Subpart H).

(2) When circumstances warrant denial or withdrawal of service, the

field office manager or cooperator manager must report the

circumstances in accordance with FGIS Directive 9070.6,

“Reporting Violations of the U.S. Grain Standards Act, and The

Agricultural Marketing Act of 1946.”

Note: If a situation, such as assault, occurs that threatens the

safety of official personnel and also is a violation of the AMA,

the field office managers and cooperator managers may

withhold service on the grounds that official personnel are

subject to hazardous conditions. Such situations should be

reported in accordance with FGIS Directive 9070.6, “Reporting

Violations of the U.S. Grain Standards Act & the Agricultural

Marketing Act of 1946.”

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-30

c. Withholding Notice.

(1) When deemed necessary by the field office manager and

cooperator mangers, notify the applicant why service may be

withheld and afford the applicant time to correct the problem or

demonstrate why service should not be withheld.

(2) If a resolution is not reached, the field office manager or cooperator

manger must notify the applicant, in writing, of the decision to

withhold service.

(3) Use the following statements to notify the applicant that services

are being withheld. The wording of these statements may be

modified provided the meaning is not altered and the statement is

approved by the field office manager.

(a) Unsanitary or Hazardous Conditions.

“Pursuant to the 7 CFR Part 868 regulations under the AMA,

effective immediately, all services performed by this

(cooperator or field office, Service) at your (plant, mill, etc.)

are being conditionally withheld because of (unsanitary,

hazardous plant conditions). A written description of the

(unsanitary, hazardous condition(s)) will follow. Notify the

FGIS field office at (field office location) when you have

eliminated or corrected the specified (unsanitary, hazardous

condition(s)). If it is determined upon examination of your

(plant, mill, etc.) that these conditions have been eliminated

or corrected, inspection services will be restored immediately

or as soon thereafter as a sampler or inspector can be made

available. If you have any questions concerning this action,

contact the (field office location) Field Office. Copies of the

Part 868 regulations are being mailed to you today.”

(b) Nonpayment of Bills.

“Pursuant to the 7 CFR Part 868 regulations under the

Agricultural Marketing Act of 1946, effective immediately, all

services performed by this (field office, cooperator, Service)

for your account are being conditionally withheld because of

nonpayment of bills for services. Upon payment of these

delinquent bills, services will be restored immediately, or as

soon thereafter as a sampler or inspector can be made

available. If you have any questions concerning this action,

contact the (field office location) Field Office. Copies of the

Part 868 regulations are being mailed to you today.”

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-31

d. Reinstatement of Service Notice.

(1) If the conditions causing withholding of service are corrected,

service must be reinstated. The field office manager or cooperator

manager must notify the applicant, in writing, of the decision to

reinstate service.

(2) Use the following statements to notify the applicant that service will

be reinstated. The wording of these statements may be modified

provided the meaning is not altered and the statement is approved

by the field office manager.

(a) Unsanitary or Hazardous Conditions.

“On (date of withholding), the USDA, AMS, Federal Grain

Inspection Service, conditionally withheld services from your

(plant, mill, etc.) because of (unsanitary, hazardous)

conditions. Upon reexamination of your (plant, mill, etc.) on

(date), the specified conditions were found to be (corrected

or eliminated). You are hereby informed that services are

restored effective (immediately or give date).”

(b) Nonpayment of Bills.

“On (date of withholding notice), the USDA, AMS, Federal

Grain Inspection Service, conditionally withheld services

from your (plant, mill, etc.) because of nonpayment of bills

for services. These delinquent bills have now been paid and

you are hereby informed that services are restored effective

(immediately or give date).

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-32

1.17 WEIGHTS, MEASURES, AND CONVERSION FACTORS

Weights and Measures.

1 kilogram

=

2.2046 pounds

1 metric ton

=

=

=

=

2204.6 pounds

22.046 hundredweights

10 quintals

1000 kilograms

1 hectare

=

2.4710 acres

1 acre

=

0.40469 hectares

Rough Rice Conversion Factors.

1 hundredweight = 2.22 bushels = 0.617 barrel = 0.0453 metric ton

1 bushel = 0.45 hundredweight = 0.277 barrel = 0.0204 metric ton

1 barrel = 3.6 bushels = 1.62 hundredweight = 0.0734 metric ton

1 metric ton = 48.992 bushels = 13.609 barrels = 22.046 hundredweights

bushels per acre x 0.5044 = quintals per hectare

pounds per acre x 0.01121 = quintals per hectare

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-33

1.18 RICE INSPECTION SURFACES

Minimum picking surface size: 16" x 24"

Factors Determined on Approved White Surface:

(work surface Plexiglass White 7328 or P – 95 matte)

Foreign Material

Red Rice and Damage

Smutty Kernels

Heat

Seeds

Factors Determined on Approved Blue Surface:

(work surface any Dull Blue)

Chalky

Milling Yield

Well-Milled Kernels

Class

Other Types

Factors Determined on Approved White and/or Blue Surface:

Paddy

Unrelated Material

Related Material

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-35

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-37

Rice Inspection Handbook

Chapter 1: General Information

August 2020

1-38

Rice Inspection Handbook

Chapter 2: Sampling

August 2020

2-1

CHAPTER 2:

SAMPLING

CONTENTS

2.1 SAFETY ........................................................................................................ 2-3

2.2 REPRESENTATIVE SAMPLE ....................................................................... 2-8

2.3 DETAILED WORK RECORD ......................................................................... 2-8

2.4 CARRIER, CONTAINER, AND LOT IDENTIFICATION ................................. 2-10

2.5 ACCESSIBILITY .......................................................................................... 2-12

2.6 SAMPLE HANDLING AND SECURITY ....................................................... 2-15

2.7 PLANT SANITATION EXAMINATIONS ...................................................... 2-16

2.8 EXAMINATION OF FILLED CONTAINERS ................................................. 2-17

2.9 CONTAINER MARKINGS INFORMATION .................................................. 2-18

2.10 EXAMINATION OF CARRIERS (STOWAGE EXAMS) ............................... 2-21

2.11 FACILITY EXAM ......................................................................................... 2-23

2.12 EXAMINATION OF SAMPLE PORTIONS ................................................... 2-24

2.13 SAMPLING CONTAINERS .......................................................................... 2-25

2.14 SAMPLING BULK RICE AT REST .............................................................. 2-29

2.15 SAMPLING BULK RICE DURING MOVEMENT ......................................... 2-35

2.16 UNUSUAL CONDITIONS ............................................................................ 2-39

TABLE 2.1 - SAMPLING RATE .................................................................................. 2-25

TABLE 2.2 – PROBE SAMPLING SPECIFICATION CHART .................................... 2-29

TABLE 2.3 – ODOR CLASSIFICATION CHART ....................................................... 2-41

FIGURE 2.1 – HOPPER CAR SAMPLING PATTERN ............................................... 2-31

FIGURE 2.2 – BOXCAR, TRUCK, OR TRAILER SAMPLING PATTERN .................. 2-31

FIGURE 2.3 – HOPPER BOTTOM TRUCK SAMPLING PATTERN .......................... 2-32

Rice Inspection Handbook

Chapter 2: Sampling

August 2020

2-2

FIGURE 2.4A – DUAL HOPPER-BOTTOM TRAILER SAMPLING PATTERN .......... 2-32

FIGURE 2.4B – DUAL HOPPER-BOTTOM TRAILER, SINGLE-SIDE SAMPLING ... 2-32

FIGURE 2.5 – ROLL TOP BARGE SAMPLING PATTERN ....................................... 2-33

FIGURE 2.6 – LIFT TOP BARGE SAMPLING PATTERN ......................................... 2-33

FIGURE 2.7 - WOODSIDE-TYPE MECHANICAL SAMPLER .................................... 2-35

FIGURE 2.8 – PELICAN SAMPLER .......................................................................... 2-36

FIGURE 2.9 – ELLIS CUP SAMPLER ....................................................................... 2-37

Rice Inspection Handbook

Chapter 2: Sampling

August 2020

2-3

2.1 SAFETY

The safety requirements referenced in this section are mandatory for official

personnel

1

.

a. General. Comply with all FGIS safety requirements and the AMS Safety

Handbook, as well as all pertinent Occupational Safety and Health

Administration (OSHA) requirements (e.g., 29 CFR 1910-60).

(1) Obey all posted warning signs and wear appropriate protective

equipment when conditions warrant (e.g., hard hats and dust

masks).

(2) When necessary and practical, carry a communication device (e.g.,

two-way radio for communication).

(3) Before sampling railcars, check to see if a fall assessment is

required, in accordance with FGIS Directive 9170.14, “FGIS Rolling

Stock Fall Protections.” FGIS employees must complete Fall

Hazard Awareness Training in accordance with the directive. The

requirements of this directive apply to FGIS employees only.

Official Agencies may adopt this policy or use it as a guideline to

establish their own policy to comply with local and national safety

requirements.

b. Life Vests. Wear a U.S. Coast Guard approved Type I, II, III, or V PFD life

vest while aboard barges, launch boats, or other vessels (midstream or

dockside). Before putting on the life vest, inspect it for any potential

defects and to ensure proper fit.

Note: Life vests must be international orange in color, must contain

reflective panels, and must not be of an inflatable type. If used at

night, the vests must be equipped with a light and a whistle.

1

The requirements referenced in this section are mandatory for FGIS employees. All other are strongly

encouraged to also follow these guidelines.

Rice Inspection Handbook

Chapter 2: Sampling

August 2020

2-4

c. Clothing.

(1) Wear hard hats that meet the American National Standards

Institutes (ANSI) Z89.1 or Z89.2 criteria.

(2) Wear shoes or boots that have nonslip soles and definite heels for

good footing on ladders.

(3) Wear clothes that are reasonably close fitting to reduce the

possibility of becoming snagged on ladders or other structural

elements.

(4) Wear gloves when climbing ladders and opening or closing hatches

and doors.

Note: FGIS personnel must follow the clothing requirements

found in FGIS Directive 4735.2, “Uniform and Identity Apparel

and Dress Code Policy.”

d. Gangways and Ladders. Check the gangway before boarding or

disembarking barges and other vessels. Do not use defective gangways.

Exercise extreme care when using ladders that are permanently affixed to

the carrier wall. Do not hand carry sampling equipment, radios, or other

equipment while climbing ladders.

e. Chemical Treatments. Remain alert to your physical condition, especially

when drawing samples inside carriers. Rice is sometimes treated with

chemicals, usually for the purpose of controlling insect infestation.

Contact with toxic fumes or sprays from these chemicals can cause

serious injury or death. The following symptoms can be indicative of a

dangerous atmosphere:

(1) Shortness of breath;

(2) Light- headedness;

(3) Drowsiness; and

(4) Headache.

When any of the above symptoms are experienced, leave the area

immediately and seek medical attention.

Rice Inspection Handbook

Chapter 2: Sampling

August 2020

2-5

f. Transportation.

(1) Travel to and from barges at midstream and other vessels at

anchor via U.S. Coast Guard-approved launch, tugboat, licensed

water taxi, or by Federal Aviation Administration-approved

helicopter or air taxi.

(2) Do not jump on or off a barge or other vessel. You must be able to

step easily from the launch to the vessel (or vessel to the launch)

without stretching or straining over water; expect slippery or

obstructed deck conditions when boarding a vessel.

g. Dock Areas.

(1) While walking on a dock or wharf, be alert for loose or rotting

boards that may not support your weight.

(2) Learn the locations of life rings, emergency ladders, and

telephones.

(3) Stay clear of cables whether slack or under tension.

h. Boats, Barges, and Ships.

(1) FGIS employees must not board any launch boat service to board

any ships, barges, or floating rigs unless a licensed boat captain

and deckhand are present on board the launch vessel. Before

boarding the ship, barge, or floating rig, ensure that the deckhand is

nearby and ready to provide aid in an emergency.

(2) If the launch boat is not staffed with at least one captain and one

deckhand, inform the driver that you are unable to board for safety

reasons and contact your supervisor for further assistance. Upon

boarding the launch boat, familiarize yourself with the location of

any lifesaving devices and request instruction from the captain or

deckhand as to the proper use of such equipment.

(3) Do not probe sample barges at night unless the barge is docked

and sufficient artificial light is provided. Use caution when walking

on decks and barge tops since they are uneven, slippery when wet,

and have protruding cleats and latches. Do not remain on barges

while they are being moved and be aware of nearby barges, docks,

or vessels which could collide with the barge you are working on.

Do not permit hatches to be opened or closed while you are inside

the barge.

Rice Inspection Handbook

Chapter 2: Sampling

August 2020

2-6

i. Trucks.

(1) Do not walk through a break in a string of trucks separated by only

a few feet.

(2) Be alert to such hazards as moving trucks, cables, debris, metal

strapping, or broken ladders.

(3) Avoid breathing diesel exhaust fumes.

j. Railcars.

(1) Before entering a railyard, notify your immediate supervisor, the

yardmaster, or switch-crew foreman, and any other essential

persons of your presence. Do not sample railcars in a railyard

alone unless you are being monitored by someone who is in a

position to render aid if needed. (e.g., One of the two persons that

must be present may be an elevator employee.) Inquire about

possible switching activities, cars carrying hazardous cargo, and

any other unusual activity.

(2) Require that all activity cease on the track where they are working.

Require the track to be locked out, or derails installed at both ends

of the string of cars, or other appropriate, locally-approved

precautions (e.g., using blue flags with radio communication

between you and the switch engine driver, using one or more

additional employees as a safety observer to warn off approaching

railcars, or using blue flags and a lockout switch on an elevator hold

track where no railcar or switch engine movement takes place

during the performance of official functions).

(3) Do not probe sample railcars at night unless adequate artificial light

is provided. Do not walk on the rails; walk parallel to the set of

tracks and never between the two rails. Ensure that no power lines

are close enough to present a hazard (minimum safe distance - 25

feet vertically and horizontally).

(4) Check for placarded railcars. If a car is placarded or if a car is not

placarded and a fumigant odor is detected, withhold the inspection

(do not enter the car or sample the rice) and notify your supervisor

immediately.

Rice Inspection Handbook

Chapter 2: Sampling

August 2020

2-7

(5) Never crawl under railcars. Avoid climbing through railcars and

over couplings and never walk through a break in a string of railcars

separated by only a few feet (minimum safe distance - 20 feet). Be

alert to such hazards as moving railcars, cables, debris along

tracks, metal strapping, or broken ladders hanging from railcars.

(6) Be alert to seasonal conditions, such as icy walking surfaces in the

winter, and rodents, snakes, scorpions, wasps, and hornets in the

warmer months.

(7) Exercise caution when opening or closing car hatches or doors. If

a hatch or door is stuck, request assistance from the applicant.

Use a cutting tool or pry bar to break seals; do not use your hands.

(8) Do not ride on an engine or car being moved or switched. If a car

starts to move while you are on or inside, assume a sitting or

kneeling position on top of or in the car to avoid losing your

balance, and hold on. Do not attempt to descend a ladder or jump

to the ground until the car has stopped and you can do so safely.

Report all incidents of car movement to the yardmaster and your

supervisor. (Supervisors should also report such movements to

either OSHA or the Federal Railroad Administration.)

(9) Notify the yardmaster (or foreman) when you leave the work area

and report all “bad order cars” (e.g., missing ladder rungs, broken

doors) to the car owner, the railroad, or the applicant for inspection.

k. Warehouses. Watch out for forklifts and tow-motors. Also, be alert for

bags slipping (falling) from improperly stacked pallets and overhead

conveyor belts.

Rice Inspection Handbook

Chapter 2: Sampling

August 2020

2-8

2.2 REPRESENTATIVE SAMPLE

Obtaining a representative sample from a lot of rice is an important and essential

part of the rice inspection process. If the sample is not representative, the

inspector’s final determination will not reflect the true quality of the lot. For a

sample to be considered representative, it must be the following:

a. Obtained by official personnel in accordance with official procedures;

b. Obtained using FGIS-approved equipment (see the FGIS Equipment

Handbook);

c. Of the prescribed size (3,000 grams or more for rough rice and brown rice

for processing, and 1,500 grams or more for milled rice); and

d. Handled securely and protected from manipulation, substitution, and

careless handling.

2.3 DETAILED WORK RECORD

a. The accurate recording of the lot’s identity and its condition at the time of

sampling is essential to the correct certification of the lot’s quality.

Samplers must record all unusual conditions and other pertinent

information on FGIS-919, FGIS-992, or other applicable forms. If the

condition is not reported on the detailed work record, the lot could be

inadvertently graded incorrectly.

b. Detailed work records must contain the following information:

(1) The sampler’s signature or initials;

(2) The date the sample was obtained;

(3) The location of the lot of rice at the time of sampling (if the city and/

or state in which the sampling took place is not obvious, this must

also be shown);