2006 Environmental,

Safety, and Health Report

C2 2006 Environmental, Safety, and Health Report

This report summarizes Ingersoll Rand’s environmental, safety, and health (ESH) activities for 2006,

unless otherwise noted. The format is based in part on the Global Reporting Initiative (GRI) Sustainability

Reporting Guidelines. Additional information on topics in this report is available on our website.

Contact

For information on ESH performance, including copies of this report, contact:

Aaron Kleinbaum

Director of Environmental, Safety, and Health and Assistant General Counsel

Ingersoll Rand

155 Chestnut Ridge Road

Montvale, NJ 07645

201-573-3233

aaron_kleinbaum@irco.com

© Copyright 2007 Ingersoll-Rand Company

1 Chairman’sMessage

2 CompanyProle

4 ESHStewardshipthroughProductandServiceInnovation

12 VisionandStrategy

14 GovernanceStructureandManagementSystems

22 ESHPerformanceResults

30 ESHAwardsandRecognition

33 CommunityCommitment

37 ESH—LookingForward

2006 Environmental, Safety, and Health Report

InOctober2006,IngersollRandcelebrated100

yearsofcontinuouslistingontheNewYork

StockExchange—anotableachievementthat

speaksclearlytothelong-termsustainability

ofourcompany.Weachievedthismilestone

becauseofourvision,businessstrategy,and

ourpassionforInspiringProgress.

Everyday,IngersollRandemployeesare

innovating,applyingnewtechnologies,and

workingcollaborativelytoinspireprogress.

Becauseofthis,wecanchangetheworldfor

thebetter.Thisabilitymakesourcompany

betterabletoserveourcustomersandhavea

positiveimpactontheliveswetouchthrough

ourproducts,services,solutions,expertise,

andcitizenship.

Animportantcomponentofcitizenshipis

ourenvironmental,safety,andhealth(ESH)

practices.WehaveintegratedESHintoour

corebusinessstrategy.Ofthe19common

measuresweusetoevaluateourprogressin

criticaloperationalandnancialareasacross

eachofourbusinesses,twoareESHmeasures:

lostworkdaycaserateandtotalhazardous

waste.Thesemeasuresfunctionasadiagnostic

opportunitytoadjustouractivitieswhen

necessary.Asaresult,wecanensurethatESH

managementisintegratedwithouroverall

enterpriseperformanceandourlong-term

businessgoals.

IngersollRandiscommittedtoinvesting

signicantlyinproductdevelopment,

includingsolutionsthatimproveefciencyand

deliverenvironmentalbenets.Onerecent

innovationisaThermoKingauxiliarypower

unitthatpowerstheairconditioning,heating,

andelectricalappliancesinthecabofatruck

whenitisparked,eliminatingtheneedto

continuouslyruntheengine.Thisnewproduct

reducesfueluseandvehicleairemissions,

helpscustomerscomplywithanti-idlinglaws,

andimprovesdrivercomfort.Thisproductis

oneofmanyhighlightedinthisreportthat

demonstratethestrongconnectionbetween

ESHleadershipandbusinesssuccess.

Inadditiontodescribingsolutions

thathelpourcustomersconserveenergy,

thisreporthighlightsproductsthatare

ergonomicallyinnovativeandpromotethe

healthandsafetyofourcustomersand

consumers.Ourcoldchainproductskeepfood

safefromthefarmtotheretailstore.Andour

industrialequipmentperformsavitalrolein

thedevelopmentandgrowthofeconomies

throughouttheglobe.

Asaglobalcitizen,wetakeseriouslyour

responsibilitytobeagoodstewardofthe

naturalenvironment,tobeagoodneighbor

tothecommunitiesinwhichweoperate,

andtoprovideasafeandhealthyworkplace

forouremployees.Thisreportreectsour

commitmentaswecontinuetoimproveour

facilityESHperformanceandmanagement

systems.

Iencourageyoutoreadthisreportto

learnmoreaboutIngersollRand’sESHgoals,

programs,andperformance.ESHcitizenshipis

drivenbythevaluesthatdeneourcompany:

integrity,respect,teamwork,innovation,and

courage.ESHmanagementisakeycomponent

ofourbusinessstrategyandourpassionfor

InspiringProgress.

IwelcomeyourinterestinIngersollRand

andourjourneytoESHexcellence.Your

feedbackonthisreporthelpsuscontinueto

innovateandimprove.

Sincerely,

Herbert L. Henkel

Chairman, President and

Chief Executive Ofcer

Chairman’s Message

2 2006 Environmental, Safety, and Health Report

About Ingersoll Rand.Today,weprovide

products,services,andintegratedsolutions

toindustriesrangingfromtransportationand

manufacturingtofoodretailing,construction,

andagriculture.Ourdiversicationisreected

inthedepthofourportfolioofmarket-leading

industrialandcommercialbrands.These

brandsincludeBobcatcompactequipment;

ClubCargolfandutilityvehicles;Hussmann

stationaryrefrigerationequipment;Ingersoll

Randindustrialandconstructionequipment;

Schlagelocks;andThermoKingtransport

temperature-controlequipment,amongothers.

Weinspireprogressbyunleashingthe

potentialinpeopleandtechnologies.We

dothischieythroughourtechnological

innovations,whichhelpcompaniesworldwide

tobemoreproductive,efcient,andsecure.

Ineverylineofourbusiness,IngersollRand

helpsourcustomerscreateprogress.

Company Profile

Since its inception a century ago, Ingersoll Rand has

focused on results. We create products and services that

have a positive impact on industries, on economies, and

most importantly, on our customer. We’re proud of our

heritage of inspiring progress across diverse industries,

stewarding the world’s environmental resources

responsibly, and ensuring the safety and health of our

employees.

2006 Environmental, Safety, and Health Report

Our Values

Ourvaluesrepresentthehighstandardsto

whichweholdourselvesinoureveryday

operationsatIngersollRand.Allbusiness

decisionsaremadewithconsiderationgivento

thesebasicprinciples:

Integrity. Weactinthehighestlegaland

ethicalstandardsineverythingwedo.

Respect.Wecommunicateandactin

waysthatrespectandvaluetheworth

ofallpeople,cultures,viewpoints,and

backgrounds.

Teamwork.Weworktogetherandshare

resourcestoprovidegreatervaluetoour

customers,employees,businesspartners,

andshareholders.

Innovation. Weuseourdiverseskills,

talents,andideastodevelopinnovative,

imaginative,andcreativesolutionsto

challenges.

Courage. Wespeakupforwhatisrightand

takemeasuredriskssoourcompanycan

thrive.

•

•

•

•

•

Global Operations

IngersollRandmaintainsmanufacturing

facilities,warehouses,ofces,andrepair

centersthroughouttheworld.Weemploy

approximately40,000peopleworldwide,

approximately19,000ofwhomworkin

theUnitedStates.Tosupportourgrowth

outsideNorthAmerica,wehaveexpanded

ourmanufacturingcapabilitiesinkeyglobal

regionsthroughacquisitionsandinvestments

inChinaandothercountries.

In its “Global Most Admired Companies 2007” feature, FORTUNE magazine ranked Ingersoll Rand

number 6 in its category. To arrive at the industry category rankings, the Hay Group, a management

consulting rm, started with the FORTUNE 1,000 – the 1,000 largest US companies ranked by revenue

– and the top foreign ones operating in the US. Hay sorted them by industry and selected the ten largest

in each. To create the 63 industry lists, Hay asked executives, directors, and analysts to rate companies in

their own industry on eight criteria, from investment value to social responsibility using a scale from 1 to

10. Only the best are listed as most admired: A company’s score must rank in the top half of its industry

survey. Ingersoll Rand’s overall score was 6.25.

Sales (in billions)

2002 $8.6

2003 $9.0

2004 $9.4

2005 $10.5

2006 $11.4

2006 Revenues by Sector (in billions)

Climate Control Technologies $3.2

Compact Vehicle Technologies $2.6

Construction Technologies $1.4

Industrial Technologies $1.9

Security Technologies $2.3

Number of Manufacturing Facilties by Sector

US Outside US

Climate Control Technologies 9 14

Compact Vehicle Technologies 3 2

Construction Technologies 3 3

Industrial Technologies 11 14

Security Technologies 10 20

2006 Environmental, Safety, and Health Report

Acrossthecompany,IngersollRanddevelops

productsandservicesthathelpbusinesses

toreduceenergyconsumptionandcosts,

decreaseharmfulenvironmentalemissions,

andprotecthumanhealthandsafety.Inthis

report,wehighlightsomeofthedozensof

technologiesandservicesIngersollRandhas

pioneeredinrecentyears.Frommicroturbines

thattransformmethanegasintopower,to

antiviral,antibacterial,andodorprotection

forbusandrailpassengers,IngersollRand

providestechnologiesandservicesthatreduce

ESHimpactsacrossarangeofglobalmarkets.

Eachofourbusinesssectorspromotes

ESHstewardshipthroughproductandservice

innovation.Inthisreport,wedescribehow

theseproductsandservicesareenabling

businessestoreducetheirESHimpacts.And

wetouchuponwaysthattheseinnovations

areshapingthelifestylesandlivelihoods

ofthepeoplewhomakecontactwiththem

aroundtheworldeachday.Throughour

productsandservices,IngersollRandis

helpingbusinessescontributetoeconomic,

social,andenvironmentalprogress.

Climate Control Technologies

TheClimateControlTechnologiesSector

providesequipmentandservicesfortransport

andstationaryrefrigerationthatincrease

energyefciency,reducefuelconsumption

andemissions,andremovecontaminantsfrom

enclosedspaces.

Hussmann’sImpactExcellowtemperature

displaycasesformerchandisefeature

technologythatenables15percentgreater

energyefciencyonaveragethanour

standardmodels,and21 percent greater

efciencyonaveragethanthecompetition.

EachdisplaycaseincludesHussmann’s

fulllength,continuous-tubecoilsthatare

designedtolowerenergycostsandreduce

refrigerantleaks.Dischargeairlouvers

furtherreduceenergyconsumptionby

decreasingturbulence.

Hussmannhasintroducedanintegrated

nightcurtainforuseinmediumtemperature,

multi-deckmerchandisers.Thenightcurtain

cuts energy use by about 41 percentwhile

thecurtainisdown,orbymorethan12

percentoverallifthecurtainisused6hours

perday.Anintegratedchannelfullyconceals

thecurtainwhennotinuse.

•

•

ESH Stewardship through

Product and Service Innovation

Through our products and services, we help companies

become more efficient, innovative and successful.

“All of us have a role to play

in making our company, our

communities, and our planet

as safe and environmentally

sound as they can be.”

— Herbert L. Henkel

Chairman, President and CEO

2006 Environmental, Safety, and Health Report

TheHussmannProtocolHEdistributedre-

frigerationsystemis20percentmoreenergy

efcientthantheexistinglow-temperature

Protocoldesign.Theproprietarydesign

reduces the refrigerant charge by 60 to

90 percentwhencomparedtoastandard

parallelrack.NamedaftertheMontreal

Protocol—therstworldwideagreement

tophaseoutchlorouorocarbon(CFC)

use—theProtocolHEhasbeendesignedto

reducetheamountoftubingjoints,thereby

decreasingthelikelihoodofrefrigerantleaks

throughoutthesystem’slife.

Comparedtostandarddoors,Impact

InnovatordoorsonHussmannrefrigeration

unitsprovide25percentenergysavings,

andImpactInnovatorIIdoorsprovide40

percent energy savings.

ThermoKingpackageselectricheating,ven-

tilating,andairconditioning(HVAC)tech-

•

•

•

nologyasasolutiontohelpreduceengine

emissionsfrombuses.Busmanufacturersin

theUnitedStateshavebeendevelopinghy-

bridvehiclesformorethantenyearsusing

acombinationofbatterypacksandsmaller

engines.Thesuccessfulapplicationofall-

electric HVAC systems further reduces

emissionsbyusingsmallersystemsthat

canrunataconstantcapacityregardless

ofenginespeed.Becausethesesystemsare

sealedandtestedatthefactorylikeahome

refrigerator,reliabilityisimprovedwhile

maintenanceandrepaircostsarereduced.

ThermoKing’sairqualityandair

puricationinitiativesaddressoneofthe

public’stopindoorairqualityconcernsby

developingproductsthatprovideantiviral,

antibacterial,andodorprotectionforbus

andrailpassengers.Threeinitiativesare

currentlybeingtestedandevaluated.The

•

Long-haul tractor-trailer rigs waste more than 800

million gallons of fuel each year in the US idling

at truck stops while their drivers sleep and rest, as

required by local and federal regulations. Recognizing

the huge burden these restrictions impose on truck

and bus companies, Ingersoll Rand business unit

Thermo King, a leading developer of refrigeration

systems for transporting food and other perishable

goods, introduced the TriPac Auxiliary Heating/Cooling

Temperature Management System in 2005 to its US

network of 200 factory-authorized service dealers.

The TriPac eliminates the need to idle truck and

tractor engines for heating, cooling, and powering

accessories in the cab or sleeper compartment. The

TriPac consumes up to 85 percent less fuel than diesel

engine idling, reducing long-haul tractor-trailer idling

emissions and alleviating trucking companies of the

nancial burden of today’s high fuel costs. With the

new technology, owner operators can save hundreds

of dollars a month in fuel costs. Depending upon how

much time a truck spends idling and other factors,

customers can gain a full return on their investment

to purchase the technology within 18 months through

savings in energy costs alone.

Smitheld Transportation Co. and its Packerland

Transport subsidiary have purchased close to 200 TriPac

units to reduce engine idling by tractor eets.

“Before TriPac, we were

averaging 40 to 50 percent

idle time. Now, we’ve reduced

idle time to basically nothing.”

—Ralph Moyle, Inc.

Ingersoll Rand customer

2006 Environmental, Safety, and Health Report

rstinitiativeisanewproductnamed

EnviroFreshthatisdispensedthroughthe

HVACsystemforodor control and anti-

bacterial protection.Theactiveingredients

inthisproductareknowntohaveanti-viral

capabilityaswell.Thesecondinitiativeisthe

applicationofultravioletlight,whichcankill

harmfulbacteriaandvirusesintheair.The

thirdinitiativeaddressesairltrationwith

theuseofnewhigh-airow,low-micron

lteringmedia.Themediawilltrapmore

andnerparticulatesoveralongerperiodof

timewithlessreductioninairowcompared

toconventionallters.Thelteringmedia

canalsobetreatedwithanti-microbial

substancesthattrapandneutralizeairborne

microbes.

ThermoKing’sinnovativetransport

refrigerationequipmentenablesfood

distributorstoaddressenvironmental

concernssuchasatmosphericozone

depletion,noise,anddieselfuelemissions.

ThermoKing’scryogenic-poweredSB-III

CRtemperaturecontrolsystemusescarbon

dioxide,anaturallyoccurringrefrigerant,for

heatingandcooling.Thissystemeliminates

the need for, and emissions of, ozone-

depleting commercial refrigerantsand

allowsrefrigerationequipmenttooperate

withoutrunningadieselengine.

ClimateControl’sservicebranchesprovide

anauditserviceformonitoringenergy

consumption.Theyassessefciencies

inrefrigeration,lighting,andother

electric-poweredequipment,revealing

opportunities to reduce electrical costs.

•

•

Industrial Technologies

TheIndustrialTechnologiesSectorisa

collectionofbusinessesthatprovideproducts

andsolutionstoenhanceindustrialefciency

andworkersafetyandofferenvironmental

benetsthroughwastereduction,pollution

prevention,andenergy-efcientpowerand

equipment.

TheAirSolutionsnitrogentireination

system,NitroFill,helpsdeliverfuel

efciency.Industryandgovernmentstudies

suggestthattireslledwithcompressed

nitrogenratherthancompressedairhold

theirpressurelonger,whichimproves

gasmileagebyasmuchas4percent.The

NitroFillsystemalsoprovidessafetybenets

astiresthatholdtheirpressurelonger,

handlebetter,andminimizetheriskof

catastrophicblowouts.Thesamestudies

alsosuggestthatnitrogen-inatedtireslast

upto40percentlongerthanthoselled

withregularcompressedair.Longertirelife

meansthatfewertiresendupaswaste.For

commercialtireusers,nitrogenhelpsreduce

theamountoftimeneededbetweentire

re-treadingorreplacement.Consideringthat

tiresareessentiallypetrochemicalproducts,

itmakesevenmoresensetoextendthe

lifeofatire.AccordingtotheTireRetread

InformationBureau,ittakesapproximately

7gallonsofcrudeoiltoproducealarge-size

tireretread,andmorethan22gallonsto

manufactureanentiretire.Inatingtires

withnitrogencansave millions of gallons

of crude oil every year.

IngersollRandistheleadingsupplierof

HeatofCompressionAirDryers.Thisunique

•

•

2006 Environmental, Safety, and Health Report

productprovides clean dry air while

consuming less power than a light bulb,

allowingourcustomerstogreatlyreduce

theirpowerconsumption.

Thecompany’sNirvanavariablespeeddrive

aircompressorhasfewerrotatingpartsthan

anyotheraircompressorinitsclass.Ina

conventionalaircompressor,startingupthe

drivemotorcreatesanenormousenergy

draw,whichcanbeasmuchas800percent

ofthefull-loadnormalrunningcurrent.

Nirvana’sHybridPermanentMagnet®motor

anddrivesystemlimitsthein-rushcurrent

tolessthan100percent.Thesignicant

decreaseinstartingamprequirements

•

minimizespeakcharges,leading to reduced

energy use and cost.

AirSolutionsalsoprovidesuniqueaudits

ofcustomeraircompressorsystems.These

auditstypicallyrevealwaystolower

energy use and costs throughimproved

systemdesign.

IngersollRandwasselectedtobethesole

providerofcompressedairsystemsfor

Tereos,aFrenchcompanyspecializinginthe

conversionofsugarbeetsintosugar.Tereos

purchasedthreeaircompressors,chemical

absorptiondryers,andaremotecontrol

systemforthenewbio-fuelproductionplant

inReims,France.Franceisaggressively

•

•

With ever-mounting pressures on the energy grid,

more companies are turning to onsite electricity

generation, also known as distributed generation (DG)

technologies, as a source of environmentally friendly

alternative energy.

Ingersoll Rand, through its Energy Systems business,

is a leading pioneer of microturbines, the cleanest-

burning type of combustion DG technology.

Microturbines combine a gas-turbine engine,

recuperator and generator as an integrated system

that converts fuel into electricity and thermal energy.

Ingersoll Rand microturbines, which are available

in 70-kilowatt and 250-kilowatt models, have been

engineered to produce electricity from a wide range

of fuels, such as methane waste gases that emanate

from landlls and wastewater treatment plants, and

high-energy associated gases generated during oil

production.

Ingersoll Rand microturbines also can harness and use

thermal heat produced during energy generation. This

heat can be circled back into the generator to promote

its efciency, as well as to heat water and power other

onsite processes. Combined heat and power (CHP)

applications can be as much as 50 percent more energy

efcient than conventional energy generation systems.

Microturbines are also a source of interest in

developing regions of the world, particularly in Asia.

China, India, Thailand, Malaysia, Indonesia, and

Singapore have begun to implement DG policies

that favor the use of technologies that enhance

power reliability, reduce energy costs, and improve

environmental conditions.

The city of Shanghai, China, for instance, has

implemented a policy supporting high-efciency CHP

projects. The government will allow connection to the

grid, provide gas price subsidies, and reduce import

duties for qualied projects. In 2006, Ingersoll Rand

became the rst DG company to receive grid-parallel

permitting from the government with a microturbine-

based CHP project at the Minhang Industrial Estate.

An Ingersoll Rand microturbine-powered installation

received a 2005 CHP Partnership certicate of

recognition from the US Environmental Protection

Agency (EPA). The CHP system is used in high-rise

apartment buildings for regulating electric and hot

water demands. The CHP system is powered by an

Ingersoll Rand natural gas-red microturbine. Heat

recovered from the microturbine’s exhaust and lube oil-

cooling circuit is used to produce hot water. The system

reduces carbon dioxide emissions by an estimated 100

tons per year.

The Ingersoll Rand 250-kilowatt microturbine system

became the rst microturbine to be certied as

complying with the California Air Resource Board’s

2007 emissions standards for DG technologies.

Compared with a typical utility scale power plant

generating the same amount of electricity, the

microturbine reduces emissions of nitrogen oxides by

more than two tons

annually.

A microturbine at a

wastewater treatment plant in

California

2006 Environmental, Safety, and Health Report

seekingalternative energy options to

replace fossil fuels.

EnergySystemsoffersclientsenergysavings

andenvironmentalbenetswithnorisk

throughinnovativeEnvironmentaland

EnergyServicesAgreements.Industrial,

commercial,andenvironmentalusers

canbenetfrompower security and

controlled energy costswhilecontributing

toacleanerenvironment.

ProductivitySolutionsoffersanoil

dispensingandevacuationunitthat

improvesanautomobiledealership’sability

tocomplywithenvironmentalregulations

andeliminate oil spillage in its facilities.

IngersollRandairstarters,fromProductivity

Solutions,provideanecologicaladvantage

overelectricstartersinavarietyof

applications,includingon-andoff-highway

vehicles,oilandgas,powergeneration,

marine,rail,andmining.Inaddition

•

•

•

toprovidingthemostreliablestarting

performance,airstartersoutlastelectric

starters3:1,aswellasreduce battery usage

and disposal.Byeliminatingexposure

tosparksfromelectricalsystemsand

optionalgas-sealedmodules,airstarters

arethesafeststartingmethod.Withtoday’s

increasinganti-idlinglawsforbusesand

trucks,theairstarter’sruggeddesignallows

forincreasedstartingfrequencyandreduced

emissionstotheenvironment.

ProductivitySolutionsoffersmany

ergonomicimprovementsthroughthe

Zimmermanhandlingsystems,ErgoPower

Tools,AROandIngersollRandbalancers,

andotherequipment.Forexample,Ingersoll

Randmanualhoistshelp prevent worker

injuriesfromliftingheavymaterials.

OtherIngersollRandequipmenthelps

autoindustryemployeesbemoreefcient

andreducestheriskofinjuriesassociated

•

Ingersoll Rand Air Solutions is the rst manufacturer in

the world to be certied Class

Zero for centrifugal air

compressors. Concurrently, Ingersoll Rand has received

Class Zero certication in their oil free rotary screw line

of compressors. The certications were granted to the

entire range of Ingersoll Rand air-cooled and water-

cooled oil-free rotary screw compressors (37 to 350kW)

and water-cooled, oil-free centrifugal air compressors

(160 to 5000 kW) by TÜV Rheinland®, an independent

testing and assessment agency.

The most stringent of all ISO 8573.1 classications,

Class

Zero certication was added in 2001 in response

to critical applications where air purity is essential, such

as the pharmaceutical, food and beverage, electronics

and textiles industries. The certication recognizes

compressors that discharge air free of added oil

aerosols, vapors and liquids.

“The rigorous tests performed by TÜV Rheinland show

our commitment to providing best-in-class equipment

for our customers,” said Eric Seidel, General Manager

for Ingersoll Rand Industrial Air Solutions Business

Unit. “The Ingersoll Rand Class

Zero solution means

lower operating costs, improved productivity and risk

avoidance.”

With maintenance expenses comprising a signicant

percent of lifecycle cost, Ingersoll Rand oil-free

centrifugal and rotary screw air compressors enable

plants to better manage operating costs, minimizing

the need for coolant oil, inline lters and oil / air

separator components. By eliminating the risk

of compressor-created contaminants, air system

components last longer and ensure higher quality air.

Ingersoll Rand oil-free technology also helps

companies avoid risk. Oil-contaminated air can spoil

and ruin products, creating signicant losses of

revenue and customer trust. High-quality air reduces

liability and the potential of product recalls.

Certied Class

Zero air compressors deliver consistently

clean air to critical applications. By providing pure

air, free from additional contaminants, Ingersoll Rand

compressors minimize downtime associated with

cleaning lters and other air system components.

Oil-free technology increases productivity and ensures

higher overall product quality.

Ingersoll Rand oil-free rotary screw and centrifugal

air compressors also help manufacturers comply with

environmental standards such as ISO 14001 and EU

requirements. Because the compressors are oil-free,

manufacturers do not encounter disposal issues with

waste oil and ltration components. Disposal of air

compressor condensation can also be an issue in

lubricated compressors. By creating a clean condensate

that is easier to dispose, oil-free compressors don’t

require special treatment for oil and water mixtures.

2006 Environmental, Safety, and Health Report

withtheuseofweldguns.Inaddition,

safetyfeaturesonthecomputerizedtorque

wrenchrelievestrainandcanhelptoreduce

repetitivemotioninjuries.

Withworkplacesafetyandliabilitya

constantconcernformanufacturers,

IngersollRandhaslaunchedatoolsafety

programfeaturingagrindersafetyvideo,

brochure,andworkplaceposters.The

18-minutevideofocusesonpotential

risks,preventivemeasures,andtherole

operatorsplayinworkplacesafety.The

programisavailableinsixlanguagesand

includesinformationoncodes,standards,

anddocumentation;personalprotective

equipment;airdeliverysystemsafety;

abrasivewheelhandlingandmounting;

protectivegrinderfeatures;andsafegrinding

techniques.Preventableaccidentsaresimply

unacceptableinindustrytoday;Ingersoll

Randwillcontinuetoimprove product

safetyandprovideprogramssuchasthis

onetohelplimitfutureaccidents.

•

Compact Vehicle Technologies

TheCompactVehicleTechnologiesSector

providesversatile,compactvehiclesand

machinesforconstructionandforefcient

movementofpeopleandgoods.Thesectorhas

focusedonreducingtheenvironmentalimpact

ofitsvehicles.

ClubCarsellsremanufacturedgolfcars.Not

onlydoesthisprovidealow-costoptionto

purchasers,itextends the useful life of

vehiclesaftergolfcourseleasesexpire.

BobcatK-Seriesloadersfeaturethe

SmartFANcoolingsystem—ahydraulically

drivencoolingfanthatsensesmachine

operatingtemperaturesandthenself-

regulatestorotateonlyasfastasneeded.

Thetemperature-controlled,variable-speed

fanoptimizesthecoolingneedsoftheloader

andcanbe30 percent quieterinsome

operatingconditions,whichisbenecialto

bothoperatorsandbystanders.

Bobcatofferspuriermufersformuch

ofitsequipment.Thesemufersreduce

certain harmful exhaust emissions.

•

•

•

Given the increase in energy prices and heightened

environmental concerns, Club Car has been at the

forefront of producing innovative technologies that

reduce the use of gasoline and in turn reduce harmful

environmental emissions. The new electrical drive,

called IQ Plus, provides power and performance similar

to gasoline-powered engines. Benets of the system,

compared to earlier electric drive vehicles, include

longer range, increased top speed, better hill climbing

ability, more customization of settings, and improved

diagnostics.

Club Car’s system is unique in delivering power and

reliability versus a gasoline-powered car with faster

charge times that equate to fewer recharges to operate

the vehicle. The Club Car IQ Plus system has the

signicant environmental benet of producing no

direct emissions.

Club Car has also created a Carryall utility vehicle

with the ability to run electric-powered outdoor

maintenance equipment. The one-of-a-kind unit is

completely electric and has no direct emissions. This

“Green Vehicle” was created to help New York Power

Authority employees maintain a state park. It can

power electric lawn mowers, hedge trimmers, weed

whackers, and leaf blowers.

In addition, Club Car provides comprehensive energy

management services addressing all aspects of a golf

course owner’s energy use. The Club Car system helps

owners recharge their eets during off-peak hours

when utility demands (and rates) are lowest. The

system typically yields savings of hundreds of dollars

a month.

In early 2006, Club Car launched an online Energy Cost

Estimator tool on its website (www.clubcar.com) to

help eet golf car and utility vehicle owners as well as

golf course operators calculate the cost of ownership

for gasoline versus electric golf cars.

Club Car’s Carryall 2 Plus utility vehicle

0 2006 Environmental, Safety, and Health Report

MostBobcatproductsareequippedwith

sparkarrestormufersapprovedbytheUS

DepartmentofAgriculture.Theseminimize

the risk of creating a potential re

hazardincertainworkenvironments.

Bobcatusespowdercoatpaintonitsprod-

ucts,aprocessthatresultsinvirtually no

hazardous wasteatthepointofmanu-

facture,aswellasnonhazardouspropylene

glycolinmachinecoolingsystems.

Bobcatmachineshaveavarietyoffeatures

specicallydesignedforoperatorsafety:

roll-overprotectivestructuresandfalling

objectprotectivestructures;various

patentedlock-outsystems;skid-resistant

steps,treads,andgrabhandlesforentering

andexitingmachines;andpatented

secondaryrestraintsystems(seatbars)

andseatbelts.TheexclusiveBobcatdeluxe

instrumentpanelincludesakeylessstart

securitysystem,functionlockouts,and

catastrophicfailureshutdownsystems—all

ofwhichprovidesafety advantages.The

panelcanreportthisinformationineight

differentlanguages.

Bobcatoffersoperatorandservicesafety

training kitstoownersandoperators,

promotingproperuseofmachinesinEnglish

andSpanish.

BobcatoffersadedicatedTrainingResources

website,providingpublic access to all of

its training materials(www.bobcat.comor

training.bobcat.com).

•

•

•

•

•

Construction Technologies

TheConstructionTechnologiesSectorprovides

equipmentthatsupportsresponsibleESH

performanceintheconstruction,renovation,

andrepairofpublicworksandprivate

projects.

Lighttowersprotect the safety of

construction workersatnight.Product

innovationsincludeeffortstoreduce

ambientlightpollution.

AnewlineofPowerSourcemobile

generatorsintroducedin2006has

environmentallyresponsiblefeatures,

includingnoisereductionanduid

containment.ThePowerSourcelineisthe

onlyoneintheindustrytooffervoltage

selectorswitchprotectionwithanautomatic

shut-off.PowerSourcegeneratorsfeature

environmentalskidbasesthatprovidea

minimum 110-percent containment of

all generator uids for cleaner, safer

worksitesandreducedpotentialfor

environmentalcontamination.Allcontrols

andconnectionpointsaregroupedinan

ergonomicallydesignedpowerpedestalfor

convenienceandsafety.

•

•

2006 Environmental, Safety, and Health Report

When teachers and school

police ofcers train at the

Safe Schools Institute in

Boca Raton, Florida, US, they

also receive an education

on products offered by

Ingersoll Rand Security

Technologies. The institute’s

campus includes the Don

Estridge High Tech Middle

School which is a showcase

for cutting-edge teaching

technologies and cutting-

edge safety and security. The

classes at Don Estridge are

monitored from the institute,

via cameras, for training

educators, administrators

and school police ofcers

on how to offer the safest

academic environment

possible. The school is

equipped with a number

of Security Technologies

offerings, including Schlage

VIP locksets, Recognition

Systems HandKey II biometric

handreaders, and Schlage’s

Security Management

Software (SMS). The SMS

system controls the classroom

doors and monitors the

school’s security cameras.

Security Technologies

TheSecurityTechnologiesSectorprovides

productsandsolutionstoenhancethesecurity

andsafetyofresidential,commercial,and

industrialfacilitiesandequipment.

Whenconsideringexitdevices,safetyis

thenumberoneconcern.Evenwithadoor

loadedto250pounds,theVonDuprin

XP98/99requireslessthan40poundsof

pressuretoopen.Thatis25percentlessthan

theUSrecoderequires.Inanemergency

situation,peoplecanmore easily get to

safety.TheXP98/99hasastaticloadforce

resistanceofmorethan2,000pounds—twice

thatofcompetitiveexitdevices.The“smart”

latchchangesshapewhensubjectedto

externalforces.Thisnewdesignenablesthe

exitdoortowithstandanexternalattackand

remainsecure.Additionally,thepatented

latchboltdesignprovidesagreater,long-

lastinglatchbolt/strikecontact—noteasily

affectedbythetwistingmotionofaweak

frame—resultinginanopeningthatremains

strong.

•

OthersafetybenetsofSecurity

Technologiesproductsincludesafe egress

during res or other emergencieswith

VonDuprinpanicbarsandenhanced

personal safety and securitythrough

locksandlocksets,doorclosers,steeldoors

andframes,portablesecuritydevices,

electronicandbiometricaccesscontrol

systems,andclosed-circuittelevision

monitoring.

NORMBAU,partofSecurityTechnologies,

istherstworldwidemanufacturerto

offerarchitecturalhardware,bathroom

accessoriesandttings,andtoiletpartitions

withlong-lasting,effectiveantibacterial

protection.NORMBAUincorporates

Microban®antibacterialprotectionintothe

polymerstructureofthenylonduringthe

productionprocess.Itcannotbewashed

awayorrubbedoff,andremainscontinually

activetoensurethattheantibacterialeffect

remainsforthedurationoftheproduct’s

lifecycle.Thehomogeneousdistributionof

theagentthroughouttheproductprovides

effectiveandlong-lasting prevention of

germ build-up,signicantlyreducingcross-

contaminationfromcontactareas—even

inthemostinaccessibleplaces.Thevicious

cycleofcontinualgermtransmissioncan

therebybebrokeninaneffectivemannerin

placessuchasschoolsandhospitals.

•

•

2 2006 Environmental, Safety, and Health Report

Our Business Vision

OurpursuitofDramaticGrowthisbased

onourcommitmenttodevelopingnew,

innovativesolutionsforourcustomers.In

addition,DramaticGrowthinvolvesthepursuit

ofmarketshareandrevenuegrowththrough

strategicacquisitionsthatexpandourproduct

offeringsandenhanceourcompetitiveness.It

alsoinvolvesthegrowthofrecurringrevenues

fromaftermarketpartsandinstallation,

maintenance,andotherservices.

OperationalExcellenceisastrategythat

aimstoimproveoperatingperformance.By

pursuingcontinuousimprovementinallofour

operationsthroughinitiativessuchasLeanSix

Sigma,weintendtocontrolcostsandimprove

efcienciesforgreatercashowsfrom

operationsandoperatingprot.

DualCitizenshipisourtermfor

collaborationamongourpeopleandour

businesses.ThroughDualCitizenship,we

areunleashingthecollectivestrengthofthe

enterprisebyworkingcollaborativelyacross

ourbusinesses,markets,andgeographies;

applyingbestpractices;sharinginformation;

transferringknowledge;anddelivering

enhancedproductandserviceofferingstoour

customers.

Ingersoll Rand Leadership

IngersollRandhasanalignedleadership

structurecomprisedoftwoteamsofsenior

managers—theEnterpriseLeadershipTeam

andtheBusinessLeadershipTeam—whowork

togethertodrivecustomer,shareholder,and

internalvalue.

TheEnterpriseLeadershipTeamis

comprisedofIngersollRandChairman,

PresidentandChiefExecutiveOfcerHerb

Henkel,thesectorpresidents,andother

seniorleaders.TheEnterpriseLeadershipTeam

providesstrategicdirectionacrosstheIngersoll

Randenterprise,positioningthecompanyto

achieveDramaticGrowth,Operational

Excellence,andDualCitizenship.TheBusiness

LeadershipTeamconsistsofseniorleaders

fromIngersollRandbusinessunitsandthe

CorporateCenter.TheBusinessLeadership

Teamexecutesstrategyatthebusiness/

functionallevel.

To keep management apprised and en-

gaged, the ESH corporate director reviews the

company’s ESH performance with the Enter-

prise Leadership Team. In 2006, each business

sector president met with the ESH corporate

director and corporate ESH staff to review the

sector’s ESH performance results. In addition,

Vision and Strategy

Ingersoll Rand’s corporate vision is dedicated to driving

shareholder value by achieving Dramatic Growth,

Operational Excellence, and Dual Citizenship.

2006 Environmental, Safety, and Health Report

starting in 2007, the sector presidents and

senior management will receive an update on

ESH performance at least annually.

ESH Vision and Strategy:

Supporting the Company’s Vision

OurESHvisionwasdevelopedtoreecteach

ofthethreecomponentsofthecorporate

vision:DramaticGrowth,Operational

Excellence,andDualCitizenship.Fromthis

vision,wecreatedanESHstrategytodriveour

programsandperformance.

OurstrategyincludesESHpolicies

andpracticesthatsupportIngersollRand’s

DramaticGrowth.OurESHprofessionalstrack

andevaluateever-changingglobalESHissues,

includingsustainabledevelopment,climate

change,andproductendoflife;prepare

shareholderdocuments;assistwithdue

diligencesupportformergersandacquisitions;

integrateESHpoliciesandproceduresof

acquiredcompanies;anddevelopESH

managementsystemstoproperlyaddressall

IngersollRandoperations.

TohelpIngersollRandcompaniesachieve

andmaintainESHOperationalExcellence,ESH

professionalsprovideassistancewithachieving

regulatorycompliance;trackandplanfornew

regulations;establishESHrequirementsforall

IngersollRandcompanies;provideportfolio

managementassistanceforremediation

projects;assistproductmanufacturingwith

processdevelopment;managedata;and

identifyandmanagecoststoensureresources

areprudentlyspent.

WesupportDualCitizenshipthrough

oursystemforsharingbestpracticesacross

thecompany;bycommunicatingacrossthe

companyonESHissuesthataffectIngersoll

Randfacilities;andbyprovidingregional

guidanceonimplementingprogramsandbest

practicesthroughourregionalcouncils.

Sector and Business Unit ESH Goals Drive

Performance Improvement

ContinuouslyimprovingESHperformance

contributestoourcorporatevisionandESH

strategy.Eachyear,thesectorsestablishESH

goalsatthesector,businessunit,orfacility

levelintheareasoflostworkdaycaserate,

totalrecordablecaserate,hazardouswaste

disposal,orotherareasasappropriatetoeach

businessunit’soperations.

Engaging Stakeholders

Ourstakeholdersaresimilartothoseofother

publiclytradedcompanies.Theyinclude:

customersandconsumers;

employeesandtheirfamilies;

retirees;

shareholdersandinvestorgroups;

suppliersandcontractors;

neighborsandcommunitygroups;

regulators,legislators,andpoliticalleaders;

nongovernmentalorganizations(NGOs);and

academia.

•

•

•

•

•

•

•

•

•

Ingersoll Rand is a member of the Business Roundtable, an association of chief executive ofcers of

leading US companies. The Roundtable is committed to advocating public policies that ensure vigorous

economic growth, a dynamic global economy, and a well-trained and productive US workforce essential

for future competitiveness. Ingersoll Rand participates in the Business Roundtable’s Climate RESOLVE

(Responsible Environmental Steps, Opportunities to Lead by Voluntary Efforts) initiative, which seeks to

have every company in every sector of the economy undertake voluntary actions to control greenhouse

gas (GHG) emissions and reduce the GHG intensity of the US economy. In addition, Ingersoll Rand

participates in the Business Roundtable’s S.E.E. (Social, Environmental, Economic) Change Initiative,

which promotes better business and a better world by encouraging Roundtable members to adopt

sustainability principles as a business planning tool and to showcase the results achieved. The initiative

asks America’s leading companies to set challenging goals for environmental and social improvement,

and to meet these goals in a manner that creates business value.

Ingersoll Rand is also a member of the Organization Resources Counselors (ORC). The ORC mission is to

contribute to the denition and achievement of human relations and organizational goals by executives

in business, government, and nonprot organizations worldwide. Ingersoll Rand actively participates in

the Occupational Safety and Health Group, Lawyers Group, and Medical Benets Group within ORC.

Ingersoll Rand is a member of the Manufacturers Alliance/MAPI. The alliance promotes technological

and economic progress of the United States through studies and seminars on changing legal, economic,

and regulatory conditions affecting industry. Ingersoll Rand actively participates in many of the MAPI

councils, including the environmental council.

2006 Environmental, Safety, and Health Report

Achieving Goals through Our ESH Policy

Ourglobaloperations,andcompaniesin

whichIngersollRandhasgreaterthana50

percentownership,operateunderacommon

ESHpolicy.WeperiodicallyreviewourESH

policytoensureitcontinuestomeetour

needsandthegrowingexpectationsofour

keystakeholders.Thepolicywasformally

reviewedin2007andlastrevisedin2006.

TheIngersollRandESHpolicyisavailable

inEnglish,Chinese,Czech,Danish,Dutch,

French,German,Gujarati,Italian,Japanese,

Kannada,Portuguese,Russian,Spanish,and

TurkishandispostedatallIngersollRand

facilities.

Governance Structure and

Management Systems

Ingersoll Rand conducts its worldwide business

operations in a safe and environmentally responsible

manner.

2006 Environmental, Safety, and Health Report

Ingersoll Rand embraces its responsibility to operate in

a manner that protects the environment, and human

health and safety in order to support the company’s

long-term growth and reputation as a responsible

corporate citizen. We will meet this responsibility by the

following actions:

As a minimum level of performance, we will

comply with global, national, state, and local statutes,

regulations, standards, and other requirements

protecting the environment, and human health and

safety. In the absence of laws and regulations, or where

they are simply not adequate for our operations, we will

apply sound environmental, safety, and health (ESH)

management practices.

We will establish global internal ESH standards that

are robust, scientically sound, and protective of the

environment, and human health and safety.

We will conduct regular audits to verify compliance

with regulatory requirements and company standards.

We will implement ESH management systems

to identify and manage ESH risks, obligations, and

opportunities. We will establish specic ESH metrics to

measure and report on our performance.

We will incorporate ESH considerations into our

business decision-making processes. We will work to

prevent accidents, injuries, and unsafe work conditions,

promote energy and water conservation, encourage the

reuse and recycling of materials, and reduce waste and

emissions, and the use of hazardous substances in our

operations. We will share ESH best practices across the

company.

We will monitor emerging issues and keep abreast

of regulatory changes, technological innovations, and

stakeholder interests. We will strive to develop effective

and sustainable solutions to ESH challenges arising

from our business activities.

We will regularly communicate relevant and

meaningful information about our ESH performance to

our internal and external stakeholders.

It is the responsibility of corporate ESH staff

to establish policy, govern compliance, and review

the company’s ESH performance with company

and business unit management on a periodic basis,

including compliance with this policy. In addition,

corporate ESH will facilitate participation in training and

conferences to foster sharing of best practices across

the enterprise.

Each business unit is responsible for implementing

this policy, allocating adequate resources, and

developing ESH programs. Employees and on-site

contractors are responsible for integrating sound ESH

practices into their everyday activities, and acting in

a manner that is protective of the environment, and

human health and safety.

Thispolicywillbereviewedannuallyand

updatedasneeded.

Ingersoll Rand Environmental, Safety, and Health Policy

2006 Environmental, Safety, and Health Report

Global ESH Management and Organization

IngersollRandhasanESHpolicy,

requirements,standards,andprogramsthat

enablethecompanytoconductworldwide

operationsinasafeandenvironmentally

responsiblemannerandtomeetourESHgoals.

Theserequirements,standards,andprograms

assistbusinessmanagersandfacilitiesin

developingandimplementingenvironmental

solutionstailoredtotheirneeds.Throughthe

company’sAuditCommittee,theBoardof

DirectorsoverseesESHpolicyandcompliance

aspartofitscorporategovernance.

ResponsibilityfordevelopingESH

programsandassuringthatouroperations

meetandsustaincompliancewithall

applicablelocal,national,andinternational

lawslieswithourCorporateDirectorofESH

incooperationwiththecompany’sbusiness

managers.GuidanceisprovidedbytheESH

councils,whicharecomprisedofIngersoll

RandESHprofessionalsworldwide.

ESHprofessionalspartnerwithothers

acrossIngersollRand’soperationsand

businessfunctions.Ourgoalistomove

fromacomplianceassurancemodelofESH

managementtoabusinessintegrationmodel,

inwhichESHisintegratedintoourday-to-day

andstrategicbusinessdecisions.

ThefollowingelementsofourESH

managementapproacharecriticaltoour

success:

Management Commitment—Werequire

strongleadership,support,andparticipation

bymanagersatalllevelsforourESHpolicy

andprograms.

Training—IngersollRandiscommitted

totraining.Thisincludessite-specic

trainingrelativetoapplicableregulatory

requirements.Italsoincludesworkshops

andnewslettersthataddresscompliance

withcorporatepolicies,standards,and

programs,andthatpromotetheuseof

bestmanagementpracticestoimproveESH

performancewithinthecompany.

Communication—Wecommunicatetoour

employeesandstakeholdersaboutourESH

performanceandESHmanagementsystem.

Measurement—ThroughourESHcouncils,

wemeasurecriticalESHparameters,such

asemissions,wastegeneration,recycling

efforts,energyusage,waterusage,and

frequencyandseverityofworkplace

incidents.Itisthroughthesemeasurements

thatcontinualimprovementtoward

establishedobjectivescanbemonitoredand

achieved.

Evaluation—Weconductperiodic

evaluationsatouroperatingfacilities.Each

operatingdepartmentorbusinessunitis

accountableforaddressingtheevaluation

resultsandpreparingacorrectiveaction

plan.

•

•

•

•

•

Ingersoll Rand is working

to better integrate ESH into

the company’s business

decisions and practices. For

example, we are rolling out a

new enterprisewide Business

Operating System (BOS),

which will yield benets that

extend beyond nancial

rewards. The BOS will create

a safer work environment by

implementing Lean tools and

methodologies—and weeding

out unsafe work practices. The

BOS will drive nancial and

ESH benets for the company.

Ingersoll Rand has identied

six Enterprise Focus Areas

(EFAs) to support BOS.

Our strategy is to focus on

Global Leadership, World

Class Operations, Innovation,

Life Cycle Management,

Customer Value, and Strategic

Management. Training will

be provided for each EFA

to develop companywide

practices. The goal is to take

Ingersoll Rand from being a

good company to a great one,

without settling for “good

enough.”

2006 Environmental, Safety, and Health Report

ESH Professionals

PrimaryresponsibilityforESHmanagement

resideswitheachIngersollRandsector.

Startingatthefacilitylevel,staffsefciently

managecompliancewithgovernmental

regulationsandIngersollRandpolicies.In

addition,wehavebusinessunitandsector

staffdedicatedtoESH.

Atthecorporatelevel,ESHstaffestablish

policiesandguidelines,andmanagerisks

associatedwithtransactionsandsitecleanups.

Theassistantgeneralcounselandcorporate

directorofESHreportstothevicepresident

–corporategovernanceandsecretary,whoin

turnreportstothegeneralcounsel,whoisalso

aBoardmember.Sector,businessunit,and

facilitylevelESHpersonnelareresponsible

forreportingcertainmatterstothecorporate

directorofESH.Ifasituationweretoarise

requiringimmediateattention,itwouldbe

communicatedtotheCEOthroughthegeneral

counselorasectorpresident.

Atthesector,businessunit,andfacility

levels,manypeoplehaveresponsibilityfor

ESH.TodirectESHactivitiesglobally,Ingersoll

RandformedESHcouncilsinthe1980s.

Additionally,IngersollRandsponsorsannual

ESHconferencestoshareESHpracticesandto

fosterlearningacrosstheenterprise.

Global ESH Requirements Provide Clear

Performance Expectations

IngersollRandglobalESHrequirementsapply

toallfacilitiesworldwide.Therequirements

coverabroadrangeoftopics,including:

developmentandmaintenanceofanESH

ManagementSystem;

restrictionsonasbestos,chlorinated

solvents,lead,andcyanidematerialuse;

managementandcontroloftheuseof

undergroundstoragetanks(USTs)andother

subsurfacestructures;

use,maintenance,anddisposalof

polychlorinatedbiphenyl(PCB)-containing

electricalequipment;

guidelinesforregulatoryagencyinspections

andcommunicationwithexternalaudiences;

authorizationofESHdocuments;and

internalreportingrequirements.

Inaddition,eachIngersollRandbusinessand

facilityisrequiredtoinvestigate,understand,

andaddressanyadditionalESHissuesthat

applyandthatarenotsatisfactorilycovered

bytheESHrequirements.

EachIngersollRandbusinessandfacility

isrequiredtocomplywiththespeciclocal,

state,andfederalrequirementsthataffect

theiroperation.

•

•

•

•

•

•

•

2006 Environmental, Safety, and Health Report

In 2006, Bobcat Company’s

Gwinner, North Dakota,

US, facility became the rst

Ingersoll Rand site within

the United States to receive

third-party certication to

OHSAS 18001. The facility

also became certied to ISO

14001 during the same year.

This accomplishment reects

the leadership, commitment,

and hard work of Bobcat

employees throughout the

site.

The Climate Control

Technologies plant in

Pamplona, Spain received

OHSAS 18001 certication

in 2006. By 2005, the plant

had achieved ISO 9001 and

ISO 14001 certication and

decided to add the safety and

health component addressed

by OHSAS. It took a year

of hard work, but the plant

achieved its objective, and

will continuously improve its

practices regarding employees’

safety and health.

ESH Management System

IngersollRandrequireseachfacilitytohave

anESHmanagementsystem(ESHMS).The

managementsystemismodeledafterISO

14001andOHSAS18001.In2006,theESHMS

wasupdatedtomorecloselyalignwiththe

OHSAS18001andANSIZ10standards,clarify

certainmanagementsystemrequirements,and

mandateannualESHself-assessments.

EighteenIngersollRandfacilitieshave

receivedthird-partycerticationoftheir

ESHMStotheISO14001standard.Sixofthese

facilitiesalsoreceivedOHSAS18001(health

andsafety)certication.

ISO 14001 Certied Ingersoll Rand Facilities

Sector Location

Year certication was

rst achieved

Climate Control Technologies Barcelona, Spain

Galway, Ireland

Kolin, Czech Republic

Luoyang, China

Pamplona, Spain

Prague, Czech Republic

Shenzhen, China

Suzhou, China

2005

2000

2001

2003

1999

2001

2003

2005

Compact Vehicle Technologies Gwinner, North Dakota, US 2006

Industrial Technologies Guilin, China

Naroda, India

Oberhausen, Germany

Pavlovo, Russia

Sahibabad, India

Shanghai, China

Uni

~

cov, Czech Republic

2006

2002

2005

2005

2006

2005

2003

Security Technologies Leamington Spa, UK

Walsall, UK

2006

2002

OHSAS 18001 Certied Ingersoll Rand Facilities

Sector Location

Year certication was rst

achieved

Climate Control Technologies Galway, Ireland

Kolin, Czech Republic

Pamplona, Spain

Suzhou, China

2006

2005

2006

2005

Compact Vehicle Technologies Gwinner, North Dakota, US 2006

Industrial Technologies Sahibabad, India

Uni

~

cov, Czech Republic

2006

2005

2006 Environmental, Safety, and Health Report

ESH Tools

ESHstaffareprovidedwithavarietyoftools

toachieveESHrequirementsandprogram

goals,includingacompany-widenewsletter,

intranetsite,conferences,trainingprograms,

andon-demandaccesstospecializedexpertise.

IngersollRandmaintainsanemployeehotline,

staffedbyanexternalESHconsultingrm,

tohandlespecicquestions.In2006,the

hotlinereceivednearly120callscoveringa

widevarietyofissues,suchastheEUproduct

regulationsforelectricalproducts,ESH

reviewofnewchemicals,hazardousmaterials

management,DOTrequirements,spill

management,toxicinventoryandemissions

reporting,andESHtrainingrequirements.

ACodeofConducthotlineisalsoavailable

foremployeestovoiceconcernsabout

businessconductcondentially.

ESH Councils Enhance Dual Citizenship

IngersollRandhasthreeregionalESHcouncils,

coveringNorthAmerica,Europe,andAsia-

Pacic.Thecouncilmembersincludesector,

businessunit,andfacility-levelESHstaff,and

additionalenvironmental,risk,safety,and

healthexperts.CorporateESHprofessionals

participateinallthreecouncils.Therolesand

responsibilitiesofthecouncilmembersareto:

serveasrepresentativesfortheirentire

businessunit;

participateindevelopingorrevisingESH

policy,requirements,andguidelines;

•

•

providecouncilmeetingminutesandshared

informationtoESHcontactsatthefacilities;

seekbestpracticesthroughoutthebusiness

unitstosharewiththecouncil;

serveasprimarypoint-of-contact

forthebusinessunitforcriticalESH

communications;

distributecriticalESHinformationpromptly

toallbusinessunitfacilities;and

collectrequesteddatafromallbusinessunit

facilities.

In2006,theNorthAmericanESHCouncil

metonceandheldtwoteleconferences.The

EuropeanESHCouncilheldateleconference,

andthenewlyformedAsia-PacicESH

CouncilmetforthersttimeinSeptember.

Councilmeetingsgenerallyconsistofa

reviewanddiscussionofESHsubjectsthat

impactIngersollRandfacilities.Themeetings

aretypicallyheldatornearanIngersoll

Randfacilityandincludeafacilitytour.

Topicsgenerallydiscussedduringthecouncil

meetingsinclude:

statusofongoingESHprograms;

upcomingESHprograms;

regulatorychangesandhowtheywillimpact

operations;

ESHinvolvementinmerger,acquisition,and

divestitureactivities;

updatestotheESHmanualandtraining

issues;and

ESHawardsandbestmanagementpractices.

•

•

•

•

•

•

•

•

•

•

•

20 2006 Environmental, Safety, and Health Report

TheinauguralmeetingoftheAsiaPacicESH

CouncilmeetingwasheldinShanghai,China,

inSeptember2006.Morethan25people

attended,includingESHstaff,plantmanagers,

andseniorleadershipteammembersfrom

variousbusinessunitsoperatinginChinaand

India.Duringtheone-daymeeting,attendees

shareddetailsofbestpracticesintheir

facilitiesandparticipatedindiscussionsonthe

company’sglobalESHassessmentprogram,

metrics,regulatoryupdates,pandemic

preparedness,andtheenvironmentalaspects

ofrealestateandduediligenceactivities.

Promoting ESH Excellence through the

Annual Conferences

IngersollRandhelditsrstNorthAmerican

environmentalconferencein1979and

beganmanyofitsenvironmentalprograms

shortlythereafter.AnnualNorthAmerican

conferencescontinuedthrough2005.In2006,

thecompanyhosteditsrstGlobalESH

Conference,whichtookplaceinMonterrey,

Mexico,withathemeof“OneIngersoll

RandAroundtheWorld.”Attendeesfrom

theAmericas,European-servedareasand

AsiaPacicparticipatedintheconference.It

Top left and right: Simon Liu,

ESH engineer for Thermo King

Suzhou, China, participated

in an ESH communication

conference hosted by the

Safety Surveillance Bureau of

the local government.

Bottom left: Inaugural Asia

Pacic ESH Council meeting.

Bottom right: Dave Sordi

(left), Manager Environmental

Engineering and Gretchen

Digby (right), Manager Safety

& Health Engineering, present

the 2006 ESH awards at the

Global ESH Conference.

2006 Environmental, Safety, and Health Report 2

providedaplatformforinformationsharingon

topicsofinterestgloballyandsupportedthe

company’svisionofDualCitizenship.

Theannualconferenceshelpdemonstrate

seniormanagement’scommitmentto

ESH.Throughbestpracticesharingand

benchmarkingwithotherIngersollRand

facilitiesaroundtheworld,ESHstafflearn

howtointegrateESHintothebusinessand

haveapositiveimpactontheirfacilitiesand

thecommunitiesinwhichtheyliveandwork.

Theconferencesprovideimportanttraining

forthecompany’sESHprofessionalsand

encouragecommunicationacrossdifferent

regionsandbusinesssectors.

ESH Training

IngersollRandcorporateESHofferstraining

invariousforms—forinstance,through

annualESHconferences,workshops,and

teleconferenceseminars.Pastteleconference

seminarsaddressedthefollowingtopics:

SARATitleIIIToxicReleaseInventory.The

issuesdiscussedduringtheteleconference

includedapplicabilityoftheregulations,

thresholdcalculations,formcompletion,

emissioncalculations,andde minimis

exemptions.

•

Hexavalentchromiumuse.Thetopics

discussedincludedthebanontheuseof

hexavalentchromium,lead,cadmium,and

mercuryinproductscontainingelectronicor

electricalcomponentsinEUcountries.

EUenvironmentalandsafetyregulations.

Theteleconferenceupdatedstakeholders

withinthecompanyonthestatusof

changingregulations,includingtheprogress

madebyIngersollRandoperationsinEU

countriestoimplementtheEUdirectives

regardingelectricandelectronicequipment

wasteandassociatedhazardoussubstances.

ESHcompliance.Theseteleconferences

focusedonregulatoryandIngersollRand

requirements,andtheywereheldduringthe

weekpriortotheannualconference.These

teleconferenceswillbeheldannuallygoing

forward.

•

•

•

22 2006 Environmental, Safety, and Health Report

ESH Performance Results

Ingersoll Rand is committed to improving its ESH

performance.

AsaresultofourESHrequirementsandgoals

denedbythevariousbusinessunits,there

aremanyproceduresandprogramsinplace

todecreasetheenvironmentalimpactofour

operationsandproductsonhumanhealthand

theenvironment.Thissectiondescribesthe

ESHmetricswetrackandourperformance

results.

ESH Data in this Report

ThisreportincludesESHperformance

metricscollectedfromtheNorthAmerican

manufacturingfacilities.Datafromdivested

operationsareincludedfortheyearsthey

werepartofIngersollRand.IngersollRand

isintheprocessofcreatingacompany-wide

metricscollectionsystem.

Datainthisreportinclude:

electricityused,

heatingoilandkeroseneused,

waterused,

hazardouswastegenerated,

nonhazardouswastegenerated,

•

•

•

•

•

nonhazardousoilsandcoolantsgenerated,

nonhazardouswasterecycled,

useofundergroundstoragetanks(USTs),

and

polychlorinatedbiphenyls(PCBs).

(1)

InformationregardingIngersollRand’stoxic

chemicaluseandwastemanagementinthe

UnitedStatesisavailablethroughEPA’sToxic

ReleaseInventory(TRI)database(http://

www.epa.gov/tri/tridata/index.htm).

Compliance through the ESH Assessment

Program

ESHassessmentsaregenerallyperformed

forallmanufacturingandservicelocations

worldwideonathree-yearcycle.Facilitiesare

assessedagainstlocalregulatoryandIngersoll

Randrequirements,includingtheESHmanual,

thefacility’smanagementsystem,andbest

managementpractices.Third-partyESH

professionalsareretainedbyIngersollRand’s

legaldepartmenttoperformtheassessments.

•

•

•

•

(1) PCBs are toxic chemicals,

suspected of causing cancer

in humans, which have been

used in hundreds of industrial

and commercial applications,

including electrical and

hydraulic equipment.

2006 Environmental, Safety, and Health Report 2

Environmental Performance Metrics

Water Use

TheamountofwaterusedbyIngersollRand

facilitiesincludesthetotalamountofwater

usedforprocesses,cooling,maintenance,

landscaping,sanitaryneeds,andother

activities.Thisdoesnotincludewaterin

closedloopsystemsotherthanwateradded

duringtheyear.IngersollRandmanufacturing

facilitiesinNorthAmericaused194million

gallonsofwaterduring2006.

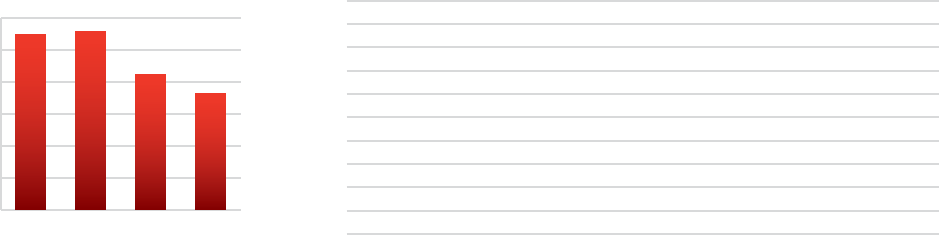

Energy Use And Greenhouse Gas Emissions

IngersollRandfacilitiesreportelectricityand

keroseneuseonanannualbasis.Kerosene

trackingincludesfueluseonlyanddoes

notincludekeroseneusedasasolventor

degreaser.

In2006,IngersollRandmanufacturing

facilitiesinNorthAmericaused303million

kilowatthours(kWh)ofelectricityand104

thousandgallonsofkerosene.

IngersollRandisworkingtoward

developingagreenhousegas(GHG)inventory.

Weareintheprocessofdeterminingwhich

GHGmetricsareusefulandtheappropriate

baselineyearfordatacollection.Inthefuture,

IngersollRandfacilitiesmaydevelopGHG

reductionplansthatwillnotonlyreduce

emissionsbutalsogeneratecostsavingsby

reducingtheamountofenergy,solvents,and

fuelused.

0

30

60

90

120

150

Heating Oil

2006200520042003

Heating Oil, Kerosene Use

North America, thousand gallons

0

50

100

150

200

250

300

350

400

Electricity

2006200520042003

Electricity Use

North America, million kilowatt-hours

0

50

100

150

200

250

300

350

400

Water Use

2006200520042003

Water Use

North America, million gallons

2 2006 Environmental, Safety, and Health Report

Hazardous Waste Management

IngersollRandfacilitiesreportonamonthly

basisthetotalsumofhazardouswaste,as

denedlocally,andalloilsandcoolantsthat

areshippedoff-sitefordisposal,recycling,or

reuse.

In2006,IngersollRandmanufacturing

facilitiesinNorthAmericagenerated1.33

millionpoundsofhazardouswaste.This

representsa43percentincreaseover2005,

andresultedprimarilyfromone-timeeventsat

severalfacilities:

Replacementanddisposalofoldwooden

boxesthatwerecoatedwithleadpaint

Leakinaplatingbaththatgeneratedchrome

waste

Contaminatedsoilandmaterialsfromsite

cleanup

One-timeshipmentoffsiteofpolishinglint

thatwasclassiedashazardous

Forthethreepreviousyears,our

hazardouswastegenerationhadbeen

declining.Weexpectthistrendtocontinuein

2007.

•

•

•

•

Nonhazardous Waste Management

IngersollRandfacilitiesreportonanannual

basistheamountofwastenotclassiedas

“hazardouswaste”thatisshippedoffsitefor

disposal,recycling,orreuse;excludingscrap

metal.Thisincludesoilsandcoolantsthatare

usedforfuelblending,aslongastheyarenot

classiedbylocalregulationsashazardous

waste.

In2006,NorthAmericanmanufacturing

facilitiesgenerated43.37millionpoundsof

nonhazardouswaste,generated1.81million

poundsofnonhazardousoilsandcoolants,and

recycled18.92millionpoundsofnonhazardous

waste.

0

0.25

0.50

0.75

1.00

1.25

1.50

HazWaste

2006200520042003

Hazardous Waste

North America, million pounds

0

10

20

30

40

50

60

70

80

Nonhazardous Waste

2006200520042003

Nonhazardous Waste

North America, million pounds

0

5

10

15

20

25

30

recyled

2006200520042003

Recycled Nonhazardous Waste

North America, million pounds

2006 Environmental, Safety, and Health Report 2

Other Environmental Reporting Metrics

Otherenvironmentalreportingmetricsinclude

chlorinatedsolvent,UST,andPCBuse.All

chlorinatedsolvents,withtheexceptionof

materialsusedforHVACequipment,re

extinguishers,andothernon-solventuses,are

reportedbythefacilitiesonanannualbasis.

USTandPCBuseisgovernedbyourESH

requirements.Facilitiesreportthenumberof

USTsinuse,excludingprocesstanks.Also,

facilitiesreportonthenumberofPCBunits

inuseatourfacilities.A“PCBunit”isdened

asatransformerorcapacitorwithoilwitha

PCBconcentrationof50milligramsperliter

orhigher(excludingcapacitorswithinlighting

ballasts).

In2006,therewasonlyoneUSTinuseat

ourNorthAmericanfacilities.

Since1986,IngersollRand’spolicyisto

dramaticallyreducetheuseofchlorinated

solventsinallprocessesandeliminatethem

unlessnoalternativesareavailable.In2004,

IngersollRandfacilitiesinNorthAmerica

eliminatedtotallytheuseofchlorinated

solventsinallmanufacturingprocesses.In

2006,weused35gallonsofachlorinated

solventwithinacontrolledlabenvironment

whichwasrequiredforperformancetestson

ourproducts.

Since2003,therehavebeennofacilitiesin

NorthAmericawithPCBunits.Internationally,

thelastPCBunitswereeliminatedinlate2005.

Environmental Expenditures

Throughproactiveprograms,suchasthe

ESHrequirementsandESHassessments,

IngersollRandstrivestoimprovehuman

healthandenvironmentalprotection.These

sameprogramsaredesignedtopreventfuture

environmentalliabilities.

AsofDecember2006,IngersollRand

wasinvolvedin56environmentalcleanups

worldwideassociatedwithpastactivities,

althoughtheactivitieswerelawfulatthetime

theyoccurred.These56sitesareinvarious

0.0

0.5

1.0

1.5

2.0

2.5

3.0

nhaz oils

2006200520042003

Nonhazardous Oils and Coolants

North America, million pounds

Environmental Metrics: North American Manufacturing Facilities

Units 2003 2004 2005 2006

Water Use million gallons 395 235 220 194

Electricity use million kWh 388 331 284 303

Heating oil/kerosene use thousand gallons 148 130 143 104

Hazardous waste million pounds 1.06 1.03 0.75 1.33

Nonhazardous waste million pounds 70.5 54.8 44.6 43.4

Recycled nonhazardous waste million pounds 28.7 24.6 19.2 18.9

Nonhazardous oils and coolants million pounds 2.73 2.79 2.11 1.81

Chlorinated solvents used gallons 466 0 0 35

PCB units (not including lights) units 0 0 0 0

2 2006 Environmental, Safety, and Health Report

stagesofremedialactivity.Atsomesites,

remedialactivitiesareoccurring;atother

sites,remediationiscompleteandthesiteis

inamonitoring-onlyphase;andsomesites

arestillintheinvestigationstage.Ingersoll

Randstrivestoutilizethemosteffective

remediationtechniquespossible.Remediation

managersregularlyinteractwithgovernment

agenciestoprovidecost-effectiveremediation

methodsandtechnologiesthatprotecthuman

healthandtheenvironment.

Todate,IngersollRandhasachieved

closureat33sites.Thesesiteshavereceived

sometypeof“NoFurtherRemedialActivity

Necessary”certicationfromtheappropriate

regulatoryagencyorremedialactivitieswere

discontinuedbecausetheriskshavebeen

mitigated.

During2006,thecompanyspent$9.4

millionforenvironmentalremediationexpen-

dituresatsitespresentlyorformerlyownedor

leasedbyIngersollRand.Theseremediation

costsarereviewedfourtimesperyearbyour

corporateESHprofessionalsandourauditor,

PricewaterhouseCoopers,toassureappropriate

reserves.InadditiontoourESHprograms,we

areestablishingaremedialscorecardsystem.

Thisscorecardwillassistinmanagingour

remedialactivities,supporttimelyinteraction

andcompliancewiththeappropriateregula-

tions,andhelptomitigateriskstoreceptors.

IngersollRandalsospentapproximately

$5millionduring2006oncapitalprojects

forpollutionabatementandcontrolatits

operatingfacilities.Itshouldbenotedthat

theseamountsaredifculttoestimate

becauseenvironmentalimprovementcostsare

generallyapartoftheoverallimprovement

costsataparticularplant.Therefore,an

accurateestimateofwhichportionofan

improvementoracapitalexpenditurerelates

toanenvironmentalimprovementisdifcult

toascertain.Thecompanybelievesthat

theseexpenditurelevelswillcontinueand

mayincreaseovertime.Giventheevolving

natureofenvironmentallaws,regulations,

andtechnology,theultimatecostoffuture

complianceisuncertain.Basedonour

evaluationofthefactsandlegalissues,

IngersollRandhasreservedfundstofully

coverourprojectedliability.Theremediation

costestimateisnotmaterialtothecompany’s

nancialstatement.Additionalinformation

regardingenvironmentalliabilitiescanbe

foundinourannualreportonForm10-Kfor

theyearendingDecember31,2006.

Employee Safety and Health Programs and

Performance

IngersollRandiscommittedtocontinuously

improvingitssafetyandhealthpractices.

IngersollRandsupportsthepromotion

ofsafetyandhealth,andtheprevention

ofdisease,illness,anddisabilityatallof

ourfacilities.Preventivehealthcareis

thecornerstoneofanyhealthcaresystem

designedtoreducecostsandhumansuffering.

Wellnessisthedynamicprocessof

promotingandpursuingideas,attitudes,and

behaviorstowardacultureandwayoflifethat

2006 Environmental, Safety, and Health Report 2

focusesonattainingbalance,goodhealth,and

peaceofmind.Byencouragingemployeesto

adoptmorehealthfulchoicesandbehaviors,

wellnesspromotionhasbeenproventolower

healthcareandinsurancecosts,decrease

absenteeism,andimproveperformanceand

productivity.

Tohelpprotectemployeesfromthe

traditionalseasonalinuenzaor“u,”Ingersoll

RandestablishedaSeasonalInuenzaVaccine

Policyin2006.Employeesworldwidehave

theopportunitytoreceiveatnocharge

theseasonalinuenzavaccine.Employee

participationintheprogramisvoluntary,but

allareencouragedtoparticipate.

IngersollRandhasdevelopedand

implementedaPandemicInuenza

PreparednessPlan.Theplanwasdesignedto

reducetheriskofillnessamongemployees

andtheirfamiliesthroughproactive

implementationofpreventivemeasuresinthe

eventofapandemicinuenza.

Safety And Health Training For Nurses

IngersollRandcorporatemedicalservices

conductsmonthlyglobalteleconference

seminarsforourmanufacturingfacilitynurses.

Topicsdiscussedduringthecallsinclude

IngersollRandpoliciesandprocedures,

medicalinformation,resourcesformedical

information,bestpractices,currentmedical

issues,andbusinesstravelrelatedinformation.

AnannualIngersollRandnursesmeeting

isheldinconjunctionwiththeannualESH

conferencetoallowfurtherdiscussionsand

presentations.Additionally,corporatemedical

servicesfacilitatescompliancewiththeHealth

InsurancePortabilityandAccountability

Actof1996(HIPAA)guidelinesforUS-

basednurses.Occupational Health Nursing

Guidelines for Primary Clinical Conditions3rd

EditionbyRogers,Randolph,andMastroianni

wasadoptedasstandard,evidence-based

guidelinesforallUS-basednurses.

IngersollRandnursesoffersafetyand

wellnessactivitiestoemployeesattheir

locationsthroughouttheyear.Ahealthand

wellnesscalendarhasbeendevelopedand

distributed,whichhighlightstopicsforraising

awarenessamongemployeesthroughoutthe

year.

Monthlyactivitiesofferedbyfacility

nursesin2006included:

tnessawarenessandweightreduction;

visionandhearingprograms;

heartdiseaseprevention;

immunizationawareness;

cancerawareness;

cholesterolandnutritioneducation;

highbloodpressureandstrokescreening;

diabetesprevention;and

casemanagementofclaims.

International Travel Health Programs

IngersollRandunderstandsthatemployees

travelingonbusinessmayexperiencein-

creasedrisktotheirpersonalhealthandsafety.

Forthisreasonthereisawell-coordinatedset

ofprogramsdesignedtominimizerisksand

protectourbusinesstravelers.

•

•

•

•

•

•

•

•

•

“When it comes to safety,

Bobcat is the gold

standard.”

During the 2006 Association

of Equipment Manufacturers

(AEM) Product Safety

Seminar in San Antonio,

Texas, US, members of AEM

credited Bobcat with being an

industry leader in safety. The

seminar, which was themed

“Product Safety – From Start