Products Solutions Services

Operating Instructions

Liquisys M CCM223/253

Transmitter for free chlorine, chlorine dioxide and total

chlorine

BA00214C/07/EN/15.15

71300499

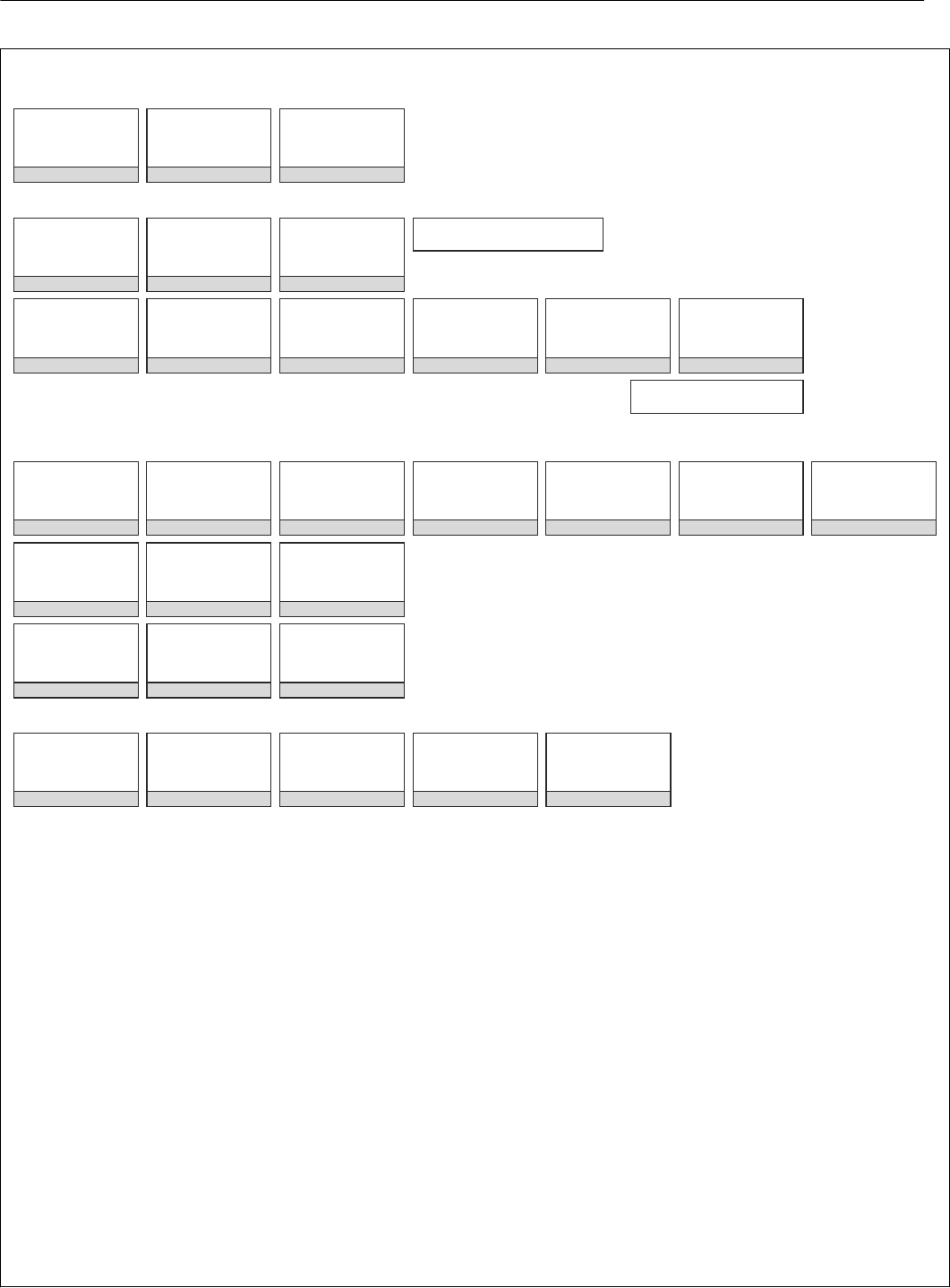

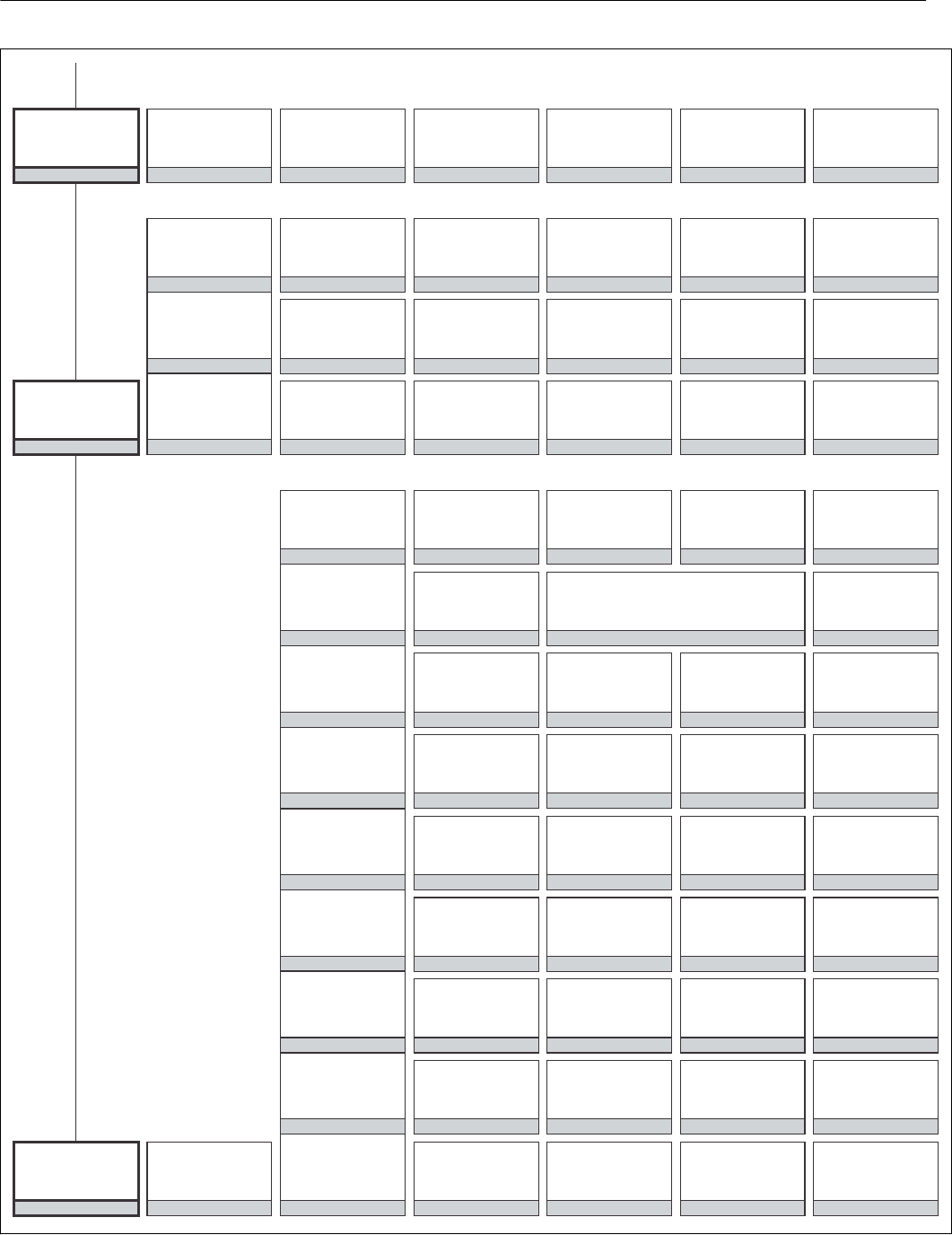

Liquisys M CCM223/253 Table of contents

Endress+Hauser 3

Table of contents

1 Document information .............. 5

1.1 Warnings ............................ 5

1.2 Symbols used .......................... 5

1.3 Symbols on the device ................... 5

1.4 Electrical symbols ...................... 6

2 Basic safety instructions ............ 7

2.1 Requirements for personnel ............... 7

2.2 Designated use ........................ 7

2.3 Occupational safety ..................... 7

2.4 Operational safety ...................... 8

2.5 Product safety ......................... 8

2.5.1 State of the art .................. 8

2.5.2 IT security ...................... 8

3 Incoming acceptance and product

identification ....................... 9

3.1 Incoming acceptance .................... 9

3.2 Scope of delivery ....................... 9

3.3 Product identification ................... 10

3.3.1 Nameplate .................... 10

3.3.2 Product identification ............ 10

3.4 Certificates and approvals ............... 10

3.4.1 mark ...................... 10

3.4.2 CSA General Purpose ............. 10

4 Installation ....................... 11

4.1 Installation at a glance .................. 11

4.1.1 Measuring system ............... 12

4.2 Installation conditions .................. 14

4.2.1 Field device .................... 14

4.2.2 Panel-mounted device ............ 15

4.3 Installation instructions ................. 16

4.3.1 Field device .................... 16

4.3.2 Panel-mounted device ............ 18

4.4 Post-installation check .................. 18

5 Electrical connection .............. 19

5.1 Wiring ............................. 19

5.2 Electrical connection, version 1 ........... 19

5.3 Electrical connection, version 2 ........... 21

5.4 Device connection ..................... 22

5.5 Measuring cables and sensor connection .... 24

5.6 Three-point step controller for Cl

2

/ ClO

2

/

total chlorine ......................... 28

5.7 Alarm contact ........................ 29

5.8 Post-connection check .................. 29

6 Operation options ................. 30

6.1 Quick operation guide .................. 30

6.2 Display and operating elements ........... 30

6.2.1 Display ....................... 30

6.2.2 Operating elements .............. 32

6.2.3 Key functions .................. 32

6.3 Local operation ....................... 35

6.3.1 Automatic/manual mode .......... 35

6.3.2 Operating concept ............... 36

7 Commissioning .................... 38

7.1 Function check ....................... 38

7.2 Switching on ......................... 38

7.3 Quick Setup .......................... 40

7.4 Device configuration ................... 42

7.4.1 Setup 1 (chlorine/chlorine dioxide) .. 42

7.4.2 Setup 2 (temperature or pH/ORP) ... 44

7.4.3 Current input .................. 47

7.4.4 Current outputs ................. 51

7.4.5 Alarm ........................ 55

7.4.6 Check ........................ 56

7.4.7 Relay configuration .............. 60

7.4.8 Service ....................... 77

7.4.9 E+H Service .................... 79

7.4.10 Interfaces ..................... 80

7.4.11 Communication ................. 80

7.5 Calibration .......................... 81

8 Diagnostics and troubleshooting ... 85

8.1 Trouble shooting instructions ............. 85

8.2 System error messages .................. 85

8.3 Process-specific errors .................. 89

8.4 Device-specific errors ................... 93

9 Maintenance ...................... 95

9.1 Maintenance of the entire measuring point .. 95

9.1.1 Cleaning the transmitter .......... 95

9.1.2 Cleaning the pH/mV sensors

(EP version) ................... 96

9.1.3 Maintenance of chlorine sensors .... 97

9.1.4 Assembly ..................... 97

9.1.5 Maintenance of pH connecting

cables and junction boxes (EP

version) ...................... 98

9.2 Test and simulation .................... 98

9.2.1 Chlorine sensors ................ 98

9.2.2 Temperature measurement ........ 99

9.2.3 pH/ORP measurement ............ 99

9.2.4 Flow monitoring ................ 99

10 Repair ........................... 101

10.1 Spare parts ......................... 101

10.2 Disassembling the panel-mounted device ... 101

10.3 Disassembling the field device ........... 104

10.4 Replacing the central module ............ 107

Table of contents Liquisys M CCM223/253

4 Endress+Hauser

10.5 Return ............................. 107

10.6 Disposal ........................... 108

11 Accessories ...................... 109

11.1 Sensors ............................ 109

11.2 Connection accessories ................. 109

11.3 Installation accessories ................ 110

11.4 Software and hardware add-ons .......... 111

11.5 Metering system ..................... 111

11.6 Calibration accessories ................. 112

12 Technical data ................... 113

12.1 Input .............................. 113

12.2 Output ............................ 113

12.3 Power supply ........................ 116

12.4 Performance characteristics ............. 117

12.5 Environment ........................ 117

12.6 Mechanical construction ............... 118

13 Appendix ........................ 119

Index ................................. 130

Liquisys M CCM223/253 Document information

Endress+Hauser 5

1 Document information

1.1 Warnings

Structure of information Meaning

L

DANGER

Causes (/consequences)

Consequences of non-compliance

(if applicable)

‣

Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious

injury.

L

WARNING

Causes (/consequences)

Consequences of non-compliance

(if applicable)

‣

Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious

injury.

L

CAUTION

Causes (/consequences)

Consequences of non-compliance

(if applicable)

‣

Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

NOTICE

Cause/situation

Consequences of non-compliance

(if applicable)

‣

Action/note

This symbol alerts you to situations which may result in damage to

property.

1.2 Symbols used

Additional information, tips

Permitted or recommended

Forbidden or not recommended

1.3 Symbols on the device

Symbol Meaning

Reference to device documentation

Document information Liquisys M CCM223/253

6 Endress+Hauser

1.4 Electrical symbols

Symbol Meaning

A0027423

Direct current

A terminal at which DC is present or through which DC flows.

A0027424

Alternating current

A terminal to which alternating voltage (sine-wave) is applied or through

which alternating current flows.

A0027425

Direct current or alternating current

A terminal at which direct voltage or alternating voltage is present or

through which direct current or alternating current flows.

A0027426

Ground connection

A terminal which, from the user's point of view, is already grounded via a

grounding system.

A0027427

Protective ground connection

A terminal which must be connected to ground prior to establishing any

other connections.

A0019929

Class II equipment

Reinforced or double insulation

A0027420

Alarm relay

A0027428

Input

A0027429

Output

A0027430

DC voltage source

A0027431

Temperature sensor

Liquisys M CCM223/253 Basic safety instructions

Endress+Hauser 7

2 Basic safety instructions

2.1 Requirements for personnel

• Installation, commissioning, operation and maintenance of the measuring system may

be carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the

specified activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions

and must follow the instructions contained therein.

• Measuring point faults may be repaired only by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided may only be carried out

directly by the manufacturer or by the service organization.

2.2 Designated use

Liquisys M CCM223/253 is a transmitter for determining the amount of free chlorine,

chlorine dioxide or total chlorine dissolved in water.

The transmitter is particularly suited for use in the following areas:

• Drinking water

• Water treatment

• Cooling water

• Gas scrubbers

• Reverse osmosis

• Food processing

• Swimming pool and bathing pool water

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Occupational safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

Electromagnetic compatibility

• The product has been tested for electromagnetic compatibility in accordance with the

applicable European standards for industrial applications.

• The electromagnetic compatibility indicated applies only to a product that has been

connected in accordance with these Operating Instructions.

Basic safety instructions Liquisys M CCM223/253

8 Endress+Hauser

2.4 Operational safety

1. Before commissioning the entire measuring point, verify that all connections are

correct. Ensure that electrical cables and hose connections are undamaged.

2. Do not operate damaged products, and safeguard them to ensure that they are not

operated inadvertently. Label the damaged product as defective.

3. If faults cannot be rectified:

Take the products out of operation and safeguard them to ensure that they are not

operated inadvertently.

2.5 Product safety

2.5.1 State of the art

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

European standards have been observed.

2.5.2 IT security

We only provide a warranty if the device is installed and used as described in the

Operating Instructions. The device is equipped with security mechanisms to protect it

against any inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

Liquisys M CCM223/253 Incoming acceptance and product identification

Endress+Hauser 9

3 Incoming acceptance and product

identification

3.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify your supplier of any damage to the packaging.

Keep the damaged packaging until the matter has been settled.

2. Verify that the contents are undamaged.

Notify your supplier of any damage to the delivery contents.

Keep the damaged products until the matter has been settled.

3. Check the delivery for completeness.

Check it against the delivery papers and your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

The permitted ambient conditions must be observed (see "Technical data").

If you have any questions, please contact your supplier or your local sales center.

3.2 Scope of delivery

The delivery of the field device comprises:

• 1 transmitter

• 1 plug-in screw terminal, 3-pin

• 1 cable gland Pg 7

• 1 cable gland Pg 16 reduced

• 2 cable glands Pg 13.5

• 1 set of Operating Instructions

• For versions with HART communication:

1 set of Operating Instructions: Field communication with HART

• For versions with PROFIBUS interface:

1 set of Operating Instructions: Field communication with PROFIBUS PA/DP

The delivery of the panel-mounted device comprises:

• 1 transmitter

• 1 set of plug-in screw terminals

• 2 tensioning screws

• Also for EP version: 1 BNC connector (solder-free)

• 1 set of Operating Instructions

• For versions with HART communication:

1 set of Operating Instructions: Field communication with HART

• For versions with PROFIBUS interface:

1 set of Operating Instructions: Field communication with PROFIBUS PA/DP

Incoming acceptance and product identification Liquisys M CCM223/253

10 Endress+Hauser

3.3 Product identification

3.3.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Extended order code

• Serial number

• Ambient and process conditions

• Input and output values

• Safety information and warnings

Compare the data on the nameplate with your order.

3.3.2 Product identification

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to the product page for your product on the Internet.

2. In the navigation area on the right-hand side, select "Check your device features"

under "Device support".

An additional window opens.

3. Enter the order code from the nameplate into the search field.

You will receive information on each feature (selected option) of the order code.

3.4 Certificates and approvals

3.4.1 mark

The product meets the requirements of the harmonized European standards. As such, it

complies with the legal specifications of the EC directives. The manufacturer confirms

successful testing of the product by affixing to it the mark.

3.4.2 CSA General Purpose

The following device versions meet the requirements of CSA and ANSI/UL for Canada and

the US:

• CCM253-**2/3/7***

• CCM223-**2/3/7***

Liquisys M CCM223/253 Installation

Endress+Hauser 11

4 Installation

4.1 Installation at a glance

Proceed as follows to completely install the measuring point:

• Install the transmitter (see the "Installation instructions" section).

• If the sensor is not yet installed in the measuring point, install it (see Technical

Information of the sensor).

• Connect the sensor to the transmitter as illustrated in the "Electrical connection" section.

• Connect the transmitter as illustrated in the "Electrical connection" section.

• Commission the transmitter as explained in the "Commissioning" section.

Installation Liquisys M CCM223/253

12 Endress+Hauser

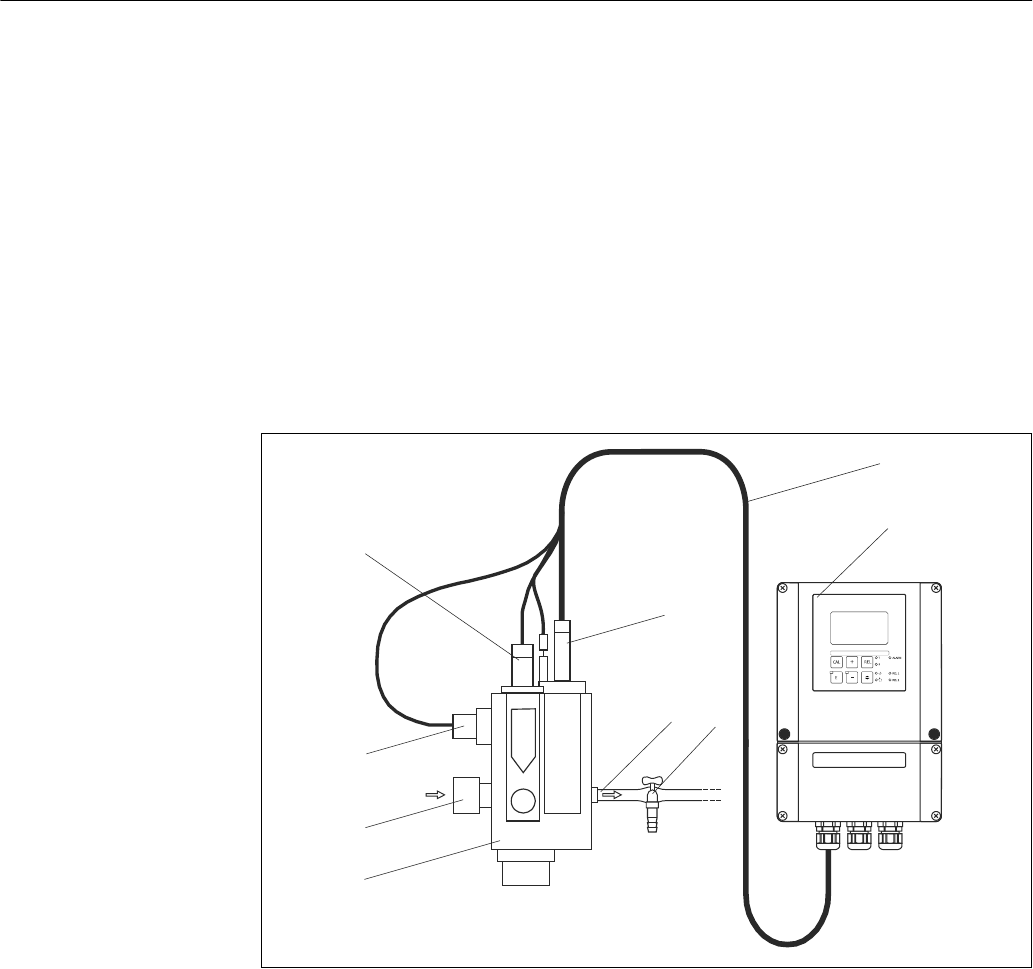

4.1.1 Measuring system

Version 1: free chlorine and chlorine dioxide

A complete measuring system comprises:

• Transmitter Liquisys M CCM223 or CCM253

• A membrane covered sensor CCS140/141 for Cl

2

or CCS240/241 for ClO

2

an open

sensor 963 for Cl

2

• Flow assembly CCA250 (not required for sensor 963)

Optionally:

• pH or ORP electrode

• Proximity switch INS for flow monitoring (not with sensor 963)

• Extension cable CMK for chlorine measurement

• Extension cable CYK71 for pH/ORP measurement

• An extension cable MK for proximity switch INS

• Junction box VBC

1

2

3

4

5

6

7

8

9

A0024088

1 Measuring system for the measurement of free chlorine or chlorine dioxide in flow operation (example)

1 Flow assembly CCA250

2 Medium inflow

3 Proximity switch INS

4 Mounting location for pH/ORP sensors

5 Chlorine sensor

6 Medium outlet

7 Sampling tap

8 Measuring cable

9 Transmitter CCM253

Version 2: total chlorine

A complete measuring system comprises:

• Transmitter Liquisys M CCM223 or CCM253

• Total chlorine sensor CCS120

• Flow assembly CCA250 or immersion assembly CYA611

• Measuring cable CPK9 with internal PML

Liquisys M CCM223/253 Installation

Endress+Hauser 13

Optionally:

• pH or ORP electrode

• Proximity switch INS for flow monitoring (only with flow assembly)

• Extension cable CPK9 with internal PML for chlorine measurement

• Extension cable CYK71 for pH/ORP measurement

• An extension cable MK for proximity switch INS

• Junction box VBC

• Weather protection cover CYY101 for field housing

1

2

4

5

3

6

A0024089

2 Measuring system for the measurement of total chlorine in immersion operation (example)

1 Junction box

2 Transmitter CCM253

3 Measuring cable

4 Immersion assembly CYA611

5 Chlorine sensor CCS120

6 Assembly adapter G1

Installation Liquisys M CCM223/253

14 Endress+Hauser

4.2 Installation conditions

4.2.1 Field device

Pg 7

Pg 16

M 5

11 (0.43)

Ø 6 (0.24)

115 (4.53)

157 (6.18)

247 (9.72)

70 (2.76)

70 (2.76)

154 (6.06)

170 (6.69)

Pg 13.5

A0024637

3 Field device, dimensions in mm (inch)

There is a hole in the perforation for the cable entry (connection of supply voltage). It

serves as a pressure balance during air shipment. Make sure no moisture penetrates

the inside of the housing before the cable installation. The housing is completely air-

tight after cable installation.

Liquisys M CCM223/253 Installation

Endress+Hauser 15

1

2

3

4

A0024640

4 View into the field housing

1 Removable electronics box

2 Terminals

3 Partition plate

4 Fuse

4.2.2 Panel-mounted device

90 (3.54)

139 (5.47)

96 (3.78)

6 (0.24)

92 (3.62)

149.5 (5.89)

A0024641

5 Panel-mounted device, dimensions in mm (inch)

Installation Liquisys M CCM223/253

16 Endress+Hauser

4.3 Installation instructions

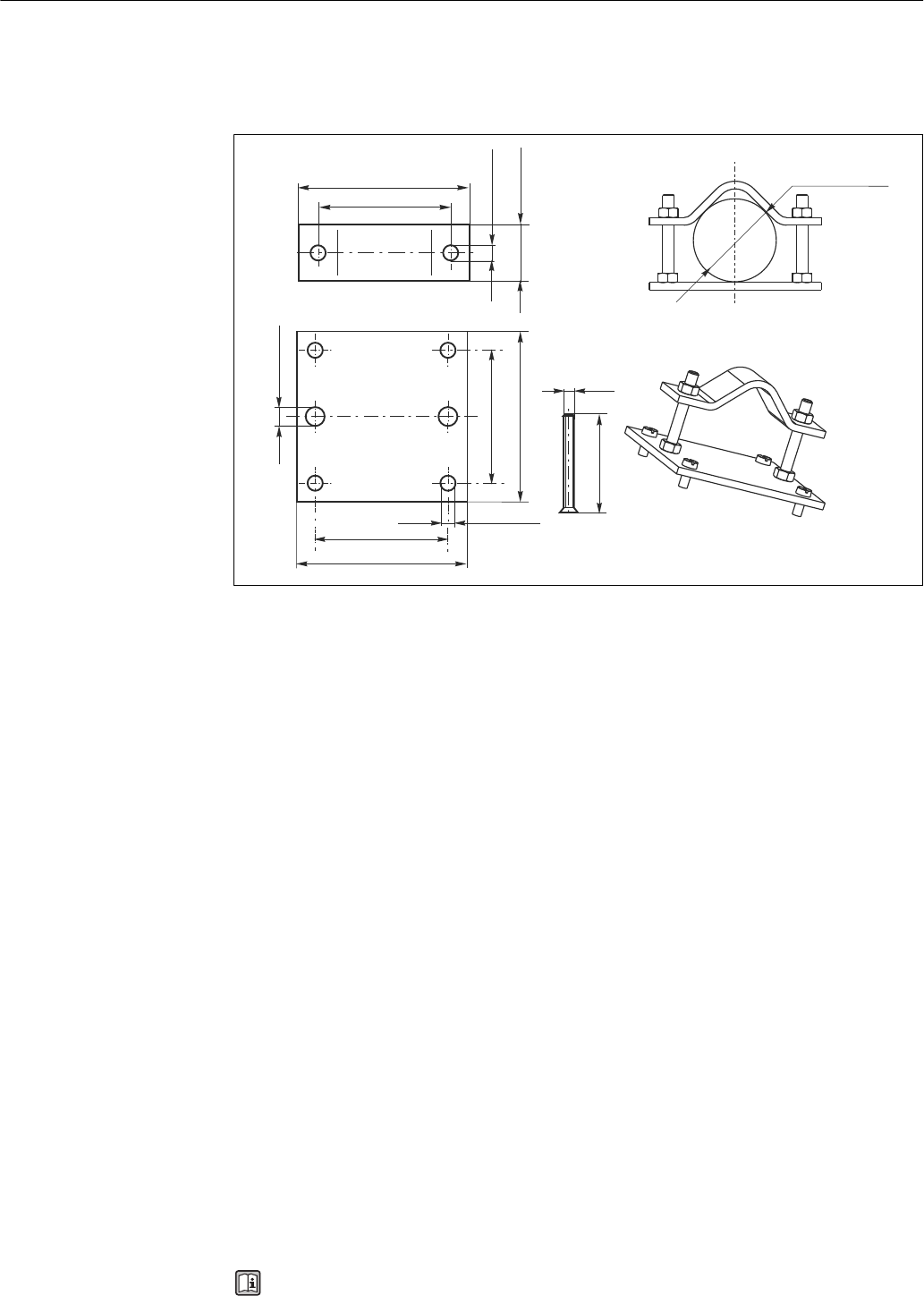

4.3.1 Field device

There are several ways of securing the field housing:

• Wall mounting with fixing screws

• Post mounting to cylindrical pipes

• Post mounting to a square securing mast

NOTICE

Effect of climatic conditions (rain, snow, direct sunlight etc.)

Impaired operation to complete transmitter failure

‣

When installing outside, always use the weather protection cover (accessory).

Transmitter wall mounting

1

2

154 (6.06)

Ø 6 (0.24)

A0024638

6 Field device wall mounting

1 Fixing bore holes

2 Plastic caps

Proceed as follows to mount the transmitter on the wall:

• Create the bore holes as shown in → 6.

• Drive two fixing screws through the fixing bore holes (1) from the front.

• Mount the transmitter on the wall as shown.

• Cover the bores with plastic caps (2).

Transmitter post mounting

You require a post mounting kit to secure the field device to horizontal and vertical

posts or pipes (max. Ø 60 mm (2.36")). This can be acquired as an accessory (see the

"Accessories" section).

Liquisys M CCM223/253 Installation

Endress+Hauser 17

1

2

3

1

1

3

Ø max. 60 (2.36)

A0024635

7 Field device on horizontal or vertical pipes

1 Securing screws

2 Fixing screws

3 Securing plate

Proceed as follows to mount the transmitter on a post:

1. Guide the two securing screws (1) of the mounting kit through the openings on the

securing plate (3).

2. Screw the securing plate onto the transmitter using the four fixing screws (2).

3. Secure the bracket with the field device on the post or pipe using the clip.

You can also secure the field device to the Flexdip CYH112 bracket in conjunction with the

weather protection cover. These can be acquired as accessories, see the "Accessories"

section.

A0027433

8 Field device on Flexdip CYH112 bracket with weather protection cover

Installation Liquisys M CCM223/253

18 Endress+Hauser

4.3.2 Panel-mounted device

The panel-mounted device is secured with the tensioning screws supplied → 9

The necessary installation depth is approx. 165 mm (6.50").

1

2

3

3

3

92 (3.62

+0.5 +0.02

)

92 (3.62

+0.5 +0.02

)

90 (3.54)

57 (2.24)

33 (1.30)

~ 25 (0.98)

139 (5.47)

max. 45 (1.77)

6 (0.24)

96 (3.78)

~ 165 (6.50)*

92 (3.62)

A0024639

9 Dimensions in mm (inch)

1 Mounting plate

2 Seal

3 Tensioning screws

* Necessary installation depth

4.4 Post-installation check

• After installation, check the transmitter for damage.

• Check whether the transmitter is protected against moisture and direct sunlight (e.g. by

the weather protection cover).

Liquisys M CCM223/253 Electrical connection

Endress+Hauser 19

5 Electrical connection

L

WARNING

Device is live

Incorrect connection may result in injury or death.

‣

The electrical connection may be performed only by an electrical technician.

‣

The electrical technician must have read and understood these Operating Instructions

and must follow the instructions contained therein.

‣

Prior to commencing connection work, ensure that no voltage is present on any cable.

5.1 Wiring

L

WARNING

Risk of electric shock!

‣

At the supply point, the power supply must be isolated from dangerous live cables by

double or reinforced insulation in the case of devices with a 24 V power supply.

NOTICE

The device does not have a power switch

‣

The customer must provide a protected circuit breaker in the vicinity of the device.

‣

The circuit breaker must be a switch or power switch, and you must label it as the

circuit breaker for the device.

The electrical connection of the transmitter depends on the sensor:

• If you are using the membrane-covered sensor CCS140 / 141 / 240 / 241 or the open

sensor 963, follow the instructions and illustrations in the "Electrical connection, version

1" section.

• If you are using the total chlorine sensor CCS120, follow the instructions and

illustrations in the "Electrical connection, version 2" section.

5.2 Electrical connection, version 1

The wiring diagram shows the connections of a device equipped with all the options. The

connection of the sensors to the various measuring cables is explained in more detail in

the "Measuring cables and sensor connection" section.

Electrical connection Liquisys M CCM223/253

20 Endress+Hauser

15 V

85

86

81

93

82

94

mA

31

32

mA

mA

33

34

54

55

56

23

24

90

12

11

91

92

S

ClO

2

ClO

2

Cl

2

Cl

2

K

A

A

K

K

A

NTC

pH

Red.

Ref.

PA/

PM

10–50 V

41

42

43

47

48

49

57

58

59

51

52

53

L+

L–N

L1

~ =

pH/

Redox

GN

BN

RD

BU

RD

BK

BN

BU

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

*

A0001903

10 Electrical connection of the transmitter (version 1)

A pH/ORP input (optional) I Auxiliary voltage output

B Sensor CCS140/141/240/241 J Alarm (current-free contact position)

C Sensor 963 (alternative) K Relay 1 (current-free contact position)

D Signal output 1, chlorine / chlorine dioxide L Relay 2 (current-free contact position)

E Signal output 2, temperature, pH or ORP M Relay 3 (current-free contact position)

F Binary input 1 (hold/cleaning) N Relay 4 (current-free contact position)

G Proximity switch INS O Current input 4 to 20 mA

H Binary input 2 P Power connection

* Auxiliary voltage of terminal 85/86 can be used

The device is approved for protection class II and is generally operated without a

protective ground connection. Circuits "E" and "I" are not galvanically isolated from each

other.

Liquisys M CCM223/253 Electrical connection

Endress+Hauser 21

5.3 Electrical connection, version 2

The wiring diagram shows the connections of a device equipped with all the options. The

connection of the sensors to the various measuring cables is explained in more detail in

the "Measuring cables and sensor connection" section.

15 V

85

86

81

93

82

94

mA

31

32

mA

mA

33

34

54

55

56

23

24

90

12

11

S

ClO

2

ClO

2

Cl

2

Cl

2

pH

Red.

Ref.

PA/

PM

10–50 V

41

42

43

47

48

49

57

58

59

51

52

53

L+

L–N

L1

~ =

pH/

Redox

YE

BK

BK

BN

BU

A

B

C

D

E

F

G

H

J

K

L

M

N

O

P

15 V

85

86

CCS

120

WH

GN

BN

C

*

A0001904

11 Electrical connection of the transmitter (version 2)

A pH/ORP input (optional) * Auxiliary voltage of terminal 85/86 can be used

B Sensor CCS120 J Alarm (current-free contact position)

C Auxiliary voltage output K Relay 1 (current-free contact position)

D Signal output 1, total chlorine L Relay 2 (current-free contact position)

E Signal output 2, temperature, pH or ORP M Relay 3 (current-free contact position)

F Binary input 1 (hold/cleaning) N Relay 4 (current-free contact position)

Electrical connection Liquisys M CCM223/253

22 Endress+Hauser

G Proximity switch INS O Current input 4 to 20 mA

H Binary input 2 P Power connection

The device is approved for protection class II and is generally operated without a

protective ground connection. Circuits "E" and "C" are not galvanically isolated from

each other.

5.4 Device connection

Field device connection

Proceed as follows to connect the field device:

1. Open the housing cover to access the terminal block in the connection compartment.

2. Break through the perforation for a cable gland, mount a Pg gland and guide the

cable through this Pg gland.

3. Connect the cable in accordance with the terminal assignment.

4. Tighten the Pg gland again.

NOTICE

Non-observance could cause incorrect measurement.

‣

Make absolutely sure to protect the cable ends and terminals from moisture.

‣

Terminals marked NC may not be connected.

‣

Unmarked terminals may not be connected.

pH / Redox

42

+

+

++++ -

-

----

434154 55 56

NC

91

90

31

11

12

32

92

PA/PM

3433

S

REF

NC 938685 94 81

23

82

24

NC

51 52 53 57 58 59 47 48 49

Cl

ClO

2

(963:92/K)

2

Temp.

pH/Redox

(opt.)

+15V

10mA

BN

(RD)GN(BU)

BN

REL 4SENSOR REL 3 REL 2 REL 1

131194-4D

CCM 253

Digital 2

(INS)

Digital 1

4..20mA

1191/A

1290/K

NC

Mains

Hilfsenergie

L1

+

N

-

(AC)

(DC)

Contacts:

max. 2A

AC: 250V/500VA

DC: 30V/60W

A0002276

12 Field device connection compartment sticker

Please label the sensor terminal block with the sticker provided.

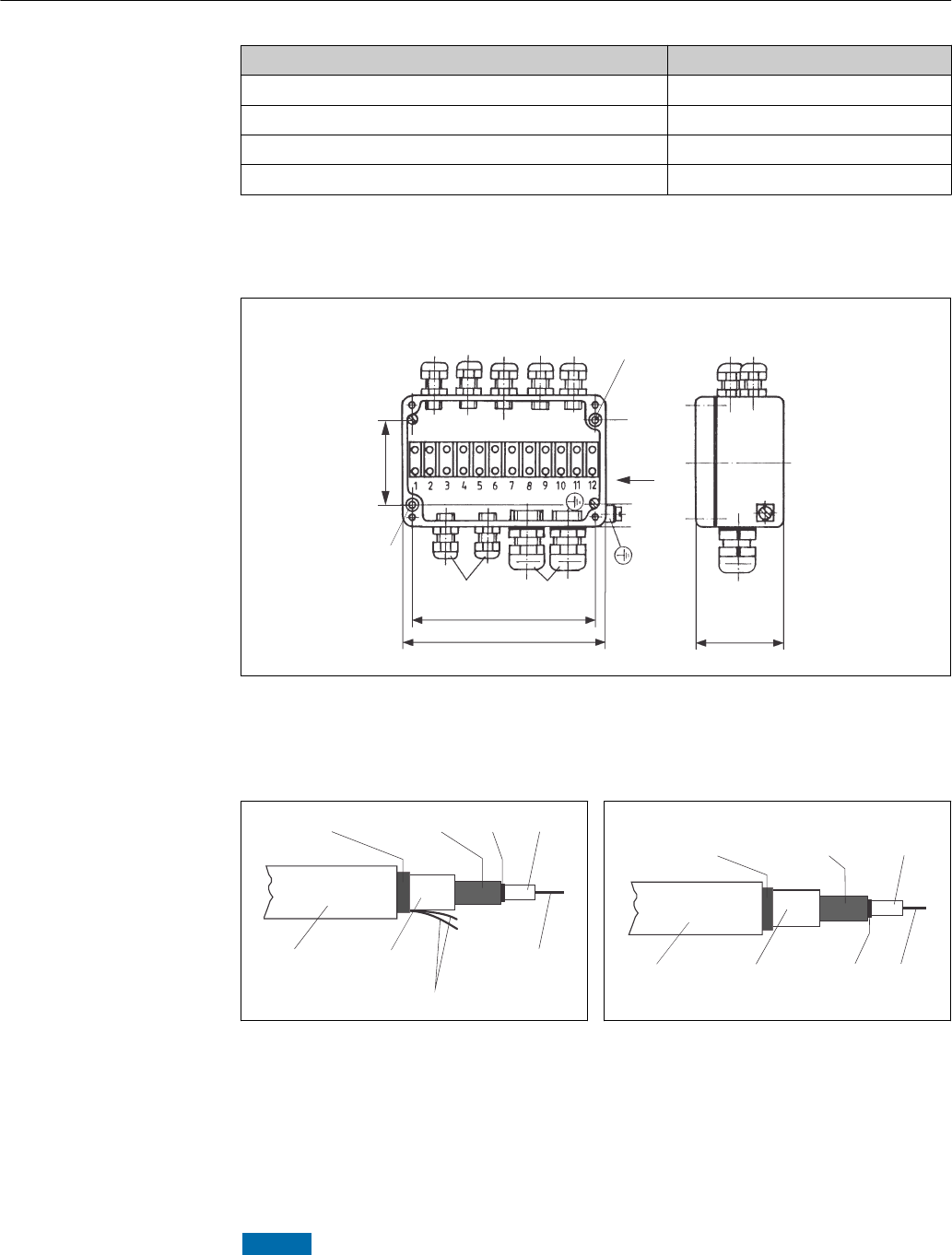

Panel-mounted device connection

To connect the panel-mounted device, connect the cables in accordance with the terminal

assignment to the terminals on the rear of the device.

Liquisys M CCM223/253 Electrical connection

Endress+Hauser 23

REL1

REL2

REL3

REL4

4..20mA

24

23

49

COM

COM

COM

COM

-

+

59

54

55

56

52

51

53

58

57

48

47

131084-4C

31 +

32 -

33 +

PA/PM

34 -

85 +

NC

91

90

NC

(REF)

Sensor

NC

86 -

93 + S

94 - 42

81 + 43

82 - 41

Cl

2

Temp.

pH

Redox

(opt.)

+15V

10mA

Digital 2

(INS)

Digital 1

92

12

11

K

A

BN

BN

GN

131192-4C

K

ClO

2

963

CCS..

963

BNC: pH/Redox + REF

RD

BU

Mains

Contacts: max. 2A, AC:250V/500VA, DC:30V/60W

L1 +

AC DC

N -

A0002277

13 Panel-mounted device connection sticker

NOTICE

Non-observance could cause incorrect measurement.

‣

Make absolutely sure to protect the cable ends and terminals from moisture.

‣

Terminals marked NC may not be connected.

‣

Unmarked terminals may not be connected.

Please label the sensor terminal block with the sticker provided.

Electrical connection Liquisys M CCM223/253

24 Endress+Hauser

5.5 Measuring cables and sensor connection

Sensor type Cable Extension

Chlorine/chlorine dioxide sensors

CCS140 / 141 / 240 / 241

3 m (9.8 ft) CMK, permanently connected VBC box + CMK

Chlorine sensor 963 - VBC box + MK

Temperature sensor for chlorine sensor 963 CPK1

Total chlorine sensor CCS120 CPK9-N*A1B VBC box + CYK71

pH or ORP sensor without temperature

sensor

CPK1 for sensors with GSA plug-in head

CPK9 for sensors with ESA plug-in head

VBC box + CYK71

Connecting the chlorine sensors CCS140 / 141 / 240 /241

The sensors are equipped with a 3 m (9.8 ft) fixed cable. Connect the sensors to the

transmitter according to the following diagram:

Sensor with 3 m fixed cable Transmitter

Assignment Core Terminal

Outer shield S

Anode [A] red 91

Cathode [K] 90

NTC temperature sensor green 11

NTC temperature sensor brown 12

Connecting the total chlorine sensor CCS120

Connect the sensor with the measuring cable CPK9-N*A1B (with internal PML) according

to the following connection diagram:

Cable with TOP68 connection Transmitter

Pin Assignment Core Terminal

1 TC signal Coax, inside (white) 90

2 AGND Coax, outside (black) 12

3

4 +UB (15 V) green 85

5 NTC1 yellow* 11

NTC1 white* 11

6 NTC2/AGND brown 86

S Shielding S S

* The white and yellow wires are interconnected in the TOP68 connector.

Liquisys M CCM223/253 Electrical connection

Endress+Hauser 25

1

2

3

5

6

4

1

2

3

5

6

4

A0026048

14 TOP68 connection; pin arrangement of connector and coupling (shown from contact side)

Connecting the chlorine sensor 963

The chlorine sensor 963 is supplied without a temperature sensor ex factory. Connect the

chlorine sensor to the transmitter as follows:

• Without temperature measurement:

Connect the 10 kΩ equivalent resistor supplied to terminals 11 and 12. The measured

value display will then constantly show 25 °C (77 °F).

• With temperature measurement:

Mount an NTC temperature sensor 10 kΩ / 25 °C (77 °F) (120 mm installation version

TSP 3692) in the chlorine sensor 963. Use the CPK1 connecting able to connect the

temperature sensor to terminals 11 and 12.

• Chlorine sensor:

Connect the red cable to terminal 92 (cathode) and the blue cable to terminal 91

(anode).

Connection of pH or ORP sensors

Connect the pH or ORP sensor always symmetrically to prevent a mutual interference of

several sensors mounted in the CCA250 assembly.

Symmetrical connection requires a potential matching pin. The pin is integrated as

standard in the CCA250 flow assembly and is connected by a PML to the PA/PM terminal.

CPK1

CPK9

PM

pH / Redox

PM

pH + Pt 100 / Pt 1000

Coax Ref.

pH or Redox

BN PM

Coax BK Ref.

inner pH

GN Temp.

WH Temp.

YE Temp.

BN PM

A0002330-EN

15 Connection of the pH or ORP sensor to the field instrument with the cables CPK1 or CPK9

Electrical connection Liquisys M CCM223/253

26 Endress+Hauser

If you are using glass electrodes with the panel-mounted device, you have to terminate the

measuring cable with a BNC connector. A solder-free BNC connector is supplied with the

device. To do this, proceed as follows:

1. Cut off end ferrules 2 and 3 of the coaxial cable.

3

4

1

2

A0005744

16 Cable CPK1: device connection

1 Coax cable

2 Inner shield BK (ref)

3 Inner coax (pH / mV)

4 Strand BN (PA)

2. Push the cable gland 5 and the washer 6 onto the

coaxial cable.

5 6

5 6

7

8

14

13 (0.51)

16 (0.63)

A0005745

17 Terminating the pH connecting cable for

mounting the BNC elbow plug. Dimensions in

mm (inch)

3. Remove the insulation (13 mm (0.51")) and screw the

clamping ring 7 onto the insulation.

Parts 5 to 7 are supplied with the BNC

connector for cable diameters 3.2 mm and

5 mm.

4. Fold the braided shield 8 of the shield over the

clamping ring and cut off the excess material.

5. There is a semiconductor layer 14 (conductive

membrane) between the inner insulation and the

braided shield 8. Strip this semiconductor layer as far

as the braided shield.

6. Remove the inner insulation (4 mm (0.16")), fit end

ferrule 13 on the stripped inner conductor and secure

the end ferrule with a crimping pliers.

13

4 (0.16)

A0005746

18 Terminating the pH connecting cable for

mounting the BNC elbow plug. Dimensions in

mm (inch)

7. Push the BNC connector housing 9 over the cable. The

inner conductor must be located on the clamping

surface 10 of the connector.

5

9

10

11

12

A0005747

19 Mounting the pH connecting cable in the BNC

elbow plug

8. Tighten the cable gland 5.

9. Insert the clamp element 11 and screw in the

connector cover 12. This creates a safe connection

between the inner conductor and the connector pin.

Liquisys M CCM223/253 Electrical connection

Endress+Hauser 27

Sensor Maximum cable length

Chlorine/chlorine dioxide sensors CCS140/141/240/ 241 Max. 30 m (98.4 ft) with cable CMK

Chlorine sensor 963 Max. 30 m (98.4 ft) with cable MK

Total chlorine sensor CCS120 Max. 15 m (49.2 ft) with cable CYK71

pH/ORP measurement Max. 50 m (164 ft) with cable CYK71

Use the junction box VBC and the appropriate extension cable to extend the measuring

cable.

2 x Pg 7

2 x Pg 11

5 x Pg 7

A

B

B

54 (2.13)

113 (4.45)

125 (4.92)

52 (2.05)

A0005740

20 Junction box VBC with grounding point

A View in arrow direction

B 2 fixing bore holes Ø 4.5 mm (0.18")

BN

GN

1

2

3

4

5

6

7

8

A0002331

21 Structure of cable CMK

1 Outer shield

2 Inner shield, anode

3 Semi-conductor layer

4 Inner insulation

5 Inner conductor, measuring signal

6 Temperature sensor connection

7 2nd insulation

8 Outer insulation

1

2 3

45

6

7

A0002332

22 Structure of cable CYK71

1 Outer shield

2 Inner shield, reference signal

3 Inner insulation

4 Inner conductor, measuring signal

5 Semi-conductor layer

6 2nd insulation

7 Outer insulation

NOTICE

Incorrect measurement due to short-circuit

‣

Make sure to remove the black semiconductor layer as far as the inner shield when

connecting cable CMK and CYK71.

Electrical connection Liquisys M CCM223/253

28 Endress+Hauser

5.6 Three-point step controller for Cl

2

/ ClO

2

/ total

chlorine

Connect the continuously variable motor valves as follows:

1. Connect the NO contact of the motor valve to relay 3.

2. Connect the NC contact of the motor valve to relay 4.

Liquisys M CCM223/253 Electrical connection

Endress+Hauser 29

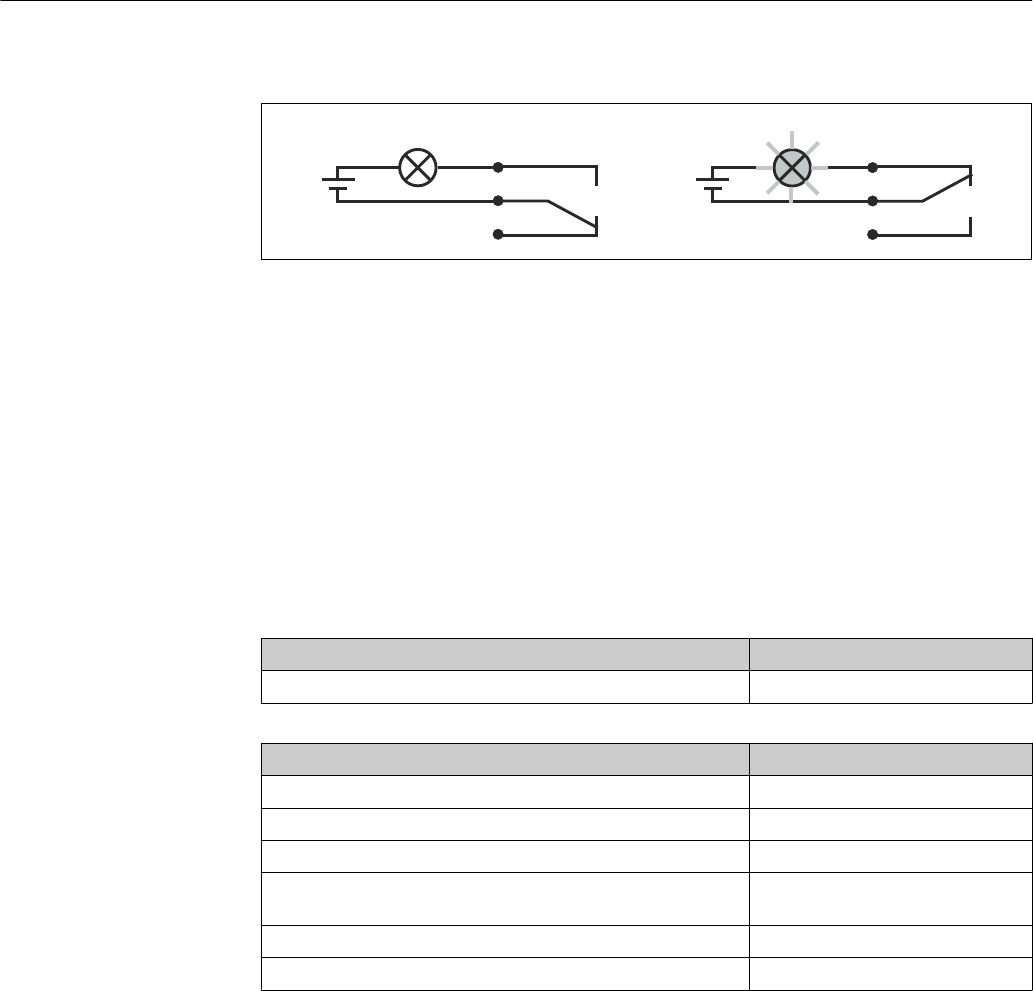

5.7 Alarm contact

41

42

43

41

42

43

A

B

A0006415

23 Recommended fail-safe switching for the alarm contact

A Normal operating status

B Alarm condition

Normal operating status Alarm condition

Device in operation and no error message

present (alarm LED off):

• Relay energized

• Contact 42/43 closed

Error message present (alarm LED red) or device

defective or de-energized (alarm LED off):

• Relay de-energized

• Contact 41/42 closed

5.8 Post-connection check

Carry out the following checks once you have made the electrical connection:

Device state and specifications Notes

Are the devices and cables free from damage on the outside? Visual inspection

Electrical connection Notes

Are the mounted cables strain relieved?

Are the connected cables provided with strain relief?

Is the cable run correct, without loops and cross-overs?

Are the power cable and signal cables connected correctly and in

accordance with the wiring diagram?

Are all the screw terminals tightened?

Are all the cable entries fitted, tightened and leak-proof?

Operation options Liquisys M CCM223/253

30 Endress+Hauser

6 Operation options

6.1 Quick operation guide

You have the following ways of operating the transmitter:

• On site via the key field

• Via the HART interface (optional, with corresponding order version) with:

– HART handheld terminal

– PC with HART modem and the Fieldcare software package

• Via PROFIBUS PA/DP (optional, with corresponding order version) by PC with a

corresponding interface and the Fieldcare software package or via a programmable logic

controller (PLC).

For operation via HART or PROFIBUS PA/DP, please read the relevant sections in the

additional Operating Instructions:

• PROFIBUS PA/DP, field communication for Liquisys M CXM223/253,

BA00209C/07/EN

• HART, field communication for Liquisys M CXM223/253, BA00208C/07/EN

The following section only explains operation via the keys.

6.2 Display and operating elements

6.2.1 Display

LED displays

A0027220

Indicates the current operating mode, "Auto" (green LED) or

"Manual" (yellow LED)

A0027222

Indicates the activated relay in the "Manual" mode (red LED)

The status of relays 3 and 4 is indicated on the LC display.

A0027221

Indicates the working status of relay 1 and 2

LED green: measured value within the permitted limit, relay

inactive

LED red: measured value outside the permitted limit, relay active

A0027218

Alarm display, e.g. in event of continuous limit value overshoot,

temperature sensor failure or system error (see error list)

Liquisys M CCM223/253 Operation options

Endress+Hauser 31

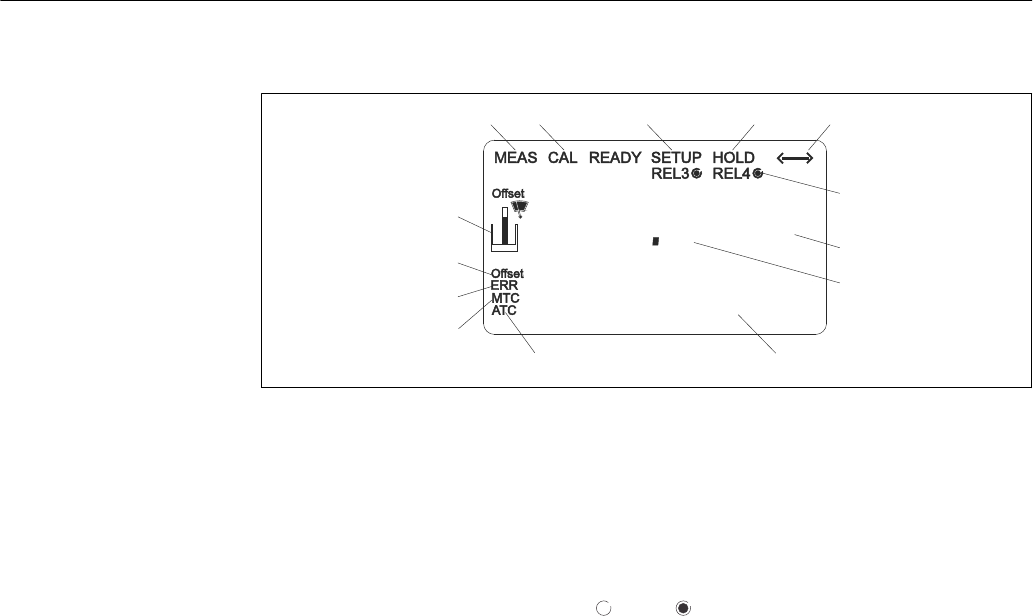

LC display

mg/l

R242

1

2 3

4

5

6

7

8

9

12

13

14

0 4 2

10

11

Setpoint

A0001924-EN

24 Transmitter LC display

1 Indicator for measuring mode (normal operation)

2 Indicator for calibration mode

3 Indicator for setup mode (configuration)

4 Indicator for "Hold" mode (current outputs remain at last current state)

5 Indicator for receipt of a message on devices with communication

6 Indicator of working status of relays 3/4: inactive, active

7 Function code

8 In measuring mode: measured variable - in setup mode: configured variable

9 In measuring mode: secondary measured value - in setup/calibr. mode: e.g. set value

10 Indicator for autom. Temperature compensation

11 Indicator for man. Temperature compensation

12 "Error": error display

13 Temperature offset

14 Sensor symbol (see the "Calibration" section)

Operation options Liquisys M CCM223/253

32 Endress+Hauser

6.2.2 Operating elements

The display shows the current measured value and the temperature simultaneously, which

means you have an overview of the most important process data at once. Help text in the

configuration menu helps users configure the device parameters.

1

7

6

4

5

3

2

A0024631-EN

25 Operating elements

1 LC display for displaying the measured values and configuration data

2 Key to switch relays in manual mode and to display the active contact

3 LED for alarm function

4 Changeover switch for automatic/manual mode

5 LEDs for limit contactor relay (switch status)

6 Main operating keys for calibration and device configuration

7 Field for user-defined information

6.2.3 Key functions

A0027235

CAL key

When you press the CAL key, the device first prompts you for the

calibration access code:

• Code 22 for calibration

• Code 0 or any other code for reading the last calibration data

Use the CAL key to accept the calibration data or to switch from

field to field within the calibration menu.

A0027236

ENTER key

When you press the ENTER key, the device first prompts you for the

setup mode access code:

• Code 22 for setup and configuration

• Code 0 or any other code for reading all the configuration data.

The ENTER key has several functions:

• Calls up the Setup menu from the measuring mode

• Saves (confirms) data entered in the setup mode

• Moves on within function groups

Liquisys M CCM223/253 Operation options

Endress+Hauser 33

A0027240

PLUS key and MINUS key

In the Setup mode, the PLUS and MINUS keys have the following

functions:

• Selection of function groups.

Press the MINUS key to select the function groups in the order

given in the "System configuration" section.

• Configuration of parameters and numerical values

• Operation of the relays in manual mode

In the measuring mode, the following sequence of functions is

accessed by repeatedly pressing the PLUS key:

• Temperature displayed in °F

• Temperature is hidden

• pH measured value or ORP (only for EP version)

• pH sensor signal in mV (only for EP version)

• Sensor current of chlorine/chlorine dioxide sensor in nA

• Zero current of sensor CCS120

• Current input signal in %

• Current input signal in mA

• Return to basic settings

In the measuring mode, the following sequence of information is

displayed by repeatedly pressing the MINUS key:

• The current errors are displayed consecutively (max. 10).

• Once all the errors have been displayed, the standard

measurement display appears. In the function group F, an alarm

can be defined separately for each error code.

A0027241

REL key

In the manual mode, you can use the REL key to switch between the

relay and the manual start of cleaning.

In automatic mode, you can use the REL key to read out the switch-

on points (for limit contactor) or set points (for PID controller)

assigned to the relay in question.

Press the PLUS key to jump to the settings of the next relay. Use the

REL key to get back to the display mode (automatic return after

30 s).

A0027234

AUTO key

Use the AUTO key to switch between automatic mode and manual

mode.

A0027237

Escape function

If you press the PLUS and MINUS key simultaneously, you return to

the main menu, or are taken to the end of calibration if calibrating.

If you press the PLUS and MINUS key again, you return to the

measuring mode.

Operation options Liquisys M CCM223/253

34 Endress+Hauser

A0027238

Locking the keyboard

Press the PLUS and ENTER key simultaneously for at least 3 s to

lock the keyboard against any unauthorized data entry. All the

settings can continue to be read.

The code prompt displays the code 9999.

A0027239

Unlocking the keyboard

Press the CAL and MINUS key simultaneously for at least 3 s to

unlock the keyboard.

The code prompt displays the code 0.

Liquisys M CCM223/253 Operation options

Endress+Hauser 35

6.3 Local operation

6.3.1 Automatic/manual mode

The transmitter normally operates in automatic mode. Here, the relays are triggered by

the transmitter. In the manual mode, you can trigger the relays manually using the REL

key or start the cleaning function.

How to change the operating mode:

A0027242

1. The transmitter is in automatic mode. The top LED (green)

next to the AUTO key is lit.

A0027243

2. Press the AUTOMATIC key.

A0027240

3. To enable the manual mode, enter the code 22 via the PLUS

and MINUS keys and press ENTER to confirm.

The lower LED (manual mode) is lit.

A0027241

4. Select the relay or the function.

You can use the REL key to switch between the relays. The

relay selected and the switch status (ON/OFF) is displayed on

the second line of the display.

In the manual mode, the measured value is displayed

continuously (e.g. for measured value monitoring for dosing

functions).

A0027240

5. Switch the relay. The relay is switched on with PLUS and

switched off with MINUS.

The relay remains in this switched state until it is switched

again.

A0027234

6. Press the AUTOMATIC key to return to the measuring mode,

i.e. to the automatic mode.

All the relays are triggered again by the transmitter.

• The operating mode remains in effect even after a power failure. The relays assume

the quiescent state, however.

• The manual mode has priority over all other automatic functions.

• Hardware locking is not possible in the manual mode.

• The manual settings are kept until they are actively reset.

• Error code E102 is signaled during manual operation.

Operation options Liquisys M CCM223/253

36 Endress+Hauser

6.3.2 Operating concept

Operating modes

Code

Measuring mode:

standard mode of

operation, displaying

current measured values

Setup mode

access to all

configuration

settings

Calibration mode:

execution of

calibration routine

The function groups

are selected with the

PLUS or MINUS key.

A0027244-EN

26 Description of the possible operating modes

If no key is pressed in the setup mode for approx. 15 min, the device automatically

returns to the measuring mode. Any active hold (hold during setup) is canceled.

Access codes

All device access codes are fixed and cannot be altered. When the device requests the

access code, it distinguishes between different codes.

• CAL key + code 22: access to Calibration and Offset menu

• ENTER key + code 22: access to the menus for the parameters which make

configuration and user-specific settings possible

• PLUS + ENTER keys simultaneously (min. 3 s): lock the keyboard

• CAL + MINUS keys simultaneously (min. 3 s): unlock the keyboard

• CAL or ENTER key + any code: access to read mode, i.e. all the settings can be read but

not modified.

The device continues measuring in the read mode. It does not shift to the "Hold" status.

The current output and the controllers remain active.

Liquisys M CCM223/253 Operation options

Endress+Hauser 37

Menu structure

The configuration and calibration functions are arranged in function groups.

• In the setup mode, select a function group with the PLUS and MINUS keys.

• In the function group itself, switch from function to function with the ENTER key.

• Within the function, select the desired option with the PLUS and MINUS keys or edit the

settings with these keys. Then confirm with the ENTER key and continue.

• Press the PLUS and MINUS keys simultaneously (Escape function) to exit programming

(return to the main menu).

• Press the PLUS and MINUS keys simultaneously again to switch to the measuring mode.

If a modified setting is not confirmed by pressing ENTER, the old setting is retained.

An overview of the menu structure is provided in the Appendix to these Operating

Instructions.

E E

-

1

2

3

E

E

E

E

A0027245

27 Menu structure

1 Functions (selection of parameters, entry of numbers)

2 Function groups, scroll backwards and forwards with the PLUS and MINUS keys

3 Switch from function to function with the ENTER key

Hold function: "freeze" the outputs

In both the setup mode and during calibration, the current output can be "frozen" (factory

setting), i.e. it constantly retains its current status. "HOLD" appears on the display. If the

controller actuating variable (steady control 4 to 20 mA) is output via current output 2, it

is set to 0/4 mA during a hold.

• Hold settings can be found in the "Service" function group.

• During a hold, all contacts assume a quiescent state.

• An active hold has priority over all other automatic functions.

• With every hold, the I-component of the controller is set to "0".

• Any alarm delay is reset to "0".

• This function can also be activated externally via the hold input (see Wiring diagram;

binary input 1).

• A manual hold (field S3) remains active even after a power failure.

Commissioning Liquisys M CCM223/253

38 Endress+Hauser

7 Commissioning

7.1 Function check

L

WARNING

Incorrect connection, incorrect supply voltage

Safety risks for staff and device malfunctions

‣

Check that all connections have been established correctly in accordance with the

wiring diagram.

‣

Ensure that the supply voltage matches the voltage indicated on the nameplate.

7.2 Switching on

Familiarize yourself with the operation of the transmitter before it is first switched on. In

particular please read the "Basic safety instructions" and "Operation options" sections. After

power-up, the device performs a self-test and then goes to the measuring mode.

Now calibrate the sensor in accordance with the instructions in the "Calibration" section.

During initial commissioning, the sensor must be calibrated so that the measuring

system can return precise measurement data.

Then perform the first configuration in accordance with the instructions in the "Quick

setup" section. The values set by the user are kept even in the event of a power failure.

The following function groups are available in the transmitter (the groups that are only

available in the Plus Package are marked accordingly in the functional description):

Setup mode

• SETUP 1 (A)

• SETUP 2 (B)

• CURRENT INPUT (Z)

• CURRENT OUTPUT (O)

• ALARM (F)

• CHECK (P)

• RELAY (R)

• SERVICE (S)

• E+H SERVICE (E)

• INTERFACE (I)

Calibration and offset mode

CALIBRATION (C)

A detailed explanation of the function groups available in the transmitter can be

found in the "Device configuration" section.

s

F3

Err.delay

Function display:

The displayed code indicates

the function position in the

function group.

Additional information

2

A0025560-EN

28 Information for the user on the display

Liquisys M CCM223/253 Commissioning

Endress+Hauser 39

C C1 C111

C121

C131

C132 C133

A0027502

29 Function code

To make it easier for you to select and find function

groups and functions, a code for the corresponding

field is displayed for each function → 28

The structure of this code is illustrated in → 29.

The function groups are indicated as letters in the first

column (see the names of the function groups). The

functions of the individual groups are displayed

incrementally by row and by column.

Factory settings

The first time the device is switched on, the factory setting is set for all the functions. The

table below provides an overview of the most important settings.

All other factory settings can be found in the description of the individual function groups

in the "System configuration" section (the factory setting is highlighted in bold).

Function Factory setting

Type of measurement Concentration of free chlorine/total chlorine in

mg/l

Temperature measurement in °C

pH value (EP version)

Sensor setting CCS140 for free chlorine

Alarm contact Steady contact

Alarm delay Setting in minutes

Error current for alarm 22 mA

Check functions* Off. Can be switched on if required

Limit value 1 and 2 for chlorine/chlorine dioxide 0.5 mg/l

Limit value 1 and 2 for pH* pH 7.2

Limit value 1 and 2 for ORP* 750 mV

Limit value 1 and 2 for temperature 50 °C

Current outputs 1 and 2 4 to 20 mA

Current output 1: measured value for 4 mA signal current 0.00 mg/l

Current output 1: measured value for 20 mA signal current 2.00 mg/l

Current output 2: temperature value for 4 mA signal current* 0 °C

Current output 2: temperature value for 20 mA signal current* 50 °C

* with appropriate version

Commissioning Liquisys M CCM223/253

40 Endress+Hauser

7.3 Quick Setup

After power-up, you must make some settings to configure the most important functions

of the transmitter which are required for correct measurement. The following section gives

an example of this.

User entry Range of

adjustment

(factory settings in

bold)

Display

1. Press the ENTER key

2. Enter the code 22 to open access to the menus.

Press the ENTER key.

3. Press the MINUS key until you get to the "Service"

function group.

S

SERVICE

A0008408-EN

4. Press ENTER to be able to make your settings.

5. Select your language in S1, e.g. "ENG" for English.

Press ENTER to confirm your entry.

ENG = English

GER = German

FRA = French

ITA = Italian

NEL = Dutch

ESP = Spanish

S1

Language

ENG

A0008409-EN

6. Press the PLUS and MINUS key simultaneously to

exit the "Service" function group.

7. Press the MINUS key until you get to the "Setup 1"

function group.

A

SETUP 1

A0007824-EN

8. Press ENTER to be able to make your settings for

"Setup 1".

9. In A1, select the desired sensor type.

Press ENTER to confirm your entry.

120 = CCS120

140 = CCS140

141 = CCS141

240 = CCS240

241 = CCS241

963

A1

Sensor

140

A0001954-EN

10. In A2, select the desired engineering unit.

Press ENTER to confirm your entry.

mg/l

ppm

ppb

A2

Unit

mg/l

A0024894-EN

11. If you have connected the INS proximity switch, you

can switch on flow monitoring of the sample

stream through the CCA250 assembly in A3.

Press ENTER to confirm your entry.

Off

INS

A3

Cont.stop

Off

A0001956-EN

12. If flow briefly falls below the threshold value, you

can suppress controller switch-off by entering a

delay time in A4.

Press ENTER to confirm your entry.

0 s

0 to 2000 s

A4

s

Off Delay

0

A0001957-EN

Liquisys M CCM223/253 Commissioning

Endress+Hauser 41

User entry Range of

adjustment

(factory settings in

bold)

Display

13. In A5, enter the delay time for controller switch-

on.

In the case of chlorine/chlorine dioxide control, a

delay until the reception of a representative

measured value is recommended after a long

period without flow.

Press ENTER to confirm your entry.

0 s

0 to 2000 s

A5

s

On Delay

0

A0001958-EN

14. In A6, select the binary input.

Press ENTER to confirm your entry.

Hold = external

hold

Clean = cleaning

trigger

A6

Digital 1

Hold

A0001959-EN

15. In A7, enter the measured value damping.

Measured value damping causes the measured

value to be averaged over the specified number of

individual measured values (if A7 = 1, no damping

takes place).

Press ENTER to confirm your entry.

The display returns to the initial display of the

"Setup 1" function group.

1

1 to 60

A7

Damping

1

A0001960-EN

16. Press PLUS and MINUS simultaneously to switch to

the measurement mode.

Commissioning Liquisys M CCM223/253

42 Endress+Hauser

7.4 Device configuration

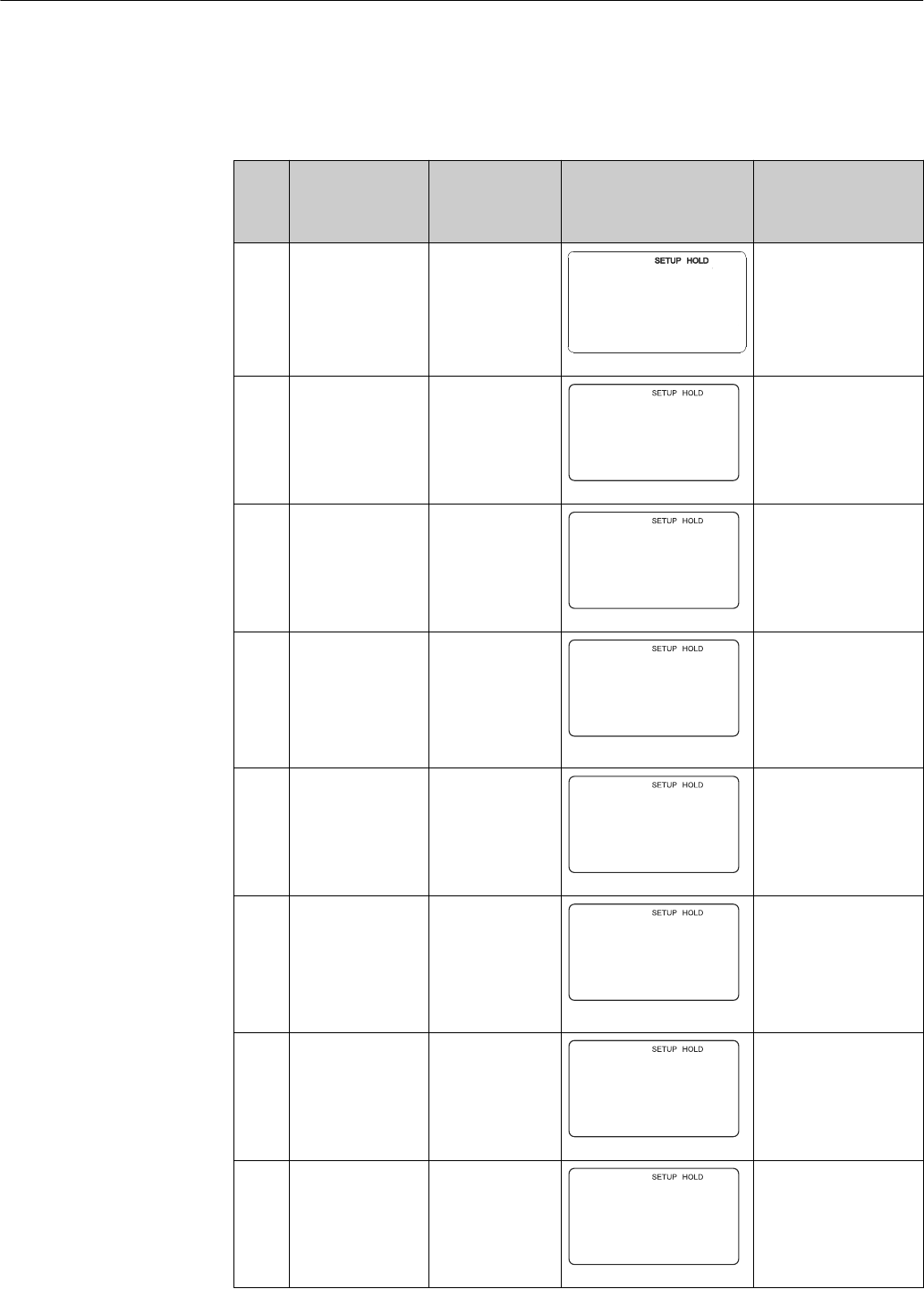

7.4.1 Setup 1 (chlorine/chlorine dioxide)

Coding Field Range of

adjustment

(factory settings

in bold)

Display Info

A

SETUP 1 function

group

A

SETUP 1

A0007824-EN

Configuration of basic

functions

A1 Select the connected

sensor type

120 = CCS120

140 = CCS140

240 = CCS240

241 = CCS241

963

A1

Sensor

140

A0001954-EN

If the device is reset in

field S9, the configured

sensor type is not

modified.

A2 Select the display

unit

mg/l

ppm

ppb

A2

Unit

mg/l

A0001955-EN

A3 Select flow

monitoring of the

sample flow through

the CCA250

assembly (with

controller switch-

off)

Off

INS

A3

Cont.stop

Off

A0001956-EN

May only be switched on

when the INS proximity

switch is connected.

A4 Enter the delay for

controller switch-off

by the sample flow

0 s

0 to 2000 s

A4

s

Off Delay

0

A0001957-EN

Brief flow shortfalls can

be suppressed by this

delay and do not result in

controller switch-off.

A5 Enter the delay for

controller switch-on

by the sample flow

0 s

0 to 2000 s

A5

s

On Delay

0

A0001958-EN

In the case of chlorine/

chlorine dioxide control, a

delay until the reception

of a representative

measured value is

recommended after a

long period without flow.

A6 Select binary input 1 Hold = external

hold

Clean = cleaning

trigger

A6

Digital 1

Hold

A0001959-EN

A7 Enter the value for

measured value

damping

1

1 to 60

A7

Damping

1

A0001960-EN

Liquisys M CCM223/253 Commissioning

Endress+Hauser 43

Flow monitoring in the sample stream

If the flow falls below 30 l/h or if sample flow through the CCA250 assembly fails

completely, this causes an alarm to be signaled when an INS proximity switch is connected.

This alarm becomes active when the switch-off delay time elapses (A4 field). The alarm is

canceled immediately as soon as the necessary rate of flow is restored. The device

automatically stops the dosing of chemicals and the Chemoclean cleaning function for the

duration of the alarm. All the relays assigned to the PID controller or to a cleaning function

go to the quiescent state. The NO contact closes in the case of the three-point step

controller. Dosing and cleaning actions are only resumed once the switch-on delay time

has elapsed (A5 field).

0

1

1

1

1

0

0

0

A

B

C

D

E

F

G

A4

A4

A5

A5

A0002018

30 Alarm signaling and dosing switch-off by the sample stream

A Flow in sample stream

B Relay contacts of PID controller

C NO contact on three-point step controller

D Alarm relay

E Flow < 30 l/h or flow failure

F Flow alarm

G Flow restored

0 Off

1 On

A4 Field A4 (controller switch-off delay)

A5 Field A5 (controller switch-on delay)

Commissioning Liquisys M CCM223/253

44 Endress+Hauser

7.4.2 Setup 2 (temperature or pH/ORP)

Use this function group to change the settings for temperature measurement and pH/ORP

measurement.

You already made all the settings for this function group during initial commissioning.

However, you can change the values chosen at any time.

Coding Field Range of

adjustment

(factory settings

in bold)

Display Info

B

SETUP 2

function group

B

SETUP 2

A0007830-EN

Initial display screen in the

SETUP 2 function group

B1 Select operating

mode

Off

pH

ORPmV

B1

Oper.Mode

Off

A0001963-EN

Field only available for EP

version.

ORPmV = ORP (oxidation-

reduction potential) in mV.

When the operating mode is

changed, all user settings are

automatically reset to the basic

settings.

If the device is reset in field

S9, the configured operating

mode is not modified.

B2 Select pH

compensation

Off

Manu

Auto

B2

pH comp.

Off

A0001964-EN

Field only available for ES and

EP versions. (operation with

CCS140/141)

B3 Enter the value

for manual pH

compensation

Last

compensation

value

pH 4.00 to 9.00

B3

pH

7.20

Manu.Comp

A0001965-EN

The field is only displayed if »

manual« (Manu) was selected

in the B2 field.

The measured pH value is

displayed as the secondary

parameter.

B4 Enter the

process

temperature

Current

measured value

0 to 50 °C

B4

¡C

RealTemp.

0.0

A0001966-EN

You can edit the displayed

value.

The value can be changed by a

maximum of ±5 °C.

As the measurements are very

accurate, the value generally

does not need to be adjusted.

B5 Enter the

temperature

differential

(offset)

Current offset

-5.0 to 5.0 °C

¡

C

B5

Temp.Offs

0.0

A0007835-EN

The offset is the difference

between the actual value

entered and the measured

temperature.

Types of chlorine

A distinction is made between free chlorine and combined chlorine.

Free chlorine

Liquisys M CCM223/253 Commissioning

Endress+Hauser 45

Free chlorine is understood as the sum of elementary chlorine (Cl

2

), hypochlorous acid

(HOCl) and hypochlorite ions (OCl

–

). These forms of chlorine are able to kill bacteria,

inactivate viruses and oxidize organic substances within a short period of time.

Combined chlorine

Combined chlorine refers to the forms of chlorine in water and consists of chemical

compounds made up of chlorine and ammonia (NH

3

) or ammonium (NH

4

+

) entstehen.

Combined chlorine still has a disinfectant property, but far less than that of free chlorine.

Total chlorine

Total chlorine is the sum of free chlorine and combined chlorine.

Measuring free chlorine with the CCS140 and CCS141 sensors

Molecular chlorine (Cl

2

) is present at pH values < 4. Consequently, hypochlorous acid

(HOCl) and hypochlorite (OCl– remain as components of free chlorine within the range of

pH 4 to 11.

As hypochlorous acid splits up (dissociates) with an increasing pH value to form

hypochlorite ions (OCl

–

) and hydrogen ions (H

+

), the amounts of the individual

components of free effective chlorine change with the pH value. For example, if the

amount of hypochlorous acid is 97% at pH 6, it drops to approx. 3% at pH 9.

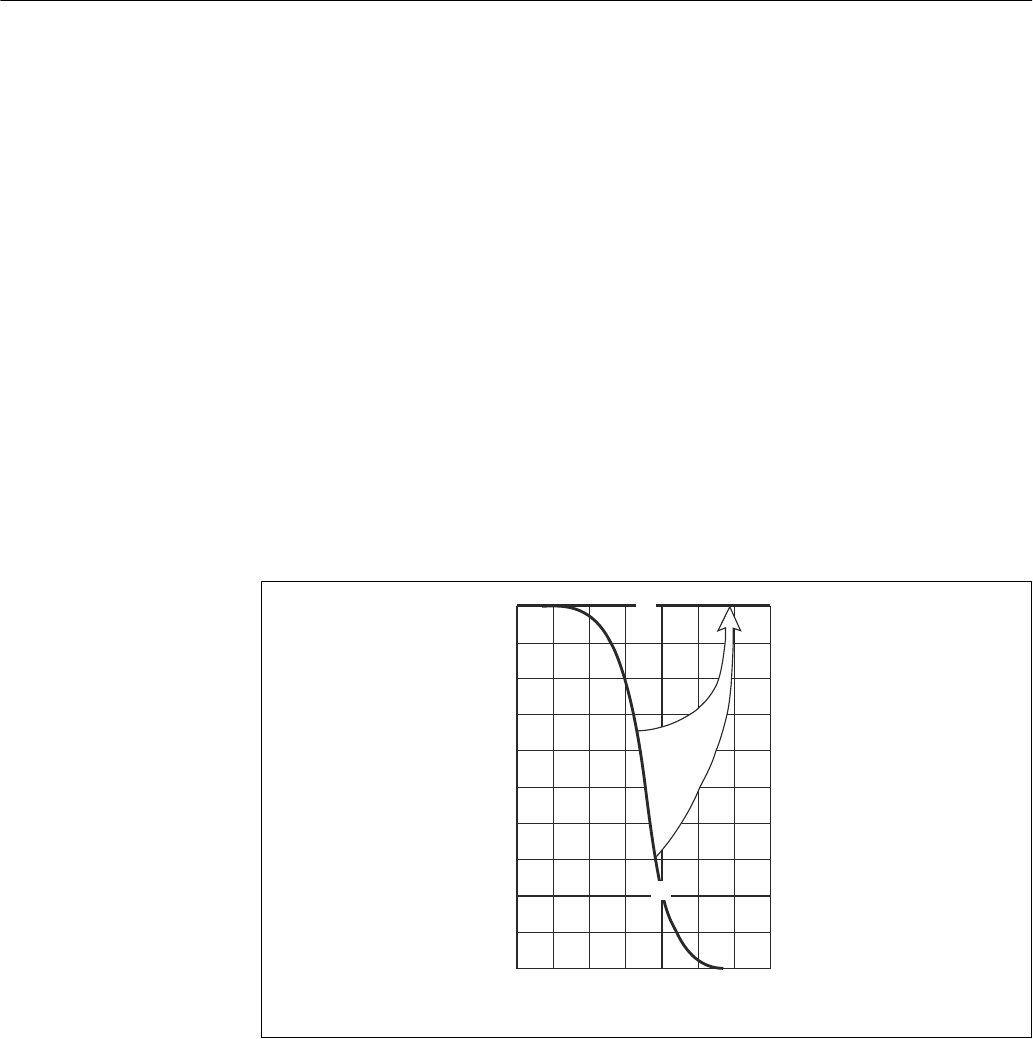

%

100

80

60

40

20

0

4

5 6 7 8 9 10 11

100

%

80

60

40

20

0

A

B

C

pH

OCl

-

HOCl

A0002017

31 Basic representation of pH compensation

A Measured value with pH compensation

B Measured value without pH compensation

C pH compensation

The CCS140 or CCS141 chlorine sensors selectively measure the amount of hypochlorous

acid in amperometric measurement.. This works as a powerful disinfectant in a watery

solution. In contrast to this, hypochlorite is an extremely weak disinfectant. Therefore,

when used as a disinfectant at higher pH values, the effectiveness of chlorine is limited. As

hypochlorite ions cannot permeate the sensor membrane, the sensors do not record this

value.

Measuring total chlorine with the CCS120 sensor

If, in addition to free available chlorine, ammonium is also present in the medium -

preferably water - chloramines (Cl

n

NH

m

) form quickly. This compound is formed in various

Commissioning Liquisys M CCM223/253

46 Endress+Hauser

degrees of dimerization. It is known as "combined chlorine". Combined chlorine has a lower

disinfecting effect but it forms larger depots compared to free chlorine. This means:

• Significantly slower elimination of existing germs.

• Disinfectant effect over considerably longer periods.

• Disinfectant effect over considerably longer transport distances.

The CCS120 amperometric sensor measures the total chlorine content, i.e. free chlorine as

well as chloramine components.

This type of measurement is only slightly pH dependent.

pH compensation of the chlorine sensor signal during free chlorine measurement

(only for ES and EP versions, for CCS140/141 sensors)

To calibrate and verify the chlorine measuring system, a colorimetric reference

measurement must be carried out using the DPD method. Free chlorine reacts with

diethyl-p-phenylendiamine to form a red dye. The intensity of the red color increases

proportionally to the chlorine content. With the DPD method, the water under

measurement is constantly buffered to a pH value of approx. 6.3. Therefore, the pH value

of the water under measurement is not included in the DPD measurement here. Due to the

buffer function in the DPD method, all components of free effective chlorine are recorded

and thus the total free chlorine is measured.

If you select pH compensation in fields B2 or B3, the sum of hypochlorous acid and

hypochlorite corresponding to the DPD measurement is calculated from the hypochlorous

acid measured by the sensor and the pH value in the region of pH 4 to 9. For this

calculation, the curve is stored in the transmitter.

When free chlorine is measured with pH compensation switched on, always perform

calibration in pH-compensated mode.

When you use pH compensation, the measured chlorine value that is displayed and applied

to the device output corresponds to the DPD measured value even if the pH values

fluctuate. If you do not use pH compensation, the measured chlorine value corresponds to

the DPD measurement only if the pH value remains unchanged compared with the

calibration. Without pH compensation, the chlorine measuring system must be

recalibrated when the pH value changes.

pH compensation can be performed both automatically using the connected pH electrode

(EP version) and manually (ES version) by entering the pH value in the B3 field.

Chlorine dioxide and total chlorine measurement is largely or entirely independent of the

pH value and therefore no pH compensation is required.

Accuracy of pH compensation when measuring free chlorine

The accuracy of the pH-compensated measured chlorine value is derived from the sum of

several individual deviations (chlorine, pH, temperature, DPD measurement etc.).

High levels of hypochlorous acid (HOCl) during chlorine calibration have a positive effect

on accuracy, whereas low levels of hypochlorous acid have a negative effect.

The inaccuracy of the pH-compensated measured chlorine value increases the greater the

pH difference between measuring mode and chlorine calibration or the more inaccurate

the underlying individual measured values are.

Calibration of free chlorine taking the pH value into consideration

The reference measurement (DPD method, photometer) determines the total free chlorine

by buffering to pH 6.2. In contrast to this, amperometric measurement determines only

the HOCl component.

During operation, pH compensation is effective up to a pH value of 9. However, there is

hardly any HOCl left at this pH value, and the measured current is very low. At this point,

pH compensation has the effect of increasing the measured HOCl value to the actual value

of the free chlorine.

Liquisys M CCM223/253 Commissioning

Endress+Hauser 47

Calibration of the complete measuring system makes sense only up to a pH value of the

medium of 8 or 8.2.

Sensor pH value HOCl content Uncompensated value Compensated value

CCS141 8.2 15 % 12 nA 80 nA

CCS140 8 20 % 4 nA 20 nA

Above these pH values, the total error of the measuring system is unacceptably high.

7.4.3 Current input

For the "Current input" function group, you require a relay card with a current input which

is not available in the basic device version. With this function group, you can monitor

process parameters and use them for feedforward control. For this purpose, you must

connect the current output of an external measured variable (e.g. flowmeter) to the 4 to

20mA input of the transmitter. The following assignment applies:

Flow in main stream Current signal in mA Current input signal in %

Flowmeter start of measuring range 4 0

Flowmeter end of measuring range 20 100

Flow monitoring in the main stream

This arrangement is particularly practical if the sample flow through the CCA250 assembly

is completely independent of the flow in the main stream.

This permits signaling of an alarm condition in the main stream (flow too low or has

completely stopped) and triggers dosing switch-off even if the medium flow is maintained

due to the method of installation.

This monitoring method corresponds to monitoring the flow rate in the sample stream

(see SETUP 1).

0

1

1

1

1

0

0

0

A

B

C

D

E

F

G

Z2

Z2

Z3

Z3

A0002019

32 Alarm signaling and dosing switch-off by the main stream

A Flow in main stream F Flow alarm

B Relay contacts of PID controller G Flow restoration

Commissioning Liquisys M CCM223/253

48 Endress+Hauser

C NO contact on three-point step controller Z2 Delay for controller switch-off, see field Z2

D Alarm relay Z3 Delay for controller switch-on, see field Z3

E Flow below switch-off limit Z 4 or flow failure 0 Off

1 On

Feedforward control to PID controller

You can optimize control on control systems with very short response times by measuring

the medium flow rate in addition to the oxygen content. Then apply this flow rate value (4

to 20 mA) as feedforward control to the PID controller.

F

4 ... 20 mA

Cl

2

pH

1

2

3

4

5

6

ENDRESS+HAUSER

LIQUISYS S

A0025120

33 Sample arrangement for feedforward control of the flow in the main stream to the PID controller

1 Medium tapping point 5 Flow assembly CCA250

2 Static mixer 6 Liquisys CCM253

3 Injection points

4 Flowmeter

Feedforward control is a multiplying function as illustrated in the figure below (example

with factory setting):

Liquisys M CCM223/253 Commissioning

Endress+Hauser 49

1

0 20 40 60 80 100Z7

1.5

0.5

Y

X

A0008942

34 Multiplying feedforward control

Y Gain K

infl

X Current input signal in [%]

Commissioning Liquisys M CCM223/253

50 Endress+Hauser

Functions marked in italics are not supported by the basic device version.

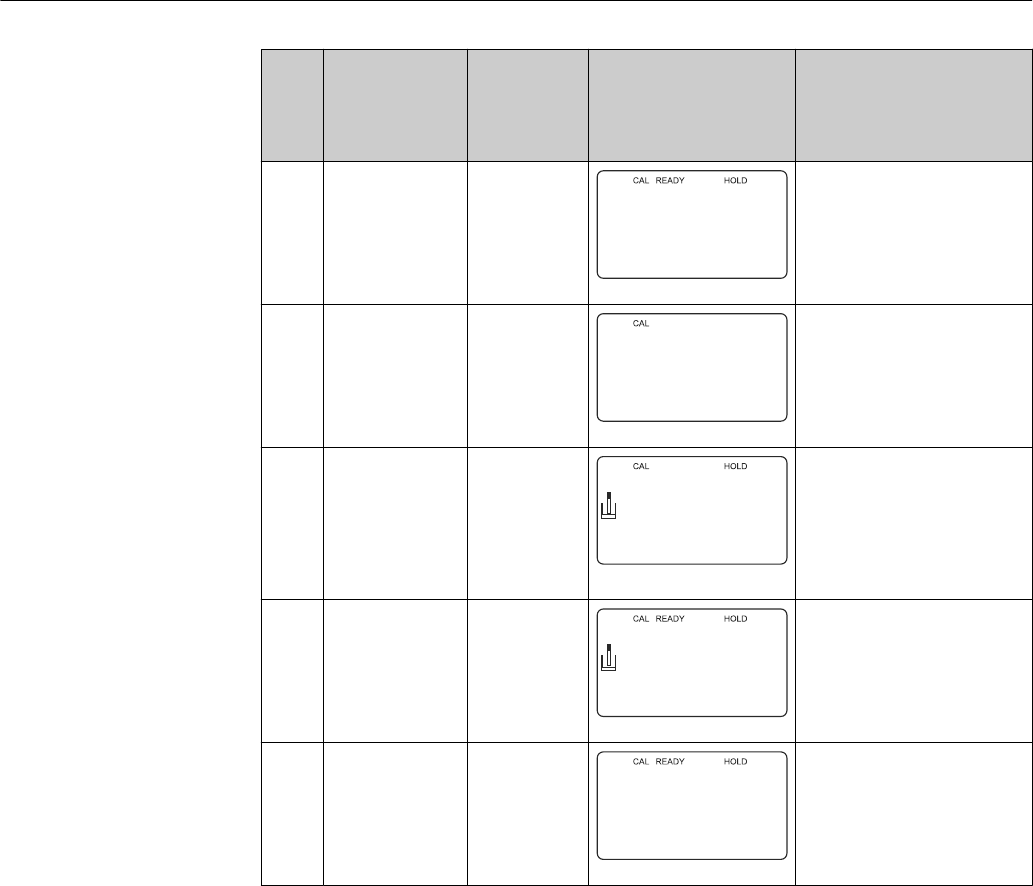

Coding Field Range of

adjustment

(factory

settings in

bold)

Display Info

Z

CURRENT INPUT

function group

Z

CUR.INPUT

A0024903-EN

Current input settings

Z1 Select flow

monitoring of main

stream (with

controller switch-

off)

Off

On

Z1

Cont.stop

Off

A0024904-EN

Flow monitoring may only be

switched on if the flowmeter is

connected in the main stream. If

Z1 = off, fields Z2 to Z5 are not

available.

Z2 Enter the delay for

controller switch-

off through current

input

0 s

0 to 2000 s

Z2

s

Off Delay

0

A0024905-EN

Brief flow shortfalls can be

suppressed by this delay and do

not result in controller switch-

off.

Z3 Enter the delay for

controller switch-

on through current

input

0 s

0 to 2000 s

Z3

s

On Delay

0

A0024934-EN

In the case of a controller, a

delay until the reception of a

representative measured value

is recommended after a long

period without flow.

Z4 Enter the switch-off

limit value for the

current input

50 %

0 to 100 %

Z4

%

A.Thresh

50

A0024935-EN

0 to 100% corresponds to 4 to

20 mA at the current input.

Observe measured value

assignment to the current

output of the flowmeter.

Z5 Enter the switch-off

direction for the

current input

Low

High

Z5

Stop Dir

Low

A0024939-EN

The controller is switched off if

the value entered in Z4 is

undershot or overshot.

Z6 Select feedforward

control to PID

controller

Off

Lin = linear

Basic

Z6

PID influ

Off

A0024940-EN

If Z6 = off, the field Z7 is not

available.