SERVICE MANUAL

TABLE OF

CONTENTS

I Introduction 2

II Assembly of a standard ballnut 3

III Mounting of a standard ballnut 4

IV Instruction for preload installation 5

V Setting the preload ballnut 6-7

VI Lubrication 8

VII Bellows & Wipers 9

VIII Bearing Mounts 10-13

IX Troubleshooting 14

X Retrofit for Bridgeport Series 1 Mills 15-17

XI Contact Information 18

I. INTRODUCTION

This service manual was prepared to insure proper

installation and performance of the RBS ball screw

assembly throughout the life of the screw. It is only

meant as a convenient reference and not a complete

guide of the topics within.

The products shown in this catalog are intended

for industrial use only and should not be used

to lift, support or otherwise transport people,

unless you obtain a written authorization for each

individual application from Rockford Ball Screw Co.

The specifications and data in this publication are

believed to be accurate and reliable. However, it is

the responsibility of the product user to determine

the suitability of Rockford Ball Screw products for a

specific application.

3

rockfordballscrew.com

800-475-9532

II. ASSEMBLY OF A STANDARD BALLNUT

1 Remove the return tube clamp and the return tube

from the ballnut.

2 Place the nut mid-way on the screw and align the

ball grooves in the nut with those on the screw.

3 Place a short length of rod or dowel into one return

tube hole to prevent loss of balls.

4 Place balls successively into the other return tube

hole, rotating the screw so that the balls are fed

along the thread and through the nut until the ball

circuit is completely full.

5 Remove rod or dowel, being careful not to rotate the

nut. The balls must not be in the return tube holes.

Balls should only be in the mesh between the ball

nut and screw.

6 On both ends of the return tube, place a small

amount of light grease.

7 Load this half tube full of balls.

8 Place the second half of the return tube over the

balls and hold the two halves tightly together.

9 Place the return tube ends into the ball circuit holes

in the nut (the grease in the tube holes will prevent

the balls from dropping out).

10 Place the tube clamp over the tube (taking care to

keep the two halves together) and secure with the

clamp screws.

CLAMP SCREWS

TUBE CLAMP

RETURN TUBE LOADED

WITH BALLS

A

PPLY GREASE HERE

BALLNUT

FIGURE 1

BALLNUT ASSEMBLY

rockfordballscrew.com

800-475-9532

4

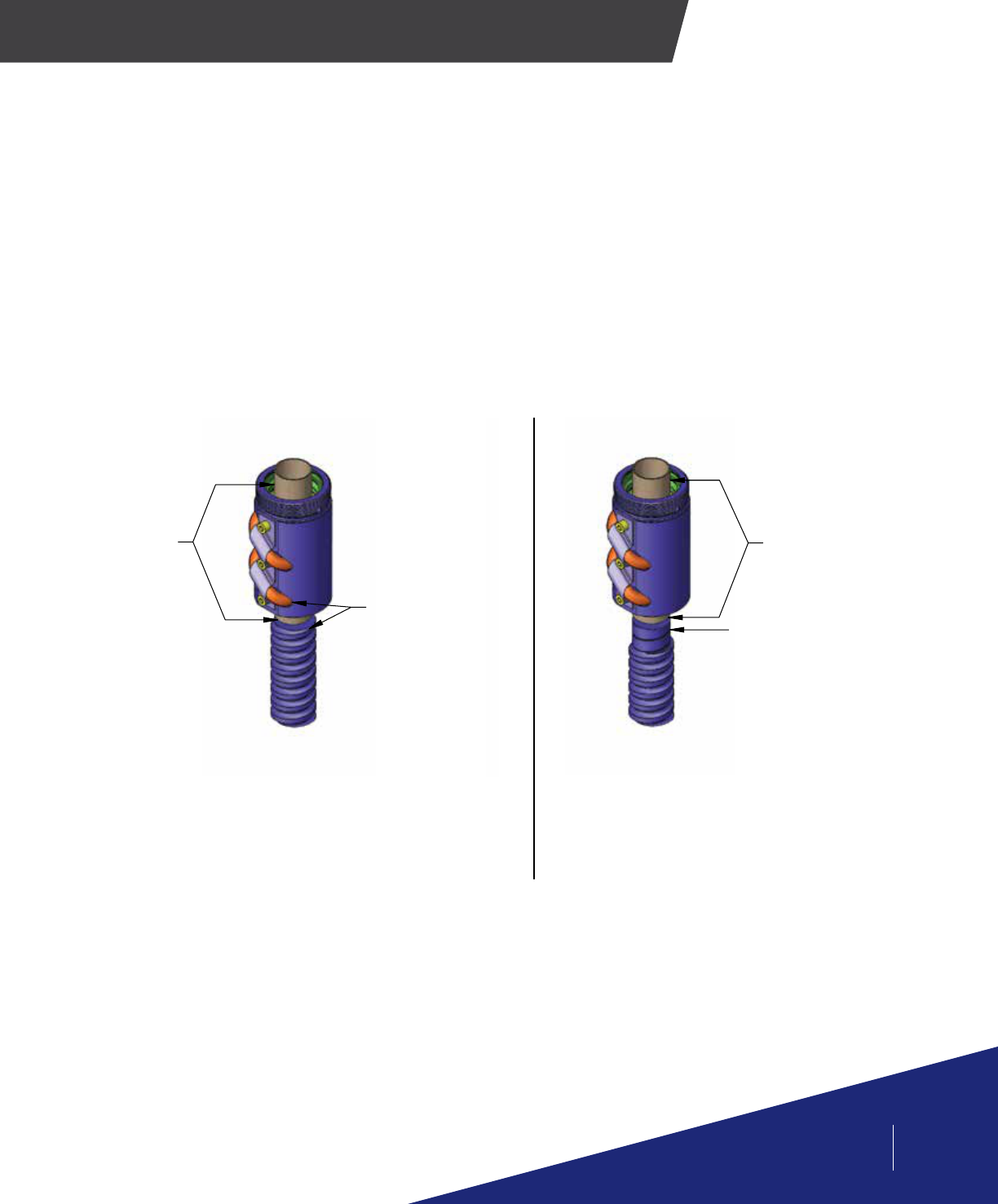

III. MOUNTING OF A STANDARD BALLNUT

1 Remove the tie from the ballnut/arbor assembly.

2 Butt the assembly onto the end of the screw while

continuously holding the arbor (cardboard tube)

steady. Align the bottom of the return tube with the

beginning of the first thread. Do not allow arbor to

come out of contact with screw thread. Failure to do

so could result in the loss of balls from within the

assembly. (See figure 2).

3 If you find that the arbor does not fit up to the

beginning of the thread due to interference from

the journal, (See figure 3).Then it is recommended

that the journal be wrapped in masking tape or

something similar so that the journal OD equals that

of the arbor. This in effect would act as an extension

to the arbor and would fill the same role.

4 Then gently rotate and apply pressure onto the

nut to mount the nut. The arbor should only lose

contact with the end of the screw when the ballnut

is engaged on the screw.

(Not a preload nut or Bridgeport nut)

A

RBOR

BOTTOM OF RETURN

TUBE LINED UP WITH

START OF THREAD

FIGURE 2

MOUNTING ALIGNMENT

JOURNAL

ARBOR

FIGURE 3

JOURNAL INTERFERENCE

A

RBOR

BOTTOM OF RETURN

TUBE LINED UP WITH

START OF THREAD

FIGURE 2

MOUNTING ALIGNMENT

JOURNAL

ARBOR

FIGURE 3

JOURNAL INTERFERENCE

5

rockfordballscrew.com

800-475-9532

IV. INSTRUCTION FOR PRELOAD INSTALLATION

1 Remove the tie that is through the arbor, being

careful not to let the arbor sliding out from within

the assembly.

2 Align the nut assembly to appear like drawing

figure 4.

3 The tangs of the coupler are to be aligned so as to

mate with the ballnuts. An external preload coupler

needs to engage the roll pins to prevent rotation.

4 Transfer the assembly to the screw with some

downward pressure till the threads are engaged

then roll the nut on. Be sure to hold the arbor while

transferring the screw. The arbor should not come

out of contact with the screw until the nuts are fully

engaged. The preload nut is now ready to be set.

BACK BALLNUT

COLLAR

PRELOAD

COUPLER

WAVY

SPRINGS

FRONT BALLNUT

SQUARE NUTS

FRONT BALLNUT

BELLVILLE

SPRINGS

PRELOAD

COUPLER

COLLARBACK BALLNUT

ROUND NUTS

FIGURE 4

DISSASSEMBLED PRELOAD

rockfordballscrew.com

800-475-9532

6

1 Remove the setscrews in the adjusting collar.

2 2. With a spanner wrench (see table 1), tighten the

collar until the desired load is achieved (see table 2,

page 7).

3 3. Put the set screws back in and tighten the set

screws in order to not let the adjusting collar back

off. It is preferred not to tighten the setscrews on the

tang section of the coupler.

Note:

Setting the preload increases the torque on screw by .034 x preload setting x lead of screw.

TABLE 1: SPANNER WRENCH SIZING

MODEL # SPANNER WRENCH HOLE SIZE

RP-10 to RP-16 1/8"

RP-20 to RP-46 3/16"

RP-50 to RP-58 1/4"

RP-60 to RP-74 3/8"

RP-80 1/2"

V. SETTING THE PRELOAD BALLNUT

7

rockfordballscrew.com

800-475-9532

V. SETTING THE PRELOAD BALLNUT - CONTINUED

Note: Due to spring load tolerances, these figures are ±20%, use the number of turns as a guide only.

TABLE 2: PRELOAD SETTINGS

MODEL NO.

RECOMMENDED MAXIMUM

PRELOAD (LB) # OF TURNS PRELOAD (LB) # OF TURNS

RP10 15 0.10 45 0.30

RP11 30 0.20 90 0.50

RP12 17 0.10 51 0.30

RP15 3 0.03 8 0.05

RP16 5 0.03 15 0.10

RP20 85 0.10 255 0.30

RP21 14 0.05 42 0.20

RP30/31 83 1.25 248 1.50

RP30A/31A 165 1.25 495 1.50

RP32 17 0.30 51 0.90

RP34/34A 190 0.30 570 1.0 0

RP35/35A 95 0.20 285 0.50

RP36 16 0.05 48 0.10

RP37 340 0.60 1020 1.25

RP38 60 0.10 180 0.30

RP40/41 163 0.10 488 0.30

RP40A/40AR/40RF/41LF 325 0.20 975 0.60

RP40B 450 0.30 1350 0.80

RP42 345 0.20 1035 0.60

RP43 425 0.40 1275 1. 10

RP44 230 0.20 690 0.40

RP45/47 245 0.20 735 0.50

BRP45/47 145 0.10 435 0.30

RP46 49 0.05 147 0.10

RP48 330 0.20 990 0.60

RP50 905 0.60 2715 1.80

RP50A/51A 1290 1.20 3870 3.20

RP53/54 425 0.80 1275 2.00

RP53A/54A 640 1.30 1920 2.00

RP55/56 800 0.50 2400 1.70

RP57 1005 0.60 3015 2.00

RP58/58A 735 0.50 2205 1.60

RP60/63 1980 1.20 5940 2.00

RP60A 2970 1.80 8910 2.10

RP61 2250 0.40 6750 1.20

RP62 1800 0.30 5400 1.00

RP70 2200 1.20 6600 2.80

RP71 2650 1.50 7950 2.80

RP74 630 0.80 1890 2.00

RP75 3250 0.60 9750 1.90

RP80/80A/81A 4200 1.80 12600 3.20

rockfordballscrew.com

800-475-9532

8

VI. LUBRICATION

Apply lubrication between the ball & raceway to avoid

friction failure, deformation, and the shortening of life

of the ball screw. It is only necessary to prevent the ball

nut assembly from becoming dry. Lubrication should be

applied on the surface of the shaft or through the fitting

into the nut. A 90% reduction in ball bearing screw life

should be allowed where dry operation is unavoidable.

At speeds greater than 200 in/min it is recommended

oil be used. Grease can be used for speeds below 200

in/min. In the event that oil or grease is not an option,

dry film lubrication is recommended. Surfaces should

be phosphate coated before being coated with dry film

lubrication.

For a list of acceptable lubricants see table 3.

Note:

For general application use, the range of NLGI 2-3 of lithium base grease

or the range of 46-100 CST at 40 ºC of oil is recommended. Graphite

based lubricants are not recommended due to their abrasive qualities.

TABLE 3: ACCEPTABLE LUBRICANTS

LUBRICANT BRAND NAME MANUFACTURER

Grease

Alvania No. 2

Mobilux No. 2

Beacon 2

Shell

Mobil

Esso

Oil

Tellus 33

D.T.E. Heavy Medium

Teresso 52

Shell

Mobil

Esso

Dry Film

Dow Corning 321

Perma-Silk

Dow Corning

EM Corporation

9

rockfordballscrew.com

800-475-9532

VII. BELLOWS AND WIPERS

Conditions for Wipers, Wiper Installation

Wipers are recommended in any conditions where the

ball nut and/or screws are exposed to debris.

Slide two wipers into the ballnut along the screw. Make

sure the brush and wiper is held entirely within the nut.

Push the snap ring into the snap ring groove just inside

the nut. Repeat this process for the other side.

Installation of ballnut onto the screw would be made

more difficult if wipers are already installed in the ballnut.

If you prefer the wiper could be temporarily removed to

ease installation. However, it is not possible to remove

wipers that have been installed in the nut with epoxy.

Bellows

Bellows (or boot) should be considered when a wiper

is unable to adequately prevent the entry of debris into

the nut. Here is a list of manufactures to consider when

ordering a bellows.

Dynatech

Manufacturing

2300 S Calhoun Rd

New Berlin, WI 53151

phone: (262) 317-919

fax: (262) 786-3280

Heeco Protekto Boots

P.O. Box 9279

Tampa, FL 33674

phone: (813)886-7584

fax: (813) 885-2350

Hennig Inc

9900 N Alpine RD

Machesney Park, IL 61115

phone: (815) 636-9900

fax: (815) 636-9737

rockfordballscrew.com

800-475-9532

10

VIII. BEARING MOUNTS

BM Series Bearing Mounts are SIMPLE supports that

utilize a set of angular contact ball bearings mounted back

to back. These bearing mounts are designed to support

radial and axial load components of force. (see page 11)

BMF Series Bearing Mounts are FIXED RIGID

supports that utilize a set of spaced angular contact ball

bearings. These bearing mounts are designed to support

radial and axial load components of force. (see page 12)

BMR Series Bearing Mounts are SIMPLE RADIAL

supports utilizing shielded radial ball bearings for

supporting radial load components. These bearing

mounts are NOT intended to support axial load

components of force. (see page 13)

REAR

FRONT

BM BEARING BLOCK

FRONT

BMF BEARING BLOCK

REAR

FRONT

REAR

BMR BEARING BLOCK

FIGURE 5

BEARING MOUNT

Note:

1 A tubular arbor should be made from aluminum to prevent damage to the journal and bearings. The arbor’s OD

is to be the same diameter as rear ring seal and ID to have clearance on journal.

2 Do not over tighten the bearings, this will increase the drag torque and shorten the life of the bearings.

3 Rockford Ball Screw is not responsible for damage or personal injury due to incorrect assembly, sizing or

mounting of R/B/S bearing block assemblies.

TABLE 4: LOCKNUT TORQUE TABLE FOR BEARING MOUNT MODEL #BM/BMF/BMR

Bearing Size 10 12 15 20 25 30 45

Torque (FT-LB)

10-20 10-20 10-20 12-35 23-50 32-60 32-60

11

rockfordballscrew.com

800-475-9532

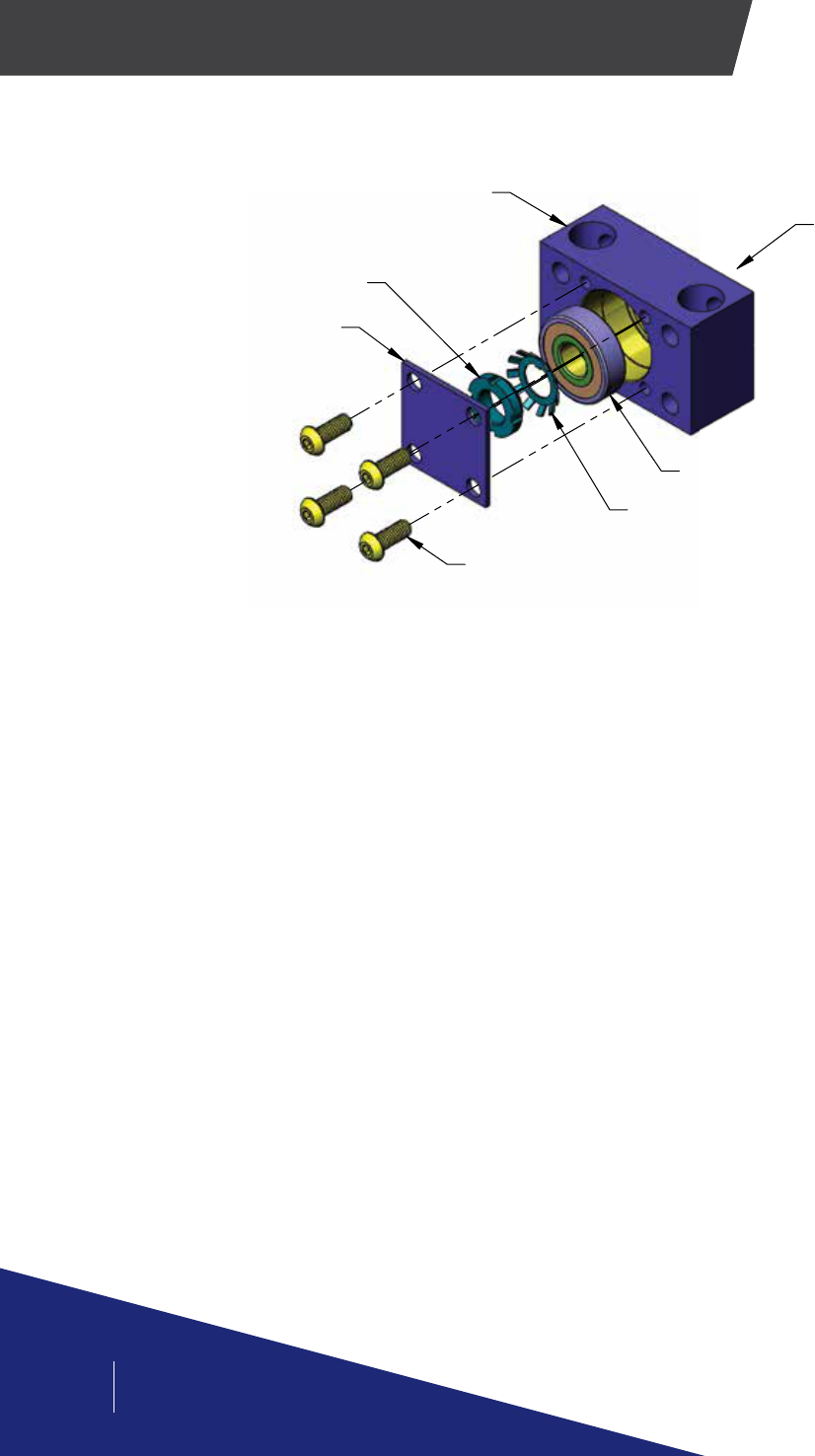

VIII. BEARING MOUNTS - CONTINUED

1 Install the entire block either horizontal or vertical

onto the journal of the screw until the bearings and

front ring seal are seated against the shoulder of the

ball screw's journal.

2 Next, install rear ring seal, locknut and lock washer;

torque the locknut to the proper setting (See table 4,

page 10 for recommended torque).

3 Tighten the four button head cap screws until there

is no axial or radial play in the bearing block, this will

cause a slight increase in drag of the bearings.

BM Bearing Series Installation Instructions

BEARING PLATE

ANGULAR CONTACT BEARINGSANGULAR CONTACT BEARINGS

OIL SEAL

OIL SEAL

FRONT RING SEAL

REAR RING SEAL

LOCK WASHER

LOCKNUT

BUTTON HEAD CAP SCREWS

BALL SCREW JOURNAL

WILL ENTER BM BLOCK

FROM THIS DIRECTION

FIGURE 6

BM BEARING BLOCK

BEARING BLOCK

rockfordballscrew.com

800-475-9532

12

1 Install the entire block either horizontal or vertical

onto the journal of the screw until the bearings and

front ring seal are seated against the shoulder of the

ball screw’s journal.

2 Next, install rear ring seal, locknut and lock washer;

torque the locknut to the proper setting (See table 4,

page 10 for recommended torque).

3 Tighten the four button head cap screws until there

is no axial or radial play in the bearing block, this will

cause a slight increase in drag of the bearings.

BEARING PLATE

ANGULAR CONTACT BEARINGSANGULAR CONTACT BEARINGS

OIL SEAL

OIL SEAL

FRONT RING SEAL

REAR RING SEAL

LOCK WASHER

LOCKNUT

BUTTON HEAD CAP SCREWS

BALL SCREW JOURNAL

WILL ENTER BM BLOCK

FROM THIS DIRECTION

FIGURE 7

BMF BEARING BLOCK

BEARING BLOCK

INNER BEARING SPACER

OUTER BEARING SPACER

BMF Bearing Series Installation Instructions

VIII. BEARING MOUNTS - CONTINUED

13

rockfordballscrew.com

800-475-9532

1 Install the entire block either horizontal or vertical onto

the journal of the screw until the bearing is seated

against the shoulder of the ball screw’s journal.

2 Next, install locknut and lock washer; torque the

locknut to the proper setting (See table 4, page 10 for

recommended torque).

BEARING PLAT

E

RADIAL BALL BEARING

LOCK WASHER

LOCKNUT

BUTTON HEAD CAP SCREWS

BALL SCREW JOURNAL

WILL ENTER BM BLOCK

FROM THIS DIRECTION

FIGURE 8

BMR BEARING BLOCK

BEARING BLOCK

BMR Bearing Series Installation Instructions

VIII. BEARING MOUNTS - CONTINUED

rockfordballscrew.com

800-475-9532

14

IX. TROUBLESHOOTING

BALLSCREW WOBBLES/VIBRATES

DURING OPERATION:

1 Inspect mounts; check to make sure ballnut and end

supports are tight and properly aligned.

2 Check critical speed and column loading per R/B/S

catalog. Do not exceed the safe critical speed or

column loading as stated in the catalog.

3 Check straightness of screw.

4 Consult Factory.

BALLSCREW MAKING EXCESSIVE NOISE:

1 Make sure adequate and proper lubrication is present

on screw.

2 Check for excessive debris on screw or in nut.

3 Check alignment and mounting areas for adequate

rigidity. Be sure to inspect for moment (cocking)

loading on the nut. This could cause ball binding and

reduction in life.

4 Consult factory.

EXCESSIVE BACKLASH IN SYSTEM:

1 Inspect mounting areas for tight assembly.

2 Inspect support bearing backlash to determine if

backlash is coming from bearings.

3 If preloaded ballnut assembly, tighten per pages 6 &

7 in this manual.

4 Consult factory.

BALLNUT DRIFTING (BACK-DRIVING)

UNDER LOAD:

1 Install motor brake to hold load. Consult catalog to

determine torque required.

2 Consult factory (a screw with a finer lead may be

required).

BALLSCREW EXPERIENCING

PREMATURE FAILURE:

1 Premature failure may be caused by many reasons

such as, lack of lubrication, misalignment, metal

chips or other debris, over loading of screw and

excessive speed.

2 Consult R/B/S catalog or WEB Site.

15

rockfordballscrew.com

800-475-9532

X. RETROFIT FOR BRIDGEPORT SERIES 1 MILLS

ASSEMBLY INSTRUCTIONS: RETROFIT FOR

BRIDGEPORT SERIES 1 MILLS

The Rockford Ball Screw retrofit kits are factory set

with the proper preload. Should the ball nut and screw

become disengaged, please contact Rockford Ball Screw

Co. Upon receiving screw, make sure the packing slip

lists the proper screws for your machine.

REMOVING EXISTING SCREWS

1 Run the table all the way (Y-Axis) out toward you.

2 Remove the jam nuts and all three bearing brackets.

(One bracket for Y-Axis, one each end of X-Axis.) The

brackets are not all the same so remember where

each one belongs.

3 Remove the gib adjusting screw and pull out the gib.

4 The table should now be loose; slide the table onto a

flat surface which has the same height as the table.

CAUTION: The table is quite heavy.

5 Remove the support housing cap screws and 5/32”

oil lines attached to support housing. (Be careful not

to kink or bend oil lines excessively.)

6 Unscrew both X & Y acme screws from support

housing and remove support housing.

INSTALLING RETROFIT KIT

1 Insert the X-Axis ball screw in the housing. Install (2)

5/16”-24 cap screws provided. Tighten, finger tight

only. The return tubes on ball nut should face up and

fit within slot opening at top of housing.

2 Place housing (and X-Axis screw) in opening in

saddle. The ball nut flange should face to the left.

The bolt holes for the Y-Axis face back of machine.

3 Insert the (4) 3/8” bolts you removed from the old

support housing into the holes in the supplied

housing. Tighten bolts finger tight only.

4 By hand, rotate the Y-Axis nut towards the

unmachined end of the screw. Stop about 1-1 1/2”

from the end of the screw. DO NOT rotate the end of

the screw into the ball nut.

5 Angle the Y-Axis screw into the saddle opening.

(Fig. #1)

6 Push the ball nut beyond the slot in the bottom of

the supplied housing. Then slide the screw into the

slot and pull the ball screw assembly back towards

yourself to seat ball nut in housing.

7 Slide chip plates forward until a 4” x 4” hole appears

behind the supplied housing.

8 Fasten the Y-Axis flange to the housing, using (3)

5/16”-24 screws furnished. This is done through the

chip plate hole behind the saddle. An extension on

a 1/4” socket hex head or a long length of 1/4” hex

stock will make the screw tightening easier. Make

sure the three screws are tight at this time.

9 Clean the ways and oil grooves on the machine.

Test the Bijur System (if applicable) to see if oil is

flowing through the oil holes and through the 5/32”

tubing that lubricates the screw. If you have proper

lubrication, proceed.

10 Install the 5/32” lubrication tubing into the 5/32”

diameter holes located in the flanges on each ball nut

assembly. Just press the tubing into hole as far as it

will go.

ALIGNMENT & REASSEMBLY

1 Replace the bearing bracket (see “Replacement of

Bearings” below) onto the Y-Axis screw. Place one

of the woodruff keys (remove from original screws)

into the Y-Axis screw. Install the handle assembly.

Replace and tighten the bearing bracket bolts.

2 Rotate the Y-Axis handle counterclockwise to move

the table towards you. Snug (slightly) the four bolts

that attach the housing to the saddle. Rotate the

screw to move the table away from you. Let the

housing find its “center” and tighten the screws a bit

more. Repeat this procedure until the torque to turn

the Y-Axis screw seems to be the same throughout

the travel of the screw. Tighten the screws to secure

the housing to the saddle. You may want to drill

some pin holes to secure the housing to the saddle

(optional).

3 Make sure the X-Axis screw ends are equidistant

from center of housing.

4 Install the other woodruff keys into the ends of the

screw.

rockfordballscrew.com

800-475-9532

16

X. RETROFIT FOR BRIDGEPORT SERIES 1 MILLS - CONTINUED

5 Slide table back onto ways and assemble the

table gib.

6 Reassemble the right-hand table bearing bracket

finger tight.

7 Reassemble the left-hand table bearing bracket (see

“Replacement of Bearings” below) finger tight.

8 Assemble the dials and handles on both ends.

Run the table through its complete travel in both

directions to center the ball nut within the support

housing. With the table as far to the left (thrust

bearing end) as possible. (Allowing room between

the ball nut and thrust bearings to tighten the cap

screw.) You will need approximately 7” of extension

with a 1/4” hex end to reach the 5/16”-24 screws that

secure the X-Axis nut to support housing.

9 Tighten the X-Axis screws that secure the flange on

the ball nut to the support housing.

10 Tighten the thrust bearing bracket.

11 Run table to far right end. Tighten right hand end

bracket.

12 Check both X-Axis and Y-Axis for full travel and

check torque for alignment. Realign if necessary.

ASSEMBLY INSTRUCTIONS: RETROFIT FOR BRIDGEPORT SERIES 1 MILLS

PROBLEM CAUSES SOLUTION

X-Axis screw won’t accept

bearing brackets.

#1 - Wrong screw length.

#2 - Misalignment.

#1 - Check packing slip

and overall length of screw.

#2 - Realign.

Backlash and/or

“spring” in handle.

#1 - Original bearings are overly worn.

#2 - Preload setting not tight enough.

#1 - Replace bearings with

angular contact bearings.

See attached sheet.

#2 - Consult factory.

Supplied housing bolt holes

won’t line up with saddle.

Slight differences in saddle assembly. Elongate holes in housing.

Screw(s) hard to turn

towards end of travel.

Screw(s) misaligned. Elongate holes in housing.

Rough feel to screw.

#1 - Lack of lubrication.

#2 - Excessive chips or dirt on screw.

#1 - Check lubrication.*

#2 - Clean off screws.

*Lubrication with light weight oil (SAE 5 or 10) is required periodically. If central lube system (Bijur or equivalent) is

available on machine, install a 5/32 diameter line from oil system to ball nut flange. Lubricate with way oil periodically.

17

rockfordballscrew.com

800-475-9532

REPLACEMENT OF BEARINGS

The Y-Axis and left-hand end of X-Axis have factory

thrust bearings. These bearings are adequate for use

with acme screws. But if you require zero backlash

and repeatability that our preloaded ball screws allow,

changing the bearings may be required.

There are different grades of angular contact bearings.

The 7204 series of angular contact bearings are the size

required. Be sure to purchase sets that have ground

faces. The minimum type bearings are as follows (or

equivalent):

• Fafnir 7204 WNSU

• FAG 7204B. TVP. UA

• SKF 7204 BYG

There are more precise bearings (much more expensive),

but for most applications on Series I mills, they are not

necessary.

All of the angular contact bearing sets are going to

require a set of spacers. The inner race spacer should

be .115 - .120 thick, an I.D. of .790/.800 and an O.D. of

1.195/1.205. The outer race spacer should be the same

thickness (.115-.120), I.D. of 1.255/1.265 and O.D. of

1.848/1.838 diameter. The inner race spacer should be

placed on the screw before the bearings. The outer race

spacer should be placed in the bearing bore before

installing the bearings. When tightening the bearing

retaining ring, be sure not to tighten too tight. The

bearing retaining ring is made of aluminum and the

screw heads can break through.

The bearings should be packed with grease prior to

assembling and periodically re-greased.

If you have any further problems with bearing

installation, contact your bearing supplier.

X. RETROFIT FOR BRIDGEPORT SERIES 1 MILLS - CONTINUED

CROSS VIEW OF FINAL ASSEMBLY

C

B

A

FIGURE 9

CROSS VIEW OF FINAL ASSEMBLY

940 Southrock Dr. Rockford, IL 61102

800-475-9532

P 815-961-7700

F 815-961-7703

sales@rockfordballscrew.com

rockfordballscrew.com